Articles

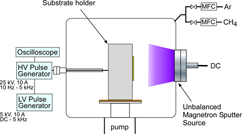

Properties of hydrogenated DLC films as prepared by a combined method of plasma source ion implantation and unbalanced magnetron sputtering

-

- Published online by Cambridge University Press:

- 31 October 2011, pp. 845-849

-

- Article

- Export citation

Nanoscale structure of Ti1−xNbyO2 mixed-phase thin films: Distribution of crystal phase and dopants

-

- Published online by Cambridge University Press:

- 23 January 2012, pp. 944-950

-

- Article

- Export citation

Kinetic study of the intermetallic compound formation between eutectic Sn–3.5Ag alloys and electroplated Ni metallization in flip-chip solder joints

-

- Published online by Cambridge University Press:

- 28 February 2012, pp. 1169-1177

-

- Article

- Export citation

Performance and kinetics of Pt–CNT catalyst electrodes in a PEM fuel cell

-

- Published online by Cambridge University Press:

- 21 March 2012, pp. 1497-1505

-

- Article

- Export citation

Towards electroformed nanostructured aluminum alloys with high strength and ductility

-

- Published online by Cambridge University Press:

- 24 April 2012, pp. 1638-1651

-

- Article

-

- You have access

- HTML

- Export citation

High-strain-rate nanoindentation behavior of fine-grained magnesium alloys

-

- Published online by Cambridge University Press:

- 20 March 2012, pp. 1295-1302

-

- Article

-

- You have access

- HTML

- Export citation

Finite element analysis of nanowire indentation on a flat substrate

-

- Published online by Cambridge University Press:

- 16 December 2011, pp. 586-591

-

- Article

- Export citation

Mechanism of La0.6Sr0.4Co0.2Fe0.8O3 cathode degradation

-

- Published online by Cambridge University Press:

- 31 July 2012, pp. 1992-1999

-

- Article

- Export citation

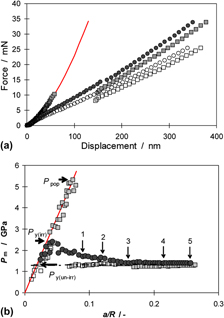

Nanoindentation investigation of ion-irradiated Fe–Cr alloys using spherical indenters

-

- Published online by Cambridge University Press:

- 17 October 2011, pp. 85-90

-

- Article

- Export citation

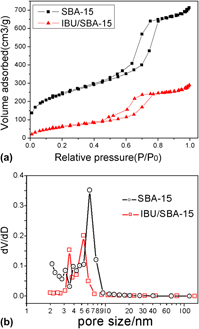

Preparation of controlled release nanodrug ibuprofen supported on mesoporous silica using supercritical carbon dioxide

-

- Published online by Cambridge University Press:

- 28 September 2012, pp. 2902-2910

-

- Article

- Export citation

Novel proton conductive hybrid membranes based on sulfonated polysulfone and benzotriazole

-

- Published online by Cambridge University Press:

- 06 August 2012, pp. 2650-2656

-

- Article

- Export citation

Expandable graphite modification by boric acid

-

- Published online by Cambridge University Press:

- 21 February 2012, pp. 1054-1059

-

- Article

- Export citation

Grain refinement of Mg–10Gd alloy by Al additions

-

- Published online by Cambridge University Press:

- 01 October 2012, pp. 2790-2797

-

- Article

- Export citation

Evaluation of the catalytic activity of oxide nanoparticles synthesized by the polymeric precursor method on biodiesel production

-

- Published online by Cambridge University Press:

- 13 November 2012, pp. 3020-3026

-

- Article

- Export citation

Formation of nanopore arrays on stainless steel surface by anodization for visible-light photocatalytic degradation of organic pollutants

-

- Published online by Cambridge University Press:

- 05 July 2012, pp. 2417-2424

-

- Article

- Export citation

Synthesis and characterization of germanium-centered three-dimensional crystalline porous aromatic framework

-

- Published online by Cambridge University Press:

- 09 January 2012, pp. 1417-1420

-

- Article

- Export citation

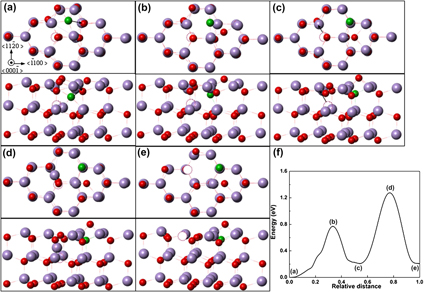

Migration of point defects and a defect pair in zinc oxide using the dimer method

-

- Published online by Cambridge University Press:

- 25 May 2012, pp. 2241-2248

-

- Article

- Export citation

Broadband nanoindentation of glassy polymers: Part II. Viscoplasticity

-

- Published online by Cambridge University Press:

- 18 November 2011, pp. 475-484

-

- Article

- Export citation

Enhancement of yellow emission and afterglow in Sr3SiO5: Eu2+, Dy3+ by adding alkaline earth metal fluorides

-

- Published online by Cambridge University Press:

- 20 September 2012, pp. 2535-2539

-

- Article

- Export citation

Thermal conductivity of tunable lamellar aluminum oxide/polymethyl methacrylate hybrid composites

-

- Published online by Cambridge University Press:

- 09 May 2012, pp. 1869-1876

-

- Article

- Export citation