Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Gao, Michael C.

Gao, Pan

Hawk, Jeffrey A.

Ouyang, Lizhi

Alman, David E.

and

Widom, Mike

2017.

Computational modeling of high-entropy alloys: Structures, thermodynamics and elasticity.

Journal of Materials Research,

Vol. 32,

Issue. 19,

p.

3627.

Senkov, Oleg N.

Miracle, Daniel B.

Chaput, Kevin J.

and

Couzinie, Jean-Philippe

2018.

Development and exploration of refractory high entropy alloys—A review.

Journal of Materials Research,

Vol. 33,

Issue. 19,

p.

3092.

Zhang, Boliang

Zhang, Yi

and

Guo, S. M.

2018.

A thermodynamic study of corrosion behaviors for CoCrFeNi-based high-entropy alloys.

Journal of Materials Science,

Vol. 53,

Issue. 20,

p.

14729.

Cui, Xiaodan

Zhang, Boliang

Zeng, Congyuan

and

Guo, Shengmin

2018.

Electrocatalytic activity of high-entropy alloys toward oxygen evolution reaction.

MRS Communications,

Vol. 8,

Issue. 3,

p.

1230.

2019.

High-Entropy Alloys.

p.

299.

2019.

High-Entropy Alloys.

p.

259.

2019.

Xiang, Chao

Zhang, Zhi-Ming

Fu, Hua-Meng

Han, En-Hou

Wang, Jian-Qiu

Zhang, Hai-Feng

and

Hu, Guo-Dong

2019.

Microstructure, Mechanical Properties, and Corrosion Behavior of MoNbFeCrV, MoNbFeCrTi, and MoNbFeVTi High-Entropy Alloys.

Acta Metallurgica Sinica (English Letters),

Vol. 32,

Issue. 9,

p.

1053.

Zhang, Ze-Qun

Song, Kai-Kai

Guo, Shu

Xue, Qi-Sen

Xing, Hui

Cao, Chong-De

Dai, Fu-Ping

Völker, Bernhard

Hohenwarter, Anton

Maity, Tapabrata

Chawake, Niraj

Kim, Jeong-Tae

Wang, Li

Kaban, Ivan

and

Eckert, Jürgen

2019.

Optimizing mechanical properties of Fe26.7Co26.7Ni26.7Si8.9B11 high entropy alloy by inducing hypoeutectic to quasi-duplex microstructural transition.

Scientific Reports,

Vol. 9,

Issue. 1,

Couzinié, J.-P.

and

Dirras, G.

2019.

Body-centered cubic high-entropy alloys: From processing to underlying deformation mechanisms.

Materials Characterization,

Vol. 147,

Issue. ,

p.

533.

Takeuchi, Akira

2020.

Mixing Entropy of Exact Equiatomic High-Entropy Alloys Formed into a Single Phase.

MATERIALS TRANSACTIONS,

Vol. 61,

Issue. 9,

p.

1717.

Steurer, Walter

2020.

Single-phase high-entropy alloys – A critical update.

Materials Characterization,

Vol. 162,

Issue. ,

p.

110179.

Guo, Yueling

He, Junyang

Lu, Wenjun

Jia, Lina

and

Li, Zhiming

2021.

The evolution of compositional and microstructural heterogeneities in a TaMo0.5ZrTi1.5Al0.1Si0.2 high entropy alloy.

Materials Characterization,

Vol. 172,

Issue. ,

p.

110836.

Hoi, K.C.

Lei, W.H.

Liu, Yining

Shek, C.H.

Ferreira, Jessica T.G.

Cortez, Nicete F.T.

Kwok, C.T.

Sun, Y.F.

Cristino, Valentino A.M.

and

Lo, K.H.

2023.

Cavitation erosion of the CoCrFeNi high entropy alloy having elemental segregation.

Wear,

Vol. 530-531,

Issue. ,

p.

204990.

Karimi, J.

Kollo, L.

and

Prashanth, K. G.

2023.

Characterization of Gas-Atomized Equiatomic AlCoCrFeNi Powder for Additive Manufacturing.

Metallurgical and Materials Transactions A,

Vol. 54,

Issue. 9,

p.

3417.

Vela, Brent

Acemi, Cafer

Singh, Prashant

Kirk, Tanner

Trehern, William

Norris, Eli

Johnson, Duane D.

Karaman, Ibrahim

and

Arróyave, Raymundo

2023.

High-throughput exploration of the WMoVTaNbAl refractory multi-principal-element alloys under multiple-property constraints.

Acta Materialia,

Vol. 248,

Issue. ,

p.

118784.

Duan, Chuyi

Kostka, Aleksander

Li, Xiaohu

Peng, Zirong

Kutlesa, Peter

Pippan, Reinhard

and

Werner, Ewald

2023.

Deformation-induced homogenization of the multi-phase senary high-entropy alloy MoNbTaTiVZr processed by high-pressure torsion.

Materials Science and Engineering: A,

Vol. 871,

Issue. ,

p.

144923.

Xiang, Chao

Han, En-Hou

Zhang, Zhiming

Fu, Huameng

Zhang, Haifeng

Wang, Jianqiu

and

Hu, Guodong

2024.

Microstructure, Mechanical Properties and Corrosion Resistance of the Mo0.5V0.5NbTiZrx High-Entropy Alloys with Low Thermal Neutron Sections.

Acta Metallurgica Sinica (English Letters),

Vol. 37,

Issue. 10,

p.

1643.

Huang, Li

Sun, Shuo

Xue, Jianrong

Lin, Xiaohui

Gao, Xuanqiao

Li, Yanchao

Li, Jianfeng

Ma, Chunfang

and

Zhang, Wen

2024.

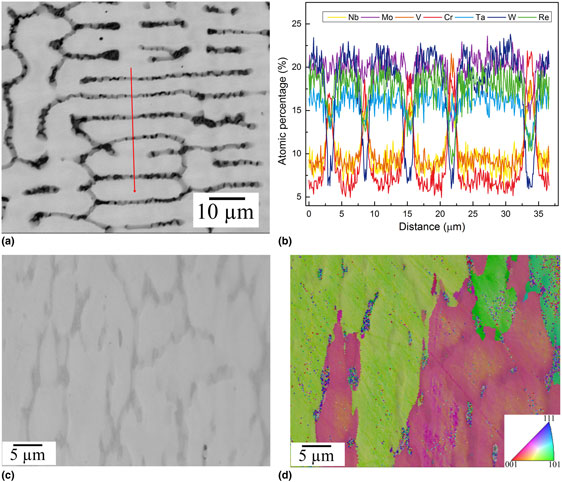

Enhanced irradiation-resistance in NbMoTaW refractory high-entropy alloy via rhenium addition.

Heliyon,

Vol. 10,

Issue. 23,

p.

e40553.

Cantor, Brian

2024.

Fundamentals of Multicomponent High-Entropy Materials.

p.

139.