Published online by Cambridge University Press: 12 August 2011

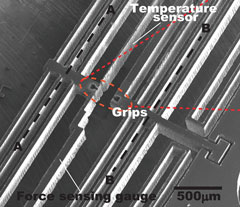

A novel method for the in situ thermomechanical test of micro/nanoscale samples at high temperature is presented. During the in situ test, the stage is resistively heated while the temperature is measured by a cofabricated temperature sensor. For experimental demonstration of the thermomechanical testing method, we fabricate the Micro-Electro-Mechanical Systems (MEMS) stage using silicon carbide (SiC) and carry out in situ uniaxial tests for single-crystal silicon (SCS) microsamples at temperatures from room temperature to 400 °C. We recover the known elastic modulus of SCS within 1% error in this temperature range.