Published online by Cambridge University Press: 09 May 2019

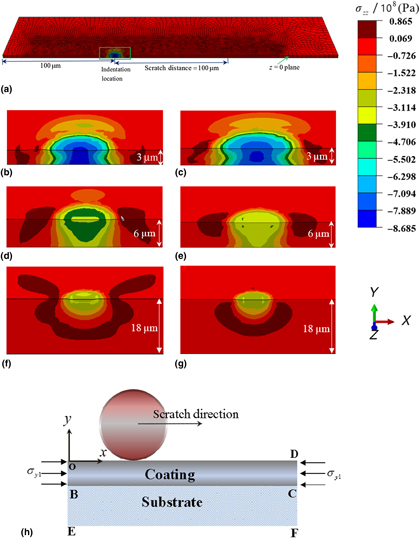

Indentation and scratch models are proposed to numerically investigate effects of compressive prestress on film's mechanical responses. In indentation, normal stress distributions are strongly dependent on film thickness; the applied force and the maximum normal stresses with a prestress are much larger than without prestress. For various film thicknesses the change in the normal force in scratch between the non-prestressed and prestressed films is 4%–23%. The scratch friction coefficient is larger with prestress than without prestress. With biaxial or uniaxial prestress the material becomes more difficult to deform or to slide at the contact surface compared with cases without prestress.