Article contents

Effects of an interfacial layer on stress relaxation mechanisms active in the Cu–Si thin film system during thermal cycling

Published online by Cambridge University Press: 14 January 2020

Abstract

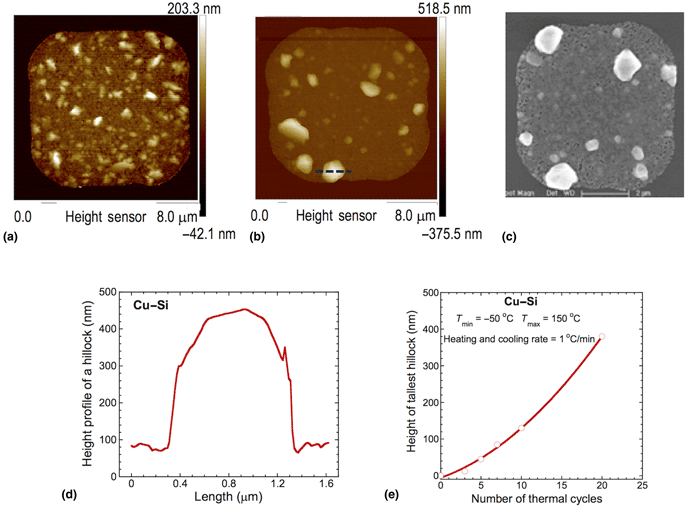

The authors report effects of placing a very thin metallic interlayer, such as W and Ni, in between the Cu film and the Si substrate on cyclic thermal stress-induced interfacial sliding and hillock growth in Cu. Cu–Si samples with no interlayer were the most prone to both interfacial sliding and hillock growth, whereas samples with the Ni interlayer were the most resistant against these deleterious phenomena. While the rate of interfacial sliding decreased with each consecutive thermal cycle, hillocks continued to grow undeterred. The obtained experimental results are discussed, considering the compressive stress field generated in the Cu film.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 3

- Cited by