Article contents

Effect of temperature on the suppression of twinning in textured magnesium

Published online by Cambridge University Press: 05 August 2019

Abstract

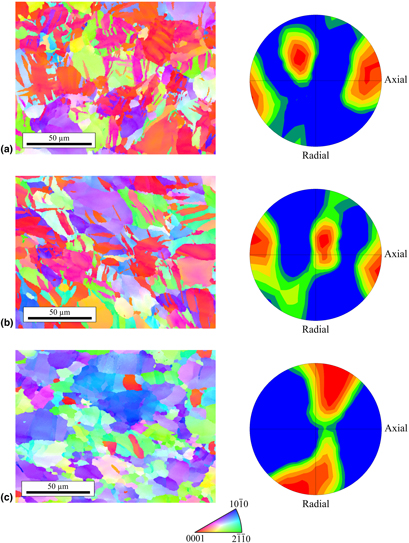

In this work, the effect of temperature, in the range of 25 to 250 °C, on deformation twinning in textured polycrystalline pure magnesium (Mg) was investigated. Compression loading was applied perpendicular to the c-axis texture direction. The yield strength and strain hardening rate are shown to drastically decrease with increasing temperature with total suppression of twinning at 200 °C. This behavior is attributed to the decrease in the critical resolved shear stress for prismatic slip and temperature insensitivity of tensile twinning. These results provide a first step in fundamentally understanding the deformation of Mg at elevated temperatures and quantify the mechanisms that lead to their improved formability at elevated temperatures.

- Type

- Research Letters

- Information

- Copyright

- Copyright © The Author(s) 2019

References

- 4

- Cited by