Article contents

Effect of growth temperature on the key properties of aluminum-doped zinc oxide thin films prepared by atomic layer deposition

Published online by Cambridge University Press: 27 August 2019

Abstract

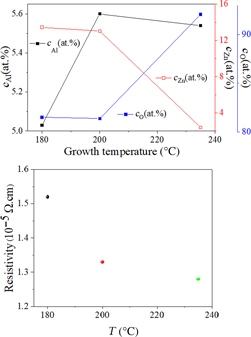

Aluminum-doped zinc oxide films were prepared by atomic layer deposition using diethylzinc, trimethylaluminum, and water. High-purity water was used with low vacuum. The effect of growth temperature on characteristics of the films was investigated. The crystallinity was improved as growth temperature was increased from 180 to 235 °C, with the grain sizes increasing from 32.830 to 47.020 nm. The films possessed high transparency with a 95% transmission window blue shifted with growth temperature. This shift was seen in the energy-band gaps which changed from 3.46 to 3.68 eV, leading to a decreased resistivity from 1.52 × 10−5 to 1.28 × 10−5 Ω cm.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 7

- Cited by