Published online by Cambridge University Press: 15 May 2020

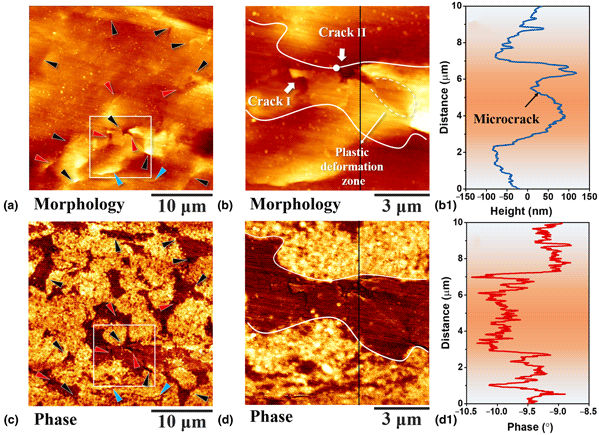

Heterogeneous magnesium matrix nanocomposites (Hetero-Mg-NCs) exhibited excellent strength–toughness synergy, but their damage behavior and toughness mechanism lacked of investigation. Here, atomic force microscopy was first employed to characterize the microstructure evolution and damage behavior of the Hetero-Mg-NCs after indentation. The heterogeneous structure comprised of pure Mg areas (soft phase) and Mg nanocomposite areas (hard phase) was revealed by the electrostatic force microscopy. Furthermore, the surface morphology and cracks of the deformed area were investigated with high resolution. The results indicated the soft phase undertook most of the deformation and played an important role in capturing and blunting the crack.