Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Gobaille‐Shaw, Gael. P. A.

Celorrio, Veronica

Calvillo, Laura

Morris, Louis J.

Granozzi, Gaetano

and

Fermín, David. J.

2018.

Effect of Ba Content on the Activity of La1‐xBaxMnO3 Towards the Oxygen Reduction Reaction.

ChemElectroChem,

Vol. 5,

Issue. 14,

p.

1922.

Celorrio, V.

Calvillo, L.

Granozzi, G.

Russell, A. E.

and

Fermin, D. J.

2018.

AMnO3 (A = Sr, La, Ca, Y) Perovskite Oxides as Oxygen Reduction Electrocatalysts.

Topics in Catalysis,

Vol. 61,

Issue. 3-4,

p.

154.

Dzara, Michael J.

Christ, Jason M.

Joghee, Prabhuram

Ngo, Chilan

Cadigan, Christopher A.

Bender, Guido

Richards, Ryan M.

O'Hayre, Ryan

and

Pylypenko, Svitlana

2018.

La and Al co-doped CaMnO3 perovskite oxides: From interplay of surface properties to anion exchange membrane fuel cell performance.

Journal of Power Sources,

Vol. 375,

Issue. ,

p.

265.

Tsuji, Etsushi

Motohashi, Teruki

Noda, Hiroyuki

Aoki, Yoshitaka

and

Habazaki, Hiroki

2018.

Strong Lanthanoid Substitution Effect on Electrocatalytic Activity of Double-Perovskite-Type BaLnMn2O5 (Ln = Y, Gd, Nd, and La) for Oxygen Reduction Reaction.

The Journal of Physical Chemistry C,

Vol. 122,

Issue. 13,

p.

7081.

Celorrio, Veronica

Calvillo, Laura

van den Bosch, Celeste A. M.

Granozzi, Gaetano

Aguadero, Ainara

Russell, Andrea E.

and

Fermín, David J.

2018.

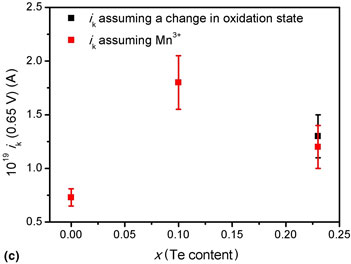

Mean Intrinsic Activity of Single Mn Sites at LaMnO3 Nanoparticles Towards the Oxygen Reduction Reaction.

ChemElectroChem,

Vol. 5,

Issue. 20,

p.

3044.

Dessie, Yilkal

Tadesse, Sisay

Eswaramoorthy, Rajalakshmanan

and

Abebe, Buzuayehu

2019.

Recent developments in manganese oxide based nanomaterials with oxygen reduction reaction functionalities for energy conversion and storage applications: A review.

Journal of Science: Advanced Materials and Devices,

Vol. 4,

Issue. 3,

p.

353.

Xia, Weiren

Pei, Zhipeng

Leng, Kai

and

Zhu, Xinhua

2020.

Research Progress in Rare Earth-Doped Perovskite Manganite Oxide Nanostructures.

Nanoscale Research Letters,

Vol. 15,

Issue. 1,

Celorrio, V.

Tiwari, D.

Calvillo, L.

Leach, A.

Huang, H.

Granozzi, G.

Alonso, J.A.

Aguadero, A.

Pinacca, R.M.

Russell, A.E.

and

Fermin, D.J.

2021.

Electrocatalytic Site Activity Enhancement via Orbital Overlap in A2MnRuO7 (A = Dy3+, Ho3+, and Er3+) Pyrochlore Nanostructures.

ACS Applied Energy Materials,

Vol. 4,

Issue. 1,

p.

176.

Hamdi, R

Smari, M

Bajorek, A

Hayek, S S

Dhahri, E

and

Haik, Y

2023.

La0.6X0.1Te0.3MnO3 system with significant refrigerant capacity at low magnetic field and double magnetic entropy change peaks: effect of ball-milling time on physical and critical behaviors.

Physica Scripta,

Vol. 98,

Issue. 8,

p.

085952.