Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Cao, Simeng

Bennett, J. Craig

Wang, Yukun

Gracious, Shayne

Zhu, Min

and

Obrovac, M.N.

2019.

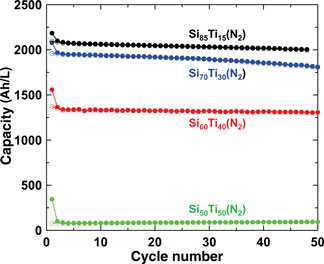

Si–TiN alloy Li-ion battery anode materials prepared by reactive N2 gas milling.

Journal of Power Sources,

Vol. 438,

Issue. ,

p.

227003.

Ryan, Emily

Pollard, Zoe A.

Ha, Quang-Thinh

Roshandelpoor, Athar

Vakili, Pirooz

and

Goldfarb, Jillian L.

2019.

Designing heterogeneous hierarchical material systems: a holistic approach to structural and materials design.

MRS Communications,

Vol. 9,

Issue. 2,

p.

628.

Cao, Simeng

Tahmasebi, Mohammad H.

Bennett, J. Craig

and

Obrovac, M.N.

2021.

Si-TiN alloy anode materials prepared by reactive N2 gas milling: thermal stability and electrochemistry in Li-cells.

Electrochimica Acta,

Vol. 396,

Issue. ,

p.

139259.

Feng, Zhi-yuan

Peng, Wen-jie

Wang, Zhi-xing

Guo, Hua-jun

Li, Xin-hai

Yan, Guo-chun

and

Wang, Jie-xi

2021.

Review of silicon-based alloys for lithium-ion battery anodes.

International Journal of Minerals, Metallurgy and Materials,

Vol. 28,

Issue. 10,

p.

1549.

Cao, Simeng

Tahmasebi, Mohammad H.

Gracious, Shayne

Bennett, J. Craig

and

Obrovac, M. N.

2022.

Preparation of Low Surface Area Si-Alloy Anodes for Li-Ion Cells by Ball Milling.

Journal of The Electrochemical Society,

Vol. 169,

Issue. 6,

p.

060540.

Shuangyu, Liu

Mengran, Liu

Ping, Lu

Fulong, Zhang

Juan, Hong

and

Liyan, Wang

2023.

Study on the electrical properties of Cu-based ECMs prepared by TiBN powder instead of W.

International Journal of Refractory Metals and Hard Materials,

Vol. 117,

Issue. ,

p.

106402.

Amna, Riffat

and

Alhassan, Saeed M.

2024.

A Comprehensive Exploration of Polysulfides, From Synthesis Techniques to Diverse Applications and Future Frontiers.

ACS Applied Polymer Materials,

Vol. 6,

Issue. 8,

p.

4350.