Published online by Cambridge University Press: 04 April 2018

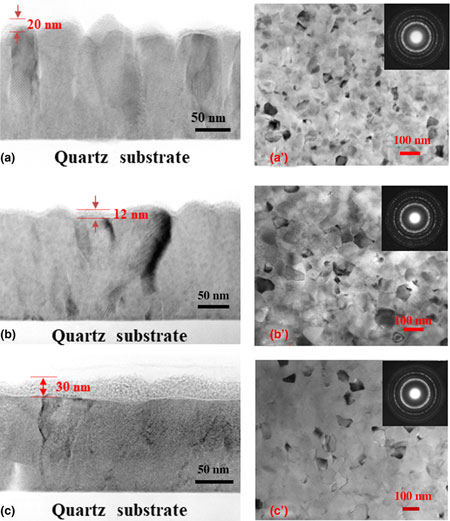

The use of zinc nitride (Zn3N2) films as a transparent electrode in various electronic devices has attracted much attention owing to its high-carrier mobility. In this study, we investigate the influence of the sputtering process on structural, optical, and electrical properties of a Zn3N2 film deposited by reactive magnetron sputtering. The reactivity of nitrogen species can be improved by changing the type of sputtering gas. Compared with Ar or Ne sputtering gas, polycrystalline Zn3N2 films deposited using He sputtering gas have a larger grain size. The optical band gap of the Zn3N2 films varied from ~1.2 to 1.5 eV depending on the N2 flow ratio and type of sputtering gas. The maximum mobility was 91.1 cm2/Vs when the Zn3N2 film was deposited using Ar sputtering gas with an N2 flow ratio of 40%. The carrier density of Zn3N2 films deposited using Ar sputtering gas was notably higher than those deposited using Ne or He sputtering gas, and more oxygen atoms are considered to substitute into nitrogen sites, where oxygen is considered to be from the residual water vapor in the sputtering chamber.