Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Liu, Yu-chen

Yu, Yung-si

Lin, Shih-kang

and

Chiu, Shang-Jui

2019.

Electromigration effect upon single- and two-phase Ag-Cu alloy strips: An in situ study.

Scripta Materialia,

Vol. 173,

Issue. ,

p.

134.

Jacobs, Ryan

Mayeshiba, Tam

Afflerbach, Ben

Miles, Luke

Williams, Max

Turner, Matthew

Finkel, Raphael

and

Morgan, Dane

2020.

The Materials Simulation Toolkit for Machine learning (MAST-ML): An automated open source toolkit to accelerate data-driven materials research.

Computational Materials Science,

Vol. 176,

Issue. ,

p.

109544.

Morgan, Dane

and

Jacobs, Ryan

2020.

Opportunities and Challenges for Machine Learning in Materials Science.

Annual Review of Materials Research,

Vol. 50,

Issue. 1,

p.

71.

Kunwar, Anil

Hektor, Johan

Nomoto, Sukeharu

Coutinho, Yuri Amorim

and

Moelans, Nele

2020.

Combining multi-phase field simulation with neural network analysis to unravel thermomigration accelerated growth behavior of Cu6Sn5 IMC at cold side Cu–Sn interface.

International Journal of Mechanical Sciences,

Vol. 184,

Issue. ,

p.

105843.

Chu, Liu

Shi, Jiajia

and

Braun, Robin

2021.

The Impacts of Material Uncertainty in Electro-Migration of SAC Solder Electronic Packaging by Monte Carlo-Based Stochastic Finite-Element Model.

IEEE Transactions on Components, Packaging and Manufacturing Technology,

Vol. 11,

Issue. 11,

p.

1864.

Liu, Yu-chen

Liu, Tzu-Yu

Huang, Tien-Heng

Chiu, Kuo-Chuang

and

Lin, Shih-kang

2021.

Exploring Dielectric Constant and Dissipation Factor of LTCC Using Machine Learning.

Materials,

Vol. 14,

Issue. 19,

p.

5784.

Liu, Yu-Chen

Yang, Chih-Han

and

Lin, Shih-Kang

2022.

Sn-based solder design using machine learning approach.

p.

43.

Liu, Yu-chen

Wu, Henry

Mayeshiba, Tam

Afflerbach, Benjamin

Jacobs, Ryan

Perry, Josh

George, Jerit

Cordell, Josh

Xia, Jinyu

Yuan, Hao

Lorenson, Aren

Wu, Haotian

Parker, Matthew

Doshi, Fenil

Politowicz, Alexander

Xiao, Linda

Morgan, Dane

Wells, Peter

Almirall, Nathan

Yamamoto, Takuya

and

Odette, G. Robert

2022.

Machine learning predictions of irradiation embrittlement in reactor pressure vessel steels.

npj Computational Materials,

Vol. 8,

Issue. 1,

Polak, Maciej P.

Jacobs, Ryan

Mannodi-Kanakkithodi, Arun

Chan, Maria K. Y.

and

Morgan, Dane

2022.

Machine learning for impurity charge-state transition levels in semiconductors from elemental properties using multi-fidelity datasets.

The Journal of Chemical Physics,

Vol. 156,

Issue. 11,

Zhou, Youzhi

Lin, Pengcheng

Ke, Xin

Hu, Qiang

Shi, Qi

Zhang, Jingguo

Wang, Zhong

and

Wang, Limin

2022.

Machine learning‐based analysis and prediction of the interfacial corrosion processes of copper cathode plates during the electrolytic production of copper powders.

Materials and Corrosion,

Vol. 73,

Issue. 5,

p.

811.

Chu, Liu

Shi, Jiajia

and

de Cursi, Eduardo Souza

2022.

Monte Carlo-Based Stochastic Finite Element Model for Electromigration in the Interfaces of SAC Solder and Cu Conductors with Uncertainties in Boundary Conditions.

Journal of Electronic Materials,

Vol. 51,

Issue. 6,

p.

3173.

Xu, Wenwu

Jiang, Runjian

Xu, Mingjie

Hasan, Md Shahrier

Polifrone, Kyrel

Gu, Jing

Yang, Yang

Torresani, Elisa

and

Olevsky, Eugene

2023.

Localized engineering of grain boundary morphology by electro-nano-pulsing processing.

Materials Today Advances,

Vol. 20,

Issue. ,

p.

100442.

Wu, Peichen

Farmer, William

Iquebal, Ashif

and

Ankit, Kumar

2023.

A Novel Data-Driven Emulator for Predicting Electromigration-Mediated Damage in Polycrystalline Interconnects.

Journal of Electronic Materials,

Vol. 52,

Issue. 4,

p.

2746.

Liu, Yu-Chen

Kholik, Ahmad

and

Lin, Shih-Kang

2023.

A machine learning approach to explore tensile properties of low-temperature solders.

p.

71.

Al-Mamun, Nahid Sultan

Wolfe, Douglas E.

Haque, Aman

Yim, Jae-Gyun

and

Kim, Seong Keun

2023.

Room temperature annealing of SnS2 films with electron impulse force.

Scripta Materialia,

Vol. 224,

Issue. ,

p.

115107.

Banda, Tiyamike

Liu, Yu-chen

Farid, Ali Akhavan

and

Lim, Chin Seong

2023.

A machine learning model for flank wear prediction in face milling of Inconel 718.

The International Journal of Advanced Manufacturing Technology,

Vol. 126,

Issue. 3-4,

p.

935.

Tsai, Ming‐Hsuan

Lin, Tuan‐Yue

Su, Tian‐Shun

Chen, Guan‐Min

Liu, Yu‐chen

and

Chen, Yu‐Ze

2023.

Regulating Zinc Deposition via Zincophilic 2D‐Cu2Te as the Current Collector to Suppress Dendrite Formation toward High Performance Aqueous Zinc‐Ion Batteries.

Batteries & Supercaps,

Vol. 6,

Issue. 8,

Zeng, Xin

Huang, Zhiheng

Xiao, Min

Meng, Yuezhong

Yan, Hui

and

Liu, Yang

2023.

Simulation on Microstructural Evolution under Electromigration in Backside Power Delivery Network.

p.

1.

Zhang, Yumin

Hong, Zijian

Ye, Zhizhen

and

Pan, Xinhua

2024.

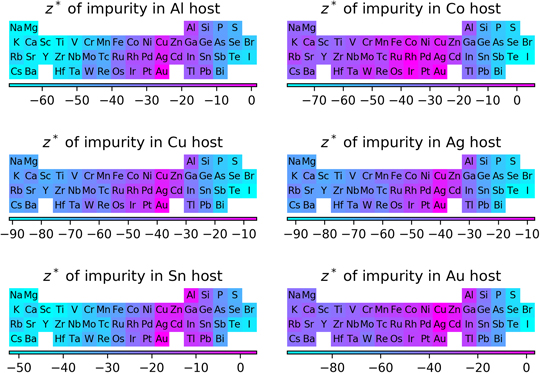

Theoretical Understanding of Electromigration-Related Surface Diffusion and Current-Induced Force in Ag–Pd Systems.

ACS Omega,

Vol. 9,

Issue. 27,

p.

29576.