Article contents

Direct urea fuel cells based on CuNi-plated polymer cloth as a anode catalyst

Published online by Cambridge University Press: 29 January 2019

Abstract

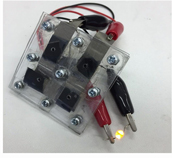

Direct urea fuel cells were fabricated using CuNi-plated polymer cloth for anode catalyst and current collector, and Pt-black for cathode catalyst. The output power was significantly enhanced by coating the CuNi cloth with a conducting polymer, poly(3,4-ethylenedioxythiophene)polystyrene sulfonate (PEDOT*PSS). The open circuit voltage, 0.80 V and the maximum output power, 3.0 mW/cm2 were obtained for the fuel of 0.5 M urea water solution under ambient conditions. Improvement over the cell structure demonstrated to lighten a light emitting diode.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 5

- Cited by