Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Ferro, Gio

Ganjam, Dithi

Gibson, Maia

Partington, Katie

Trikha, Akshay

Wu, Mandy

Domrzalski, Jessica

Dato, Albert

and

Monson, Todd

2021.

Investigating the dielectric properties of barium titanate nanocomposites using transmission electron microscopy image processing.

MRS Advances,

Vol. 6,

Issue. 25,

p.

631.

Sejati, Prima Asmara

Saito, Noritaka

Prayitno, Yosephus Ardean Kurnianto

Tanaka, Koji

Darma, Panji Nursetia

Arisato, Miku

Nakashima, Kunihiko

and

Takei, Masahiro

2022.

On-Line Multi-Frequency Electrical Resistance Tomography (mfERT) Device for Crystalline Phase Imaging in High-Temperature Molten Oxide.

Sensors,

Vol. 22,

Issue. 3,

p.

1025.

Cooper, Emma

De Anda, Eduardo

Flitz, Evan

Kim, Halie

Casañas, Nicholas

Johnson, Lillian

Kedzierski, Zoe

Domrzalski, Jessica

Dato, Albert

and

Monson, Todd

2022.

Investigating the dielectric constant of barium titanate in a polymer-matrix nanocomposite.

MRS Advances,

Vol. 7,

Issue. 31,

p.

799.

CHOI, Yoorina

HWANG, Yun-Chan

YU, Mi-Kyung

LEE, Kwang-Won

and

MIN, Kyung-San

2023.

Effects of barium titanate on the dielectric constant, radiopacity, and biological properties of tricalcium silicate-based bioceramics.

Dental Materials Journal,

Vol. 42,

Issue. 1,

p.

55.

Marvin, Jessica

Nicholson, James

Turek, Cedar

Iwasa, Erina

Pangrekar, Nilay

Fowler, Whitney C.

Van Ginhoven, Renee

and

Monson, Todd C.

2023.

Analyzing barium titanate TiO2 surface interactions with tert-butylphosphonic acid using density functional theory.

MRS Communications,

Vol. 13,

Issue. 6,

p.

1209.

Pritchard, Avery

Fuentes, Heather

Santosa, Jessica

Gonzalez, Madison

Garan, Josiah

Bartling, Vanessa

Nelson, Katrina

Dato, Albert

Monson, Todd

and

Van Ginhoven, Renee

2024.

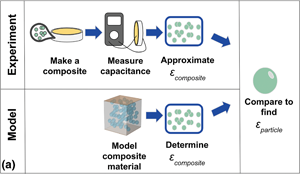

Understanding surfaces and interfaces in nanocomposites of silicone and barium titanate through experiments and modeling.

MRS Communications,

Vol. 14,

Issue. 6,

p.

1319.

Iverson, Ethan T.

Legendre, Hudson

Killgore, Jason P.

Grunlan, Jaime C.

and

Kolibaba, Thomas J.

2024.

Remarkable Dielectric Breakdown Strength of Printable Polyelectrolyte Photopolymer Complexes.

ACS Macro Letters,

Vol. 13,

Issue. 10,

p.

1325.