Published online by Cambridge University Press: 03 December 2018

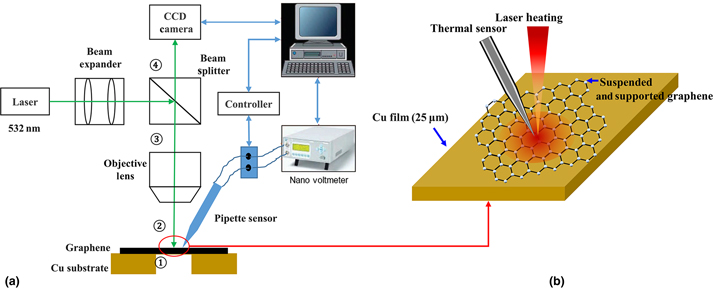

We have investigated interfacial thermal resistance (ITR) between single-layer graphene and Cu substrate by using both experimental and numerical methods. For experiments, the micropipette sensing technique was utilized to measure the thermal conductivity of suspended graphene and temperature profile of supported graphene on Cu film subjected to heating with a point source continuous wave laser. The thermal conductivity of suspended single-layer graphene was measured to be 3492 ± 453 W/m°C from measurements of temperature profile on the suspended graphene. This intrinsic graphene thermal conductivity and the finite element method integrated with a multi-parameter fitting technique were used to estimate ITR between graphene and Cu film. In the multi-parameter fitting technique, the simulated temperature profile is compared with experimentally measured temperature profile on the supported graphene surface and the best-fitted parameters including thermal interface resistance was obtained. The estimated interface thermal resistance between single graphene and Cu substrate is 2.3 × 10−7 m2 K/W and the difference between experiment and simulation result during multi-parameter fitting is 6.9%.