Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Mokhtari, Fatemeh

Cheng, Zhenxiang

Raad, Raad

Xi, Jiangtao

and

Foroughi, Javad

2020.

Piezofibers to smart textiles: a review on recent advances and future outlook for wearable technology.

Journal of Materials Chemistry A,

Vol. 8,

Issue. 19,

p.

9496.

McCollum, Jena M.

and

Serrano Delgado, Irene

2020.

Opportunities for Fluoropolymers.

p.

275.

Li, Jun

Long, Yin

Yang, Fan

and

Wang, Xudong

2020.

Degradable piezoelectric biomaterials for wearable and implantable bioelectronics.

Current Opinion in Solid State and Materials Science,

Vol. 24,

Issue. 1,

p.

100806.

Shepelin, Nick A.

Sherrell, Peter C.

Goudeli, Eirini

Skountzos, Emmanuel N.

Lussini, Vanessa C.

Dicinoski, Greg W.

Shapter, Joseph G.

and

Ellis, Amanda V.

2020.

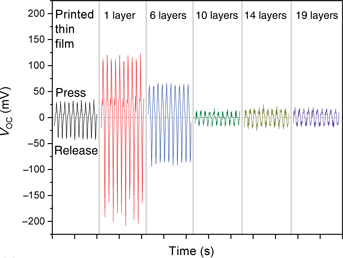

Printed recyclable and self-poled polymer piezoelectric generators through single-walled carbon nanotube templating.

Energy & Environmental Science,

Vol. 13,

Issue. 3,

p.

868.

Yang, Tzu-Chuan

Jiang, Yi-Pei

Lin, Ting-Han

Chen, Shih-Hsuan

Ho, Ching-Mei

Wu, Ming-Chung

and

Wang, Jer-Chyi

2021.

N-butylamine-modified graphite nanoflakes blended in ferroelectric P(VDF-TrFE) copolymers for piezoelectric nanogenerators with high power generation efficiency.

European Polymer Journal,

Vol. 159,

Issue. ,

p.

110754.

Liu, Xingang

Shang, Yinghao

Zhang, Jihai

and

Zhang, Chuhong

2021.

Ionic Liquid-Assisted 3D Printing of Self-Polarized β-PVDF for Flexible Piezoelectric Energy Harvesting.

ACS Applied Materials & Interfaces,

Vol. 13,

Issue. 12,

p.

14334.

Pei, Haoran

Xie, Yeping

Xiong, Yu

Lv, Qinniu

and

Chen, Yinghong

2021.

A novel polarization-free 3D printing strategy for fabrication of poly (Vinylidene fluoride) based nanocomposite piezoelectric energy harvester.

Composites Part B: Engineering,

Vol. 225,

Issue. ,

p.

109312.

Ye, Lanlin

Chen, Liyi

Yu, Jinlong

Tu, Shijian

Yan, Bin

Zhao, Yinghui

Bai, Xue

Gu, Yingchun

and

Chen, Sheng

2021.

High-performance piezoelectric nanogenerator based on electrospun ZnO nanorods/P(VDF-TrFE) composite membranes for energy harvesting application.

Journal of Materials Science: Materials in Electronics,

Vol. 32,

Issue. 4,

p.

3966.

Shepelin, Nick A.

Sherrell, Peter C.

Skountzos, Emmanuel N.

Goudeli, Eirini

Zhang, Jizhen

Lussini, Vanessa C.

Imtiaz, Beenish

Usman, Ken Aldren S.

Dicinoski, Greg W.

Shapter, Joseph G.

Razal, Joselito M.

and

Ellis, Amanda V.

2021.

Interfacial piezoelectric polarization locking in printable Ti3C2Tx MXene-fluoropolymer composites.

Nature Communications,

Vol. 12,

Issue. 1,

Guo, Jiajun

Nie, Min

and

Wang, Qi

2021.

Self-Poling Polyvinylidene Fluoride-Based Piezoelectric Energy Harvester Featuring Highly Oriented β-Phase Structured at Multiple Scales.

ACS Sustainable Chemistry & Engineering,

Vol. 9,

Issue. 1,

p.

499.

Wiklund, Jenny

Karakoç, Alp

Palko, Toni

Yiğitler, Hüseyin

Ruttik, Kalle

Jäntti, Riku

and

Paltakari, Jouni

2021.

A Review on Printed Electronics: Fabrication Methods, Inks, Substrates, Applications and Environmental Impacts.

Journal of Manufacturing and Materials Processing,

Vol. 5,

Issue. 3,

p.

89.

Imtiaz, Beenish

Shepelin, Nick A.

Sherrell, Peter C.

Kentish, Sandra E.

and

Ellis, Amanda V.

2021.

Direct ink writing of dehydrofluorinated Poly(Vinylidene Difluoride) for microfiltration membrane fabrication.

Journal of Membrane Science,

Vol. 632,

Issue. ,

p.

119347.

Zhang, Shuo

Lin, Xiujuan

Liu, Huan

Yuan, Zie

Huan, Yu

Yuan, Xi

Huang, Shifeng

and

Cheng, Xin

2021.

High‐performance flexible piezoelectric nanogenerator based on necklace‐like PZT particle chains.

International Journal of Energy Research,

Vol. 45,

Issue. 4,

p.

6213.

Mokhtari, Fatemeh

2022.

Self-Powered Smart Fabrics for Wearable Technologies.

p.

1.

Ikram, Hamid

Al Rashid, Ans

and

Koç, Muammer

2022.

Additive manufacturing of smart polymeric composites: Literature review and future perspectives.

Polymer Composites,

Vol. 43,

Issue. 9,

p.

6355.

Cardoso, V.F.

Costa, C.M.

Correia, D.M.

Carvalho, E.O.

Peřinka, N.

Martins, P.M.

Meira, R.M.

Marques-Almeida, T.

Rodrigues-Marinho, T.

and

Lanceros-Mendez, S.

2022.

Organic Ferroelectric Materials and Applications.

p.

375.

Han, Cheng

He, Lirong

Wang, Qi

and

Zhang, Chuhong

2022.

Solvent-Exchange-Assisted 3D Printing of Self-Polarized High β-PVDF for Advanced Piezoelectric Energy Harvesting.

ACS Applied Electronic Materials,

Vol. 4,

Issue. 6,

p.

3125.

Corletto, Alexander

Ellis, Amanda V.

Shepelin, Nick A.

Fronzi, Marco

Winkler, David A.

Shapter, Joseph G.

and

Sherrell, Peter C.

2022.

Energy Interplay in Materials: Unlocking Next‐Generation Synchronous Multisource Energy Conversion with Layered 2D Crystals.

Advanced Materials,

Vol. 34,

Issue. 36,

Imtiaz, Beenish

Sherrell, Peter C.

Barlow, Anders J.

Shepelin, Nick A.

Kentish, Sandra E.

Khan, Muhammad Yasir

and

Ellis, Amanda V.

2022.

Non-templated manufacturing of patterned fluoropolymer membranes via immersion precipitation printing.

Additive Manufacturing,

Vol. 58,

Issue. ,

p.

103017.

Mustapha, K.B.

Metwalli, Khaled Mohamed

Baharuddin, Ab Aziz Bin

and

Abakr, Yousif

2022.

3D printing of polyvinylidene fluoride composite films with enhanced electroactive beta-phase for flexible wearable pressure sensors.

Materials Today: Proceedings,

Vol. 70,

Issue. ,

p.

321.