Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Fan, Cuncai

Xie, Dongyue

Li, Jin

Shang, Zhongxia

Chen, Youxing

Xue, Sichuang

Wang, Jian

Li, Meimei

El-Azab, Anter

Wang, Haiyan

and

Zhang, Xinghang

2019.

9R phase enabled superior radiation stability of nanotwinned Cu alloys via in situ radiation at elevated temperature.

Acta Materialia,

Vol. 167,

Issue. ,

p.

248.

Zhang, Y. F.

Su, R.

Xie, D. Y.

Niu, T. J.

Xue, S.

Li, Q.

Shang, Z.

Ding, J.

Richter, N. A.

Wang, Jian

Wang, H.

and

Zhang, X.

2020.

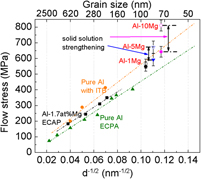

Design of super-strong and thermally stable nanotwinned Al alloys via solute synergy.

Nanoscale,

Vol. 12,

Issue. 39,

p.

20491.

Zhang, Y.F.

Li, Qiang

Gong, M.

Xue, S.

Ding, J.

Li, Jin

Cho, J.

Niu, T.

Su, Ruizhe

Richter, N.A.

Wang, H.

Wang, J.

and

Zhang, X.

2020.

Deformation behavior and phase transformation of nanotwinned Al/Ti multilayers.

Applied Surface Science,

Vol. 527,

Issue. ,

p.

146776.

Roy, Abir

Tiwari, Manish

Sahu, Sandeep

Mishra, Sumeet

and

Kumar, Abhishek

2020.

Microstructure, Texture and Mechanical Properties of Al-Mg-Si Alloy Processed by Multiaxial Compression.

Journal of Materials Engineering and Performance,

Vol. 29,

Issue. 6,

p.

3876.

Li, Qiang

Xue, Sichuang

Zhang, Yifan

Sun, Xing

Wang, Haiyan

and

Zhang, Xinghang

2020.

Plastic anisotropy and tension-compression asymmetry in nanotwinned Al–Fe alloys: An in-situ micromechanical investigation.

International Journal of Plasticity,

Vol. 132,

Issue. ,

p.

102760.

Li, Qiang

Xie, Dongyue

Shang, Zhongxia

Sun, Xing

Cho, Jaehun

Zhang, Yifan

Xue, Sichuang

Wang, Haiyan

Wang, Jian

and

Zhang, Xinghang

2020.

Coupled solute effects enable anomalous high-temperature strength and stability in nanotwinned Al alloys.

Acta Materialia,

Vol. 200,

Issue. ,

p.

378.

Li, Qiang

Xue, Sichuang

Fan, Cuncai

Richter, Nicholas A.

Zhang, Yifan

Chen, Youxing

Wang, Haiyan

and

Zhang, Xinghang

2021.

Epitaxial nanotwinned metals and alloys: synthesis-twin structure–property relations.

CrystEngComm,

Vol. 23,

Issue. 38,

p.

6637.

Gong, Mingyu

Wu, Wenqian

Xie, Dongyue

Richter, Nicholas A.

Li, Qiang

Zhang, Yifan

Xue, Sichuang

Zhang, Xinghang

and

Wang, Jian

2021.

First-principles calculations for understanding microstructures and mechanical properties of co-sputtered Al alloys.

Nanoscale,

Vol. 13,

Issue. 35,

p.

14987.

Lei, Tianjiao

Shin, Jungho

Gianola, Daniel S.

and

Rupert, Timothy J.

2021.

Bulk nanocrystalline Al alloys with hierarchical reinforcement structures via grain boundary segregation and complexion formation.

Acta Materialia,

Vol. 221,

Issue. ,

p.

117394.

Ding, Jie

Xue, S.

Shang, Z.

Li, Jin

Zhang, Y.

Su, R.

Niu, T.

Wang, H.

and

Zhang, X.

2021.

Characterization of precipitation in gradient Inconel 718 superalloy.

Materials Science and Engineering: A,

Vol. 804,

Issue. ,

p.

140718.

Li, Qiang

Wang, Jian

Wang, Haiyan

and

Zhang, Xinghang

2022.

Achieving strong and stable nanocrystalline Al alloys through compositional design.

Journal of Materials Research,

Vol. 37,

Issue. 1,

p.

183.

Yang, Bo

Shang, Z.

Ding, Jie

Lopez, Jack

Jarosinski, William

Sun, T.

Richter, N.

Zhang, Y.

Wang, H.

and

Zhang, X.

2022.

Investigation of strengthening mechanisms in an additively manufactured Haynes 230 alloy.

Acta Materialia,

Vol. 222,

Issue. ,

p.

117404.

Sheng, X. Y.

Richter, N. A.

Shang, A. Y.

Wang, H.

and

Zhang, X.

2023.

Twin density and twin thickness evolution in sputtered Al–Mg alloys.

Journal of Applied Physics,

Vol. 133,

Issue. 20,

Zhang, Jingfan

Zhou, Dengshan

Pang, Xueyong

Zhang, Bowen

Li, Yue

Sun, Binhan

Valiev, Ruslan Z.

and

Zhang, Deliang

2023.

Deformation-induced concurrent formation of 9R phase and twins in a nanograined aluminum alloy.

Acta Materialia,

Vol. 244,

Issue. ,

p.

118540.

Song, Chang-Rong

Zhang, Si-Yu

Liu, Lin

Yang, Hong-Yu

Kang, Jie

Meng, Jia

Luo, Chang-Jie

Wang, Cheng-Gang

Cao, Kuang

Qiao, Jian

Shu, Shi-Li

Zhu, Ming

Qiu, Feng

and

Jiang, Qi-Chuan

2024.

Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation.

Materials,

Vol. 17,

Issue. 17,

p.

4235.

Sheng, X.Y.

Shang, Z.

Shang, A.Y.

Wang, H.

and

Zhang, X.

2024.

Grain boundary and twin boundary solute segregations in nanocrystalline Al-Mg alloy.

Scripta Materialia,

Vol. 245,

Issue. ,

p.

116053.

KRÁLÍK, Rostislav

KŘIVSKÁ, Barbora

BAJTOŠOVÁ, Lucia

STOLBCHENKO, Mykhailo

SCHAPER, Mirko

GRYDIN, Olexandr

and

CIESLAR, Miroslav

2024.

Effect of Sc addition on downstream processing of twin-roll cast Al−Cu−Li−Mg−Zr-based alloys.

Transactions of Nonferrous Metals Society of China,

Vol. 34,

Issue. 6,

p.

1759.

Zhang, Jingfan

Zhang, Xiuzhen

Wei, Shaolou

Chen, Xinren

Pan, Shuaihang

Yang, Chao

Pan, Hucheng

Zhou, Dengshan

Zhang, Deliang

and

Qin, Gaowu

2025.

Deformation faulting in ultrafine-grained aluminum alloys: Nucleation mechanisms and critical assessment of strengthening-ductilization contributions.

Acta Materialia,

Vol. 286,

Issue. ,

p.

120750.