Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wu, Chan-Sheng

Tsai, Ping-Hsiu

Kuo, Chia-Ming

and

Tsai, Che-Wei

2018.

Effect of Atomic Size Difference on the Microstructure and Mechanical Properties of High-Entropy Alloys.

Entropy,

Vol. 20,

Issue. 12,

p.

967.

Derimow, N.

MacDonald, B.E.

Lavernia, E.J.

and

Abbaschian, R.

2019.

Duplex phase hexagonal-cubic multi-principal element alloys with high hardness.

Materials Today Communications,

Vol. 21,

Issue. ,

p.

100658.

Gwalani, Bharat

Gangireddy, Sindhura

Shukla, Shivakant

Yannetta, Christopher J.

Valentin, Sheena Grace

Mishra, Rajiv S.

and

Banerjee, Rajarshi

2019.

Compositionally graded high entropy alloy with a strong front and ductile back.

Materials Today Communications,

Vol. 20,

Issue. ,

p.

100602.

Cao, Z.H.

Ma, Y.J.

Cai, Y.P.

Wang, G.J.

and

Meng, X.K.

2019.

High strength dual-phase high entropy alloys with a tunable nanolayer thickness.

Scripta Materialia,

Vol. 173,

Issue. ,

p.

149.

Zhao, Yakai

Park, Jeong-Min

Lee, Dong-Hyun

Song, Eun Ju

Suh, Jin-Yoo

Ramamurty, Upadrasta

and

Jang, Jae-il

2019.

Influences of hydrogen charging method on the hydrogen distribution and nanomechanical properties of face-centered cubic high-entropy alloy: A comparative study.

Scripta Materialia,

Vol. 168,

Issue. ,

p.

76.

Qin, Gang

Chen, Ruirun

Liaw, Peter K.

Gao, Yanfei

Li, Xiaoqing

Zheng, Huiting

Wang, Liang

Su, Yanqing

Guo, Jingjie

and

Fu, Hengzhi

2019.

A novel face-centered-cubic high-entropy alloy strengthened by nanoscale precipitates.

Scripta Materialia,

Vol. 172,

Issue. ,

p.

51.

Cai, Y.P.

Wang, G.J.

Ma, Y.J.

Cao, Z.H.

and

Meng, X.K.

2019.

High hardness dual-phase high entropy alloy thin films produced by interface alloying.

Scripta Materialia,

Vol. 162,

Issue. ,

p.

281.

Meng, Lu

Qiu, Ji

Wang, Zhihua

Liu, Erqiang

Shu, Xuefeng

and

Xiao, Gesheng

2020.

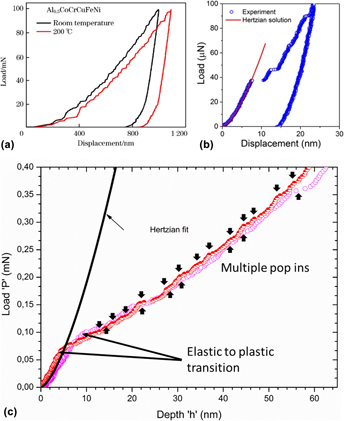

Indentation pop-in behavior of CoCrFeNiAl0.3 high-entropy alloy.

Materials Research Express,

Vol. 6,

Issue. 12,

p.

1265d4.

Bahramyan, Mehran

Taherzadeh Mousavian, Reza

and

Brabazon, Dermot

2020.

Determination of atomic-scale structure and compressive behavior of solidified AlxCrCoFeCuNi high entropy alloys.

International Journal of Mechanical Sciences,

Vol. 171,

Issue. ,

p.

105389.

Basu, Indranil

and

De Hosson, Jeff Th.M.

2020.

Strengthening mechanisms in high entropy alloys: Fundamental issues.

Scripta Materialia,

Vol. 187,

Issue. ,

p.

148.

Siska, Filip

Cech, Jaroslav

Hausild, Petr

Hadraba, Hynek

Chlup, Zdenek

Husak, Roman

and

Stratil, Ludek

2020.

Twinning in CoCrFeNiMn high entropy alloy induced by nanoindentation.

Materials Science and Engineering: A,

Vol. 784,

Issue. ,

p.

139297.

Basu, Indranil

and

De Hosson, Jeff Th. M.

2020.

High Entropy Alloys: Ready to Set Sail?.

Metals,

Vol. 10,

Issue. 2,

p.

194.

Qin, Gang

Chen, Ruirun

Liaw, Peter K.

Gao, Yanfei

Wang, Liang

Su, Yanqing

Ding, Hongsheng

Guo, Jingjie

and

Li, Xiaoqing

2020.

An as-cast high-entropy alloy with remarkable mechanical properties strengthened by nanometer precipitates.

Nanoscale,

Vol. 12,

Issue. 6,

p.

3965.

Xiao, Yuan

Zou, Yu

Sologubenko, Alla S.

Spolenak, Ralph

and

Wheeler, Jeffrey M.

2020.

Size-dependent strengthening in multi-principal element, face-centered cubic alloys.

Materials & Design,

Vol. 193,

Issue. ,

p.

108786.

Soto, Angelo Oñate

Salgado, Alexis Salas

and

Niño, Elizabeth Berrio

2020.

Thermodynamic analysis of high entropy alloys and their mechanical behavior in high and low-temperature conditions with a microstructural approach - A review.

Intermetallics,

Vol. 124,

Issue. ,

p.

106850.

Bahramyan, Mehran

Mousavian, Reza Taherzadeh

and

Brabazon, Dermot

2020.

Study of the plastic deformation mechanism of TRIP–TWIP high entropy alloys at the atomic level.

International Journal of Plasticity,

Vol. 127,

Issue. ,

p.

102649.

Chawake, Niraj

Zálešák, Jakub

Gammer, Christoph

Franz, Robert

Cordill, Megan J.

Kim, Jeong Tae

and

Eckert, Jürgen

2020.

Microstructural characterization of medium entropy alloy thin films.

Scripta Materialia,

Vol. 177,

Issue. ,

p.

22.

Xu, Haitao

Shi, Lei

Lu, Chuanyang

Li, Huaxin

He, Yanming

Chen, Weijian

Li, Yafei

Yang, Jianguo

Zheng, Wenjian

Ma, Yinghe

Wang, Donghong

Ding, Zhenyu

Zou, Hai

and

Gao, Zengliang

2021.

A novel joining of Cf/C composites using AlCoCrFeNi2.1 high-entropy brazing filler alloys.

Materials Characterization,

Vol. 179,

Issue. ,

p.

111368.

Cao, Zhenhua

Ma, Yujie

Cai, Yunpeng

Wang, Gengjie

Pan, Guanjun

Ren, Hua

Zhai, Gaoyang

Zhang, Zijian

Li, Pengfei

and

Meng, Xiangkang

2021.

Nanolamellar medium entropy alloy composites with high strength and large plasticity.

Journal of Alloys and Compounds,

Vol. 873,

Issue. ,

p.

159775.

Huang, Kai

Sumigawa, Takashi

and

Kitamura, Takayuki

2021.

Experimental evaluation of loading mode effect on plasticity of microscale single-crystal copper.

Materials Science and Engineering: A,

Vol. 806,

Issue. ,

p.

140822.