Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Yang, T.

Zhao, Y.L.

Luan, J.H.

Han, B.

Wei, J.

Kai, J.J.

and

Liu, C.T.

2019.

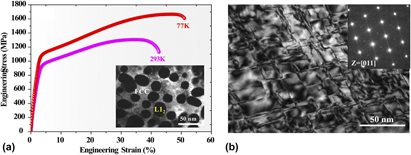

Nanoparticles-strengthened high-entropy alloys for cryogenic applications showing an exceptional strength-ductility synergy.

Scripta Materialia,

Vol. 164,

Issue. ,

p.

30.

Wang, Cheng

Li, Tsung-Hsiung

Liao, Yi-Chia

Li, Chia-Lin

Jang, Jason Shian-Ching

and

Hsueh, Chun-Hway

2019.

Hardness and strength enhancements of CoCrFeMnNi high-entropy alloy with Nd doping.

Materials Science and Engineering: A,

Vol. 764,

Issue. ,

p.

138192.

Zhao, Shijun

Osetsky, Yuri

and

Zhang, Yanwen

2019.

Diffusion of point defects in ordered and disordered Ni–Fe alloys.

Journal of Alloys and Compounds,

Vol. 805,

Issue. ,

p.

1175.

Poulia, Anthoula

Georgatis, Emmanuel

and

Karantzalis, Alexander

2019.

Evaluation of the Microstructural Aspects, Mechanical Properties and Dry Sliding Wear Response of MoTaNbVTi Refractory High Entropy Alloy.

Metals and Materials International,

Vol. 25,

Issue. 6,

p.

1529.

Wang, Jianying

Yang, Hailin

Ruan, Jianming

Wang, Yun

and

Ji, Shouxun

2019.

Microstructure and properties of CoCrNi medium-entropy alloy produced by gas atomization and spark plasma sintering.

Journal of Materials Research,

Vol. 34,

Issue. 12,

p.

2126.

Zhao, Yilu

Yang, Tao

Han, Bin

Luan, Junhua

Chen, Da

Kai, Wu

Liu, Chain Tsuan

and

Kai, Ji-jung

2019.

Exceptional nanostructure stability and its origins in the CoCrNi-based precipitation-strengthened medium-entropy alloy.

Materials Research Letters,

Vol. 7,

Issue. 4,

p.

152.

Huang, Shuo

2019.

The chemical ordering and elasticity in FeCoNiAl1−Ti high-entropy alloys.

Scripta Materialia,

Vol. 168,

Issue. ,

p.

5.

Li, Ziyong

Fu, Liming

Peng, Jian

Zheng, Han

Ji, Xinbo

Sun, Yanle

Ma, Shuo

and

Shan, Aidang

2020.

Improving mechanical properties of an FCC high-entropy alloy by γ′ and B2 precipitates strengthening.

Materials Characterization,

Vol. 159,

Issue. ,

p.

109989.

Vamsi, K.V.

and

Pollock, Tresa M.

2020.

A new proximate structure for the APB (111) in L12 compounds.

Scripta Materialia,

Vol. 182,

Issue. ,

p.

38.

Yang, T.

Zhao, Y.L.

Cao, B.X.

Kai, J.J.

and

Liu, C.T.

2020.

Towards superior mechanical properties of hetero-structured high-entropy alloys via engineering multicomponent intermetallic nanoparticles.

Scripta Materialia,

Vol. 183,

Issue. ,

p.

39.

Yang, T.

Zhao, Y.L.

Fan, L.

Wei, J.

Luan, J.H.

Liu, W.H.

Wang, C.

Jiao, Z.B.

Kai, J.J.

and

Liu, C.T.

2020.

Control of nanoscale precipitation and elimination of intermediate-temperature embrittlement in multicomponent high-entropy alloys.

Acta Materialia,

Vol. 189,

Issue. ,

p.

47.

Zhao, Y.L.

Yang, T.

Li, Y.R.

Fan, L.

Han, B.

Jiao, Z.B.

Chen, D.

Liu, C.T.

and

Kai, J.J.

2020.

Superior high-temperature properties and deformation-induced planar faults in a novel L12-strengthened high-entropy alloy.

Acta Materialia,

Vol. 188,

Issue. ,

p.

517.

Cao, B.X.

Wang, C.

Yang, T.

and

Liu, C.T.

2020.

Cocktail effects in understanding the stability and properties of face-centered-cubic high-entropy alloys at ambient and cryogenic temperatures.

Scripta Materialia,

Vol. 187,

Issue. ,

p.

250.

Adil, Shaik

Suraj, M.V.

Pillari, Lava Kumar

Sridar, Soumya

Nagini, M.

Pradeep, K.G.

and

Murty, B.S.

2020.

On the effect of Fe in L12 strengthened Al–Co–Cr–Fe–Ni–Ti complex concentrated alloy.

Materialia,

Vol. 14,

Issue. ,

p.

100909.

Peng, Hanlin

Hu, Ling

Li, Liejun

and

Zhang, Weipeng

2020.

Ripening of L12 nanoparticles and their effects on mechanical properties of Ni28Co28Fe21Cr15Al4Ti4 high-entropy alloys.

Materials Science and Engineering: A,

Vol. 772,

Issue. ,

p.

138803.

An, Ning

Sun, Yanan

Wu, Yidong

Tian, Jianjun

Li, Zhenrui

Li, Qing

Chen, Jingyang

and

Hui, Xidong

2020.

High temperature strengthening via nanoscale precipitation in wrought CoCrNi-based medium-entropy alloys.

Materials Science and Engineering: A,

Vol. 798,

Issue. ,

p.

140213.

Peng, Hanlin

Hu, Ling

Li, Liejun

Gao, Jixiang

and

Zhang, Qi

2020.

On the correlation between L12 nanoparticles and mechanical properties of (NiCo)52+2x(AlTi)4+2xFe29-4xCr15 (x=0-4) high-entropy alloys.

Journal of Alloys and Compounds,

Vol. 817,

Issue. ,

p.

152750.

Yeli, Guma

Chen, Da

Yabuuchi, Kiyohiro

Kimura, Akihiko

Liu, Shaofei

Lin, Weitong

Zhao, Yilu

Zhao, Shijun

and

Kai, Ji-Jung

2020.

The stability of γ′ precipitates in a multi-component FeCoNiCrTi0.2 alloy under elevated-temperature irradiation.

Journal of Nuclear Materials,

Vol. 540,

Issue. ,

p.

152364.

Rieger, T.

Joubert, J.-M.

Laurent-Brocq, M.

Perrière, L.

Guillot, I.

and

Couzinié, J.-P.

2020.

Study of the FCC+L12 two-phase region in complex concentrated alloys based on the Al–Co–Cr–Fe–Ni–Ti system.

Materialia,

Vol. 14,

Issue. ,

p.

100905.

Liu, Junqi

Wang, Xiaopeng

Singh, Ajit

Xu, Hui

Kong, Fantao

and

Yang, Fei

2021.

The Evolution of Intermetallic Compounds in High-Entropy Alloys: From the Secondary Phase to the Main Phase.

Metals,

Vol. 11,

Issue. 12,

p.

2054.