Article contents

Improved strengthening efficiency of nanoreinforcements realized by a novel melt spinning process

Published online by Cambridge University Press: 26 June 2018

Abstract

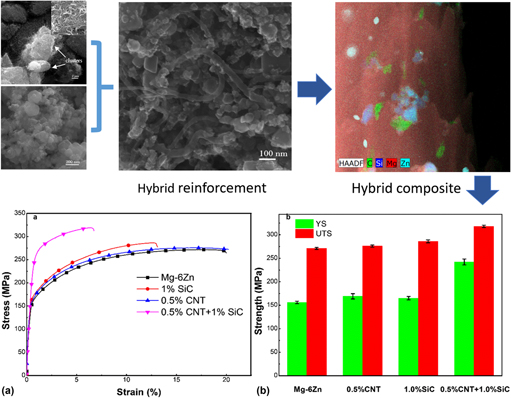

Carbon nanotubes (CNTs) and silicon carbide nanoparticle (nano-SiCp)-reinforced magnesium (Mg) matrix hybrid composites were prepared through a three-step melt spinning process (ball milling, mechanical stirring, and ultrasonic vibration processing). The hybrid nanoreinforcements showed high strengthening efficiency by which the yield and tensile strength of the hybrid composites experienced 46.7 and 15.2% increment, respectively, compared with the matrix alloy. Obviously, the mixed ball-milling process of SiC nanoparticles and CNTs promoted the dispersion of each other, and both the uniformly distributed SiC nanoparticles and CNTs contributed to the enhanced mechanical performance of the hybrid composites. Besides, the addition of the hybrid nanoreinforcements induced the precipitation of nanosized rod-like MgZn2 phases in the as-extruded composites which also made a contribution to the enhanced performance of the composites. Investigations on the strengthening mechanisms of the hybrid composites show that it originates from grain refinement, load transfer, precipitation enhancement, and Orowan reinforcing. More importantly, the contribution made by each part was analyzed in detail.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 2

- Cited by