Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Din, M. F. Md

Wang, J. L.

Rahman, A. R. Abdul

Norizan, Y. N. A.

Suhaimi, N. S.

Idris, N. H.

Ismail, M.

Zamri, W. F. H. Wan

and

Aziz, F. Abdul

2019.

Structure analysis using XRD refinement for replacement of copper (Cu) with manganese (Mn) in NdMn2Si2 compound.

Vol. 2068,

Issue. ,

p.

020062.

Coroş, Maria

Pogăcean, Florina

Măgeruşan, Lidia

Socaci, Crina

and

Pruneanu, Stela

2019.

A brief overview on synthesis and applications of graphene and graphene-based nanomaterials.

Frontiers of Materials Science,

Vol. 13,

Issue. 1,

p.

23.

Fraga, Mariana

and

Pessoa, Rodrigo

2020.

Progresses in Synthesis and Application of SiC Films: From CVD to ALD and from MEMS to NEMS.

Micromachines,

Vol. 11,

Issue. 9,

p.

799.

Dai, Cheng-Yu

Wang, Wei-Chun

Tseng, Chi-Ang

Ding, Fang-Chi

Chen, Yit-Tsong

and

Chen, Chiao-Chen

2020.

Spatial Confinement Approach Using Ni to Modulate Local Carbon Supply for the Growth of Uniform Transfer-Free Graphene Monolayers.

The Journal of Physical Chemistry C,

Vol. 124,

Issue. 42,

p.

23094.

Braeuninger-Weimer, Philipp

Burton, Oliver J.

Zeller, Patrick

Amati, Matteo

Gregoratti, Luca

Weatherup, Robert S.

and

Hofmann, Stephan

2020.

Crystal Orientation Dependent Oxidation Modes at the Buried Graphene–Cu Interface.

Chemistry of Materials,

Vol. 32,

Issue. 18,

p.

7766.

Fauzi, Fatin Bazilah

Ismail, Edhuan

Syed Abu Bakar, Syed Noh

Ismail, Ahmad Faris

Mohamed, Mohd Ambri

Md Din, Muhamad Faiz

Illias, Suhaimi

and

Ani, Mohd Hanafi

2020.

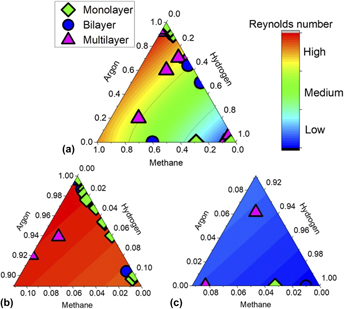

The role of gas-phase dynamics in interfacial phenomena during few-layer graphene growth through atmospheric pressure chemical vapour deposition.

Physical Chemistry Chemical Physics,

Vol. 22,

Issue. 6,

p.

3481.

Karthik, V.

Selvakumar, P.

Senthil Kumar, P.

Vo, Dai-Viet N.

Gokulakrishnan, M.

Keerthana, P.

Tamil Elakkiya, V.

and

Rajeswari, R.

2021.

Graphene-based materials for environmental applications: a review.

Environmental Chemistry Letters,

Vol. 19,

Issue. 5,

p.

3631.

Kanwal, Ansa

Yaqoob, Asim Ali

Siddique, Affia

Bhawani, Showkat Ahmad

Ibrahim, Mohamad Nasir Mohamad

and

Umar, Khalid

2021.

Graphene and Nanoparticles Hybrid Nanocomposites.

p.

261.

Bahru, Raihana

Zamri, Mohd Faiz Muaz Ahmad

Shamsuddin, Abd Halim

Shaari, Norazuwana

and

Mohamed, Mohd Ambri

2021.

A review of thermal interface material fabrication method toward enhancing heat dissipation.

International Journal of Energy Research,

Vol. 45,

Issue. 3,

p.

3548.

Yang, Zhou

Zhang, Yue

Cheng, Yi

Liu, Zhongfan

and

Chen, Songze

2021.

Flow characteristics of low pressure chemical vapor deposition in the micro-channel.

Physics of Fluids,

Vol. 33,

Issue. 8,

Jiang, Bei

Wang, Shiwei

Sun, Jingyu

and

Liu, Zhongfan

2021.

Controllable Synthesis of Wafer‐Scale Graphene Films: Challenges, Status, and Perspectives.

Small,

Vol. 17,

Issue. 37,

Barbe, Timothée

Flamant, Gilles

Nadal, Elie

Vossier, Alexis

Olalde, Gabriel

Gordon, Jeffrey M.

and

Bataille, Françoise

2022.

Elucidating the gas flow dynamics in a nanomaterial synthesis solar reactor.

Chemical Engineering Journal,

Vol. 442,

Issue. ,

p.

135846.

Liu, Wei

Shi, Mengyi

Li, Yingting

Wu, Ziyi

Yang, Lixia

Zhang, Shuqu

Xiao, Xiao

Liu, Chengjin

Dai, Weili

Chen, Congjing

Tu, Xinman

Zou, Jianping

and

Luo, Xubiao

2022.

Congregated-electrons-strengthened anchoring and mineralization of gaseous formaldehyde on a novel self-supporting Cu2-xSe/Cu2O heterojunction photocatalyst under visible lights: A viable mesh for designing air purifier.

Applied Catalysis B: Environmental,

Vol. 312,

Issue. ,

p.

121427.

Yu, Taejong

Yoon, Daegeun

and

You, Donghyun

2022.

Numerical analysis of non-uniform Cu(In, Ga)Se2 growth in a selenization process on large-area substrates for mass production.

Engineering Applications of Computational Fluid Mechanics,

Vol. 16,

Issue. 1,

p.

646.

Arya, Abhishek Kumar

Raman, R.K. Singh

Parmar, Rahul

Amati, Matteo

Gregoratti, Luca

and

Saxena, Sumit

2022.

Spectroscopic investigation of improved corrosion resistance of nickel due to multilayer graphene coating developed with suitably tilted substrate during CVD.

Carbon,

Vol. 200,

Issue. ,

p.

215.

Ali, Faria

Khan, Ayesha

Qadir, Abdul

Aqil, Mohd.

and

Beg, Sarwar

2022.

Multifunctional Nanocarriers.

p.

53.

Ullah, Sami

Ta, Huy Q.

Yang, Xiaoqin

Liu, Yu

Hasan, Maria

Bachmatiuk, Alicja

Liu, Lijun

and

Rümmeli, Mark H.

2022.

Quasistatic Equilibrium Chemical Vapor Deposition of Graphene.

Advanced Materials Interfaces,

Vol. 9,

Issue. 1,

Ullah, Sami

Liu, Yu

Hasan, Maria

Zeng, Wenwen

Shi, Qitao

Yang, Xiaoqin

Fu, Lei

Ta, Huy Q.

Lian, Xueyu

Sun, Jingyu

Yang, Ruizhi

Liu, Lijun

and

Rümmeli, Mark H.

2022.

Direct synthesis of large-area Al-doped graphene by chemical vapor deposition: Advancing the substitutionally doped graphene family.

Nano Research,

Vol. 15,

Issue. 2,

p.

1310.

Thakur, Esha

Ye, Tang

Zhang, Yong

Zhang, Haitao

and

Walter, Michael G.

2023.

A Quantitative Analysis of the Effect of Various Growth Parameters on the Lithography-Free Grown Si Microwires for Photodetector Applications.

Silicon,

Vol. 15,

Issue. 18,

p.

7785.

Talreja, Neetu

Chauhan, Divya

and

Ashfaq, Mohammad

2023.

Emerging Contaminants and Plants.

p.

333.