Article contents

Bonding characteristic and electronic property of TiCxN1−x(001)/TiC(001) interface: A first-principles study

Published online by Cambridge University Press: 17 April 2018

Abstract

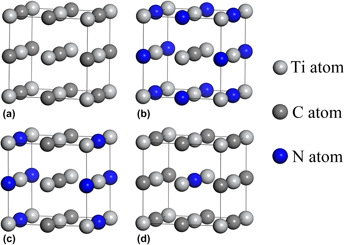

The TiCxN1−x(001)/TiC(001) interface was studied by the first-principles method to provide the theoretical basis for developing TiCxN1−x/TiC coatings. The partial density of state (PDOS), charge density, charge density difference, and Mulliken population analysis were utilized to investigate the bonding nature and the electronic characteristic of the TiC0.25N0.75/TiC interface. The corresponding results indicate that the bonding nature at the interface is ionic and covalent characteristics, which also exist in bulk materials. The extreme similarity of PDOS among interfacial C, N, and Ti atoms and their bulk counterparts reveals that the electronic structure transition at the interface is smooth. The results of Mulliken population analysis and plots of charge density and charge density difference demonstrate that the charge increased for C in the TiC side is less than that for N in the TiC0.25N0.75 side, which reveals that the ionic bond in TiC0.25N0.75 is stronger than that in TiC. Therefore, TiC0.25N0.75 coating can be an alternative choice to combine with TiC coating in the actual production process of multilayer coatings.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

These authors contributed equally to this work.

References

REFERENCES

- 7

- Cited by