Article contents

Future of nanoindentation in archaeometry

Published online by Cambridge University Press: 20 August 2018

Abstract

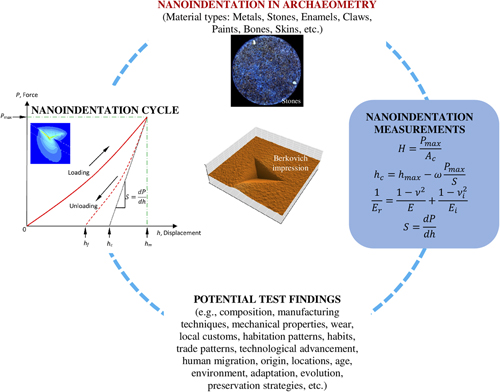

This review aims to consolidate scarce literature on the use of modern nanomechanical testing technique like instrumented nanoindentation in the field of archaeometry materials research. The review showcase on how can the nanoindentation tests provide valuable data about mechanical properties which, in turn, relate to the evolution of ancient biomaterials as well as human history and production methods. This is particularly useful when the testing is limited by confined volumes and small material samples (since the contact size is in the order of few microns). As an emerging novel application, some special considerations are warranted for characterization of archaeometry materials. In this review, potential research areas relating to how nanoindentation is expected to benefit and help improve existing practices in archaeometry are identified. It is expected that these insights will raise awareness for use of nanoindentation at various world heritage sites as well as various museums.

- Type

- REVIEW

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.

References

REFERENCES

- 9

- Cited by