1. Introduction

The drag force acting on an object typically increases with the speed of the surrounding fluid flow, as the pressure and shear stress exerted on its surface grow. For flexible bodies, this increase can be partially offset by the deformations induced by fluid forces, as it produces a more streamlined shape and reduced frontal area (Vogel Reference Vogel1984; Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2002; Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin, de Langre & Machado-Almeida Reference Gosselin, de Langre and Machado-Almeida2010; de Langre, Gutierrez & Cossé Reference de Langre, Gutierrez and Cossé2012; Schouveiler & Eloy Reference Schouveiler and Eloy2013). This reconfiguration reduces the load compared with that of a non-deformable body; nonetheless, drag still increases monotonically with speed, although at a lower rate. However, there are a few instances where drag has been observed to drop sharply with velocity. One such phenomenon occurs due to a sudden change in flow regime, referred to as drag crisis, which happens when the boundary layer transitions from laminar to turbulent, moving its separation downstream and narrowing the wake (von Wieselsberger Reference von Wieselsberger1921; Achenbach Reference Achenbach1972). Another scenario involves abrupt and significant shape changes in the body, which can notably occur due to partial breakage, as observed in wind-induced tree pruning (Lopez et al. Reference Lopez, Eloy, Michelin and De Langre2014). While this process effectively provokes a sharp decrease in the drag force and preserves the integrity of the rest of the structure, it is not reversible.

An attractive alternative is snap-through events in flexible structures, during which the elastic system undergoes a rapid transition from one equilibrium state to another. This process is swift, repeatable and produces significant shape changes, making it increasingly popular in engineering for obtaining switchable optical properties, reusable energy trapping materials, microfluidic pumps or in soft robotics (Han, Ko & Korvink Reference Han, Ko and Korvink2004; Tavakol et al. Reference Tavakol, Bozlar, Punckt, Froehlicher, Stone, Aksay and Holmes2014; Overvelde et al. Reference Overvelde, Kloek, D'haen and Bertoldi2015; Shan et al. Reference Shan, Kang, Raney, Wang, Fang, Candido, Lewis and Bertoldi2015). Snapping instabilities occur through the application of an external input such as a point load, electrostatic forces or thermal effects, and can also be triggered by fluid flows. For example, a post-buckled sheet snaps-through and snaps-back in response to air flowing at different speeds, thus opening and closing an air inlet for flow regulation applications (Arena et al. Reference Arena, Groh, Brinkmeyer, Theunissen, Weaver and Pirrera2017, Reference Arena, Groh, Theunissen, Weaver and Pirrera2018). The snapping of a slender membrane or arc has also been used to modify a channel resistance for passive control of viscous flow (Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017; Peretz et al. Reference Peretz, Mishra, Shepherd and Gat2020) or for energy harvesting from wind-induced snapping oscillations (Kim et al. Reference Kim, Zhou, Kim and Oh2020, Reference Kim, Lahooti, Kim and Kim2021). The critical flow speed to initiate the instability can be adjusted through the nonlinear structural mechanics of the post-buckled member. Note that the system passively responds to flows, which makes it inherently autonomous and leverages the need for additional complex actuation. A few studies focused on the effect of such fast-changing geometries on aerodynamic loading. In the context of wind turbines, bistable winglets or airfoil trailing edges transition autonomously to another stable state that alleviates excessive fluid load (Arrieta et al. Reference Arrieta, Bilgen, Friswell and Hagedorn2012; Cavens, Chopra & Arrieta Reference Cavens, Chopra and Arrieta2021). While reported drag reduction is limited to about 15 % (Cavens et al. Reference Cavens, Chopra and Arrieta2021), primarily due to a focus on lift applications, it shows potential for more substantial drag drops with appropriate designs.

A promising framework for manufacturing shape-morphing structures with nonlinear mechanical properties is the technique of origami, inspired by the Japanese art of paper folding. A surface is equipped with a set of folds, which act as a linkage mechanism, producing large three-dimensional shape changes along selected kinematic pathways that are prescribed by the folding pattern. Origami has also proven to be a powerful method to tailor targeted mechanical properties and, in particular, multistability (Li et al. Reference Li, Fang, Sadeghi, Bhovad and Wang2019). Some specimens can thus settle in more than one stable state in the absence of external load and produce a rapid snap-through response as they pass from one equilibrium to the other (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014; Jianguo et al. Reference Jianguo, Xiaowei, Ya, Jian and Yongming2015; Yasuda, Chen & Yang Reference Yasuda, Chen and Yang2016; Li et al. Reference Li, Fang, Sadeghi, Bhovad and Wang2019). It offers predictable and reversible shape transformation, with the possibility to tune the shape and number of designated stable configurations through the fold arrangement, crease torsional stiffness and assigned rest angle (Waitukaitis et al. Reference Waitukaitis, Menaut, Chen and Van Hecke2015). Those transformable structures with programmable snap-through mechanisms have the potential to produce a controlled drop in drag at targeted flow conditions.

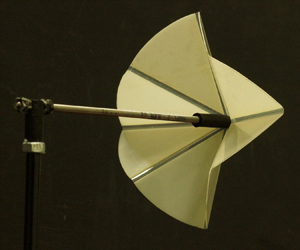

As a starting point, we demonstrate the potential for drag collapse with the waterbomb base, a single vertex bistable origami mechanism that is one of the fundamental origami units (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014; Lechenault, Thiria & Adda-Bedia Reference Lechenault, Thiria and Adda-Bedia2014). This umbrella-like cell has two stable states and features a rapid snap-through response as it transitions from one to the other. Origami structures have already raised interest for drag control, due to their large morphing capabilities (Cozmei et al. Reference Cozmei, Hasseler, Kinyon, Wallace, Deleo and Salviato2020; Zhang et al. Reference Zhang, Li, Wang and Yan2021; Marzin, de Langre & Ramananarivo Reference Marzin, de Langre and Ramananarivo2022; Zhang, Changguo & Zhang Reference Zhang, Changguo and Zhang2022). In particular, a previous study on the waterbomb base showed that its extreme reconfiguration tends to reduce drag to the point that it no longer increases with flow speed in the regime of large deformation (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). Here, we make use of its bistable nature, which has not been utilised before for drag applications. We show that it produces a discontinuous evolution of drag with flow speed, marked by a sudden and significant drop as the structure snaps through. We systematically vary the geometrical and mechanical properties of the unit and show that it allows us to tune the drag discontinuity and the critical speed and loading at which it occurs. Experiments are captured by a simplified theoretical model that is further used for inverse design, which is finding the structural origami parameters that produce a targeted drag collapse.

2. Drag collapse through snapping

The waterbomb base consists of a disc of radius ![]() $R$, featuring alternating mountain and valley folds distributed evenly around a central vertex. The present study focuses on the traditional version of the origami waterbomb, comprising a total of eight folds. Additional results for different numbers of folds are presented in the supplementary material available at https://doi.org/10.1017/jfm.2024.985. The unit is rigid-foldable, meaning that facets are considered rigid, with all movement occurring at the joints, thus simplifying the kinematic analysis. In addition, we assume symmetry of motion, based on experimental observation, meaning that all the mountain folds deflect by the same amount, and the same holds for the valley folds. As a result, the mechanism reduces to a one-degree-of-freedom system (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014, Reference Hanna, Magleby, Lang and Howell2015), where the shape of the entire structure can be determined from a single variable, chosen as the angle

$R$, featuring alternating mountain and valley folds distributed evenly around a central vertex. The present study focuses on the traditional version of the origami waterbomb, comprising a total of eight folds. Additional results for different numbers of folds are presented in the supplementary material available at https://doi.org/10.1017/jfm.2024.985. The unit is rigid-foldable, meaning that facets are considered rigid, with all movement occurring at the joints, thus simplifying the kinematic analysis. In addition, we assume symmetry of motion, based on experimental observation, meaning that all the mountain folds deflect by the same amount, and the same holds for the valley folds. As a result, the mechanism reduces to a one-degree-of-freedom system (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014, Reference Hanna, Magleby, Lang and Howell2015), where the shape of the entire structure can be determined from a single variable, chosen as the angle ![]() $\theta$ between a valley fold and the central axis passing through vertex (see figure 1a).

$\theta$ between a valley fold and the central axis passing through vertex (see figure 1a).

Figure 1. Drag collapse through flow-induced snap-through of a bistable origami unit. (a) Waterbomb base with radius ![]() $R$, composed of eight alternating valley and mountain folds with respective angles

$R$, composed of eight alternating valley and mountain folds with respective angles ![]() $\psi _v$ and

$\psi _v$ and ![]() $\psi _m$, and with unimodal kinematics described by the angle

$\psi _m$, and with unimodal kinematics described by the angle ![]() $\theta$. In the absence of loading, the bistable unit sits in one of two stable equilibria with angle

$\theta$. In the absence of loading, the bistable unit sits in one of two stable equilibria with angle ![]() $\theta _0$ and

$\theta _0$ and ![]() $\theta _0^*$. Evolution of (b) the drag force

$\theta _0^*$. Evolution of (b) the drag force ![]() $F_d$ in a uniform airflow with increasing velocity

$F_d$ in a uniform airflow with increasing velocity ![]() $U$, (c) the dimensionless frontal area

$U$, (c) the dimensionless frontal area ![]() $S/{\rm \pi} R^2$ projected in the plane perpendicular to the flow (see schematics of the experimental set-up in the inset of b) and (d) the drag coefficient defined with respect to the instantaneous area

$S/{\rm \pi} R^2$ projected in the plane perpendicular to the flow (see schematics of the experimental set-up in the inset of b) and (d) the drag coefficient defined with respect to the instantaneous area ![]() $S$. The drag collapse observed in the snapping unit (with

$S$. The drag collapse observed in the snapping unit (with ![]() $R=5$ cm,

$R=5$ cm, ![]() $\kappa =19\times 10^{-3}$ N and

$\kappa =19\times 10^{-3}$ N and ![]() $\theta _0 = 41^{\circ }$, blue solid curves) is compared with the quadratic drag of a rigid unit with the same geometry (same

$\theta _0 = 41^{\circ }$, blue solid curves) is compared with the quadratic drag of a rigid unit with the same geometry (same ![]() $R$ and

$R$ and ![]() $\theta _0$, grey dashed curves). Three tests were conducted on the same specimen, with error bars indicating the standard deviation (the grey zone denotes the variation in critical speed). Error bars for the drag coefficient are omitted for readability but are provided in the supplementary material.

$\theta _0$, grey dashed curves). Three tests were conducted on the same specimen, with error bars indicating the standard deviation (the grey zone denotes the variation in critical speed). Error bars for the drag coefficient are omitted for readability but are provided in the supplementary material.

Importantly, this unimodal origami mechanism has two stable equilibrium states and can transition between them through snapping. When at rest, the folded unit sits in one of these stable positions with its vertex pointing in one direction (see figure 1a i). Upon applying an external force, the structure flattens out towards a plane that represents an unstable equilibrium. When displaced beyond this plane, it snaps through and moves to a second stable position with the vertex pointing in the opposite direction (see figure 1a ii). These two stable positions are characterised by angles ![]() $\theta _0$ and

$\theta _0$ and ![]() $\theta _0^*$, and although they may look similar in figure 1(a), they are not mirror images of each other. The relationship between the angles of mountain and valley folds,

$\theta _0^*$, and although they may look similar in figure 1(a), they are not mirror images of each other. The relationship between the angles of mountain and valley folds, ![]() $\varPsi _m$ and

$\varPsi _m$ and ![]() $\varPsi _v$ (measured in terms of deviation to straightness, see figure 1a), and

$\varPsi _v$ (measured in terms of deviation to straightness, see figure 1a), and ![]() $\theta$ also differs on both sides of the unstable equilibrium (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014).

$\theta$ also differs on both sides of the unstable equilibrium (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014).

The origami bistable mechanism presents the advantage of being readily tunable. The stiffness of the folds notably influences the forces required to transition between stable states. One additional tuning parameter is the rest configuration, characterised by the angle ![]() $\theta _0$ in the first stable state. A compact unit (with a smaller

$\theta _0$ in the first stable state. A compact unit (with a smaller ![]() $\theta _0$) requires more elastic energy to pass through the unstable planar state, as it has to undergo a greater deflection. The second equilibrium state

$\theta _0$) requires more elastic energy to pass through the unstable planar state, as it has to undergo a greater deflection. The second equilibrium state ![]() $\theta _0^*$ also changes correspondingly with

$\theta _0^*$ also changes correspondingly with ![]() $\theta _0$, modulating the amplitude of the shape change upon snapping (the relationship between

$\theta _0$, modulating the amplitude of the shape change upon snapping (the relationship between ![]() $\theta _0$ and

$\theta _0$ and ![]() $\theta _0^*$ is illustrated in Supplementary figure 6).

$\theta _0^*$ is illustrated in Supplementary figure 6).

Specimens are fabricated using a technique developed in a previous study (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022) and inspired by the literature (Overvelde et al. Reference Overvelde, De Jong, Shevchenko, Becerra, Whitesides, Weaver, Hoberman and Bertoldi2016; Zuliani et al. Reference Zuliani, Liu, Paik and Felton2018), which is based on layer superposition. The rigid facets are laser cut from a ![]() $350$-

$350$-![]() $\mathrm {\mu }{\rm m}$-thick sheet of Mylar, which is then attached to a thinner sheet using double-sided tape, forming the creases. These folds act as elastic hinges of specific stiffness and rest angles. Rest angles are prescribed by utilising the thermoformable property of PET (see Appendix A). As shown in a previous study, the folds then operate as torsional springs, exhibiting elastic behaviour around their assigned rest angle (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). The stiffness can be adjusted by using different thicknesses of the thin sheet, ranging from

$\mathrm {\mu }{\rm m}$-thick sheet of Mylar, which is then attached to a thinner sheet using double-sided tape, forming the creases. These folds act as elastic hinges of specific stiffness and rest angles. Rest angles are prescribed by utilising the thermoformable property of PET (see Appendix A). As shown in a previous study, the folds then operate as torsional springs, exhibiting elastic behaviour around their assigned rest angle (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). The stiffness can be adjusted by using different thicknesses of the thin sheet, ranging from ![]() $40\unicode{x2013}100\ \mathrm {\mu }{\rm m}$. To measure the stiffness experimentally, a single fold is fabricated using the same process and is tested by tracking the opening angle as an increasing torque is applied to the hinge (see Appendix A and Supplementary figure 1). The value of the stiffness is then obtained from the slope of the torque–angle curve. The fabrication process shows a standard deviation of 8

$40\unicode{x2013}100\ \mathrm {\mu }{\rm m}$. To measure the stiffness experimentally, a single fold is fabricated using the same process and is tested by tracking the opening angle as an increasing torque is applied to the hinge (see Appendix A and Supplementary figure 1). The value of the stiffness is then obtained from the slope of the torque–angle curve. The fabrication process shows a standard deviation of 8![]() $\%$ for

$\%$ for ![]() $\kappa$.

$\kappa$.

We conducted tests on 10 origami units, sequentially varying the radius ![]() $R=4\unicode{x2013}7$ cm, the stiffness of the folds

$R=4\unicode{x2013}7$ cm, the stiffness of the folds ![]() $\kappa =8$–

$\kappa =8$–![]() $92 \times 10^{-3}$ N, and the rest configuration characterised by the angle

$92 \times 10^{-3}$ N, and the rest configuration characterised by the angle ![]() $\theta _0=32^{\circ }\unicode{x2013}66^{\circ }$. These units are subjected to a steady air flow generated by an open jet wind tunnel with a square cross-section of width

$\theta _0=32^{\circ }\unicode{x2013}66^{\circ }$. These units are subjected to a steady air flow generated by an open jet wind tunnel with a square cross-section of width ![]() $40$ cm and flow speed varied in

$40$ cm and flow speed varied in ![]() $1\unicode{x2013}16\ {\rm m}\ {\rm s}^{-1}$. An elbow arm is used upstream, to hold the unit at its vertex in the centre of the cross-section (see the inset of figure 1b). This arm is connected to a six-component force sensor, measuring the drag component of the fluid force in the direction of the flow. For each measurement, we average the drag over 30 s and subtract the drag on the support system alone. The flow-induced shape changes are characterised through the projected area

$1\unicode{x2013}16\ {\rm m}\ {\rm s}^{-1}$. An elbow arm is used upstream, to hold the unit at its vertex in the centre of the cross-section (see the inset of figure 1b). This arm is connected to a six-component force sensor, measuring the drag component of the fluid force in the direction of the flow. For each measurement, we average the drag over 30 s and subtract the drag on the support system alone. The flow-induced shape changes are characterised through the projected area ![]() $S$ of the unit in the plane perpendicular to the flow, captured by a camera placed downstream and extracted through Matlab custom image analysis. The observed kinematics align with the unimodal mechanism described earlier, which is rigidly foldable with motion restricted to the joint and exhibits rotational symmetry of motion. The entire geometry of the unit can be reconstructed from

$S$ of the unit in the plane perpendicular to the flow, captured by a camera placed downstream and extracted through Matlab custom image analysis. The observed kinematics align with the unimodal mechanism described earlier, which is rigidly foldable with motion restricted to the joint and exhibits rotational symmetry of motion. The entire geometry of the unit can be reconstructed from ![]() $S$, which will be further used as the observable to measure shape reconfiguration (the relationship between

$S$, which will be further used as the observable to measure shape reconfiguration (the relationship between ![]() $S$ and

$S$ and ![]() $\theta$ is illustrated in Supplementary figure 5).

$\theta$ is illustrated in Supplementary figure 5).

Figure 1(b) displays the evolution of drag with flow speed for a typical experiment (solid blue curve), alongside the frontal area in figure 1(c), and the drag coefficient calculated using this instantaneous area ![]() $C_d=F_d/(1/2 \rho S U^2)$ in figure 1(d), to isolate the effect of shape on drag. Results are compared with the drag behaviour of a rigid cell frozen in its initial configuration (dashed grey curves), which exhibits a classical

$C_d=F_d/(1/2 \rho S U^2)$ in figure 1(d), to isolate the effect of shape on drag. Results are compared with the drag behaviour of a rigid cell frozen in its initial configuration (dashed grey curves), which exhibits a classical ![]() $U^2$ law, associated with a relatively constant drag coefficient. Initially, the unit is in its first stable position

$U^2$ law, associated with a relatively constant drag coefficient. Initially, the unit is in its first stable position ![]() $\theta _0$, with the concave side facing the flow. As the flow speed gradually increases, the cell symmetrically opens up, leading to a faster increase of drag compared with its rigid counterpart. This enhanced drag is attributed solely to the expansion in frontal area, as the drag coefficient actually decreases with the cell adopting a less deep, parachute-like shape, consistent with observations from simpler geometries such as hemispherical caps (Hoerner Reference Hoerner1965; Ganedi et al. Reference Ganedi, Oza, Shelley and Ristroph2018). This drag coefficient reaches approximately

$\theta _0$, with the concave side facing the flow. As the flow speed gradually increases, the cell symmetrically opens up, leading to a faster increase of drag compared with its rigid counterpart. This enhanced drag is attributed solely to the expansion in frontal area, as the drag coefficient actually decreases with the cell adopting a less deep, parachute-like shape, consistent with observations from simpler geometries such as hemispherical caps (Hoerner Reference Hoerner1965; Ganedi et al. Reference Ganedi, Oza, Shelley and Ristroph2018). This drag coefficient reaches approximately ![]() $C_d=1.1$ as the cell approaches the flat unstable state (close to the 1.17 value for a flat disc), after which the unit snaps to a more compact and streamlined configuration. Note that slight cell vibrations make it challenging to precisely attain

$C_d=1.1$ as the cell approaches the flat unstable state (close to the 1.17 value for a flat disc), after which the unit snaps to a more compact and streamlined configuration. Note that slight cell vibrations make it challenging to precisely attain ![]() $S/{\rm \pi} R^2=1$. The sudden reconfiguration results in a discontinuity in the drag force on the unit, with a drop by up to

$S/{\rm \pi} R^2=1$. The sudden reconfiguration results in a discontinuity in the drag force on the unit, with a drop by up to ![]() $69\,\%$ among the specimens tested in this study, produced by both the significant area reduction in figure 1(c) and shape streamlining in figure 1(d). As

$69\,\%$ among the specimens tested in this study, produced by both the significant area reduction in figure 1(c) and shape streamlining in figure 1(d). As ![]() $U$ is further increased, the unit closes up. This closing regime has been studied extensively in a previous study (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022); it features an increase of drag that is slower than the quadratic

$U$ is further increased, the unit closes up. This closing regime has been studied extensively in a previous study (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022); it features an increase of drag that is slower than the quadratic ![]() $U^2$ law for rigid objects, owing to the reduction in frontal area exposed to the flow, combined with a decreasing drag coefficient resulting from shape streamlining.

$U^2$ law for rigid objects, owing to the reduction in frontal area exposed to the flow, combined with a decreasing drag coefficient resulting from shape streamlining.

To estimate the measurement uncertainty, we conducted three repetition of the experiments on the same specimen, re-annealed between each iteration to ensure a consistent initial configuration. Error bars in figure 1 represent the standard deviation, indicating relative variation in drag force and frontal area within 2 %. Small vibrations of the unit, especially as it approaches the unstable flat state, likely contribute to variations in the critical snapping velocity, which however remain within 2 %. Variability in the experiments were found to mainly results from the origami fabrication process. Additional tests conducted on five distinct units, all fabricated with identical parameters, exhibited a higher but reasonable dispersion, with about 10 % for the drag data, 9.5 % for the frontal area and 5 % for the critical snapping velocity (see Supplementary figure 3 and the supplementary material for more details on sources of uncertainties and measurement precision).

We thus observe a non-continuous evolution of drag with flow speed with a marked collapse. This behaviour can be described by selected observable parameters, namely the critical flow velocity of the snapping ![]() $U_c$, the maximum drag force reached just before snapping

$U_c$, the maximum drag force reached just before snapping ![]() $F_{d,max}$ and the subsequent drag drop

$F_{d,max}$ and the subsequent drag drop ![]() $\Delta F_d$. These parameters are prominent features characterising the discontinuity but are also relevant for practical applications, such as designing protection devices or valves. They determine a maximum load, the amount of load reduction, or the critical speed at which the structure would operate. In the following section, we investigate how those quantities are related to the origami geometrical and mechanical properties, specifically its size

$\Delta F_d$. These parameters are prominent features characterising the discontinuity but are also relevant for practical applications, such as designing protection devices or valves. They determine a maximum load, the amount of load reduction, or the critical speed at which the structure would operate. In the following section, we investigate how those quantities are related to the origami geometrical and mechanical properties, specifically its size ![]() $R$, rest configuration

$R$, rest configuration ![]() $\theta _0$ and fold stiffness

$\theta _0$ and fold stiffness ![]() $\kappa$.

$\kappa$.

3. Aeroelastic mechanism

We first vary the radius ![]() $R$ of the unit, while keeping the stiffness at

$R$ of the unit, while keeping the stiffness at ![]() $\kappa =19\times 10^{-3}$ N and the rest angle at

$\kappa =19\times 10^{-3}$ N and the rest angle at ![]() $\theta _0=41^{\circ }$. Note that fabrication produces a small variability in the rest angle among specimens, which is visible in figure 2(b) in the

$\theta _0=41^{\circ }$. Note that fabrication produces a small variability in the rest angle among specimens, which is visible in figure 2(b) in the ![]() $6\,\%$ dispersion in the dimensionless frontal area in the absence of flow (

$6\,\%$ dispersion in the dimensionless frontal area in the absence of flow (![]() $U=0$). As shown in figure 2(a,b), all units exhibit the characteristic behaviour described earlier, that is a non-continuous evolution of drag with flow speed with a sudden drop associated with the snap-through of the origami unit. However, bigger units (darker orange curves) initially experience a higher fluid loading, because of the larger area exposed to the flow. As a result, they reach the flat state

$U=0$). As shown in figure 2(a,b), all units exhibit the characteristic behaviour described earlier, that is a non-continuous evolution of drag with flow speed with a sudden drop associated with the snap-through of the origami unit. However, bigger units (darker orange curves) initially experience a higher fluid loading, because of the larger area exposed to the flow. As a result, they reach the flat state ![]() $S/{\rm \pi} R^2=1$ faster and flip at a lower critical speed (see figure 2b). Interestingly, in figure 2(a), the maximum drag

$S/{\rm \pi} R^2=1$ faster and flip at a lower critical speed (see figure 2b). Interestingly, in figure 2(a), the maximum drag ![]() $F_{d,max}$ experienced by the units before snapping is the same, and they feature similar jumps amplitude

$F_{d,max}$ experienced by the units before snapping is the same, and they feature similar jumps amplitude ![]() $\Delta F_d$. Changing the radius of the unit thus primarily shifts the critical velocity

$\Delta F_d$. Changing the radius of the unit thus primarily shifts the critical velocity ![]() $U_c$ at which the drag collapse occurs, while preserving

$U_c$ at which the drag collapse occurs, while preserving ![]() $F_{d,max}$ and

$F_{d,max}$ and ![]() $\Delta F_d$.

$\Delta F_d$.

Figure 2. Influence of the origami structural parameters on drag. Evolution of (a,c,e) the drag force ![]() $F_d$ and (b,d,f) the dimensionless frontal area

$F_d$ and (b,d,f) the dimensionless frontal area ![]() $S/ {\rm \pi}R^2$ as a function of flow velocity

$S/ {\rm \pi}R^2$ as a function of flow velocity ![]() $U$, for origami units with different (a,b) radii

$U$, for origami units with different (a,b) radii ![]() $R$, (c,d) fold stiffness

$R$, (c,d) fold stiffness ![]() $\kappa$ and (e,f) rest angle

$\kappa$ and (e,f) rest angle ![]() $\theta _0$. The unit

$\theta _0$. The unit ![]() $R=5$ cm,

$R=5$ cm, ![]() $\kappa =19 \times 10^{-3}\ {\rm N}$ and

$\kappa =19 \times 10^{-3}\ {\rm N}$ and ![]() $\theta _0=41^{\circ }$ is common to all graphs.

$\theta _0=41^{\circ }$ is common to all graphs.

Figure 2(c,d) shows the results for origami cells with different fold stiffness, but the same size ![]() $R=5$ cm and rest angle

$R=5$ cm and rest angle ![]() $\theta _0=41^{\circ }$ (with a similar degree of variability as earlier). Stiffer units (darker blue curves) deploy slower with increasing

$\theta _0=41^{\circ }$ (with a similar degree of variability as earlier). Stiffer units (darker blue curves) deploy slower with increasing ![]() $U$ owing to larger resistance to deformation, and reach the flat state at larger critical velocities (see figure 2d). The most rigid one does not reach this unstable point within the range of flow covered here. Snapping at larger speeds

$U$ owing to larger resistance to deformation, and reach the flat state at larger critical velocities (see figure 2d). The most rigid one does not reach this unstable point within the range of flow covered here. Snapping at larger speeds ![]() $U_c$ results both in higher drag peak values

$U_c$ results both in higher drag peak values ![]() $F_{d,max}$ and larger jumps

$F_{d,max}$ and larger jumps ![]() $\Delta F_d$ (see figure 2c). Stiffness thus affects all three drag features, offering an additional lever for control.

$\Delta F_d$ (see figure 2c). Stiffness thus affects all three drag features, offering an additional lever for control.

Finally, we vary the degree of opening of the cell rest state ![]() $\theta _0$, while keeping the size and stiffness constant as

$\theta _0$, while keeping the size and stiffness constant as ![]() $R=5$ cm and

$R=5$ cm and ![]() $\kappa =19\times 10^{-3}$ N, respectively. Starting from a more compact rest state (lighter green curves) delays the flipping towards higher flow velocities, as depicted in figure 2(f). Intuitively, reaching the flat state that is further away requires greater work from fluid loading. As was the case for the

$\kappa =19\times 10^{-3}$ N, respectively. Starting from a more compact rest state (lighter green curves) delays the flipping towards higher flow velocities, as depicted in figure 2(f). Intuitively, reaching the flat state that is further away requires greater work from fluid loading. As was the case for the ![]() $\kappa$-series of units, snapping at greater

$\kappa$-series of units, snapping at greater ![]() $U_c$ results in larger maximal drag

$U_c$ results in larger maximal drag ![]() $F_{d,max}$ in figure 2(e). As mentioned earlier and illustrated in the schematics of figure 2(f), changing

$F_{d,max}$ in figure 2(e). As mentioned earlier and illustrated in the schematics of figure 2(f), changing ![]() $\theta _0$ also affects the degree of closure of the second stable state. Small

$\theta _0$ also affects the degree of closure of the second stable state. Small ![]() $\theta _0$ (light green) results in a larger collapse in the frontal area post-snapping compared with units initially more opened (dark green) in figure 2(f). It correspondingly leads to larger jumps in drag

$\theta _0$ (light green) results in a larger collapse in the frontal area post-snapping compared with units initially more opened (dark green) in figure 2(f). It correspondingly leads to larger jumps in drag ![]() $\Delta F_d$ in figure 2(e). The rest angle thus completes the set of three parameters that will allow us to adjust the three drag characteristics

$\Delta F_d$ in figure 2(e). The rest angle thus completes the set of three parameters that will allow us to adjust the three drag characteristics ![]() $U_c$,

$U_c$, ![]() $F_{d,max}$ and

$F_{d,max}$ and ![]() $\Delta F_d$.

$\Delta F_d$.

The trends observed through variations in parameters reflect the interplay between external fluid loading and elastic restoring forces of the origami unit, which governs the unit's reconfiguration process. This fluid–elastic competition can be analysed in terms of Cauchy number ![]() $C_y$, as introduced in a previous study (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022) and frequently used in the literature (Alben et al. Reference Alben, Shelley and Zhang2002; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; de Langre et al. Reference de Langre, Gutierrez and Cossé2012). This dimensionless number examines the relative magnitudes of the work done by fluid forces,

$C_y$, as introduced in a previous study (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022) and frequently used in the literature (Alben et al. Reference Alben, Shelley and Zhang2002; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; de Langre et al. Reference de Langre, Gutierrez and Cossé2012). This dimensionless number examines the relative magnitudes of the work done by fluid forces, ![]() $\rho U^2 R^3$, and the elastic energy of folding,

$\rho U^2 R^3$, and the elastic energy of folding, ![]() $\kappa R$:

$\kappa R$:

In figure 3(a), drag measurements are re-plotted in the dimensionless form ![]() $\overline {F_d}=F_d/\kappa$ as a function of

$\overline {F_d}=F_d/\kappa$ as a function of ![]() $C_y$, using the fold stiffness

$C_y$, using the fold stiffness ![]() $\kappa$ as a characteristic force scale, in line with Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). Here, we only report data for units with different stiffness

$\kappa$ as a characteristic force scale, in line with Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). Here, we only report data for units with different stiffness ![]() $\kappa$ and radius

$\kappa$ and radius ![]() $R$, which share the same initial rest configuration

$R$, which share the same initial rest configuration ![]() $\theta _0$. Data collapse onto a master curve, with a drag peak and subsequent jump that are solely set by the fold stiffness, and which occur at a critical Cauchy number of

$\theta _0$. Data collapse onto a master curve, with a drag peak and subsequent jump that are solely set by the fold stiffness, and which occur at a critical Cauchy number of ![]() $C_{y,c} \approx 14$ for all units. Alternatively, the reconfiguration number

$C_{y,c} \approx 14$ for all units. Alternatively, the reconfiguration number ![]() $\mathcal {R}=F_d/F_{d,r}$ is often used to discuss the effect of deformability on drag (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010). It compares the drag force

$\mathcal {R}=F_d/F_{d,r}$ is often used to discuss the effect of deformability on drag (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010). It compares the drag force ![]() $F_d$ on the deforming cell to that on a rigid unit with the same geometry

$F_d$ on the deforming cell to that on a rigid unit with the same geometry ![]() $F_{d,r}$, which is evaluated by fitting a

$F_{d,r}$, which is evaluated by fitting a ![]() $U^2$ law to drag measurements at low speeds where deformation is minimal. The curve of

$U^2$ law to drag measurements at low speeds where deformation is minimal. The curve of ![]() $\mathcal {R}$ as a function of

$\mathcal {R}$ as a function of ![]() $C_y$ in figure 3(a) highlights distinct drag scaling regimes. At low

$C_y$ in figure 3(a) highlights distinct drag scaling regimes. At low ![]() $C_y$, where fluid loading is small compared with structural rigidity, the drag behaves like that of a rigid body, and

$C_y$, where fluid loading is small compared with structural rigidity, the drag behaves like that of a rigid body, and ![]() $\mathcal {R} \sim 1$. As

$\mathcal {R} \sim 1$. As ![]() $C_y$ increases,

$C_y$ increases, ![]() $\mathcal {R}$ rises due to the larger frontal area of the cell, then drops sharply below 1 at the critical Cauchy number

$\mathcal {R}$ rises due to the larger frontal area of the cell, then drops sharply below 1 at the critical Cauchy number ![]() $C_{y,c}$, and continues to decrease continuously with further deformation. In the large-deformation regime,

$C_{y,c}$, and continues to decrease continuously with further deformation. In the large-deformation regime, ![]() $\mathcal {R}$ declines with a logarithmic slope approaching

$\mathcal {R}$ declines with a logarithmic slope approaching ![]() $-1$, consistent with the plateau-like behaviour for drag observed in a previous study on the waterbomb unit (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). We previously showed that the dimensionless quantities

$-1$, consistent with the plateau-like behaviour for drag observed in a previous study on the waterbomb unit (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). We previously showed that the dimensionless quantities ![]() $C_y$ and

$C_y$ and ![]() $\overline {F_d}$ capture the effect of origami size and stiffness in fluid–elastic mechanisms. However, it does not account for the more intricate influence of the rest angle

$\overline {F_d}$ capture the effect of origami size and stiffness in fluid–elastic mechanisms. However, it does not account for the more intricate influence of the rest angle ![]() $\theta _0$. As shown in figure 3(b i), the latter affects the peak and jump value of

$\theta _0$. As shown in figure 3(b i), the latter affects the peak and jump value of ![]() $\overline {F_d}$, as well as the critical Cauchy number for snapping.

$\overline {F_d}$, as well as the critical Cauchy number for snapping.

Figure 3. Aeroelastic mechanism. (a) Evolution of the dimensionless drag ![]() $\overline {F_d}=F_d/\kappa$ as a function of the Cauchy number

$\overline {F_d}=F_d/\kappa$ as a function of the Cauchy number ![]() $C_y=\rho U^2R^2/\kappa$ for origami units with different radii

$C_y=\rho U^2R^2/\kappa$ for origami units with different radii ![]() $R$ and fold stiffness

$R$ and fold stiffness ![]() $\kappa$ (with the same rest angle

$\kappa$ (with the same rest angle ![]() $\theta _0=41^{\circ }$). The inset shows the reconfiguration number

$\theta _0=41^{\circ }$). The inset shows the reconfiguration number ![]() $\mathcal {R}=F_d/F_{d,r}$, which compares the drag force

$\mathcal {R}=F_d/F_{d,r}$, which compares the drag force ![]() $F_d$ with that of a rigid unit having the same geometry

$F_d$ with that of a rigid unit having the same geometry ![]() $F_{d,r}$. (b) Plot of

$F_{d,r}$. (b) Plot of ![]() $\overline {F_d}$ as a function of

$\overline {F_d}$ as a function of ![]() $C_y$ for units with different initial degree of opening

$C_y$ for units with different initial degree of opening ![]() $\theta _0$ (with the same

$\theta _0$ (with the same ![]() $R=5$ cm and

$R=5$ cm and ![]() $\kappa =19 \times 10^{-3}$ N). Experimental force data are compared with theoretical predictions (solid curves).

$\kappa =19 \times 10^{-3}$ N). Experimental force data are compared with theoretical predictions (solid curves).

Next, we develop a simplified theoretical model to further explore and corroborate the link between the origami unit's characteristics and drag. This model will also be used for the inverse problem. It employs the same energy approach as previous work on the closing dynamics of the waterbomb unit in a flow (Marzin et al. Reference Marzin, de Langre and Ramananarivo2022) and has been extended to account for the snapping. We provide a brief overview of the main elements of the model here, and additional details can be found in Appendix A and in Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). The static equilibrium of the unit in a flow is determined through the minimisation of its energy ![]() $E_{el}-W$, comprising both the elastic potential energy associated with folding

$E_{el}-W$, comprising both the elastic potential energy associated with folding ![]() $E_{el}$ and the work done by fluid forces

$E_{el}$ and the work done by fluid forces ![]() $W$ as the unit deforms:

$W$ as the unit deforms:

\begin{align} E_{el}-W =4\frac{\kappa R}{2}[(\psi_m - \psi_m^0)^2 + (\psi_v - \psi_v^0)^2] - 8 \int_{\theta_0}^{\theta} \int_{S_f} \rho(\boldsymbol{U}\boldsymbol{\cdot}\boldsymbol{n}_{\theta'})^2 \,{\rm d}S_f \boldsymbol{n}_{\theta'}\boldsymbol{\cdot}{\rm d} \boldsymbol{X}_{\theta'}, \end{align}

\begin{align} E_{el}-W =4\frac{\kappa R}{2}[(\psi_m - \psi_m^0)^2 + (\psi_v - \psi_v^0)^2] - 8 \int_{\theta_0}^{\theta} \int_{S_f} \rho(\boldsymbol{U}\boldsymbol{\cdot}\boldsymbol{n}_{\theta'})^2 \,{\rm d}S_f \boldsymbol{n}_{\theta'}\boldsymbol{\cdot}{\rm d} \boldsymbol{X}_{\theta'}, \end{align}

where ![]() $\rho$ is the air density and

$\rho$ is the air density and ![]() $S_f={\rm \pi} R^2/8$ is the facet area (with other quantities introduced subsequently). The first term of (3.2) corresponds to the elastic potential energy of the four mountain and four valley folds, modelled as elastic torsional springs with stiffness

$S_f={\rm \pi} R^2/8$ is the facet area (with other quantities introduced subsequently). The first term of (3.2) corresponds to the elastic potential energy of the four mountain and four valley folds, modelled as elastic torsional springs with stiffness ![]() $\kappa$. It scales with the square of the deviation of their respective angles

$\kappa$. It scales with the square of the deviation of their respective angles ![]() $\psi _m$ and

$\psi _m$ and ![]() $\psi _v$ to their rest values

$\psi _v$ to their rest values ![]() $\psi _{m}^{0}$ and

$\psi _{m}^{0}$ and ![]() $\psi _{v}^{0}$ (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014). The second term corresponds to the work done by fluid forces acting on the unit facets, which is the same for all eight facets owing to the rotational symmetry of motion. The Reynolds number for our experiments falls within the range

$\psi _{v}^{0}$ (Hanna et al. Reference Hanna, Lund, Lang, Magleby and Howell2014). The second term corresponds to the work done by fluid forces acting on the unit facets, which is the same for all eight facets owing to the rotational symmetry of motion. The Reynolds number for our experiments falls within the range ![]() $Re=UR/\nu \approx 10^3\unicode{x2013}10^5$, where form drag predominates over friction drag, and the latter is neglected. As discussed in Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022), friction forces likely become significant in regimes with substantial deformation, where facets nearly align with the flow. However, this particular regime is not reached in our present study. Consistent with earlier studies on the reconfiguration of flexible structures in a flow (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Schouveiler & Eloy Reference Schouveiler and Eloy2013; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022), pressure is computed using conservation of momentum principles. It is proportional to the square of the component of flow momentum perpendicular to the facet, denoted as

$Re=UR/\nu \approx 10^3\unicode{x2013}10^5$, where form drag predominates over friction drag, and the latter is neglected. As discussed in Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022), friction forces likely become significant in regimes with substantial deformation, where facets nearly align with the flow. However, this particular regime is not reached in our present study. Consistent with earlier studies on the reconfiguration of flexible structures in a flow (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Schouveiler & Eloy Reference Schouveiler and Eloy2013; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022), pressure is computed using conservation of momentum principles. It is proportional to the square of the component of flow momentum perpendicular to the facet, denoted as ![]() $\rho (\boldsymbol {U} \boldsymbol {\cdot } \boldsymbol {n}_{\theta })^2$, where

$\rho (\boldsymbol {U} \boldsymbol {\cdot } \boldsymbol {n}_{\theta })^2$, where ![]() $\boldsymbol {n}_{\theta }$ represents the normal unit vector. While simplified, this model has demonstrated effectiveness in capturing fluid–elastic behaviours (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Schouveiler & Eloy Reference Schouveiler and Eloy2013; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). It offers a reasonable approximation of more complex potential flow expressions (Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2004; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022), which would be challenging to implement for three-dimensional geometries. The pressure force is integrated over the facet area

$\boldsymbol {n}_{\theta }$ represents the normal unit vector. While simplified, this model has demonstrated effectiveness in capturing fluid–elastic behaviours (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Schouveiler & Eloy Reference Schouveiler and Eloy2013; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022). It offers a reasonable approximation of more complex potential flow expressions (Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2004; Marzin et al. Reference Marzin, de Langre and Ramananarivo2022), which would be challenging to implement for three-dimensional geometries. The pressure force is integrated over the facet area ![]() $S_f$ and its work is computed along the facet trajectory, with

$S_f$ and its work is computed along the facet trajectory, with ![]() $d \boldsymbol {X}_{\theta }$ the local displacement. By expressing the energy in a dimensionless form as

$d \boldsymbol {X}_{\theta }$ the local displacement. By expressing the energy in a dimensionless form as ![]() $\overline {E_{el}-W}=(E_{el}-W)/\kappa R$, the previously introduced Cauchy number

$\overline {E_{el}-W}=(E_{el}-W)/\kappa R$, the previously introduced Cauchy number ![]() $C_y$ emerges as the pertinent fluid–elastic parameter:

$C_y$ emerges as the pertinent fluid–elastic parameter:

\begin{align} \overline{E_{el}-W} =2\big[(\psi_m - \psi_m^0)^2 + (\psi_v - \psi_v^0)^2\big] - 8 C_y \int_{\theta_0}^{\theta} \int_{\bar{S}_f} \rho(\boldsymbol{e}_z\boldsymbol{\cdot}\boldsymbol{n}_{\theta'})^2 \,{\rm d}\bar{S}_f \boldsymbol{n}_{\theta'}\boldsymbol{\cdot}{\rm d} \bar{\boldsymbol{X}}_{\theta'}, \end{align}

\begin{align} \overline{E_{el}-W} =2\big[(\psi_m - \psi_m^0)^2 + (\psi_v - \psi_v^0)^2\big] - 8 C_y \int_{\theta_0}^{\theta} \int_{\bar{S}_f} \rho(\boldsymbol{e}_z\boldsymbol{\cdot}\boldsymbol{n}_{\theta'})^2 \,{\rm d}\bar{S}_f \boldsymbol{n}_{\theta'}\boldsymbol{\cdot}{\rm d} \bar{\boldsymbol{X}}_{\theta'}, \end{align}

where ![]() $\bar {\cdot }$ denotes dimensionless quantities, using the radius as characteristic length, and

$\bar {\cdot }$ denotes dimensionless quantities, using the radius as characteristic length, and ![]() $\boldsymbol {e}_z$ is the unit vector in the direction of the flow. In (3.3), all kinematic variables of the one-degree-of-freedom mechanism depend on a single parameter

$\boldsymbol {e}_z$ is the unit vector in the direction of the flow. In (3.3), all kinematic variables of the one-degree-of-freedom mechanism depend on a single parameter ![]() $\theta$. However, these relationships differ on each side of the flat state. The equilibrium angle

$\theta$. However, these relationships differ on each side of the flat state. The equilibrium angle ![]() $\theta$, which satisfies

$\theta$, which satisfies ![]() ${\rm d}\overline {(E_{el}-W)}/{\rm d}\theta =0$, is determined numerically while gradually increasing the Cauchy number, first addressing the opening phase of the kinematics. As the system approaches the flat state at

${\rm d}\overline {(E_{el}-W)}/{\rm d}\theta =0$, is determined numerically while gradually increasing the Cauchy number, first addressing the opening phase of the kinematics. As the system approaches the flat state at ![]() $\theta =90^{\circ }$ beyond a specific criterion, the kinematic relations are modified to describe the closing phase. From the static equilibrium angle

$\theta =90^{\circ }$ beyond a specific criterion, the kinematic relations are modified to describe the closing phase. From the static equilibrium angle ![]() $\theta$, we can determine the drag force acting on the unit as the component of fluid pressure forces in the direction of the flow (see Appendix A).

$\theta$, we can determine the drag force acting on the unit as the component of fluid pressure forces in the direction of the flow (see Appendix A).

Theoretical drag results are presented in figure 3(a) in dimensionless form, considering a given rest angle ![]() $\theta _0=41^{\circ }$ based on experiments (black solid line). The simplified model successfully captures experimental features, displaying a peak in drag that remains unaffected by the unit's size, followed by a sudden drop at a critical Cauchy number. Although the model tends to overestimate

$\theta _0=41^{\circ }$ based on experiments (black solid line). The simplified model successfully captures experimental features, displaying a peak in drag that remains unaffected by the unit's size, followed by a sudden drop at a critical Cauchy number. Although the model tends to overestimate ![]() $F_{d,max}$ and

$F_{d,max}$ and ![]() $\Delta F_d$, the quantitative agreement is reasonable, considering that no adjustable parameters were used and the simplifications made. As depicted in figure 3(b ii), the model also effectively captures the effect of varying the initial rest angle

$\Delta F_d$, the quantitative agreement is reasonable, considering that no adjustable parameters were used and the simplifications made. As depicted in figure 3(b ii), the model also effectively captures the effect of varying the initial rest angle ![]() $\theta _0$ on drag. A more compact unit exhibits a higher drag peak and jump, along with a higher critical Cauchy number. This model will be valuable for the inverse design of origami units to achieve the desired drag, as we discuss in the next section.

$\theta _0$ on drag. A more compact unit exhibits a higher drag peak and jump, along with a higher critical Cauchy number. This model will be valuable for the inverse design of origami units to achieve the desired drag, as we discuss in the next section.

4. Inverse design approach

We have characterised how the waterbomb unit features influence its drag behaviour. We now pose the question: ‘Can we identify the specific geometrical and mechanical origami parameters that would lead to a targeted drag collapse in a uniform fluid flow?’. More specifically, we formulate the inverse problem where the objective is to find the optimal set of parameters ![]() $(R,\kappa,\theta _0)$ that will result in a collapse of drag, with a predefined target peak drag force

$(R,\kappa,\theta _0)$ that will result in a collapse of drag, with a predefined target peak drag force ![]() $F_{d,max}^t$ and jump

$F_{d,max}^t$ and jump ![]() $\Delta F_d^t$ value at a critical flow speed

$\Delta F_d^t$ value at a critical flow speed ![]() $U_c^t$. To address this, we use the model presented earlier and validated experimentally, which establishes a relationship between the parameters

$U_c^t$. To address this, we use the model presented earlier and validated experimentally, which establishes a relationship between the parameters ![]() $(R, \kappa, \theta _0)$ and the resulting drag characteristics

$(R, \kappa, \theta _0)$ and the resulting drag characteristics ![]() $(F_{d,max}, \Delta F_d, U_c)$. The optimisation is implemented numerically in Matlab using the trust-region-dogleg algorithm of fsolve solver. It solves the system of equations

$(F_{d,max}, \Delta F_d, U_c)$. The optimisation is implemented numerically in Matlab using the trust-region-dogleg algorithm of fsolve solver. It solves the system of equations ![]() $F_d-F_{d,max}^t=0$,

$F_d-F_{d,max}^t=0$, ![]() $\Delta F_d-\Delta F_d^t=0$ and

$\Delta F_d-\Delta F_d^t=0$ and ![]() $U_c-U_c^t=0$ with respect to the origami unit's features

$U_c-U_c^t=0$ with respect to the origami unit's features ![]() $(R,\kappa,\theta _0)$. The algorithm finds a single solution, satisfying the constraints by a maximum residual of

$(R,\kappa,\theta _0)$. The algorithm finds a single solution, satisfying the constraints by a maximum residual of ![]() $O(10^{-19})$ within a hundred iterations.

$O(10^{-19})$ within a hundred iterations.

To validate the inverse design approach, we test our prediction experimentally by fabricating the optimised design and measuring the evolution of its drag with flow speed. While the specific radius ![]() $R$ and rest angle

$R$ and rest angle ![]() $\theta _0$ can be easily implemented through laser-cutting and an adjustable mount, achieving an arbitrary fold stiffness

$\theta _0$ can be easily implemented through laser-cutting and an adjustable mount, achieving an arbitrary fold stiffness ![]() $\kappa$ is more challenging. This limitation arises from the finite number of sheet thicknesses available for manufacturing the folds. To overcome this constraint, we introduce slits in the folds. These slits modulate the effective length of the folds and, consequently, their stiffness, enabling a controlled variation of

$\kappa$ is more challenging. This limitation arises from the finite number of sheet thicknesses available for manufacturing the folds. To overcome this constraint, we introduce slits in the folds. These slits modulate the effective length of the folds and, consequently, their stiffness, enabling a controlled variation of ![]() $\kappa$ by adjusting their number (see Appendix A and Supplementary figure 2).

$\kappa$ by adjusting their number (see Appendix A and Supplementary figure 2).

To demonstrate our ability to control the drag behaviour, we create sets of specimens with one parameter gradually changing while keeping the other two fixed. We first vary the targeted critical flow speed for snapping, as ![]() $U_c^t=[4, 7, 10]\ {\rm m}\ {\rm s}^{-1}$, while prescribing constant peak drag value

$U_c^t=[4, 7, 10]\ {\rm m}\ {\rm s}^{-1}$, while prescribing constant peak drag value ![]() $F_{d,max}^t=0.8$ N and jump

$F_{d,max}^t=0.8$ N and jump ![]() $\Delta F_d^t=0.6$ N. The corresponding optimised origami parameters

$\Delta F_d^t=0.6$ N. The corresponding optimised origami parameters ![]() $(R,\kappa,\theta _0)$ are provided in Appendix A. Consistent with the differences observed earlier in figure 3 between experiments and theory, the experimental realisations exhibit lower values in figure 4(b), namely

$(R,\kappa,\theta _0)$ are provided in Appendix A. Consistent with the differences observed earlier in figure 3 between experiments and theory, the experimental realisations exhibit lower values in figure 4(b), namely ![]() $U_c=[3.7,6.0,8.8]\ {\rm m}\ {\rm s}^{-1}$,

$U_c=[3.7,6.0,8.8]\ {\rm m}\ {\rm s}^{-1}$, ![]() $F_{d,max}=0.29$ N and

$F_{d,max}=0.29$ N and ![]() $\Delta F_d=0.10$ N. Nevertheless, we successfully achieved a gradual variation in

$\Delta F_d=0.10$ N. Nevertheless, we successfully achieved a gradual variation in ![]() $U_c$ while keeping the other two parameters unchanged. Note that the optimised designs have the same rest angle and fold stiffness, but varying radius, which is consistent with the previous results shown in figure 2(a). We indeed demonstrated that

$U_c$ while keeping the other two parameters unchanged. Note that the optimised designs have the same rest angle and fold stiffness, but varying radius, which is consistent with the previous results shown in figure 2(a). We indeed demonstrated that ![]() $F_{d,max}$ and

$F_{d,max}$ and ![]() $\Delta F_d$ are size-independent and, therefore, determined by the specific combination of

$\Delta F_d$ are size-independent and, therefore, determined by the specific combination of ![]() $(\kappa,\theta _0)$. In figure 4(c,d), we systematically vary the jump

$(\kappa,\theta _0)$. In figure 4(c,d), we systematically vary the jump ![]() $\Delta F_d$ and peak

$\Delta F_d$ and peak ![]() $F_{d,max}$, respectively (target values are reported in Appendix A). Similarly, although the physical samples have drag quantities below the target values, they still showcased the intended selective variations. Our results confirm the validity of our inverse design approach, but there are limitations to how closely we can match desired drag behaviours. These limitations arise primarily from the theoretical model employed in the optimisation procedure. While it accurately captures the effect of origami parameters on drag, it only provides semi-quantitative agreement with the experimental data. Note that deviations between the targeted drag features and those of the resulting optimised design in figure 4 align with differences reported in prior experimental–theoretical comparisons of figure 3 (see Supplementary figures 11 and 12). Refining the model, notably using a more realistic representation for the fluid dynamics, is thus expected to produce better quantitative results.

$F_{d,max}$, respectively (target values are reported in Appendix A). Similarly, although the physical samples have drag quantities below the target values, they still showcased the intended selective variations. Our results confirm the validity of our inverse design approach, but there are limitations to how closely we can match desired drag behaviours. These limitations arise primarily from the theoretical model employed in the optimisation procedure. While it accurately captures the effect of origami parameters on drag, it only provides semi-quantitative agreement with the experimental data. Note that deviations between the targeted drag features and those of the resulting optimised design in figure 4 align with differences reported in prior experimental–theoretical comparisons of figure 3 (see Supplementary figures 11 and 12). Refining the model, notably using a more realistic representation for the fluid dynamics, is thus expected to produce better quantitative results.

Figure 4. Targeting drag collapse features. (a) The inverse design approach consists of finding the set of origami structural parameters (![]() $R$,

$R$, ![]() $\kappa$,

$\kappa$, ![]() $\theta _0$) that will lead to a collapse of drag with a targeted maximum before snapping

$\theta _0$) that will lead to a collapse of drag with a targeted maximum before snapping ![]() $F_{d,max}$, jump

$F_{d,max}$, jump ![]() $\Delta F_d$ and occurring at a defined critical flow speed

$\Delta F_d$ and occurring at a defined critical flow speed ![]() $U_c$. Evolution of drag with flow speed for physical prototypes of optimised origami designs, which are calculated to produce a selective variation of (b)

$U_c$. Evolution of drag with flow speed for physical prototypes of optimised origami designs, which are calculated to produce a selective variation of (b) ![]() $U_c$, (c)

$U_c$, (c) ![]() $\Delta F_d$ and (d)

$\Delta F_d$ and (d) ![]() $F_{d,max}$, while keeping the two remaining features identical. Respective target values of (

$F_{d,max}$, while keeping the two remaining features identical. Respective target values of (![]() $U_c$,

$U_c$, ![]() $\Delta F_d$,

$\Delta F_d$, ![]() $F_{d,max}$) are indicated in Appendix A.

$F_{d,max}$) are indicated in Appendix A.

5. Conclusion and discussion

In this study, we leverage the waterbomb base's bistability to sharply reduce drag force with flow velocity. A uniform airflow unfolds the origami unit, which, upon reaching a flat state, undergoes a snap-through to a more streamlined shape, causing a sudden collapse of drag. While the use of elastic deformation to mitigate drag increase with flow speed is not novel (Vogel Reference Vogel1984; Alben et al. Reference Alben, Shelley and Zhang2002; Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; de Langre et al. Reference de Langre, Gutierrez and Cossé2012; Schouveiler & Eloy Reference Schouveiler and Eloy2013); here, a decrease is achieved through significant and abrupt shape changes over a small increment of fluid input load. Importantly, the snap-through is tunable based on the cell radius, fold stiffness and rest angle, providing control over drag characteristics.

We show that the cell behaviour results from the quasi-static mechanical equilibrium between actuating fluid loading and restoring elastic forces, captured by a Cauchy number. The snap-through occurs at a fixed critical Cauchy number for a given cell rest angle. The later serves as an additional control, influencing both snap-through onset and drag changes. These experimental features are captured by a theoretical fluid–elastic model, portraying the cell as rigid facets with folds acting as elastic hinges, and utilising an empirical formulation for fluid pressure forces, consistent with prior studies. The model effectively accounts for the influence of cell structural parameters on drag, demonstrating reasonable predictiveness despite a tendency to overestimate drag. However, such discrepancies are expected due to the absence of adjustable parameters and the simplified representation of the origami's elastic response and fluid dynamics. Force-deflection tests on the waterbomb unit show reasonable agreement with the idealised mechanical model, though some softening near the flat state is observed, possibly due to vertex effects or fabrication imperfections (see Supplementary figure 8). A modified model, using elastic potential energy derived from these tests, suggests that this softening might cause snap-through at a lower critical speed and a reduced peak drag. Nevertheless, it only marginally accounts for the discrepancies between the theoretical predictions and the experimental results shown in figure 3(a). These differences likely arise from the simplified description of fluid dynamics, which notably does not account for the object's feedback on the flow. Local fluid forces, which are not influenced by the object's overall shape or wake, result in a drag coefficient of ![]() $C_d=2$ when the unit reaches the flat state, where drag is typically overestimated, compared with the expected value of 1.17 for a disc. To address this, we can introduce a corrective pressure coefficient

$C_d=2$ when the unit reaches the flat state, where drag is typically overestimated, compared with the expected value of 1.17 for a disc. To address this, we can introduce a corrective pressure coefficient ![]() $C$, such that

$C$, such that ![]() $P = C \rho (\boldsymbol {U}\boldsymbol {\cdot }\boldsymbol {n_{\theta }})^2$, to align the drag coefficient to that of a disc in the flat configuration. This adjustment changes the critical Cauchy number for snapping, but it does not resolve the peak drag overestimation. Further improvements could involve using a variable pressure coefficient or a more refined spatial pressure force distribution that adapts to the cell reconfiguration. Flow visualisation or computational fluid dynamics simulations would then be instrumental in determining the shape dependence of this pressure field and improving the predictive accuracy of the model.

$P = C \rho (\boldsymbol {U}\boldsymbol {\cdot }\boldsymbol {n_{\theta }})^2$, to align the drag coefficient to that of a disc in the flat configuration. This adjustment changes the critical Cauchy number for snapping, but it does not resolve the peak drag overestimation. Further improvements could involve using a variable pressure coefficient or a more refined spatial pressure force distribution that adapts to the cell reconfiguration. Flow visualisation or computational fluid dynamics simulations would then be instrumental in determining the shape dependence of this pressure field and improving the predictive accuracy of the model.

The modelling framework provides the system equations to guide inverse design, intending to identify the combination of structural parameters leading to a targeted drag collapse. Our implementation showcases an advanced level of control, allowing selective adjustment of key drag features: namely, the peak drag before snapping, the drag drop and the critical flow speed at which it occurs. Although the number of folds is not included in our current inverse design framework, it has a distinctive effect on drag (see supplementary material). It could be a valuable parameter for expanding the design space and controlling additional drag characteristics, such as the rate at which drag increases again after dropping. Currently, quantitative predictability is contingent on the model's accuracy and the precise control of the origami's mechanical properties during fabrication. Improved closeness to the target is anticipated with more refined fluid–elastic models and advancements in manufacturing techniques, positioning this work as promising proof of concept. It illustrates the potential of origami as a platform for programming drag-vs-speed behaviour.

This programmability holds value for self-protection strategies, mitigating excessive aerodynamic loads beyond a predetermined threshold. Force transitions above a tunable critical flow velocity could also serve as a velocity threshold detector. The switch-like response of the waterbomb base also holds the potential for fluidic control in a channel, for example, acting as a relief valve. It would obstruct a conduct as it deploys and discharges the fluid beyond a predetermined pressure level, limiting pressure built up. For the waterbomb base, snap-through involves passing through an unstable flat state, leading to an initial drag increase greater than that of a rigid object. This enhanced drag could be advantageous for stabilisation or speed-reduction in applications such as sea anchors, drogues or stabilisers for aerial refuelling pipes (Holler Reference Holler1985; Wei et al. Reference Wei, Dai, Quan and Cai2016). Such shape-adaptive drag may offer better control and stabilisation compared with fixed-shape designs in varying fluid environments. However, drag enhancement is not a universal feature of bistable origami mechanisms, as some do not require transitioning through a flat state (Waitukaitis et al. Reference Waitukaitis, Menaut, Chen and Van Hecke2015). Rapid morphing can also result from torsional instabilities caused by axial asymmetry in the folds, though this was not observed in this study. In addition, ‘hidden’ degrees of freedom not explicit in the crease pattern, such as facet bending (Liu & Felton Reference Liu and Felton2018), could enable substantial shape changes while maintaining minimal deformation and a relatively constant drag coefficient before snap-through.

Here, morphing is driven aeroelastically, enabling the component to autonomously respond to the local environment, and eliminating the need for additional sensing and control systems. Such passive mechanisms allow for a more streamlined structural design of the aerodynamic control surface. However, a bistable mechanism requires external intervention or a counter-flow to return to its original state. This ability to retain the inverted state could be advantageous for functioning as a memory unit, storing information about past fluid conditions, similar to (Jules et al. Reference Jules, Reid, Daniels, Mungan and Lechenault2022). Alternatively, using a monostable system that snaps through when loaded but returns to its original state when the load is removed could address this limitation (Arena et al. Reference Arena, Groh, Brinkmeyer, Theunissen, Weaver and Pirrera2017; Gomez et al. Reference Gomez, Moulton and Vella2017; Arena et al. Reference Arena, Groh, Theunissen, Weaver and Pirrera2018). This could be achieved with restoring springs that pull the unit back to its original position when the airspeed decreases. Further study is needed to assess the multistability of such systems and to identify configurations where they are bistable, monostable with snap-through or stable without snap-through.

Another advantage of origami is the ability to easily combine multiple bistable elements to produce multistable structures (Silverberg et al. Reference Silverberg, Evans, McLeod, Hayward, Hull, Santangelo and Cohen2014; Li & Wang Reference Li and Wang2015; Sengupta & Li Reference Sengupta and Li2018; Jules et al. Reference Jules, Reid, Daniels, Mungan and Lechenault2022). An example is shown in figure 5, featuring a chain made of two waterbomb cells with the same size and different rest angle and fold stiffness (see also Supplementary figure 9). It produces two successive sharp transitions in the drag force. With sufficient spatial separation, each unit is expected to have its independent flow velocity threshold initiating snap-through. Other configurations might, however, lead to interactions between cells through external flow, resulting in a more complex collective response, as observed in fluidic cellular origami (albeit for internal pressurisation) (Li & Wang Reference Li and Wang2015). Alternatively, if cells share facets, they can also communicate the mechanical state of one unit to its neighbour, forming logic elements (Treml et al. Reference Treml, Gillman, Buskohl and Vaia2018). This has the potential to generate more complex snapping sequences and subsequent drag evolution with flow speed for advanced adaptive functionalities.

Figure 5. Leveraging multistability for a double drag collapse. A multistable origami structure is formed through the assembly of two waterbomb units, with different fold stiffness ![]() $\kappa _1=19 \times 10^{-3}$ N and

$\kappa _1=19 \times 10^{-3}$ N and ![]() $\kappa _2=53 \times 10^{-3}$ N and rest angle

$\kappa _2=53 \times 10^{-3}$ N and rest angle ![]() $\theta _{0,1}=56^{\circ }$ and

$\theta _{0,1}=56^{\circ }$ and ![]() $\theta _{0,2}=71^{\circ }$, and the same radius

$\theta _{0,2}=71^{\circ }$, and the same radius ![]() $R=5$ cm (inset). The successive snap-throughs lead to sequential drag collapses when exposed to a uniform flow with increasing speed.

$R=5$ cm (inset). The successive snap-throughs lead to sequential drag collapses when exposed to a uniform flow with increasing speed.

Supplementary material

Supplementary material is available at https://doi.org/10.1017/jfm.2024.985.

Funding

We acknowledge support from a JCJC grant of the Agence Nationale de la Recherche (ANR-20-CE30-0009-01) to S.R. and from the Agence Innovation Défense to T.M.

Data availability statement

The datasets generated during the current study are available from the corresponding author upon request.

Declaration of interests

The authors report no conflict of interest.

Appendix A

A.1. Origami fabrication

Specimens are fabricated using a layer superposition method. The rigid facets are laser cut from a ![]() $350$-

$350$-![]() $\mathrm {\mu }{\rm m}$-thick sheet of Mylar, which is then attached to a thinner sheet using double-sided tape with a 2.5 mm spacing that forms the creases. The folded unit is then maintained in a desired configuration on a mount, placed in a heating chamber for an hour at

$\mathrm {\mu }{\rm m}$-thick sheet of Mylar, which is then attached to a thinner sheet using double-sided tape with a 2.5 mm spacing that forms the creases. The folded unit is then maintained in a desired configuration on a mount, placed in a heating chamber for an hour at ![]() $75\,^{\circ }{\rm C}$, and then left to cool down at room temperature. It thus effectively prescribes the first stable state

$75\,^{\circ }{\rm C}$, and then left to cool down at room temperature. It thus effectively prescribes the first stable state ![]() $\theta _0$. This annealing process relaxes any residual stresses that might have been created during folding (Lechenault et al. Reference Lechenault, Thiria and Adda-Bedia2014) so that the first stable state is close to a zero-energy state.

$\theta _0$. This annealing process relaxes any residual stresses that might have been created during folding (Lechenault et al. Reference Lechenault, Thiria and Adda-Bedia2014) so that the first stable state is close to a zero-energy state.

A.2. Fold stiffness

To measure fold stiffness, a prototype of a single crease was designed using the manufacturing process outlined in § A.1 and in Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). While keeping one of the facets fixed vertically, we apply a variable increasing point load to the geometrical centre of the free facet and extract the opening angle of the fold ![]() $\varPsi$ (see Supplementary figure 1a). The opening angle in the absence of load is set to

$\varPsi$ (see Supplementary figure 1a). The opening angle in the absence of load is set to ![]() $\varPsi _0 \approx 113^{\circ } \pm 8^{\circ }$ for all the tests, but note that the stiffness was found independent of

$\varPsi _0 \approx 113^{\circ } \pm 8^{\circ }$ for all the tests, but note that the stiffness was found independent of ![]() $\varPsi _0$ in the previous study of Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). The fold acts as a torsional spring, exhibiting a linear relationship between the torque applied

$\varPsi _0$ in the previous study of Marzin et al. (Reference Marzin, de Langre and Ramananarivo2022). The fold acts as a torsional spring, exhibiting a linear relationship between the torque applied ![]() $T$ (accounting for the weight of the hanging facet as well) and the angular deviation

$T$ (accounting for the weight of the hanging facet as well) and the angular deviation ![]() $\varPsi -\varPsi _0$ (see Supplementary figure 1b). The stiffness is extracted from the slope as

$\varPsi -\varPsi _0$ (see Supplementary figure 1b). The stiffness is extracted from the slope as ![]() $T=\kappa L (\varPsi -\varPsi _0)$, with

$T=\kappa L (\varPsi -\varPsi _0)$, with ![]() $L=4$ cm the crease length. Table 1 lists

$L=4$ cm the crease length. Table 1 lists ![]() $\kappa$ values for the four thin sheets. Repeatability and robustness were assessed by measuring

$\kappa$ values for the four thin sheets. Repeatability and robustness were assessed by measuring ![]() $\kappa$ for eight folds from a

$\kappa$ for eight folds from a ![]() $50\ \mathrm {\mu }{\rm m}$ sheet, resulting in an

$50\ \mathrm {\mu }{\rm m}$ sheet, resulting in an ![]() $8\,\%$ variability based on standard deviation relative to the mean value.

$8\,\%$ variability based on standard deviation relative to the mean value.

Table 1. Stiffness measured for folds made from sheets with different thickness.

To expand the range of achievable stiffness values, we employ a strategy inspired by prior work (Zuliani et al. Reference Zuliani, Liu, Paik and Felton2018) and introduce slits in the folds. Slits with ![]() $5$ mm length are evenly distributed along the crease length, and span its width (see Supplementary figure 2a). Adjusting their number modulates the effective length of the fold, thereby changing its stiffness and facilitating the attainment of diverse

$5$ mm length are evenly distributed along the crease length, and span its width (see Supplementary figure 2a). Adjusting their number modulates the effective length of the fold, thereby changing its stiffness and facilitating the attainment of diverse ![]() $\kappa$ values. As shown in Supplementary figure 2(b), the stiffness of a slitted fold scales linearly with its effective length, with a

$\kappa$ values. As shown in Supplementary figure 2(b), the stiffness of a slitted fold scales linearly with its effective length, with a ![]() $7\,\%$ deviation from the expected linear relationship. To ensure that the presence of slits has minimal effect on the interaction of the origami unit with the flow, we conducted experiments with two specimens, one with slitted folds and another with unslitted folds, both having the same stiffness. These two specimens exhibited identical drag curves, indicating that the slits did not significantly affect the performance in the flow (see Supplementary figure 2).