1. Introduction

Colasante (Reference Colasante2015) communicates an interesting experiment involving a flexible plate that is oscillated along its normal axis by an actuator affixed to its centre. When the plate is brought close to a non-adhesive parallel surface, it becomes subject to an attractive force that allows the exertion of a steady pulling load on the vibrating device, as depicted in figure 1(a). For example, when oscillating near a smooth concrete surface a square aluminium plate (with a thickness of ![]() $1$ mm and a side length of

$1$ mm and a side length of ![]() $61$ cm) at a frequency of

$61$ cm) at a frequency of ![]() $15$ Hz, Colasante (Reference Colasante2023) measures a load capacity of nearly

$15$ Hz, Colasante (Reference Colasante2023) measures a load capacity of nearly ![]() $200$ kgf (kilograms force) with a power consumption of

$200$ kgf (kilograms force) with a power consumption of ![]() ${\approx }200$ W (watts). The device exhibits remarkably low resistance to lateral motion (Colasante Reference Colasante2016), suggesting the presence of a lubricating layer of air that separates the undulating plate from the opposite surface.

${\approx }200$ W (watts). The device exhibits remarkably low resistance to lateral motion (Colasante Reference Colasante2016), suggesting the presence of a lubricating layer of air that separates the undulating plate from the opposite surface.

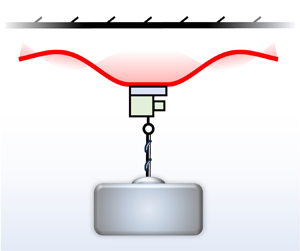

Figure 1. (a) Cartoon and free-body diagram of a load-bearing SFL system enabled by the flexural oscillation of a thin, locally excited disk and (b) a formal schematic of the axisymmetric system geometry used in the problem definition § 2.

In 2021, Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021) exploited this phenomenon (having arrived at it independently) in the design of a load-carrying robotic device capable of travelling underneath horizontal surfaces and up vertical walls with use of a standard wheel base and a thin, oscillating plastic disk. The device produced an attractive force exceeding ![]() $0.6$ kgf using less than

$0.6$ kgf using less than ![]() $0.3$ W of power (Precision Microdrives 2021), thereby achieving an impressive operating efficiency of over

$0.3$ W of power (Precision Microdrives 2021), thereby achieving an impressive operating efficiency of over ![]() $2$ kgf W

$2$ kgf W![]() $^{-1}$. Subsequently, Jia et al. (Reference Jia, Ramanarayanan, Sánchez and Tolley2023) designed a robot that travelled and rotated controllably beneath a horizontal surface without the use of wheels. Instead, multiple vibration actuators were employed to excite travelling-wave deformations of the plate, the resulting streaming of air within the air layer providing propulsive/rotary shear stresses on the plate (Ramanarayanan & Sánchez Reference Ramanarayanan and Sánchez2023).

$^{-1}$. Subsequently, Jia et al. (Reference Jia, Ramanarayanan, Sánchez and Tolley2023) designed a robot that travelled and rotated controllably beneath a horizontal surface without the use of wheels. Instead, multiple vibration actuators were employed to excite travelling-wave deformations of the plate, the resulting streaming of air within the air layer providing propulsive/rotary shear stresses on the plate (Ramanarayanan & Sánchez Reference Ramanarayanan and Sánchez2023).

The phenomenon described above is commonly referred to as ‘squeeze-film levitation’ (SFL) (Shi et al. Reference Shi, Feng, Hu, Zhu and Cui2019), a method of gaseous lubrication discovered seemingly in the mid 1950s by which the required overpressure inside a wall-bounded gas layer is effectively provided by relative perpendicular oscillation of the walls (Taylor & Saffman Reference Taylor and Saffman1957). In contrast to aerodynamic and aerostatic lubrication, which directly provide quasi-steady overpressures due to relative translational motion of non-parallel walls or external pumping of air, respectively, the oscillating pressure inside a squeeze film exhibits a cycle-averaged value that differs from the ambient value due to the nonlinear effects of gaseous compressibility and convective fluid acceleration (Melikhov et al. Reference Melikhov, Chivilikhin, Amosov and Jeanson2016; Ramanarayanan, Coenen & Sánchez Reference Ramanarayanan, Coenen and Sánchez2022). The resulting pressure difference across the oscillating plate generates a time-averaged normal force that provides a steady load-bearing capacity.

Typical SFL systems involve highly stiff oscillators that are driven by bulky piezoelectric transducers at ultrasonic frequencies, and produce large repulsive forces that render them suitable for conventional bearing lubrication. For example, Zhao (Reference Zhao2010) measured a steady repulsive force of ![]() ${\approx }11.7$ kgf, with an operating efficiency of

${\approx }11.7$ kgf, with an operating efficiency of ![]() ${\approx }0.24\ {\rm kgf}\ {\rm W}^{-1}$, by oscillating a cylindrical oscillator of diameter

${\approx }0.24\ {\rm kgf}\ {\rm W}^{-1}$, by oscillating a cylindrical oscillator of diameter ![]() $5$ cm at a frequency of

$5$ cm at a frequency of ![]() $20\ 000$ Hz. Prior to the experiments by Colasante (Reference Colasante2015), attractive forces had been found to occur only under a limited range of operating conditions – relatively low frequencies or oscillators with small surface area, the corresponding load capacities being thousands of times weaker. For example, a maximal attractive force of just

$20\ 000$ Hz. Prior to the experiments by Colasante (Reference Colasante2015), attractive forces had been found to occur only under a limited range of operating conditions – relatively low frequencies or oscillators with small surface area, the corresponding load capacities being thousands of times weaker. For example, a maximal attractive force of just ![]() ${\approx }0.5$ gf (grams-force) was measured by Sadayuki (Reference Sadayuki2002) using a cylindrical oscillator of diameter

${\approx }0.5$ gf (grams-force) was measured by Sadayuki (Reference Sadayuki2002) using a cylindrical oscillator of diameter ![]() $7$ cm and frequency

$7$ cm and frequency ![]() $200$ Hz. Correspondingly, throughout history, levitation and transportation/rotation systems enabled by repulsive forces have garnered considerable theoretical attention (Zhao Reference Zhao2010; Feng, Liu & Cheng Reference Feng, Liu and Cheng2015; Chen et al. Reference Chen, Gao, Pan and Guo2016; Davis, Gabai & Bucher Reference Davis, Gabai and Bucher2018; Guo & Gao Reference Guo and Gao2018; Shi et al. Reference Shi, Feng, Hu, Zhu and Cui2019), while fewer studies have addressed the emergence of the much weaker attractive forces (Yoshimoto, Shou & Somaya Reference Yoshimoto, Shou and Somaya2013; Andrade et al. Reference Andrade, Ramos, Adamowski and Marzo2020; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022).

$200$ Hz. Correspondingly, throughout history, levitation and transportation/rotation systems enabled by repulsive forces have garnered considerable theoretical attention (Zhao Reference Zhao2010; Feng, Liu & Cheng Reference Feng, Liu and Cheng2015; Chen et al. Reference Chen, Gao, Pan and Guo2016; Davis, Gabai & Bucher Reference Davis, Gabai and Bucher2018; Guo & Gao Reference Guo and Gao2018; Shi et al. Reference Shi, Feng, Hu, Zhu and Cui2019), while fewer studies have addressed the emergence of the much weaker attractive forces (Yoshimoto, Shou & Somaya Reference Yoshimoto, Shou and Somaya2013; Andrade et al. Reference Andrade, Ramos, Adamowski and Marzo2020; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022).

A recent theoretical study (Ramanarayanan & Sánchez Reference Ramanarayanan and Sánchez2022) posited that the impressive magnification of attractive load capacity and energy efficiency observed in the recent experiments by Colasante (Reference Colasante2015) and Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021), which may conceivably expand the range of practical applications of SFL, can be attributed to the pronounced dynamic bending experienced by the highly flexible oscillators utilized. Through a rigorous analysis of the fluid-flow dynamics in the air layer and its immediate periphery, the authors proved that the attractive force provided by resonant flexural oscillation of a thin circular plate may be thousands of times greater than that provided by rigid-body oscillation under otherwise identical conditions – specifically, the same central displacement amplitude. However, the theoretical predictions of Ramanarayanan & Sánchez (Reference Ramanarayanan and Sánchez2022) and the detailed experimental measurements provided by Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021) exhibit fundamental disagreements regarding crucial aspects of the underlying physics. For instance, while the experimental data show a gradual rise of the force to a maximal value as the cycle-averaged separation distance between the centre of the oscillating plate and the opposite wall is increased to a value of ![]() ${\approx }1$–

${\approx }1$–![]() $3$ mm, as exemplified in figure 2(a), the theory predicts a rapid growth of comparable magnitude as the distance is increased to values of order

$3$ mm, as exemplified in figure 2(a), the theory predicts a rapid growth of comparable magnitude as the distance is increased to values of order ![]() $50\ \mathrm {\mu }$m. Furthermore, measurements show that the time-averaged gauge pressure in the air layer features a localized region of negative values at its centre, as exemplified in figure 2(b), while the theoretically predicted distribution varies gradually and always features a positive central value.

$50\ \mathrm {\mu }$m. Furthermore, measurements show that the time-averaged gauge pressure in the air layer features a localized region of negative values at its centre, as exemplified in figure 2(b), while the theoretically predicted distribution varies gradually and always features a positive central value.

Figure 2. Approximate reproduction of selected experimental measurements by Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021): (a) variation of the applied pulling load with the mean central separation distance and (b) time-averaged radial distribution of the gauge pressure in the air layer ![]() $\langle p \rangle (r) - p_a$ (blue) along with the accompanying time-averaged deformation of the oscillating disk in relation to its mean central position

$\langle p \rangle (r) - p_a$ (blue) along with the accompanying time-averaged deformation of the oscillating disk in relation to its mean central position ![]() $\langle w \rangle$(r) (red) (see figure 1 for notation).

$\langle w \rangle$(r) (red) (see figure 1 for notation).

We argue in this paper that these fundamental differences may be attributed to the presence of two-way-coupled fluid–structure interactions in practical systems, whereby the dynamics of the flexible oscillator is affected non-negligibly by the overpressure generated in the air layer due to its motion. The effects of two-way coupling are demonstrably negligible in the case of the highly stiff oscillators used in earlier studies to generate repulsive forces (Li, Liu & Ding Reference Li, Liu and Ding2014). They are, however, palpable in the experiments of Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021), as evidenced by the observed cycle-averaged deformation of the thin plastic oscillator, exemplified in figure 2(b), which correlates closely with the associated distribution of the time-averaged overpressure pictured in the same panel. Fluid–structure coupling has been explored before in repulsive SFL configurations where a rigid body is levitated above an oscillating plate/piston. The influence of film pressure on the Newtonian dynamics of the levitated body has been studied in the case of rigid oscillators (Brunetière, Blouin & Kastane Reference Brunetière, Blouin and Kastane2018) and those undergoing prescribed standing-wave deformations (Ilssar, Bucher & Flashner Reference Ilssar, Bucher and Flashner2017). Ilssar & Bucher (Reference Ilssar and Bucher2017) additionally explored effects of coupling on the displacement amplitude of a rigid oscillator. Zhang, Xu & Jiang (Reference Zhang, Xu and Jiang2004) and Pandey & Pratap (Reference Pandey and Pratap2007) elucidated the damping effect of viscous flow in the air layer on the resonant dynamic bending of a compliant plate. To the best of our knowledge, a theoretical investigation is yet to be conducted into the effects of two-way coupling on the time-averaged repulsive/attractive load capacity of an SFL system equipped with a flexible oscillator, that being the objective of the present study.

We formulate below in § 2 a reduced mathematical description of the compressible gas flow in a squeeze-film system driven by the flexural oscillation of a compliant plate, by application of the nonlinear theory of elastohydrodynamic lubrication (Sim & Kim Reference Sim and Kim2008; Greenwood Reference Greenwood2020; Wu et al. Reference Wu, Yang, Xu and Wu2020; Poulain et al. Reference Poulain, Carlson, Mandre and Mahadevan2022; Rallabandi Reference Rallabandi2024). The equations governing the fluid–structure dynamics are coupled with a statement of Newton's second law involving the sinusoidal excitation force exerted by the vibration actuator, and the resulting system of equations is solved approximately under the asymptotic limit of small oscillations. The leading-order analysis, presented in § 3, leads to an explicit expression relating the known forcing amplitude of excitation and the consequent displacement amplitude of material points on the oscillating plate. The nonlinear problem that emerges at the following asymptotic order is solved in § 4 to provide a concise analytical expression for the operating efficiency of a flexural SFL system: the ratio of the generated time-averaged force to the supplied excitation amplitude. Simplified forms of these expressions are derived in § 5 to describe centrally forced systems, as a singular limiting case of the general problem. Results of the asymptotic theory are verified in § 6 by comparison with finite-difference computations, and shown in §§ 6 and 7 to provide improved agreement with salient aspects of recently obtained experimental data. Finally, recommendations are provided in § 8 for further theoretical research that may inspire and inform future innovations that exploit this emerging technology.

2. Problem definition

2.1. Modelling approach

Represented in figures 1(a) and 1(b) are simplified schematics of the mechanical configuration involved in recent experiments where strong attractive forces were generated with an SFL system (Colasante Reference Colasante2016; Weston-Dawkes et al. Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021; Omodia, Das & Mahadevan Reference Omodia, Das and Mahadevan2022). A flexible disk of radius ![]() $a$ and uniform thickness

$a$ and uniform thickness ![]() $t_d$ is located near a parallel wall. Glued coaxially to the opposite surface of the disk is a rigid, circular cylinder of radius

$t_d$ is located near a parallel wall. Glued coaxially to the opposite surface of the disk is a rigid, circular cylinder of radius ![]() $r_c < a$, to which a vibration actuator is affixed. The actuator exerts on the cylinder an oscillatory axial force that varies sinusoidally in time with frequency

$r_c < a$, to which a vibration actuator is affixed. The actuator exerts on the cylinder an oscillatory axial force that varies sinusoidally in time with frequency ![]() $\omega /(2{\rm \pi} )$ (where

$\omega /(2{\rm \pi} )$ (where ![]() $\omega$ denotes the associated angular frequency), causing the disk to undergo dynamic bending. The nonlinear dynamics of the oscillatory airflow excited in the air layer separating the disk and the wall (Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022), the ‘squeeze film’, gives rise to a cycle-averaged pressure field in the film that provides a steady force attracting the disk toward the wall. This attractive force is able to support an applied pulling load of magnitude

$\omega$ denotes the associated angular frequency), causing the disk to undergo dynamic bending. The nonlinear dynamics of the oscillatory airflow excited in the air layer separating the disk and the wall (Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022), the ‘squeeze film’, gives rise to a cycle-averaged pressure field in the film that provides a steady force attracting the disk toward the wall. This attractive force is able to support an applied pulling load of magnitude ![]() ${\mathcal {F}}_\ell$, steadied at the point of application by a vibration damper.

${\mathcal {F}}_\ell$, steadied at the point of application by a vibration damper.

Application of Newton's second law for the rigid central assembly on which the load is exerted and the central portion of the disk to which it is affixed (see the inset in figure 1(a) for clarification) provides

where ![]() $t$ and

$t$ and ![]() $r$ denote, respectively, the time and the radial distance from the axis of symmetry,

$r$ denote, respectively, the time and the radial distance from the axis of symmetry, ![]() ${\mathcal {F}}_m$ denotes the amplitude of the sinusoidal excitation force,

${\mathcal {F}}_m$ denotes the amplitude of the sinusoidal excitation force, ![]() $p(r,t)-p_a$ denotes the distributed gauge pressure acting on the disk surface (with

$p(r,t)-p_a$ denotes the distributed gauge pressure acting on the disk surface (with ![]() $p_a$ denoting the ambient pressure),

$p_a$ denoting the ambient pressure), ![]() $\mathcal {V}_c$ represents the axial structural stress resultant within the disk at the critical radius

$\mathcal {V}_c$ represents the axial structural stress resultant within the disk at the critical radius ![]() $r_c$,

$r_c$, ![]() $m_c$ quantifies the collective mass of the cylinder and other structures involved in the transfer of the vibrational force to the disk,

$m_c$ quantifies the collective mass of the cylinder and other structures involved in the transfer of the vibrational force to the disk, ![]() $\rho _d$ denotes the uniform density of the disk and

$\rho _d$ denotes the uniform density of the disk and ![]() $h_c(t)$ represents the time-varying distance between the wall and the central portion of the disk. The phase shift

$h_c(t)$ represents the time-varying distance between the wall and the central portion of the disk. The phase shift ![]() $\phi$ included in the argument of the excitation force is introduced to facilitate the analysis, and will be discussed later. In writing (2.1), the gravitational acceleration is assumed to be negligibly small in comparison with that induced by the high-frequency excitation, and the weight of the central assembly is assumed to be small relative to the steady pulling load, both assumptions being consistent with the operating conditions used by Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021).

$\phi$ included in the argument of the excitation force is introduced to facilitate the analysis, and will be discussed later. In writing (2.1), the gravitational acceleration is assumed to be negligibly small in comparison with that induced by the high-frequency excitation, and the weight of the central assembly is assumed to be small relative to the steady pulling load, both assumptions being consistent with the operating conditions used by Weston-Dawkes et al. (Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021).

Experimental data suggest that the central separation distance ![]() $h_c$ fluctuates periodically about a constant mean value

$h_c$ fluctuates periodically about a constant mean value ![]() $h_o$ if the imposed load

$h_o$ if the imposed load ![]() ${\mathcal {F}}_\ell$ is steady. The mean distance

${\mathcal {F}}_\ell$ is steady. The mean distance ![]() $h_o$ grows as the load is quasi-statically increased, until a critical value is reached beyond which the attractive force becomes insufficient and the disk detaches abruptly from the wall, as depicted in figure 2(a) (Weston-Dawkes et al. Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021). It is of great interest to devise a solution of (2.1) that allows prediction of the ‘load capacity’ of an SFL system, the maximal pulling force

$h_o$ grows as the load is quasi-statically increased, until a critical value is reached beyond which the attractive force becomes insufficient and the disk detaches abruptly from the wall, as depicted in figure 2(a) (Weston-Dawkes et al. Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021). It is of great interest to devise a solution of (2.1) that allows prediction of the ‘load capacity’ of an SFL system, the maximal pulling force ![]() $max[{\mathcal {F}}_\ell (h_o)]$ that can be supported without failure. In practical systems, known quantities are typically limited to the structural properties of the disk, the thermodynamic properties of the operating fluid and the amplitude

$max[{\mathcal {F}}_\ell (h_o)]$ that can be supported without failure. In practical systems, known quantities are typically limited to the structural properties of the disk, the thermodynamic properties of the operating fluid and the amplitude ![]() ${\mathcal {F}}_m$ and frequency of the excitation force (Burroughs Reference Burroughs2021). Solution thus requires determining simultaneously the oscillating position

${\mathcal {F}}_m$ and frequency of the excitation force (Burroughs Reference Burroughs2021). Solution thus requires determining simultaneously the oscillating position ![]() $h_c(t)$ of the central assembly and the reactive aerodynamic and structural forces affecting its motion. The nonlinear fluid–structure dynamics involved complicates the solution, in that the periodic cylinder motion may exhibit multiple harmonics in addition to the excitation frequency

$h_c(t)$ of the central assembly and the reactive aerodynamic and structural forces affecting its motion. The nonlinear fluid–structure dynamics involved complicates the solution, in that the periodic cylinder motion may exhibit multiple harmonics in addition to the excitation frequency ![]() $\omega$.

$\omega$.

As shown in the following derivation, the problem simplifies in the case of small axial displacements of the disk relative to the mean separation distance ![]() $h_o$, allowing approximate solution of (2.1) with use of classical perturbation methods. Under the limit of small relative amplitudes, the cylinder may be assumed in the first approximation to oscillate sinusoidally along its axis with a given amplitude

$h_o$, allowing approximate solution of (2.1) with use of classical perturbation methods. Under the limit of small relative amplitudes, the cylinder may be assumed in the first approximation to oscillate sinusoidally along its axis with a given amplitude ![]() $b \ll h_o$ – as indicated in figure 1(b) – and an angular frequency equal to that of the excitation force, so that

$b \ll h_o$ – as indicated in figure 1(b) – and an angular frequency equal to that of the excitation force, so that

Secondary frequencies arising from weak nonlinear dynamics will enter as asymptotic corrections to ![]() $h_c/h_o$ of order

$h_c/h_o$ of order ![]() $(b/h_o)^2 \ll 1$ and smaller, to be discussed later. As indicated in (2.1), the cylinder displacement (2.2) is expected to exhibit a phase lag

$(b/h_o)^2 \ll 1$ and smaller, to be discussed later. As indicated in (2.1), the cylinder displacement (2.2) is expected to exhibit a phase lag ![]() $\phi$ with respect to the excitation force, which is affected non-negligibly by the dissipative effects of viscous stresses in the squeeze film and material friction within the disk (Bettini Reference Bettini2016). In general, the evolving width

$\phi$ with respect to the excitation force, which is affected non-negligibly by the dissipative effects of viscous stresses in the squeeze film and material friction within the disk (Bettini Reference Bettini2016). In general, the evolving width ![]() $h(r,t)$ of the film may be expressed with use of the function

$h(r,t)$ of the film may be expressed with use of the function

which denotes the position of the disk surface bounding the air film. Since the central portion of the disk is glued to the cylinder, it follows from (2.2) that, in the first approximation,

In pursuit of determining simultaneously the central oscillation amplitude ![]() $b$ and the reactive forces modulating its value, we introduce below a reduced theoretical description of the relevant fluid–structure dynamics, which couples the Reynolds equation governing the variation of air pressure

$b$ and the reactive forces modulating its value, we introduce below a reduced theoretical description of the relevant fluid–structure dynamics, which couples the Reynolds equation governing the variation of air pressure ![]() $p$ in the squeeze film with the Kirchhoff–Love equation governing the dynamic displacement

$p$ in the squeeze film with the Kirchhoff–Love equation governing the dynamic displacement ![]() $w$ of the flexible annular portion of the disk

$w$ of the flexible annular portion of the disk ![]() $r_c \le r \le a$. We show that, when

$r_c \le r \le a$. We show that, when ![]() $b/h_o \ll 1$, the coupled equations can be solved with use of (2.4) as the driving kinematic boundary condition to provide analytical expressions for the reactive forces in terms of

$b/h_o \ll 1$, the coupled equations can be solved with use of (2.4) as the driving kinematic boundary condition to provide analytical expressions for the reactive forces in terms of ![]() $b$. Substituting these expressions in (2.1) allows straightforward computation of the value of

$b$. Substituting these expressions in (2.1) allows straightforward computation of the value of ![]() $b$ with relative errors of order

$b$ with relative errors of order ![]() $b/h_o \ll 1$. Solving the nonlinear system of equations that emerges at the following order in the asymptotic description for

$b/h_o \ll 1$. Solving the nonlinear system of equations that emerges at the following order in the asymptotic description for ![]() $b/h_o \ll 1$ allows analytical determination of the levitation force

$b/h_o \ll 1$ allows analytical determination of the levitation force ![]() ${\mathcal {F}}_\ell$ with the same level of accuracy.

${\mathcal {F}}_\ell$ with the same level of accuracy.

The asymptotic formulation will be shown below to provide promising agreement with experimental measurements of the pull-off curve ![]() ${\mathcal {F}}_\ell (h_o)$, the time-averaged overpressure in the squeeze film

${\mathcal {F}}_\ell (h_o)$, the time-averaged overpressure in the squeeze film ![]() $\langle p \rangle (r) - p_a$ and the accompanying steady deformation of the disk

$\langle p \rangle (r) - p_a$ and the accompanying steady deformation of the disk ![]() $\langle w \rangle (r)$ (see figures 1(b) and 2 for clarification). Here, the angled brackets are used to denote the cycle-averaging operator

$\langle w \rangle (r)$ (see figures 1(b) and 2 for clarification). Here, the angled brackets are used to denote the cycle-averaging operator

2.2. Description of the squeeze-film gas dynamics

In modelling the gas flow, it will be assumed that the squeeze film is slender, i.e. ![]() $h_o \ll \lambda$, with the characteristic flexural wavelength

$h_o \ll \lambda$, with the characteristic flexural wavelength ![]() $\lambda$ of the disk being comparable to its radius

$\lambda$ of the disk being comparable to its radius ![]() $a$. Additionally, the viscous time scale

$a$. Additionally, the viscous time scale ![]() $h_o^2/(\mu _a/\rho _a)$, where

$h_o^2/(\mu _a/\rho _a)$, where ![]() $\mu _a$ and

$\mu _a$ and ![]() $\rho _a$ denote respectively the ambient dynamic viscosity and density of the gas, is taken to be much smaller than the oscillation period

$\rho _a$ denote respectively the ambient dynamic viscosity and density of the gas, is taken to be much smaller than the oscillation period ![]() $2{\rm \pi} /\omega$, so that the momentum balance is dominated by viscous forces and the energy balance by transverse heat conduction (since the Prandtl number of air is of order unity (Rohsenow, Hartnett & Cho Reference Rohsenow, Hartnett and Cho1998, p. 2.4)). In this approximation, the gas temperature across the film equals that of the solid boundaries, which is assumed here to equal the ambient gas temperature. In the associated limit of isothermal lubrication theory, the gas flow is determined, with relative errors of order

$2{\rm \pi} /\omega$, so that the momentum balance is dominated by viscous forces and the energy balance by transverse heat conduction (since the Prandtl number of air is of order unity (Rohsenow, Hartnett & Cho Reference Rohsenow, Hartnett and Cho1998, p. 2.4)). In this approximation, the gas temperature across the film equals that of the solid boundaries, which is assumed here to equal the ambient gas temperature. In the associated limit of isothermal lubrication theory, the gas flow is determined, with relative errors of order ![]() $(h_o/a)^2 \!\ll\! 1$ and

$(h_o/a)^2 \!\ll\! 1$ and ![]() $h_o^2\omega /(\mu _a/\rho _a) \!\ll\! 1$, by the familiar equations (Langlois Reference Langlois1962; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022)

$h_o^2\omega /(\mu _a/\rho _a) \!\ll\! 1$, by the familiar equations (Langlois Reference Langlois1962; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022)

where ![]() $y$ is the normal distance to the wall,

$y$ is the normal distance to the wall, ![]() $u$ and

$u$ and ![]() $v$ denote respectively the radial and axial components of the flow velocity and

$v$ denote respectively the radial and axial components of the flow velocity and ![]() $\rho$ and

$\rho$ and ![]() $p$ denote respectively the variable gas density and pressure, the subscript ‘

$p$ denote respectively the variable gas density and pressure, the subscript ‘![]() $a$’ denoting ambient values found in the unperturbed surroundings.

$a$’ denoting ambient values found in the unperturbed surroundings.

The flow velocity in the film must satisfy the no-slip condition ![]() $u=0$ on both bounding surfaces

$u=0$ on both bounding surfaces ![]() $y=0$ and

$y=0$ and ![]() $y=h$ as well as the corresponding no-penetration conditions given by

$y=h$ as well as the corresponding no-penetration conditions given by ![]() $v=0$ at

$v=0$ at ![]() $y=0$ and

$y=0$ and ![]() $v=\partial w/\partial t$ at

$v=\partial w/\partial t$ at ![]() $y=h$. Note that the condition

$y=h$. Note that the condition ![]() $u(y=h)=0$ ignores negligibly small radial displacements of material points on the disk, of the order of

$u(y=h)=0$ ignores negligibly small radial displacements of material points on the disk, of the order of ![]() $(b/h_o)^2(h_o/a)^2a \ll a$. The associated gas pressure must satisfy the conditions of regularity at the central axis of the film and relaxation at its edge

$(b/h_o)^2(h_o/a)^2a \ll a$. The associated gas pressure must satisfy the conditions of regularity at the central axis of the film and relaxation at its edge

respectively, the latter of which neglects variations of pressure existing beyond the edge, which are negligibly small in the lubrication limit, as explained in Appendix A.

The problem defined above affords straightforward reduction to the single equation

the relevant Reynolds lubrication equation for compressible flow (Harrison Reference Harrison1913; Langlois Reference Langlois1962; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022), which relates the disk deformation ![]() $w(r,t)=h-h_o$ with the coupled film pressure

$w(r,t)=h-h_o$ with the coupled film pressure ![]() $p(r,t)$, the latter independent of

$p(r,t)$, the latter independent of ![]() $y$, as follows from (2.6c). The evolving pressure is to be determined by integration of (2.8) subject to the boundary conditions (2.7). Solution requires knowledge of the disk position

$y$, as follows from (2.6c). The evolving pressure is to be determined by integration of (2.8) subject to the boundary conditions (2.7). Solution requires knowledge of the disk position ![]() $w$, whose value for

$w$, whose value for ![]() $0 \le r \le r_c$ is determined in the first approximation by the presumed cylinder motion, as stated in (2.4), while its unknown value in the annular region

$0 \le r \le r_c$ is determined in the first approximation by the presumed cylinder motion, as stated in (2.4), while its unknown value in the annular region ![]() $r_c < r \le a$ must be obtained from an analysis of the disk structural dynamics, as described below.

$r_c < r \le a$ must be obtained from an analysis of the disk structural dynamics, as described below.

2.3. Description of the disk structural dynamics

In analysing the oscillations of the deformable portion of the disk extending for ![]() $r_c \le r \le a$, it will be assumed that the disk is made of a homogeneous, isotropic material, and that its axial deflections, comparable in magnitude to the central amplitude

$r_c \le r \le a$, it will be assumed that the disk is made of a homogeneous, isotropic material, and that its axial deflections, comparable in magnitude to the central amplitude ![]() $b$, are much smaller than its uniform thickness

$b$, are much smaller than its uniform thickness ![]() $t_d$, which in turn is much smaller than its radius

$t_d$, which in turn is much smaller than its radius ![]() $a$, i.e.

$a$, i.e. ![]() $b \ll t_d \ll a$. The excitation frequency is assumed to be sufficiently low for the characteristic flexural wavelength

$b \ll t_d \ll a$. The excitation frequency is assumed to be sufficiently low for the characteristic flexural wavelength ![]() $\lambda$ of the disk to be comparable to the disk radius

$\lambda$ of the disk to be comparable to the disk radius ![]() $a$, consistent with the slender-flow assumption drawn in § 2.2. Under these conditions the disk can be assumed to undergo pure bending (Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 47–49), whence its dynamic deformations, influenced non-negligibly by the squeeze-film overpressure

$a$, consistent with the slender-flow assumption drawn in § 2.2. Under these conditions the disk can be assumed to undergo pure bending (Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 47–49), whence its dynamic deformations, influenced non-negligibly by the squeeze-film overpressure ![]() $p(r,t)-p_a$, can be described with use of the Kirchhoff–Love equation (Kelly Reference Kelly2013; Ducceschi Reference Ducceschi2014)

$p(r,t)-p_a$, can be described with use of the Kirchhoff–Love equation (Kelly Reference Kelly2013; Ducceschi Reference Ducceschi2014)

involving the axisymmetric Laplacian operator ![]() $\bar \nabla ^2 = [\partial ^2/\partial r^2 + (1/r)\partial /\partial r]$ and the flexural rigidity

$\bar \nabla ^2 = [\partial ^2/\partial r^2 + (1/r)\partial /\partial r]$ and the flexural rigidity ![]() $\mathcal {D}$ of the disk, the latter defined in terms of the disk Young's modulus

$\mathcal {D}$ of the disk, the latter defined in terms of the disk Young's modulus ![]() $E_d$, mass density

$E_d$, mass density ![]() $\rho _d$ and Poisson's ratio

$\rho _d$ and Poisson's ratio ![]() $\nu _d$. Correspondingly, the axial stress resultant

$\nu _d$. Correspondingly, the axial stress resultant ![]() $\mathcal {V}_c$ affecting the dynamics of the central assembly (2.1) can be expressed as (Yang Reference Yang2005)

$\mathcal {V}_c$ affecting the dynamics of the central assembly (2.1) can be expressed as (Yang Reference Yang2005)

Note that the displacement of the neutral plane of the disk has been substituted in (2.9a) and (2.10) with that of its film-adjacent surface ![]() $w$ (2.3), introducing negligible relative errors of order

$w$ (2.3), introducing negligible relative errors of order ![]() $(b/h_o)(t_d h_o/a^2) \ll 1$. Also, in-plane stresses induced due to fluid shear acting on this surface (Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 378–380) are smaller than the expected overpressure by a factor of order

$(b/h_o)(t_d h_o/a^2) \ll 1$. Also, in-plane stresses induced due to fluid shear acting on this surface (Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 378–380) are smaller than the expected overpressure by a factor of order ![]() $(b/h_o)(h_o/a)^2 \ll 1$ (Watanabe & Hara Reference Watanabe and Hara1997; Tulchinsky & Gat Reference Tulchinsky and Gat2016) and, hence, neglected when writing (2.9a).

$(b/h_o)(h_o/a)^2 \ll 1$ (Watanabe & Hara Reference Watanabe and Hara1997; Tulchinsky & Gat Reference Tulchinsky and Gat2016) and, hence, neglected when writing (2.9a).

Equation (2.9a) must be integrated for ![]() $r_c \le r \le a$ with the four boundary conditions

$r_c \le r \le a$ with the four boundary conditions

\begin{equation} \begin{cases} w - b

\cos(\omega t)={\dfrac{\partial w}{\partial

r}}=0 & {\rm at}\ r = r_c \\ \left(

{\dfrac{\partial ^2}{\partial r^2}} +

\dfrac{\nu_d}{r}{\dfrac{\partial }{\partial r}}

\right) w = {\dfrac{\partial }{\partial r}} (

\bar{\nabla}^2 w) = 0 & {\rm at}\ r = a \end{cases},

\end{equation}

\begin{equation} \begin{cases} w - b

\cos(\omega t)={\dfrac{\partial w}{\partial

r}}=0 & {\rm at}\ r = r_c \\ \left(

{\dfrac{\partial ^2}{\partial r^2}} +

\dfrac{\nu_d}{r}{\dfrac{\partial }{\partial r}}

\right) w = {\dfrac{\partial }{\partial r}} (

\bar{\nabla}^2 w) = 0 & {\rm at}\ r = a \end{cases},

\end{equation}

which state that the annular portion of the disk is clamped at its inner edge ![]() $r=r_c$, where it follows the driving motion of the cylinder (2.4), and that neither bending moments nor axisymmetric axial stresses are supported at its free outer edge

$r=r_c$, where it follows the driving motion of the cylinder (2.4), and that neither bending moments nor axisymmetric axial stresses are supported at its free outer edge ![]() $r=a$ (see Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 83–84 and Yang Reference Yang2005, pp. 840–841).

$r=a$ (see Timoshenko & Woinowsky-Krieger Reference Timoshenko and Woinowsky-Krieger1959, pp. 83–84 and Yang Reference Yang2005, pp. 840–841).

2.4. Dimensionless formulation and governing parameters

It is useful to reformulate the fluid–structure problem defined in §§ 2.2 and 2.3 in terms of appropriate dimensionless variables, beginning with the temporal and spatial variables ![]() $\tau =\omega t$ and

$\tau =\omega t$ and ![]() $\xi =r/a$. The disk displacement is scaled with the central amplitude

$\xi =r/a$. The disk displacement is scaled with the central amplitude ![]() $b$ to give

$b$ to give ![]() $W(\xi,\tau )=w/b$. We may then use (2.3) to write

$W(\xi,\tau )=w/b$. We may then use (2.3) to write ![]() $h/h_o=1+\varepsilon W$, where

$h/h_o=1+\varepsilon W$, where

defines the relative central oscillation amplitude. It follows from (2.4) that, in the first approximation, ![]() $W=\cos \tau$ for

$W=\cos \tau$ for ![]() $\xi \le {\xi _c}$, where

$\xi \le {\xi _c}$, where ![]() ${\xi _c} = r_c/a$ defines the dimensionless clamping radius. The characteristic scale of film overpressure, deduced readily from (2.6a,b) (see Appendix A), is used to define the variable

${\xi _c} = r_c/a$ defines the dimensionless clamping radius. The characteristic scale of film overpressure, deduced readily from (2.6a,b) (see Appendix A), is used to define the variable ![]() $P=12 (p-p_a)/(\varepsilon \sigma p_a)$, where

$P=12 (p-p_a)/(\varepsilon \sigma p_a)$, where

the classical dimensionless ‘squeeze number’ (Langlois Reference Langlois1962), quantifies the degree of gaseous compressibility in the film induced by viscous retardation of radial airflow.

The Reynolds lubrication equation (2.8) can now be written in the dimensionless form

while the Kirchhoff–Love equation (2.9a) takes the form

where ![]() $\nabla ^2 = [\partial ^2/\partial \xi ^2 + (1/\xi )\partial /\partial \xi ]$. As seen from (2.15), consideration of the disk dynamics introduces two additional dimensionless parameters defined by

$\nabla ^2 = [\partial ^2/\partial \xi ^2 + (1/\xi )\partial /\partial \xi ]$. As seen from (2.15), consideration of the disk dynamics introduces two additional dimensionless parameters defined by

where ![]() $K$ represents the well-known elastic wavenumber characterizing the bending of an isolated disk, i.e. one for which

$K$ represents the well-known elastic wavenumber characterizing the bending of an isolated disk, i.e. one for which ![]() ${\mathcal {C}}=0$ (Warren Reference Warren1930; Yang Reference Yang2005; Ramanarayanan & Sánchez Reference Ramanarayanan and Sánchez2022). In the proceeding analysis, the ratio of the scale of film overpressure to that of disk inertia,

${\mathcal {C}}=0$ (Warren Reference Warren1930; Yang Reference Yang2005; Ramanarayanan & Sánchez Reference Ramanarayanan and Sánchez2022). In the proceeding analysis, the ratio of the scale of film overpressure to that of disk inertia, ![]() ${\mathcal {C}}^6/K^4$, is found to be an important quantity that characterizes the ‘degree’ of flow–structure coupling. Interestingly, in the extreme case of strong coupling

${\mathcal {C}}^6/K^4$, is found to be an important quantity that characterizes the ‘degree’ of flow–structure coupling. Interestingly, in the extreme case of strong coupling ![]() ${\mathcal {C}}^6/K^4 \gg 1$, the parameter

${\mathcal {C}}^6/K^4 \gg 1$, the parameter ![]() $K$ is found to disappear from the formulation and is replaced by

$K$ is found to disappear from the formulation and is replaced by ![]() ${\mathcal {C}}$ as the relevant flexural wavenumber.

${\mathcal {C}}$ as the relevant flexural wavenumber.

As follows from (2.7), (2.14) must be integrated with the boundary conditions

while, based on (2.11), (2.15) must be integrated with

\begin{equation} \begin{cases} W - \cos

\tau=\partial{W}/\partial{\xi} = 0 & {\rm at}\ \xi =

{\xi_c} \\ \left( {\dfrac{\partial ^2}{\partial

\xi^2}} + \dfrac{\nu_d}{\xi}{\dfrac{\partial

}{\partial \xi}} \right) W = {\dfrac{\partial

}{\partial \xi}} ( \nabla^2 W ) = 0 & {\rm at}\ \xi = 1

\end{cases}. \end{equation}

\begin{equation} \begin{cases} W - \cos

\tau=\partial{W}/\partial{\xi} = 0 & {\rm at}\ \xi =

{\xi_c} \\ \left( {\dfrac{\partial ^2}{\partial

\xi^2}} + \dfrac{\nu_d}{\xi}{\dfrac{\partial

}{\partial \xi}} \right) W = {\dfrac{\partial

}{\partial \xi}} ( \nabla^2 W ) = 0 & {\rm at}\ \xi = 1

\end{cases}. \end{equation}

The problem defined above is to be addressed below for order-unity values of the distinguished dimensionless parameters ![]() $\sigma$,

$\sigma$, ![]() $K$ and

$K$ and ![]() ${\mathcal {C}}$, in order to develop a unifying theoretical description that reconciles the remarkable recent discoveries with the well-understood physics of conventional SFL systems which, together, span a wide parametric range (see, for example, Salbu Reference Salbu1964; Hatanaka et al. Reference Hatanaka, Yoshikazu, Kentaro, Sadayuki and Yoshiki1999; Sadayuki Reference Sadayuki2002; Zhao Reference Zhao2010; Yoshimoto et al. Reference Yoshimoto, Shou and Somaya2013; Colasante Reference Colasante2015; Weston-Dawkes et al. Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021). Analytical progress will be made using classical asymptotic methods that exploit the limit of small relative amplitudes

${\mathcal {C}}$, in order to develop a unifying theoretical description that reconciles the remarkable recent discoveries with the well-understood physics of conventional SFL systems which, together, span a wide parametric range (see, for example, Salbu Reference Salbu1964; Hatanaka et al. Reference Hatanaka, Yoshikazu, Kentaro, Sadayuki and Yoshiki1999; Sadayuki Reference Sadayuki2002; Zhao Reference Zhao2010; Yoshimoto et al. Reference Yoshimoto, Shou and Somaya2013; Colasante Reference Colasante2015; Weston-Dawkes et al. Reference Weston-Dawkes, Adibnazari, Hu, Everman, Gravish and Tolley2021). Analytical progress will be made using classical asymptotic methods that exploit the limit of small relative amplitudes ![]() $\varepsilon = b/h_o \ll 1$, as similar historical approaches have afforded clear insights regarding the simplified physics of SFL configurations that feature extreme values of

$\varepsilon = b/h_o \ll 1$, as similar historical approaches have afforded clear insights regarding the simplified physics of SFL configurations that feature extreme values of ![]() $\sigma$,

$\sigma$, ![]() $K$ and/or

$K$ and/or ![]() ${\mathcal {C}}$ (Taylor & Saffman Reference Taylor and Saffman1957; Langlois Reference Langlois1962; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022).

${\mathcal {C}}$ (Taylor & Saffman Reference Taylor and Saffman1957; Langlois Reference Langlois1962; Ramanarayanan et al. Reference Ramanarayanan, Coenen and Sánchez2022).

3. Leading-order dynamics for small relative amplitudes

We begin by expressing the dimensionless disk displacement and film overpressure as regular perturbation expansions of the forms ![]() $W = W_0 + \varepsilon W_1 + \cdots$ and

$W = W_0 + \varepsilon W_1 + \cdots$ and ![]() $P = P_0 + \varepsilon P_1 + \cdots$, respectively. Substituting these expansions into the governing equations (2.14) and (2.15) and their boundary conditions (2.17) and (2.18), and collecting terms of order unity gives

$P = P_0 + \varepsilon P_1 + \cdots$, respectively. Substituting these expansions into the governing equations (2.14) and (2.15) and their boundary conditions (2.17) and (2.18), and collecting terms of order unity gives

and

\begin{align} \nabla^4 W_0 + K^4

{\dfrac{\partial ^2 W_0}{\partial \tau^2}} =

{\mathcal{C}}^6 P_0 \left\{\begin{array}{@{}ll} \xi=\xi_c: &

W_0 - \cos \tau=\partial{W_0}/\partial{\xi} = 0 \\ \xi=1 :

& \left( {\dfrac{\partial ^2}{\partial \xi^2}} +

\dfrac{\nu_d}{\xi}{\dfrac{\partial }{\partial

\xi}} \right) W_0 = {\dfrac{\partial }{\partial

\xi}} ( \nabla^2 W_0 ) = 0 \end{array} \right.

.\end{align}

\begin{align} \nabla^4 W_0 + K^4

{\dfrac{\partial ^2 W_0}{\partial \tau^2}} =

{\mathcal{C}}^6 P_0 \left\{\begin{array}{@{}ll} \xi=\xi_c: &

W_0 - \cos \tau=\partial{W_0}/\partial{\xi} = 0 \\ \xi=1 :

& \left( {\dfrac{\partial ^2}{\partial \xi^2}} +

\dfrac{\nu_d}{\xi}{\dfrac{\partial }{\partial

\xi}} \right) W_0 = {\dfrac{\partial }{\partial

\xi}} ( \nabla^2 W_0 ) = 0 \end{array} \right.

.\end{align}

Since the motion of the central portion of the disk is prescribed at leading order by the uniform sinusoidal function ![]() $W_0 =\cos \tau$, as per (2.4), in seeking time-periodic solutions of this linear problem it is convenient to introduce a piecewise-defined ansatz of the form

$W_0 =\cos \tau$, as per (2.4), in seeking time-periodic solutions of this linear problem it is convenient to introduce a piecewise-defined ansatz of the form

\begin{equation} \left.\begin{array}{c@{}}

P_0 = \mathrm{Re} \{ \bar{\varPi}(\xi)\,

\mathrm{e}^{\mathrm{i}\tau} \} \ {\rm and}\ W_0 =

\mathrm{Re} \{\mathrm{e}^{\mathrm{i}\tau} \} \quad {\rm

for}\ 0 \le \xi \le {\xi_c} \\ P_0 = \mathrm{Re} \{

\varPi(\xi)\, \mathrm{e}^{\mathrm{i}\tau} \} \ {\rm and}\

W_0 = \mathrm{Re} \{\varOmega(\xi)\,

\mathrm{e}^{\mathrm{i}\tau} \} \quad {\rm for}\ {\xi_c} \le

\xi \le 1

\end{array}\right\},\end{equation}

\begin{equation} \left.\begin{array}{c@{}}

P_0 = \mathrm{Re} \{ \bar{\varPi}(\xi)\,

\mathrm{e}^{\mathrm{i}\tau} \} \ {\rm and}\ W_0 =

\mathrm{Re} \{\mathrm{e}^{\mathrm{i}\tau} \} \quad {\rm

for}\ 0 \le \xi \le {\xi_c} \\ P_0 = \mathrm{Re} \{

\varPi(\xi)\, \mathrm{e}^{\mathrm{i}\tau} \} \ {\rm and}\

W_0 = \mathrm{Re} \{\varOmega(\xi)\,

\mathrm{e}^{\mathrm{i}\tau} \} \quad {\rm for}\ {\xi_c} \le

\xi \le 1

\end{array}\right\},\end{equation}

where the complex spatial functions ![]() $\bar {\varPi }$,

$\bar {\varPi }$, ![]() $\varPi$, and

$\varPi$, and ![]() $\varOmega$ are to be determined below.

$\varOmega$ are to be determined below.

In the central portion of the film ![]() $0 \le \xi \le {\xi _c}$, (3.1) reduces to

$0 \le \xi \le {\xi _c}$, (3.1) reduces to ![]() $\bar {\varPi }'' + \bar {\varPi }'/\xi - \sigma \mathrm {i} \bar {\varPi } = 12\,\mathrm {i}$, where a prime superscript denotes the derivative of a spatial function, i.e.

$\bar {\varPi }'' + \bar {\varPi }'/\xi - \sigma \mathrm {i} \bar {\varPi } = 12\,\mathrm {i}$, where a prime superscript denotes the derivative of a spatial function, i.e. ![]() $f'(\xi )= {\rm d} f/ {\rm d} \xi$. Integration with the regularity condition

$f'(\xi )= {\rm d} f/ {\rm d} \xi$. Integration with the regularity condition ![]() $\bar {\varPi }'(0)=0$ gives the reduced pressure

$\bar {\varPi }'(0)=0$ gives the reduced pressure

where ![]() $J_0$ represents the Bessel function of the first kind of zeroth order, and the coefficient

$J_0$ represents the Bessel function of the first kind of zeroth order, and the coefficient ![]() ${\bar A}$ is to be determined by patching the function

${\bar A}$ is to be determined by patching the function ![]() $\bar {\varPi }$ (Bender & Orszag Reference Bender and Orszag1999, pp. 335–336) with the reduced pressure

$\bar {\varPi }$ (Bender & Orszag Reference Bender and Orszag1999, pp. 335–336) with the reduced pressure ![]() $\varPi$ existing in the surrounding annular region

$\varPi$ existing in the surrounding annular region ![]() ${\xi _c} \le \xi \le 1$.

${\xi _c} \le \xi \le 1$.

In the annular region, we use (3.2) and (3.3) to write ![]() $\varPi = {\mathcal {C}}^{-6} ( \nabla ^4 - K^4 ) \varOmega$, substitution of which in (3.1) yields the relevant ‘thin-film’ equation (Poulain et al. Reference Poulain, Carlson, Mandre and Mahadevan2022)

$\varPi = {\mathcal {C}}^{-6} ( \nabla ^4 - K^4 ) \varOmega$, substitution of which in (3.1) yields the relevant ‘thin-film’ equation (Poulain et al. Reference Poulain, Carlson, Mandre and Mahadevan2022)

The general solution to (3.5) can be written in the form

\begin{equation} \varOmega = \sum_{n=1}^3 [ A_n J_0(\gamma_n \xi) + B_n Y_0(\gamma_n \xi) ] ,\end{equation}

\begin{equation} \varOmega = \sum_{n=1}^3 [ A_n J_0(\gamma_n \xi) + B_n Y_0(\gamma_n \xi) ] ,\end{equation}

whence the reduced pressure ![]() $\varPi$ assumes the form

$\varPi$ assumes the form

\begin{equation} \varPi = \frac{1}{{\mathcal{C}}^6} \sum_{n=1}^3 (\gamma_n^4-K^4 ) [ A_n J_0(\gamma_n \xi) + B_n Y_0(\gamma_n \xi) ] ,\end{equation}

\begin{equation} \varPi = \frac{1}{{\mathcal{C}}^6} \sum_{n=1}^3 (\gamma_n^4-K^4 ) [ A_n J_0(\gamma_n \xi) + B_n Y_0(\gamma_n \xi) ] ,\end{equation}

both involving the Bessel function of the second kind of zeroth order ![]() $Y_0$, the unknown coefficients

$Y_0$, the unknown coefficients ![]() $A_n$ and

$A_n$ and ![]() $B_n$ (where

$B_n$ (where ![]() $n=1:3$) and the constants

$n=1:3$) and the constants ![]() $\gamma _1,\gamma _2$ and

$\gamma _1,\gamma _2$ and ![]() $\gamma _3$, defined by

$\gamma _3$, defined by

where

The leading-order solution thus involves seven coefficients, ![]() $\bar A$,

$\bar A$, ![]() $A_1$,

$A_1$, ![]() $A_2$,

$A_2$, ![]() $A_3$,

$A_3$, ![]() $B_1$,

$B_1$, ![]() $B_2$ and

$B_2$ and ![]() $B_3$, to be determined by application of the five reduced boundary conditions

$B_3$, to be determined by application of the five reduced boundary conditions

\begin{equation} \begin{cases} \varOmega - 1 = \varOmega' = 0 & {\rm at}\ \xi = {\xi_c} \\ \varPi = \varOmega'' + \nu_d\varOmega' = \varOmega''' + \varOmega'' - \varOmega' = 0 & {\rm at}\ \xi = 1 \end{cases}, \end{equation}

\begin{equation} \begin{cases} \varOmega - 1 = \varOmega' = 0 & {\rm at}\ \xi = {\xi_c} \\ \varPi = \varOmega'' + \nu_d\varOmega' = \varOmega''' + \varOmega'' - \varOmega' = 0 & {\rm at}\ \xi = 1 \end{cases}, \end{equation}

deduced from (3.1) and (3.2), and the two additional conditions ![]() $\bar {\varPi } = \varPi$ and

$\bar {\varPi } = \varPi$ and ![]() $\bar {\varPi }' = \varPi '$ at

$\bar {\varPi }' = \varPi '$ at ![]() $\xi = {\xi _c}$, which enforce continuity of the pressure and its gradient, respectively, at the interfacial clamp radius. The last condition guarantees continuity of the radial flow speed

$\xi = {\xi _c}$, which enforce continuity of the pressure and its gradient, respectively, at the interfacial clamp radius. The last condition guarantees continuity of the radial flow speed ![]() $u \propto \partial p/\partial r$, evident from the radial momentum balance (2.6b), and involves the reduced pressure gradients in the central and annular regions

$u \propto \partial p/\partial r$, evident from the radial momentum balance (2.6b), and involves the reduced pressure gradients in the central and annular regions

\begin{align} \bar{\varPi}' ={-}\frac{12\,\mathrm{i}}{\varsigma} {\bar A} J_1(\varsigma \xi) \quad{\rm and}\quad \varPi' = \frac{1}{{\mathcal{C}}^6} \sum_{n=1}^3 \gamma_n ( K^4 - \gamma_n^4 ) [ A_n J_1(\gamma_n \xi) + B_n Y_1(\gamma_n \xi) ], \end{align}

\begin{align} \bar{\varPi}' ={-}\frac{12\,\mathrm{i}}{\varsigma} {\bar A} J_1(\varsigma \xi) \quad{\rm and}\quad \varPi' = \frac{1}{{\mathcal{C}}^6} \sum_{n=1}^3 \gamma_n ( K^4 - \gamma_n^4 ) [ A_n J_1(\gamma_n \xi) + B_n Y_1(\gamma_n \xi) ], \end{align}respectively. Application of these seven conditions with use of (3.6) and (3.7) provides

where ![]() ${\boldsymbol{\mathsf{M}}}^{-1}$ represents the inverse of the square matrix

${\boldsymbol{\mathsf{M}}}^{-1}$ represents the inverse of the square matrix

\begin{align} {\boldsymbol{\mathsf{M}}}= \small{\begin{bmatrix} 0 & 0 & \dfrac{12{\mathcal{C}}^6 J_0(\varsigma{\xi_c})}{\mathrm{i}\varsigma^2} & \dfrac{12\,\mathrm{i}{\mathcal{C}}^6 J_1(\varsigma{\xi_c})}{\varsigma} & 0 & 0 & 0\\ J_0(\gamma_1{\xi_c}) & \gamma_1J_1(\gamma_1{\xi_c}) & \varPhi_{J}(\gamma_1,{\xi_c}) & \varPsi_{J}(\gamma_1,{\xi_c}) & \varPhi_{J}(\gamma_1,1) & \varTheta_{J}(\gamma_1,1) & \gamma_1^3 J_1(\gamma_1) \\ Y_0(\gamma_1{\xi_c}) & \gamma_1Y_1(\gamma_1{\xi_c}) & \varPhi_{Y}(\gamma_1,{\xi_c}) & \varPsi_{Y}(\gamma_1,{\xi_c}) & \varPhi_{Y}(\gamma_1,1) & \varTheta_{Y}(\gamma_1,1) & \gamma_1^3 Y_1(\gamma_1) \\ J_0(\gamma_2{\xi_c}) & \gamma_2J_1(\gamma_2{\xi_c}) & \varPhi_{J}(\gamma_2,{\xi_c}) & \varPsi_{J}(\gamma_2,{\xi_c}) & \varPhi_{J}(\gamma_2,1) & \varTheta_{J}(\gamma_2,1) & \gamma_2^3 J_1(\gamma_2) \\ Y_0(\gamma_2{\xi_c}) & \gamma_2Y_1(\gamma_2{\xi_c}) & \varPhi_{Y}(\gamma_2,{\xi_c}) & \varPsi_{Y}(\gamma_2,{\xi_c}) & \varPhi_{Y}(\gamma_2,1) & \varTheta_{Y}(\gamma_2,1) & \gamma_2^3 Y_1(\gamma_2) \\ J_0(\gamma_3{\xi_c}) & \gamma_3J_1(\gamma_3{\xi_c}) & \varPhi_{J}(\gamma_3,{\xi_c}) & \varPsi_{J}(\gamma_3,{\xi_c}) & \varPhi_{J}(\gamma_3,1) & \varTheta_{J}(\gamma_3,1) & \gamma_3^3 J_1(\gamma_3) \\ Y_0(\gamma_3{\xi_c}) & \gamma_3Y_1(\gamma_3{\xi_c}) & \varPhi_{Y}(\gamma_3,{\xi_c}) & \varPsi_{Y}(\gamma_3,{\xi_c}) & \varPhi_{Y}(\gamma_3,1) & \varTheta_{Y}(\gamma_3,1) & \gamma_3^3 Y_1(\gamma_3) \end{bmatrix}} , \end{align}

\begin{align} {\boldsymbol{\mathsf{M}}}= \small{\begin{bmatrix} 0 & 0 & \dfrac{12{\mathcal{C}}^6 J_0(\varsigma{\xi_c})}{\mathrm{i}\varsigma^2} & \dfrac{12\,\mathrm{i}{\mathcal{C}}^6 J_1(\varsigma{\xi_c})}{\varsigma} & 0 & 0 & 0\\ J_0(\gamma_1{\xi_c}) & \gamma_1J_1(\gamma_1{\xi_c}) & \varPhi_{J}(\gamma_1,{\xi_c}) & \varPsi_{J}(\gamma_1,{\xi_c}) & \varPhi_{J}(\gamma_1,1) & \varTheta_{J}(\gamma_1,1) & \gamma_1^3 J_1(\gamma_1) \\ Y_0(\gamma_1{\xi_c}) & \gamma_1Y_1(\gamma_1{\xi_c}) & \varPhi_{Y}(\gamma_1,{\xi_c}) & \varPsi_{Y}(\gamma_1,{\xi_c}) & \varPhi_{Y}(\gamma_1,1) & \varTheta_{Y}(\gamma_1,1) & \gamma_1^3 Y_1(\gamma_1) \\ J_0(\gamma_2{\xi_c}) & \gamma_2J_1(\gamma_2{\xi_c}) & \varPhi_{J}(\gamma_2,{\xi_c}) & \varPsi_{J}(\gamma_2,{\xi_c}) & \varPhi_{J}(\gamma_2,1) & \varTheta_{J}(\gamma_2,1) & \gamma_2^3 J_1(\gamma_2) \\ Y_0(\gamma_2{\xi_c}) & \gamma_2Y_1(\gamma_2{\xi_c}) & \varPhi_{Y}(\gamma_2,{\xi_c}) & \varPsi_{Y}(\gamma_2,{\xi_c}) & \varPhi_{Y}(\gamma_2,1) & \varTheta_{Y}(\gamma_2,1) & \gamma_2^3 Y_1(\gamma_2) \\ J_0(\gamma_3{\xi_c}) & \gamma_3J_1(\gamma_3{\xi_c}) & \varPhi_{J}(\gamma_3,{\xi_c}) & \varPsi_{J}(\gamma_3,{\xi_c}) & \varPhi_{J}(\gamma_3,1) & \varTheta_{J}(\gamma_3,1) & \gamma_3^3 J_1(\gamma_3) \\ Y_0(\gamma_3{\xi_c}) & \gamma_3Y_1(\gamma_3{\xi_c}) & \varPhi_{Y}(\gamma_3,{\xi_c}) & \varPsi_{Y}(\gamma_3,{\xi_c}) & \varPhi_{Y}(\gamma_3,1) & \varTheta_{Y}(\gamma_3,1) & \gamma_3^3 Y_1(\gamma_3) \end{bmatrix}} , \end{align}expressed here in terms of the auxiliary functions

\begin{equation} \left.\begin{array}{c@{}}

\varPhi_{\mathcal{B}}(\gamma_n,\xi) = ( \gamma_n^4 - K^4 )

\mathcal{B}_0(\gamma_n \xi) \\

\varPsi_{\mathcal{B}}(\gamma_n,\xi) = \gamma_n ( K^4 -

\gamma_n^4 ) \mathcal{B}_1(\gamma_n \xi) \\

\varTheta_{\mathcal{B}}(\gamma_n,\xi) = \gamma_n^2 \left[

\mathcal{B}_0(\gamma_n\xi) - \dfrac{1-\nu_d}{\gamma_n\xi}

\mathcal{B}_1(\gamma_n\xi) \right] \end{array}\right\},

\end{equation}

\begin{equation} \left.\begin{array}{c@{}}

\varPhi_{\mathcal{B}}(\gamma_n,\xi) = ( \gamma_n^4 - K^4 )

\mathcal{B}_0(\gamma_n \xi) \\

\varPsi_{\mathcal{B}}(\gamma_n,\xi) = \gamma_n ( K^4 -

\gamma_n^4 ) \mathcal{B}_1(\gamma_n \xi) \\

\varTheta_{\mathcal{B}}(\gamma_n,\xi) = \gamma_n^2 \left[

\mathcal{B}_0(\gamma_n\xi) - \dfrac{1-\nu_d}{\gamma_n\xi}

\mathcal{B}_1(\gamma_n\xi) \right] \end{array}\right\},

\end{equation}

where ![]() $\mathcal {B}_m$ represents a Bessel function of the first/second kind (

$\mathcal {B}_m$ represents a Bessel function of the first/second kind (![]() $J_m$ or

$J_m$ or ![]() $Y_m$) of

$Y_m$) of ![]() $m$th order.

$m$th order.

3.1. Solving for the presumed displacement amplitude  $b$

$b$

The reactive aerodynamic and structural forces affecting the oscillation of the central assembly can now be expressed, with errors of order ![]() $\varepsilon \ll 1$, in the dimensionless forms

$\varepsilon \ll 1$, in the dimensionless forms

\begin{equation} \frac{\displaystyle \int_0^{r_c} (p-p_a) r\,{\rm d} r}{\varepsilon p_a a^2} ={-}\mathrm{Re}\{ F_c \,\mathrm{e}^{\mathrm{i}\tau} \} , \quad{\rm where}\ F_c = {\xi_c} \left[ \frac{{\xi_c}}{2} + \frac{\bar A}{\varsigma} J_1(\varsigma{\xi_c}) \right] ,\end{equation}

\begin{equation} \frac{\displaystyle \int_0^{r_c} (p-p_a) r\,{\rm d} r}{\varepsilon p_a a^2} ={-}\mathrm{Re}\{ F_c \,\mathrm{e}^{\mathrm{i}\tau} \} , \quad{\rm where}\ F_c = {\xi_c} \left[ \frac{{\xi_c}}{2} + \frac{\bar A}{\varsigma} J_1(\varsigma{\xi_c}) \right] ,\end{equation}and, based on (2.10),

\begin{equation} \frac{ r_c \mathcal{V}_c }{ \mathcal{D} b/a^2 } ={-}\mathrm{Re}\{ V_c \,\mathrm{e}^{\mathrm{i}\tau} \} , \quad{\rm where}\ V_c = \xi_c \sum_{n=1}^3 \gamma_n^3 [ A_n J_1(\gamma_n\xi_c) + B_n Y_1(\gamma_n\xi_c) ] ,\end{equation}

\begin{equation} \frac{ r_c \mathcal{V}_c }{ \mathcal{D} b/a^2 } ={-}\mathrm{Re}\{ V_c \,\mathrm{e}^{\mathrm{i}\tau} \} , \quad{\rm where}\ V_c = \xi_c \sum_{n=1}^3 \gamma_n^3 [ A_n J_1(\gamma_n\xi_c) + B_n Y_1(\gamma_n\xi_c) ] ,\end{equation}

respectively. Substituting into the governing equation of motion (2.1) the presumed central displacement (2.4), the central pressure force (3.15) and the structural impedance (3.16) reveals a linear relationship between the unknown displacement amplitude ![]() $b$ and the (generally) known excitation amplitude

$b$ and the (generally) known excitation amplitude ![]() ${\mathcal {F}}_m$, given by

${\mathcal {F}}_m$, given by

and an absolute value denotes the modulus of a complex quantity. The associated phase difference ![]() $\phi$ is given simply by

$\phi$ is given simply by ![]() $\phi = {\rm arg}(\mathcal {X})$. Note that this estimate for the value of

$\phi = {\rm arg}(\mathcal {X})$. Note that this estimate for the value of ![]() $b$, accurate with relative errors of order

$b$, accurate with relative errors of order ![]() $\varepsilon =b/h_o \ll 1$, does not require knowledge of the load

$\varepsilon =b/h_o \ll 1$, does not require knowledge of the load ![]() ${\mathcal {F}}_\ell$ which enters in (2.1) as an asymptotic correction of order

${\mathcal {F}}_\ell$ which enters in (2.1) as an asymptotic correction of order ![]() $\varepsilon$.

$\varepsilon$.

4. Time-averaged behaviour at first order

The disk displacement at leading order, ![]() $W_0$, and the associated film overpressure,

$W_0$, and the associated film overpressure, ![]() $P_0$, both vary sinusoidally with time and thus exhibit a zero time average, i.e.

$P_0$, both vary sinusoidally with time and thus exhibit a zero time average, i.e. ![]() $\langle W_0 \rangle =\langle P_0 \rangle =0$, the angled brackets denoting the cycle-averaging operator (2.5). Determining the steady pressure distribution and the steady disk deformation thus requires solving the problem that emerges at the following asymptotic order. Collecting terms of order

$\langle W_0 \rangle =\langle P_0 \rangle =0$, the angled brackets denoting the cycle-averaging operator (2.5). Determining the steady pressure distribution and the steady disk deformation thus requires solving the problem that emerges at the following asymptotic order. Collecting terms of order ![]() $\varepsilon$ in the expanded forms of (2.14) and (2.15) and their boundary conditions (2.17) and (2.18), and computing the cycle average thereof, provides the system of equations

$\varepsilon$ in the expanded forms of (2.14) and (2.15) and their boundary conditions (2.17) and (2.18), and computing the cycle average thereof, provides the system of equations

\begin{equation}

{\dfrac{\partial }{\partial \xi}} \left[ \xi

\left( 3 \left\langle W_0{\dfrac{\partial

P_0}{\partial \xi}}\right\rangle +

\frac{\sigma}{24}{\dfrac{\partial \langle P^2_0

\rangle}{\partial \xi}} + {\dfrac{\partial

\langle P_1 \rangle}{\partial \xi}} \right) \right] = 0

\left\{\begin{array}{@{}ll} \xi=0: & {\partial \langle P_1

\rangle}/{\partial \xi}=0 \\ \xi=1: & \langle P_1 \rangle=0

\end{array} \right. \end{equation}

\begin{equation}

{\dfrac{\partial }{\partial \xi}} \left[ \xi

\left( 3 \left\langle W_0{\dfrac{\partial

P_0}{\partial \xi}}\right\rangle +

\frac{\sigma}{24}{\dfrac{\partial \langle P^2_0

\rangle}{\partial \xi}} + {\dfrac{\partial

\langle P_1 \rangle}{\partial \xi}} \right) \right] = 0

\left\{\begin{array}{@{}ll} \xi=0: & {\partial \langle P_1

\rangle}/{\partial \xi}=0 \\ \xi=1: & \langle P_1 \rangle=0

\end{array} \right. \end{equation}

and

\begin{equation} \nabla^4 \langle W_1

\rangle = {\mathcal{C}}^6 \langle P_1 \rangle

\left\{\begin{array}{@{}ll} \xi=\xi_c: & \langle W_1 \rangle =

{\rm d}{\langle W_1 \rangle}/{\rm d}{\xi} = 0 \\ \xi=1 : &

\left( {\dfrac{{\rm d} ^2}{{\rm d} \xi^2}} +

\dfrac{\nu_d}{\xi}{\dfrac{{\rm d} }{{\rm d}

\xi}} \right) \langle W_1 \rangle = {\dfrac{{\rm

d} }{{\rm d} \xi}} \left( \nabla^2 \langle W_1 \rangle

\right) = 0 \end{array} \right.

,\end{equation}

\begin{equation} \nabla^4 \langle W_1

\rangle = {\mathcal{C}}^6 \langle P_1 \rangle

\left\{\begin{array}{@{}ll} \xi=\xi_c: & \langle W_1 \rangle =

{\rm d}{\langle W_1 \rangle}/{\rm d}{\xi} = 0 \\ \xi=1 : &

\left( {\dfrac{{\rm d} ^2}{{\rm d} \xi^2}} +

\dfrac{\nu_d}{\xi}{\dfrac{{\rm d} }{{\rm d}

\xi}} \right) \langle W_1 \rangle = {\dfrac{{\rm

d} }{{\rm d} \xi}} \left( \nabla^2 \langle W_1 \rangle

\right) = 0 \end{array} \right.

,\end{equation}

where the steady overpressure ![]() $\langle P_1 \rangle$ at the film edge

$\langle P_1 \rangle$ at the film edge ![]() $\xi =1$ is negligibly small in the lubrication limit considered here, as explained in Appendix A, and the value of

$\xi =1$ is negligibly small in the lubrication limit considered here, as explained in Appendix A, and the value of ![]() $\langle W_1 \rangle$ vanishes at the clamp radius

$\langle W_1 \rangle$ vanishes at the clamp radius ![]() $\xi =\xi _c$ since the driving cylinder oscillates about a constant mean position, as described below (2.1). In this connection, note from (4.1) and (4.2) that any secondary frequencies exhibited by

$\xi =\xi _c$ since the driving cylinder oscillates about a constant mean position, as described below (2.1). In this connection, note from (4.1) and (4.2) that any secondary frequencies exhibited by ![]() $W_1(\xi,\tau )$ due to nonlinear first-order interactions are irrelevant when solving for the time-averaged quantities of present interest.

$W_1(\xi,\tau )$ due to nonlinear first-order interactions are irrelevant when solving for the time-averaged quantities of present interest.

4.1. Time-averaged squeeze-film overpressure and disk deformation

The steady pressure distribution ![]() $\langle P_1 \rangle (\xi )$, independent of the steady disk deformation

$\langle P_1 \rangle (\xi )$, independent of the steady disk deformation ![]() $\langle W_1 \rangle (\xi )$ under the present perturbative formulation, can be determined by straightforward integration of (4.1) to give

$\langle W_1 \rangle (\xi )$ under the present perturbative formulation, can be determined by straightforward integration of (4.1) to give

where ![]() $x$ serves as a dummy integration variable. Substitution of the expressions given in (3.3) provides

$x$ serves as a dummy integration variable. Substitution of the expressions given in (3.3) provides

\begin{align} \langle P_1\rangle =

\begin{cases} \displaystyle \frac{1}{2} \mathrm{Re} \left\{

3\left[ \bar{\varPi}({\xi_c}) - \bar{\varPi}(\xi) +

\int_{\xi_c}^1 \varPi'^*({x}) \varOmega({x}) {\rm d}\kern 0.06em {x}

\right] - \dfrac{\sigma}{24} \bar{\varPi}\bar{\varPi}^*

\right\} & 0 \le \xi \le {\xi_c} \\ \displaystyle

\frac{1}{2} \mathrm{Re} \left\{ 3\int_\xi^1 \varPi'^*({x})

\varOmega({x}) {\rm d}\kern 0.06em {x} - \dfrac{\sigma}{24}

\varPi\varPi^* \right\} & {\xi_c} \le \xi \le 1 \end{cases}

,\end{align}

\begin{align} \langle P_1\rangle =

\begin{cases} \displaystyle \frac{1}{2} \mathrm{Re} \left\{

3\left[ \bar{\varPi}({\xi_c}) - \bar{\varPi}(\xi) +

\int_{\xi_c}^1 \varPi'^*({x}) \varOmega({x}) {\rm d}\kern 0.06em {x}

\right] - \dfrac{\sigma}{24} \bar{\varPi}\bar{\varPi}^*

\right\} & 0 \le \xi \le {\xi_c} \\ \displaystyle

\frac{1}{2} \mathrm{Re} \left\{ 3\int_\xi^1 \varPi'^*({x})

\varOmega({x}) {\rm d}\kern 0.06em {x} - \dfrac{\sigma}{24}

\varPi\varPi^* \right\} & {\xi_c} \le \xi \le 1 \end{cases}

,\end{align}

having made use of the identity ![]() $\langle \mathrm {Re}\{ \mathcal {G} \mathrm {e}^{\mathrm {i}\tau }\} \mathrm {Re}\{ \mathcal {H} \mathrm {e}^{\mathrm {i}\tau }\} \rangle = \mathrm {Re} \{ \mathcal {G}^* \mathcal {H} \} / 2$, where

$\langle \mathrm {Re}\{ \mathcal {G} \mathrm {e}^{\mathrm {i}\tau }\} \mathrm {Re}\{ \mathcal {H} \mathrm {e}^{\mathrm {i}\tau }\} \rangle = \mathrm {Re} \{ \mathcal {G}^* \mathcal {H} \} / 2$, where ![]() $\mathcal {G}$ and

$\mathcal {G}$ and ![]() $\mathcal {H}$ are complex spatial functions and an asterisk denotes a complex conjugate.

$\mathcal {H}$ are complex spatial functions and an asterisk denotes a complex conjugate.

Integration of (4.2) provides the accompanying time-averaged deformation of the disk

\begin{align} \langle W_1 \rangle &=

{\mathcal{C}}^6 \left( {\mathcal{I}}_1({\xi_c}) \ln\left(

\frac{{\xi_c}}{\xi} \right) + \frac{1}{64} \int_{\xi_c}^\xi

x^4 [ 4\ln(x)-5 ] \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x \right. \nonumber\\ & \quad -

\left.\frac{\ln(\xi)}{16} \int_{\xi_c}^\xi x^4 \langle P_1

\rangle ' (x) \, {\rm d}\kern0.7pt x \ +\ \right|_{\xi_c}^\xi

{\mathcal{I}}_2(\xi) \nonumber\\ & \quad + \left.\frac{

{\xi_c}^2 [ 1+2\ln(\xi/{\xi_c}) ] - \xi^2 }{ 2[ {\xi_c}^2-1

+ 2/(1-\nu_d) ]}\left[ {\mathcal{I}}_1({\xi_c})+

\frac{1}{16} \int_{\xi_c}^1 x^4 \langle P_1 \rangle ' (x)

\, {\rm d}\kern0.7pt x \right] \right)

\end{align}

\begin{align} \langle W_1 \rangle &=

{\mathcal{C}}^6 \left( {\mathcal{I}}_1({\xi_c}) \ln\left(

\frac{{\xi_c}}{\xi} \right) + \frac{1}{64} \int_{\xi_c}^\xi

x^4 [ 4\ln(x)-5 ] \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x \right. \nonumber\\ & \quad -

\left.\frac{\ln(\xi)}{16} \int_{\xi_c}^\xi x^4 \langle P_1

\rangle ' (x) \, {\rm d}\kern0.7pt x \ +\ \right|_{\xi_c}^\xi

{\mathcal{I}}_2(\xi) \nonumber\\ & \quad + \left.\frac{

{\xi_c}^2 [ 1+2\ln(\xi/{\xi_c}) ] - \xi^2 }{ 2[ {\xi_c}^2-1

+ 2/(1-\nu_d) ]}\left[ {\mathcal{I}}_1({\xi_c})+

\frac{1}{16} \int_{\xi_c}^1 x^4 \langle P_1 \rangle ' (x)

\, {\rm d}\kern0.7pt x \right] \right)

\end{align}

expressed here in terms of the radial pressure gradient

\begin{equation} \langle P_1 \rangle ' =

{\dfrac{{\rm d} \langle P_1 \rangle }{{\rm d}

\xi}} = \begin{cases} -\dfrac{1}{2} \mathrm{Re} \left\{

\bar{\varPi}'^* \left( 3 + \dfrac{\sigma}{12}\bar{\varPi}

\right) \right\} & 0 \le \xi \le {\xi_c} \\ -\dfrac{1}{2}

\mathrm{Re} \left\{ \varPi'^* \left( 3\varOmega +

\dfrac{\sigma}{12}\varPi \right) \right\} & {\xi_c} \le \xi

\le 1 \end{cases}, \end{equation}

\begin{equation} \langle P_1 \rangle ' =

{\dfrac{{\rm d} \langle P_1 \rangle }{{\rm d}

\xi}} = \begin{cases} -\dfrac{1}{2} \mathrm{Re} \left\{

\bar{\varPi}'^* \left( 3 + \dfrac{\sigma}{12}\bar{\varPi}

\right) \right\} & 0 \le \xi \le {\xi_c} \\ -\dfrac{1}{2}

\mathrm{Re} \left\{ \varPi'^* \left( 3\varOmega +

\dfrac{\sigma}{12}\varPi \right) \right\} & {\xi_c} \le \xi

\le 1 \end{cases}, \end{equation}

and the auxiliary integral functions

\begin{equation} \left.\begin{array}{c@{}}

\displaystyle {\mathcal{I}}_1(\xi) = \dfrac{\xi^2}{4}

\left[ \dfrac{\xi^2}{4}\langle P_1 \rangle +

\ln(\xi)\int_\xi^1 x^2 \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x - \int_\xi^1 x^2 \ln(x) \langle P_1 \rangle

' (x) \, {\rm d}\kern0.7pt x \right]\\ \displaystyle

{\mathcal{I}}_2(\xi) = \dfrac{\xi^2}{16} \left[

\dfrac{\xi^2}{4}\langle P_1 \rangle + [2\ln(\xi) - 1]

\int_\xi^1 x^2 \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x - 2 \int_\xi^1 x^2 \ln(x) \langle P_1

\rangle ' (x) \, {\rm d}\kern0.7pt x \right]

\end{array}\right\}.\end{equation}

\begin{equation} \left.\begin{array}{c@{}}

\displaystyle {\mathcal{I}}_1(\xi) = \dfrac{\xi^2}{4}

\left[ \dfrac{\xi^2}{4}\langle P_1 \rangle +

\ln(\xi)\int_\xi^1 x^2 \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x - \int_\xi^1 x^2 \ln(x) \langle P_1 \rangle

' (x) \, {\rm d}\kern0.7pt x \right]\\ \displaystyle

{\mathcal{I}}_2(\xi) = \dfrac{\xi^2}{16} \left[

\dfrac{\xi^2}{4}\langle P_1 \rangle + [2\ln(\xi) - 1]

\int_\xi^1 x^2 \langle P_1 \rangle ' (x) \, {\rm

d}\kern0.7pt x - 2 \int_\xi^1 x^2 \ln(x) \langle P_1

\rangle ' (x) \, {\rm d}\kern0.7pt x \right]

\end{array}\right\}.\end{equation}

4.2. An analytical expression for the levitation force

Consistent with the simplified description of gas dynamics presented in § 2.2, the steady, attractive squeeze-film levitation force can be expressed as ![]() ${\mathcal {F}}_\ell = -2{\rm \pi} \int _0^a \langle p-p_a \rangle \, r {\rm d}r$, which follows from a cycle-averaged statement of Newton's second law for the periodically oscillating system cartooned in figure 1(a), comprising both the central assembly and the annular portion of the disk. (This definition for

${\mathcal {F}}_\ell = -2{\rm \pi} \int _0^a \langle p-p_a \rangle \, r {\rm d}r$, which follows from a cycle-averaged statement of Newton's second law for the periodically oscillating system cartooned in figure 1(a), comprising both the central assembly and the annular portion of the disk. (This definition for ![]() ${\mathcal {F}}_\ell$ may be obtained also by integrating the Kirchhoff–Love equation (2.9a) across the annular portion of the disk

${\mathcal {F}}_\ell$ may be obtained also by integrating the Kirchhoff–Love equation (2.9a) across the annular portion of the disk ![]() $r_c \le r \le a$, substituting the resulting expression for the stress resultant

$r_c \le r \le a$, substituting the resulting expression for the stress resultant ![]() $\mathcal {V}_c$ (2.10) into the equation of motion (2.1) and taking the time average thereof.)

$\mathcal {V}_c$ (2.10) into the equation of motion (2.1) and taking the time average thereof.)

Based on the scalings introduced in § 2.4, the force ![]() ${\mathcal {F}}_\ell$ can be normalized with the supplied excitation amplitude

${\mathcal {F}}_\ell$ can be normalized with the supplied excitation amplitude ![]() ${\mathcal {F}}_m$ and the resulting relative oscillation amplitude

${\mathcal {F}}_m$ and the resulting relative oscillation amplitude ![]() $\varepsilon = b/h_o$ to provide a dimensionless expression for the operating efficiency of the system

$\varepsilon = b/h_o$ to provide a dimensionless expression for the operating efficiency of the system

and the complex constant ![]() $\mathcal {X}$ is defined in (3.17). Integration by parts in (4.8b) yields

$\mathcal {X}$ is defined in (3.17). Integration by parts in (4.8b) yields ![]() $\langle F_L \rangle = \int _0^1 \xi ^2 \langle P_1 \rangle ' \, {\rm d} \xi$, wherein substitution of the steady pressure gradient (4.6) provides

$\langle F_L \rangle = \int _0^1 \xi ^2 \langle P_1 \rangle ' \, {\rm d} \xi$, wherein substitution of the steady pressure gradient (4.6) provides

\begin{align} \langle F_L \rangle &={-} \frac{1}{2}\mathrm{Re}\left\{ \frac{12}{\sigma} {\bar A}^* \left( \frac{2{\xi_c}}{\varsigma^*} [ 2J_1(\varsigma^*{\xi_c}) - \varsigma^*{\xi_c} J_0(\varsigma^*{\xi_c}) ] - \varsigma^*{\bar A} {\mathcal{I}}_{JJ}({\xi_c} ; \varsigma,\varsigma^*) \right) \right. \nonumber\\ & \quad + \left.\left.\sum_{n=1}^3 \sum_{m=1}^3 \frac{ \gamma_n^* ( K^4 - {\gamma_n^*}^4 )}{{\mathcal{C}}^6} \left[ 3 + \frac{\sigma( \gamma_m^4 - K^4 )}{12{\mathcal{C}}^6} \right] \right|_{\xi_c}^1 \mathcal{I}_L(\xi) \right\} , \end{align}

\begin{align} \langle F_L \rangle &={-} \frac{1}{2}\mathrm{Re}\left\{ \frac{12}{\sigma} {\bar A}^* \left( \frac{2{\xi_c}}{\varsigma^*} [ 2J_1(\varsigma^*{\xi_c}) - \varsigma^*{\xi_c} J_0(\varsigma^*{\xi_c}) ] - \varsigma^*{\bar A} {\mathcal{I}}_{JJ}({\xi_c} ; \varsigma,\varsigma^*) \right) \right. \nonumber\\ & \quad + \left.\left.\sum_{n=1}^3 \sum_{m=1}^3 \frac{ \gamma_n^* ( K^4 - {\gamma_n^*}^4 )}{{\mathcal{C}}^6} \left[ 3 + \frac{\sigma( \gamma_m^4 - K^4 )}{12{\mathcal{C}}^6} \right] \right|_{\xi_c}^1 \mathcal{I}_L(\xi) \right\} , \end{align}involving the auxiliary function

and the four operators ![]() ${\mathcal {I}}_{JJ},{\mathcal {I}}_{JY},{\mathcal {I}}_{YJ}$ and

${\mathcal {I}}_{JJ},{\mathcal {I}}_{JY},{\mathcal {I}}_{YJ}$ and ![]() ${\mathcal {I}}_{YY}$, defined collectively by

${\mathcal {I}}_{YY}$, defined collectively by

\begin{align} {\mathcal{I}}_{FG}(\xi ; \beta_{F},\beta_{G}) &= 2\beta_{G}\xi [ \beta_{G} F_0(\beta_{F}\xi)G_1(\beta_{G}\xi) - \beta_{F} F_1(\beta_{F}\xi)G_0(\beta_{G}\xi) ] / ( \beta_{F}^2-\beta_{G}^2 )^2 \nonumber\\ &\quad + \xi^2 [ \beta_{G} F_0(\beta_{F}\xi)G_0(\beta_{G}\xi) + \beta_{F} F_1(\beta_{F}\xi)G_1(\beta_{G}\xi) ] / (\beta_{F}^2-\beta_{G}^2 ) , \end{align}

\begin{align} {\mathcal{I}}_{FG}(\xi ; \beta_{F},\beta_{G}) &= 2\beta_{G}\xi [ \beta_{G} F_0(\beta_{F}\xi)G_1(\beta_{G}\xi) - \beta_{F} F_1(\beta_{F}\xi)G_0(\beta_{G}\xi) ] / ( \beta_{F}^2-\beta_{G}^2 )^2 \nonumber\\ &\quad + \xi^2 [ \beta_{G} F_0(\beta_{F}\xi)G_0(\beta_{G}\xi) + \beta_{F} F_1(\beta_{F}\xi)G_1(\beta_{G}\xi) ] / (\beta_{F}^2-\beta_{G}^2 ) , \end{align}

where each ![]() $F_m$ and

$F_m$ and ![]() $G_m$ represents a Bessel function of the first or second kind (

$G_m$ represents a Bessel function of the first or second kind (![]() $J_m$ or

$J_m$ or ![]() $Y_m$) of

$Y_m$) of ![]() $m$th order (Rosenheinrich Reference Rosenheinrich2019, p. 301).

$m$th order (Rosenheinrich Reference Rosenheinrich2019, p. 301).

5. Simplified expressions describing centrally forced systems:  $\xi _c \to 0$

$\xi _c \to 0$

Of particular interest in understanding the flow–structure physics of SFL systems is the problem of a disk that is subject to a concentrated load at its centre, experiencing internal structural stresses that grow unboundedly (![]() $\propto r^{-1}$) near its axis

$\propto r^{-1}$) near its axis ![]() $r=0$. Warren (Reference Warren1930) approached this singular problem by analysing the undamped oscillation of an annular disk and considering the limit of a vanishing inner radius. Following this strategy, the general formulation developed in §§ 2–4 is exploited below to derive simplified expressions, independent of

$r=0$. Warren (Reference Warren1930) approached this singular problem by analysing the undamped oscillation of an annular disk and considering the limit of a vanishing inner radius. Following this strategy, the general formulation developed in §§ 2–4 is exploited below to derive simplified expressions, independent of ![]() ${\xi _c}$, that describe the performance of a centrally forced system.

${\xi _c}$, that describe the performance of a centrally forced system.