Published online by Cambridge University Press: 16 November 2023

We investigate the effects of fluid elasticity on the flow forces and the wake structure when a rigid cylinder is placed in a viscoelastic flow and is forced to oscillate sinusoidally in the transverse direction. We consider a two-dimensional, uniform, incompressible flow of viscoelastic fluid at  $Re=100$, and use the FENE-P model to represent the viscoelastic fluid. We study how the flow forces and the wake patterns change as the amplitude of oscillations,

$Re=100$, and use the FENE-P model to represent the viscoelastic fluid. We study how the flow forces and the wake patterns change as the amplitude of oscillations,  $A^*$, the frequency of oscillations (inversely proportional to a reduced velocity,

$A^*$, the frequency of oscillations (inversely proportional to a reduced velocity,  $U^*$), the Weissenberg number,

$U^*$), the Weissenberg number,  $Wi$, the square of maximum polymer extensibility,

$Wi$, the square of maximum polymer extensibility,  $L^2$, and the viscosity ratio,

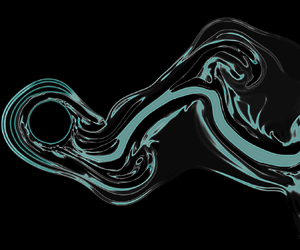

$L^2$, and the viscosity ratio,  $\beta$, change individually. We calculate the lift coefficient in phase with cylinder velocity to determine the range of different system parameters where self-excited oscillations might occur if the cylinder is allowed to oscillate freely. We also study the effect of fluid elasticity on the added mass coefficient as these parameters change. The maximum elastic stress of the fluid occurs in between the vortices that are observed in the wake. We observe a new mode of shedding in the wake of the cylinder: in addition to the primary vortices that are also observed in the Newtonian flows, secondary vortices that are caused entirely by the viscoelasticity of the fluid are observed in between the primary vortices. We also show that, for a constant

$\beta$, change individually. We calculate the lift coefficient in phase with cylinder velocity to determine the range of different system parameters where self-excited oscillations might occur if the cylinder is allowed to oscillate freely. We also study the effect of fluid elasticity on the added mass coefficient as these parameters change. The maximum elastic stress of the fluid occurs in between the vortices that are observed in the wake. We observe a new mode of shedding in the wake of the cylinder: in addition to the primary vortices that are also observed in the Newtonian flows, secondary vortices that are caused entirely by the viscoelasticity of the fluid are observed in between the primary vortices. We also show that, for a constant  $Wi$, the strength of the polymeric stresses increases with increasing reduced velocity or with decreasing amplitude of oscillations.

$Wi$, the strength of the polymeric stresses increases with increasing reduced velocity or with decreasing amplitude of oscillations.