1 Introduction

Most combustion systems are designed to operate in stable regimes but it is known that, ‘sometimes’, combustion systems exhibit unwanted oscillations. These combustion instabilities, also designated as thermoacoustic instabilities, are a manifestation of combustion dynamics. They can lead to high amplitude noise and vibration levels. In the worst cases, the resulting oscillations of the flow may give rise to flashback, a process in which the flame moves into the injector units and reaches the upstream manifold with serious consequences to the system integrity. In some cases, the large amplitude oscillations induce flame quenching or partial or total blow-off. The pressure oscillations can also become large enough to damage the combustor structure or lead to the destruction of the system.

Due to their detrimental consequences in engines, power and heat generation units, combustion instabilities (CIs) are an important field of combustion research, combining the various disciplines involved in reacting flows (fluid mechanics, thermodynamics, kinetics and transport) but also requiring the introduction of acoustics, hydrodynamic stability, system dynamics and control theory. The progress made since the initial developments in the 1950s in predicting, controlling and damping these undesirable self-sustained combustion oscillations can be gauged in the successive reviews from Crocco & Cheng (Reference Crocco and Cheng1956), Putnam (Reference Putnam1971), McManus, Poinsot & Candel (Reference McManus, Poinsot and Candel1993), Candel (Reference Candel2002), Dowling & Morgans (Reference Dowling and Morgans2005), Lieuwen & Yang (Reference Lieuwen and Yang2005), Culick (Reference Culick2006), Huang & Yang (Reference Huang and Yang2009), Gicquel, Staffelbach & Poinsot (Reference Gicquel, Staffelbach and Poinsot2012), O’Connor, Acharya & Lieuwen (Reference O’Connor, Acharya and Lieuwen2015), Poinsot (Reference Poinsot2017) and Juniper & Sujith (Reference Juniper and Sujith2018) and in the books from Poinsot & Veynante (Reference Poinsot and Veynante2012) and Lieuwen (Reference Lieuwen2012).

One of the striking features in these references is that combustion instabilities may arise in a wide variety of combustion systems. This includes, at one end, devices operating with unconfined flames powered by a gaseous fuel with less than one kilowatt thermal power output and, at the other end, rocket engines in which the combustion of liquid or solid propellants at high pressure delivers several gigawatts of thermal power. These instabilities can either be coupled by axial or transverse acoustic modes of the system, as in annular gas turbines, and their frequencies may span from a few Hertz, as observed in large industrial boilers featuring a bulk flow oscillation through the entire boiler, up to several kilo Hertz when coupled to a transverse mode as in the small thrust chamber of liquid rocket engines.

While the ultimate objective is to predict and control CIs in real large-scale turbulent combustors, understanding combustion instabilities in laminar systems is obviously a necessary first step. Many practical systems also operate in a premixed laminar mode and often suffer from CIs. Over the last 50 years, the analysis of the dynamics of laminar premixed systems has proved to be surprisingly difficult, leading to a large research effort, see for example Ducruix et al. (Reference Ducruix, Schuller, Durox and Candel2003) and De Goey et al. (Reference De Goey, van Oijen, Kornilov and ten Thije Boonkkamp2011). Many of the analytical developments made in Lieuwen (Reference Lieuwen2012) are for laminar systems. It is also worth noting that a new class of intrinsic thermoacoustic instabilities has been recently highlighted with the help of laminar combustion experiments (Hoeijmakers et al. Reference Hoeijmakers, Kornilov, Arteaga, de Goey and Nijmeijer2014; Emmert et al. Reference Emmert, Bomberg, Jaensch and Polifke2015).

Premixed laminar flames have an interesting specificity. Because of the simplicity of the base flow, they can be studied using experiments, pure theory or direct numerical simulation (DNS). They are probably the most complicated canonical flames for which all three approaches can be used simultaneously. The capacity of combining these three approaches and the clean flow conditions in which these flames can be studied, make laminar premixed flames ideal configurations for investigating flame dynamics. Results obtained on these flames may then serve as a guide for more complex cases.

Figure 1. (a) Feedback loop of thermoacoustic instabilities and (b) open loop flame transfer function  $\text{FTF}=G(\unicode[STIX]{x1D714}_{r})\exp (\text{i}\unicode[STIX]{x1D711}(\unicode[STIX]{x1D714}_{r}))$.

$\text{FTF}=G(\unicode[STIX]{x1D714}_{r})\exp (\text{i}\unicode[STIX]{x1D711}(\unicode[STIX]{x1D714}_{r}))$.

The objectives of this article are to provide an overview of the knowledge in combustion dynamics, starting from basic descriptions of acoustically coupled combustion instabilities in laminar premixed systems and closing with some recent research results. The paper is focused on premixed and laminar flames but many results apply to other types of flames as well. It is organized to provide a theoretical framework allowing analysis of CIs coupled by longitudinal as well as azimuthal acoustic modes.

The goal is to focus on analytical results obtained with the help of a series of simplifications to highlight the critical roles of the injector and flame responses to flow perturbations in the development of instabilities. Analytical expressions for the conditions leading to instabilities are derived for a set of generic configurations featuring the main components of real combustors. These results are used to discuss the respective influence of the injector dynamics and flame response. Finally, a theoretical framework is derived to model the flame response to flow-rate and mixture composition disturbances. It is illustrated in a simple case how the flame response can be tailored to reduce its susceptibility to flow perturbations.

Before examining the way acoustic waves interact with the flow and flame dynamics, it is worth describing the feedback loop leading to combustion instability. Thermoacoustic instabilities in combustion systems are due to synchronized oscillations between heat release rate disturbances produced by the flame and acoustic perturbations as illustrated in figure 1(a). In the absence of unsteady heat release, this coupling ceases. The main assumption which is used in this work, as in many others, is that the flame response to incoming flow perturbations produced by an external actuator in a stable configuration of the combustor can be used to assess the combustor dynamic stability, i.e. its capacity to induce self-sustained combustion oscillations without external actuator (Candel Reference Candel2002). In the diagram in figure 1, this means that the flame response characterized in terms of heat release rate oscillations can be studied outside the acoustic feedback loop shown in figure 1(a) by submitting the flame to acoustic disturbances to get the gain and phase information displayed in figure 1(b). This ‘open loop’ analysis leads to the definition of a flame transfer function (FTF) linking heat release rate disturbances to acoustic modulations produced by externally forcing the flow, as will be defined more precisely in § 2.

Another remarkable feature of combustion instabilities is that acoustic laws remain generally valid for the perturbed flow except at very high sound levels. Assuming acoustic disturbances and vanishingly small heat release rate perturbations, the FTF combined with an acoustic model of the combustor provides a framework for the linear stability analysis of the system dynamics. The gain  $G$ and phase lag

$G$ and phase lag  $\unicode[STIX]{x1D711}$ of the FTF (see figure 1b) can be determined from experiments, simulations or theory. The frequencies

$\unicode[STIX]{x1D711}$ of the FTF (see figure 1b) can be determined from experiments, simulations or theory. The frequencies  $f=\unicode[STIX]{x1D714}_{r}/2\unicode[STIX]{x03C0}$ and the growth rates

$f=\unicode[STIX]{x1D714}_{r}/2\unicode[STIX]{x03C0}$ and the growth rates  $\unicode[STIX]{x1D714}_{i}$ of the unstable modes are deduced by examining the stability of the closed-loop system in figure 1(a). Decoupling the acoustic analysis of the combustor from the analysis of the flame response to external flow disturbances has been so successful over the past two decades that it is now used by industry during the design process of real combustors (Lieuwen & Yang Reference Lieuwen and Yang2005). This framework underlies the theoretical analysis exploited in the present article.

$\unicode[STIX]{x1D714}_{i}$ of the unstable modes are deduced by examining the stability of the closed-loop system in figure 1(a). Decoupling the acoustic analysis of the combustor from the analysis of the flame response to external flow disturbances has been so successful over the past two decades that it is now used by industry during the design process of real combustors (Lieuwen & Yang Reference Lieuwen and Yang2005). This framework underlies the theoretical analysis exploited in the present article.

When the oscillation level of the instability increases in the combustor, nonlinearity is first manifested in the flame response by saturation of the gain and eventually also by a shift of the phase lag compared to its response at a lower perturbation amplitude. This is due to the strong nonlinearity of the heat release rate. The other flow perturbations remain in this respect less altered by the oscillation level and can often be considered to remain in the linear acoustic regime. Recognizing this feature, Dowling (Reference Dowling1999) and Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008) developed a weakly nonlinear framework in which the linear FTF filter is replaced by a nonlinear flame describing function (FDF) that accounts for effects of the perturbation level. The FDF corresponds to a set of FTFs, each determined for a range of forcing levels as illustrated in figure 2(a). Once the FTFs are determined, the methodology developed by Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008) shows how to use the FDF to predict limit cycle oscillation levels and their corresponding frequencies.

The FDF framework is a natural extension of a linear stability analysis based on FTF, in which the mode frequencies and their growth rates are calculated repeatedly for increasing forcing levels for which the FDF is known. The stability diagram is finally deduced from an analysis of the growth rate trajectories as a function of the acoustic level in the combustor. An example is given in figure 2(b). This strategy has been shown to be quite successful in determining the oscillation level of combustion instabilities reaching a limit cycle in several combustors, including configurations with complex geometries and multiple burners.

Figure 2. (a) Typical evolution of the gain  $G$ and phase lag

$G$ and phase lag  $\unicode[STIX]{x1D711}$ of a flame describing function (FDF) as the acoustic forcing level increases. (b) Growth rate

$\unicode[STIX]{x1D711}$ of a flame describing function (FDF) as the acoustic forcing level increases. (b) Growth rate  $\unicode[STIX]{x1D714}_{i}$ of an unstable mode as a function of the acoustic forcing level leading to a limit cycle.

$\unicode[STIX]{x1D714}_{i}$ of an unstable mode as a function of the acoustic forcing level leading to a limit cycle.

In this paper, the expressions derived for the frequencies and growth rates of instabilities are determined explicitly as a function of the gain  $G$ and phase lag

$G$ and phase lag  $\unicode[STIX]{x1D711}$ of the FTF, meaning that the same expressions can be used to conduct a weakly nonlinear analysis provided that the FTF is replaced by the FDF in these expressions. An analysis of the growth rate trajectories such as the one in figure 2 can then be carried out without difficulty. This is why the rest of the paper focuses on linear acoustic perturbations and vanishingly small heat release rate disturbances, remembering that it is easy to extend the analysis by replacing the FTF by the FDF.

$\unicode[STIX]{x1D711}$ of the FTF, meaning that the same expressions can be used to conduct a weakly nonlinear analysis provided that the FTF is replaced by the FDF in these expressions. An analysis of the growth rate trajectories such as the one in figure 2 can then be carried out without difficulty. This is why the rest of the paper focuses on linear acoustic perturbations and vanishingly small heat release rate disturbances, remembering that it is easy to extend the analysis by replacing the FTF by the FDF.

Basic principles of flame acoustic interactions are reviewed in § 2. Axial mode coupling is examined in § 3 for flames burning inside a combustion chamber and unconfined flames stabilized at the top of a burner. A system featuring a Helmholtz mode associated with a bulk flow oscillation is also examined. The existence and properties of intrinsic dynamical oscillations are discussed in § 4. Coupling involving azimuthal modes in annular combustion chambers is examined in § 5. The analysis takes into account a common plenum feeding a set of injectors and the impedance of these injectors. Results for the frequencies and growth rates of combustion instabilities derived in §§ 3 to 5 make use of the FTF, which is assumed to be known. The response of premixed flames to mixture and flow-rate perturbations is then revisited in § 6. This is used to show how the FTF may be obtained analytically, to highlight the role of the flame root dynamics and demonstrate how tailoring the FTF by passive or by active means can be used to lower heat release rate disturbances. References are provided in each of these sections as required by the developments. This is not intended to be an exhaustive review of the literature and many more references may be found in the cited articles.

2 Tutorial on thermoacoustics

Figure 3. Examples of tubes in which self-sustained pressure oscillations are driven by heat addition.

Thermoacoustic oscillations generally imply a driving process that is in most cases the heat released by combustion and a coupling mechanism that in most cases takes the form of resonant acoustic modes of the system. The most common thermoacoustic oscillations are driven by flames but there are examples where the oscillation is produced by another thermal process. A well-known configuration is that of the ‘Rijke’ tube that comprises a pipe and a heat source which may be a flame inserted in the tube, a metallic gauze that is initially preheated or an electrically heated resistive wire arrangement (Rijke Reference Rijke1859a,Reference Rijkeb; Mariappan & Sujith Reference Mariappan and Sujith2011). Raun et al. (Reference Raun, Beckstead, Finlinson and Brooks1993) list a series of devices made of tubes with heat addition leading to thermoacoustic instabilities, some of which are illustrated in figure 3. Sound is generated in these configurations at one of the resonant frequencies of the tube. This is perhaps the simplest device for demonstrations but may not be the best idealization of more practical situations.

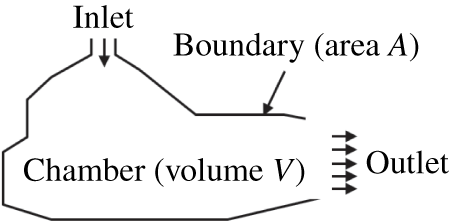

The analysis of combustion instabilities requires a coupling of descriptions of the unsteady combustion process on one hand with the acoustics of the system on the other hand. There are many complexities in these two items, so that simplifications are usually needed to develop the analysis.

One-dimensional acoustics is often assumed because acoustic waves involved in many CIs are approximately planar, one-dimensional perturbations progressing in the axial direction. In this respect, the acoustics involved in CIs are simpler than that arising in aeroacoustic problems where propagation is essentially three-dimensional or takes the form of higher-order duct modes. It is worth noting, however, that combustion systems often feature a complex geometry and this may require multidimensional calculations based on a Helmholtz solver to determine the acoustic field in the system. Section 2.1 presents the basic elements governing acoustic wave propagation in one-dimensional systems. In cases where the wavelength is of the order of or smaller than a typical transverse dimension of the system, combustion may couple to transverse acoustic modes featuring a more complex two-dimensional distribution that is considered in § 5.

Acoustic impedance characteristics are of central importance in CI analysis. This quantity introduced in § 2.2 is used to describe the acoustic response of inlet(s) and outlet(s) of combustors. In many instances, these impedances essentially control the stability of the system because they determine how much acoustic energy is reflected into the chamber and define the phase of the reflected field with respect to the incident waves.

During CIs, flames are submitted to unsteady motion caused by the flow perturbations entering the flame zone. Over the years, one approach has proved to be sufficiently powerful to analyse CIs and simple enough to be implemented in most models in the form of a FTF. In this framework, the response of the flame stabilized over an injector in a flow at fixed equivalence ratio depends directly on one single quantity, the inlet velocity. This concept is presented in § 2.3. Section 6 shows how to model this function by taking into account flow rate, as well as mixture composition perturbations.

Stability analysis based on FTF is introduced in § 2.4. The method is important because it is not feasible to analyse combustion dynamics issues by only resorting to multidimensional simulations of the reacting Navier–Stokes equations. Such calculations will generally require large eddy simulations with important computational resources and cannot be used to explore the parameter space and determine conditions assuring stability. It is then important to derive simpler models reflecting the fundamental mechanisms controlling the dynamics of the system and allowing a physical interpretation. Section 2.4 explains the basis of the stability analysis and shows how it can be used in a simple academic case where a full solution is also accessible.

2.1 Acoustics in ducts

2.1.1 Planar one-dimensional waves

It is natural to first consider combustion instabilities coupled by longitudinal modes. This corresponds to a situation where the wavelength  $\unicode[STIX]{x1D706}$ is larger than the typical transverse dimension of the system. The frequencies are usually lower than 1 kHz and the wavelengths of the order of a metre. The combustion region dimension

$\unicode[STIX]{x1D706}$ is larger than the typical transverse dimension of the system. The frequencies are usually lower than 1 kHz and the wavelengths of the order of a metre. The combustion region dimension  $\unicode[STIX]{x1D6FF}$ is in most cases much smaller than the wavelength

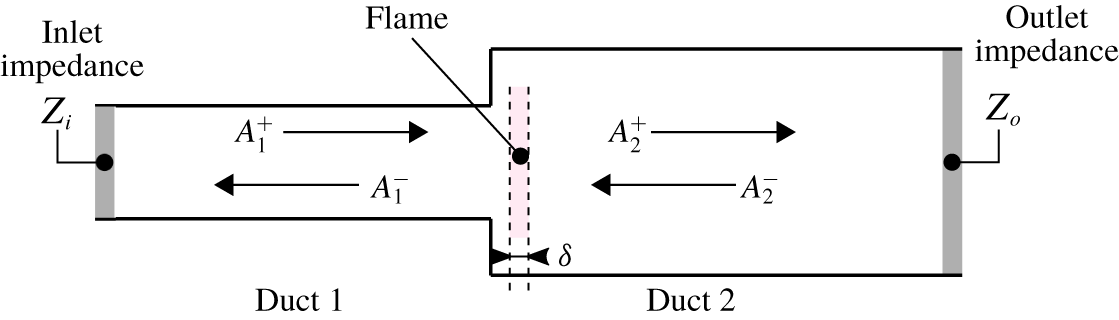

$\unicode[STIX]{x1D6FF}$ is in most cases much smaller than the wavelength  $\unicode[STIX]{x1D6FF}/\unicode[STIX]{x1D706}\ll 1$ and one may consider that this region is ‘compact’. The previous conditions may then be described by considering that the system is a network formed by a combination of elements of constant transverse dimension in which planar acoustic waves propagate axially and are affected by flames occupying a thin region corresponding to a combustion zone (figure 4).

$\unicode[STIX]{x1D6FF}/\unicode[STIX]{x1D706}\ll 1$ and one may consider that this region is ‘compact’. The previous conditions may then be described by considering that the system is a network formed by a combination of elements of constant transverse dimension in which planar acoustic waves propagate axially and are affected by flames occupying a thin region corresponding to a combustion zone (figure 4).

Figure 4. A schematic view of combustion instability network models: one-dimensional acoustic waves travel in a series of ducts. A compact flame is located in one section of the ducts. Inlet and outlet are characterized by their impedances.

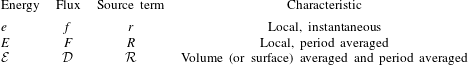

A convenient notation to describe acoustic variables during CIs is the following. Any variable  $a$, pressure, velocity, density or temperature, is decomposed into a time average value

$a$, pressure, velocity, density or temperature, is decomposed into a time average value  $\bar{a}$ and a small perturbation

$\bar{a}$ and a small perturbation  $a^{\prime }$:

$a^{\prime }$:  $a=\overline{a}+a^{\prime }$. The analysis is usually performed by assuming harmonic variations, or a sum of harmonic variations, at an angular frequency

$a=\overline{a}+a^{\prime }$. The analysis is usually performed by assuming harmonic variations, or a sum of harmonic variations, at an angular frequency  $\unicode[STIX]{x1D714}$. The perturbation

$\unicode[STIX]{x1D714}$. The perturbation  $a^{\prime }$ is written as

$a^{\prime }$ is written as  $a^{\prime }=\text{Re}[\tilde{a}\exp (-\text{i}\unicode[STIX]{x1D714}t)]$ where

$a^{\prime }=\text{Re}[\tilde{a}\exp (-\text{i}\unicode[STIX]{x1D714}t)]$ where  $i^{2}=-1$ and

$i^{2}=-1$ and  $\text{Re}$ designates the real part of a complex number. All derivations are carried out using the complex equivalent of

$\text{Re}$ designates the real part of a complex number. All derivations are carried out using the complex equivalent of  $a^{\prime }$ which is

$a^{\prime }$ which is  $\tilde{a}$ to simplify the algebra. Once

$\tilde{a}$ to simplify the algebra. Once  $\tilde{a}$ is obtained,

$\tilde{a}$ is obtained,  $a^{\prime }$ is deduced by taking the real part of

$a^{\prime }$ is deduced by taking the real part of  $\tilde{a}\exp (-\text{i}\unicode[STIX]{x1D714}t)$. It is often necessary to calculate the average over a period

$\tilde{a}\exp (-\text{i}\unicode[STIX]{x1D714}t)$. It is often necessary to calculate the average over a period  $T=2\unicode[STIX]{x03C0}/\unicode[STIX]{x1D714}$ of a product of harmonic perturbations. Such averages appear for example in the determination of acoustic energies or fluxes:

$T=2\unicode[STIX]{x03C0}/\unicode[STIX]{x1D714}$ of a product of harmonic perturbations. Such averages appear for example in the determination of acoustic energies or fluxes:

$$\begin{eqnarray}\displaystyle J=\frac{1}{T}\int _{0}^{T}a^{\prime }b^{\prime }\,\text{d}t. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle J=\frac{1}{T}\int _{0}^{T}a^{\prime }b^{\prime }\,\text{d}t. & & \displaystyle\end{eqnarray}$$ Some straightforward calculations indicate that it is possible to express this quantity in terms of the complex amplitudes  $\tilde{a}$ and

$\tilde{a}$ and  $\tilde{b}$,

$\tilde{b}$,

$$\begin{eqnarray}J={\textstyle \frac{1}{2}}\text{Re}(\tilde{a}\tilde{b}^{\ast })={\textstyle \frac{1}{2}}\text{Re}(\tilde{a}^{\ast }\tilde{b}),\end{eqnarray}$$

$$\begin{eqnarray}J={\textstyle \frac{1}{2}}\text{Re}(\tilde{a}\tilde{b}^{\ast })={\textstyle \frac{1}{2}}\text{Re}(\tilde{a}^{\ast }\tilde{b}),\end{eqnarray}$$ where  $\tilde{a}^{\ast }$ is the complex conjugate of

$\tilde{a}^{\ast }$ is the complex conjugate of  $\tilde{a}$. For example, the level of oscillation in a combustor is often measured through the root-mean-square value

$\tilde{a}$. For example, the level of oscillation in a combustor is often measured through the root-mean-square value  $p_{rms}^{\prime }$ of the pressure fluctuation. This is deduced by taking the square root of

$p_{rms}^{\prime }$ of the pressure fluctuation. This is deduced by taking the square root of  $p^{\prime 2}$ averaged over the oscillation period

$p^{\prime 2}$ averaged over the oscillation period

$$\begin{eqnarray}\displaystyle p_{rms}^{\prime 2}=\frac{1}{T}\int _{0}^{T}p^{\prime 2}\,\text{d}t=\frac{1}{2}\text{Re}(\,\tilde{p}\tilde{p}^{\ast }), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle p_{rms}^{\prime 2}=\frac{1}{T}\int _{0}^{T}p^{\prime 2}\,\text{d}t=\frac{1}{2}\text{Re}(\,\tilde{p}\tilde{p}^{\ast }), & & \displaystyle\end{eqnarray}$$where use has been made of Parseval’s identity.

2.1.2 Generic form for acoustic perturbations

The longitudinal acoustic field in a duct comprises two travelling waves that are planar and propagate in opposite axial directions. These waves are also isentropic since the only place where entropy changes is in the flame zone which is here considered to be compact. Therefore, in all duct elements composing a combustion system, acoustic perturbations can be decomposed in right (indexed  $^{+}$) and left (indexed

$^{+}$) and left (indexed  $^{-}$) travelling waves obeying to the Helmholtz equation. Using the complex notation of the previous section, one has

$^{-}$) travelling waves obeying to the Helmholtz equation. Using the complex notation of the previous section, one has

$$\begin{eqnarray}\displaystyle & \displaystyle p^{\prime }(x,t)=\text{Re}([A^{+}\text{e}^{\text{i}kx}+A^{-}\text{e}^{-\text{i}kx}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle p^{\prime }(x,t)=\text{Re}([A^{+}\text{e}^{\text{i}kx}+A^{-}\text{e}^{-\text{i}kx}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}cu^{\prime }(x,t)=\text{Re}([A^{+}\text{e}^{\text{i}kx}-A^{-}\text{e}^{-\text{i}kx}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}). & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}cu^{\prime }(x,t)=\text{Re}([A^{+}\text{e}^{\text{i}kx}-A^{-}\text{e}^{-\text{i}kx}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}). & \displaystyle\end{eqnarray}$$ In (2.4), the wavenumber  $k$ may be deduced from the angular frequency and the speed of sound:

$k$ may be deduced from the angular frequency and the speed of sound:  $k=\unicode[STIX]{x1D714}/c$. The wave amplitudes

$k=\unicode[STIX]{x1D714}/c$. The wave amplitudes  $A^{+}$ and

$A^{+}$ and  $A^{-}$ are determined using two types of information:

$A^{-}$ are determined using two types of information:

(i) The first are the boundary conditions at both ends of the system, which are usually specified by impedances as described in § 2.2. They are defined in the Fourier space and link the acoustic pressure to acoustic velocity at the boundaries.

(ii) The acoustic wavelength being large with respect to abrupt changes of the cross-section area and the flame length scales, one may link the acoustic variables by jump conditions in planes where the cross-section changes or where a flame is located as discussed in § 2.3.

One of the difficulties of combustion stability analysis is to specify impedances at the inflow and outflow boundaries and to express jump conditions at the flame reflecting the combustion response to incoming perturbations. These items are successively considered in what follows.

2.2 Impedances and admittances

The acoustic impedance is usually defined as the ratio of the pressure perturbation to the normal acoustic velocity  $Z=\tilde{p}/(\tilde{\boldsymbol{u}}\boldsymbol{\cdot }\boldsymbol{n})$ (Morse & Ingard Reference Morse and Ingard1986). In the general case, it is important to remember that the normal

$Z=\tilde{p}/(\tilde{\boldsymbol{u}}\boldsymbol{\cdot }\boldsymbol{n})$ (Morse & Ingard Reference Morse and Ingard1986). In the general case, it is important to remember that the normal  $\boldsymbol{n}$ is an outwards oriented unit vector. In the one-dimensional case, it is more convenient to use the velocity component in the axial direction and simply define the acoustic impedance as the ratio

$\boldsymbol{n}$ is an outwards oriented unit vector. In the one-dimensional case, it is more convenient to use the velocity component in the axial direction and simply define the acoustic impedance as the ratio  $Z=\tilde{p}/\tilde{u}$. The evaluation of

$Z=\tilde{p}/\tilde{u}$. The evaluation of  $Z$ is simple only in a few cases. For example, on a rigid wall, the velocity perturbations are zero and the impedance

$Z$ is simple only in a few cases. For example, on a rigid wall, the velocity perturbations are zero and the impedance  $Z$ is infinite. For a duct exhausting gases into an open atmosphere, the pressure fluctuation is nearly zero at the duct open end

$Z$ is infinite. For a duct exhausting gases into an open atmosphere, the pressure fluctuation is nearly zero at the duct open end  $p^{\prime }\simeq 0$ and the impedance

$p^{\prime }\simeq 0$ and the impedance  $Z$ is close to zero at that boundary. For all other cases, the evaluation of impedances is not as straightforward.

$Z$ is close to zero at that boundary. For all other cases, the evaluation of impedances is not as straightforward.

Figure 5. Inlet  $Z_{c}$ (compressor) and outlet

$Z_{c}$ (compressor) and outlet  $Z_{c}$ (turbine) impedances for a gas turbine engine.

$Z_{c}$ (turbine) impedances for a gas turbine engine.

It is especially complicated for engines where the combustion chamber is fed by a compressor and blows into a turbine as illustrated in figure 5. In such a situation, the determination of the compressor and turbine impedances is a problem in itself. And without knowing their values, assessing the dynamic stability of the combustion system is subject to uncertainty. For the idealized systems discussed in the present article, finding impedances is somewhat easier.

In many derivations, working with a specific impedance  $\unicode[STIX]{x1D701}$ is more convenient because it is a dimensionless complex number defined by

$\unicode[STIX]{x1D701}$ is more convenient because it is a dimensionless complex number defined by  $\unicode[STIX]{x1D701}=Z/(\unicode[STIX]{x1D70C}c)=\tilde{p}/(\unicode[STIX]{x1D70C}c\tilde{u} )$, where

$\unicode[STIX]{x1D701}=Z/(\unicode[STIX]{x1D70C}c)=\tilde{p}/(\unicode[STIX]{x1D70C}c\tilde{u} )$, where  $\unicode[STIX]{x1D70C}c$ is the characteristic impedance of the gaseous mixture. One also defines a specific admittance as the inverse of the specific impedance

$\unicode[STIX]{x1D70C}c$ is the characteristic impedance of the gaseous mixture. One also defines a specific admittance as the inverse of the specific impedance  $\unicode[STIX]{x1D6FD}=1/\unicode[STIX]{x1D701}=\unicode[STIX]{x1D70C}c\tilde{u} /\tilde{p}$. This definition may be used in combination with the linearized momentum equation to express the boundary condition in the form

$\unicode[STIX]{x1D6FD}=1/\unicode[STIX]{x1D701}=\unicode[STIX]{x1D70C}c\tilde{u} /\tilde{p}$. This definition may be used in combination with the linearized momentum equation to express the boundary condition in the form

$$\begin{eqnarray}\frac{\text{d}\tilde{p}}{\text{d}x}=\text{i}k\unicode[STIX]{x1D6FD}\tilde{p}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\text{d}\tilde{p}}{\text{d}x}=\text{i}k\unicode[STIX]{x1D6FD}\tilde{p}.\end{eqnarray}$$2.3 Jump conditions, FTF and FDF

One may first consider the relation which governs the level of velocity perturbations on the two sides of the flame. The analysis is carried out by assuming that the combustion region is compact in a low Mach number flow. Linearized Rankine–Hugoniot relations through the flame yield (see for example the recent analysis by Chen, Bomberg & Polifke (Reference Chen, Bomberg and Polifke2016))

$$\begin{eqnarray}\displaystyle & \displaystyle u_{2}^{\prime }-u_{1}^{\prime }=\frac{\unicode[STIX]{x1D6FE}-1}{\bar{\unicode[STIX]{x1D70C}}c^{2}}\frac{\dot{Q}^{\prime }}{S}, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle u_{2}^{\prime }-u_{1}^{\prime }=\frac{\unicode[STIX]{x1D6FE}-1}{\bar{\unicode[STIX]{x1D70C}}c^{2}}\frac{\dot{Q}^{\prime }}{S}, & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle p_{2}^{\prime }-p_{1}^{\prime }=0, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle p_{2}^{\prime }-p_{1}^{\prime }=0, & \displaystyle\end{eqnarray}$$ where  $S$ is the flame surface area,

$S$ is the flame surface area,  $\bar{p}$ denotes the mean pressure,

$\bar{p}$ denotes the mean pressure,  $\unicode[STIX]{x1D6FE}$ is the specific heat ratio and

$\unicode[STIX]{x1D6FE}$ is the specific heat ratio and  $\dot{Q}^{\prime }$ designates heat release rate fluctuations. Note that the pressure being nearly constant across the flame region, one may also safely consider that

$\dot{Q}^{\prime }$ designates heat release rate fluctuations. Note that the pressure being nearly constant across the flame region, one may also safely consider that  $\bar{\unicode[STIX]{x1D70C}}c^{2}=\unicode[STIX]{x1D6FE}\overline{p}$ which is nearly constant.

$\bar{\unicode[STIX]{x1D70C}}c^{2}=\unicode[STIX]{x1D6FE}\overline{p}$ which is nearly constant.

The main difficulty is to relate the heat release rate to the incident disturbances. Following the same reasoning as that used in early analysis of combustion instabilities in rocket engines (Crocco Reference Crocco1951, Reference Crocco1952), the heat release rate fluctuation may be linked to the incident velocity perturbations by a time-lag model. The unsteady heat release rate  $\dot{Q}^{\prime }$ produced by the flame only depends on the delayed value of the incoming inlet velocity

$\dot{Q}^{\prime }$ produced by the flame only depends on the delayed value of the incoming inlet velocity  $u_{1}^{\prime }$:

$u_{1}^{\prime }$:

$$\begin{eqnarray}\displaystyle \dot{Q}^{\prime }=f(u_{1}^{\prime })=nu_{1}^{\prime }(t-\unicode[STIX]{x1D70F}), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \dot{Q}^{\prime }=f(u_{1}^{\prime })=nu_{1}^{\prime }(t-\unicode[STIX]{x1D70F}), & & \displaystyle\end{eqnarray}$$ where  $n$ is an interaction index and

$n$ is an interaction index and  $\unicode[STIX]{x1D70F}$ designates a time lag. In practice, it is preferable to use a dimensionless interaction index

$\unicode[STIX]{x1D70F}$ designates a time lag. In practice, it is preferable to use a dimensionless interaction index  $N$ linking the relative heat release rate fluctuations to a delayed relative velocity perturbation

$N$ linking the relative heat release rate fluctuations to a delayed relative velocity perturbation

$$\begin{eqnarray}\displaystyle \frac{\dot{Q}^{\prime }}{\overline{\dot{Q}}}=f\left(\frac{u_{1}^{\prime }}{\bar{u}_{1}}\right)=N\frac{u_{1}^{\prime }(t-\unicode[STIX]{x1D70F})}{\bar{u}_{1}}\,\!, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \frac{\dot{Q}^{\prime }}{\overline{\dot{Q}}}=f\left(\frac{u_{1}^{\prime }}{\bar{u}_{1}}\right)=N\frac{u_{1}^{\prime }(t-\unicode[STIX]{x1D70F})}{\bar{u}_{1}}\,\!, & & \displaystyle\end{eqnarray}$$ where  $\overline{\dot{Q}}$ and

$\overline{\dot{Q}}$ and  $\bar{u}_{1}$ are the mean total heat release rate and the mean inlet velocity, respectively. The scaled interaction index

$\bar{u}_{1}$ are the mean total heat release rate and the mean inlet velocity, respectively. The scaled interaction index  $N$ measures the strength of the flame response to incident perturbations. Large values of

$N$ measures the strength of the flame response to incident perturbations. Large values of  $N$ characterize flames that are prone to CI. The delay

$N$ characterize flames that are prone to CI. The delay  $\unicode[STIX]{x1D70F}$ measures the time needed by the flame to respond to incoming perturbations originating from the upstream side. It is known that systems with delays may become unstable. In combustion systems the time lag

$\unicode[STIX]{x1D70F}$ measures the time needed by the flame to respond to incoming perturbations originating from the upstream side. It is known that systems with delays may become unstable. In combustion systems the time lag  $\unicode[STIX]{x1D70F}$ often defines regions of instability by controlling the phase relationship between heat release rate disturbances and the acoustic field. Expression (2.10) implies that the interaction index

$\unicode[STIX]{x1D70F}$ often defines regions of instability by controlling the phase relationship between heat release rate disturbances and the acoustic field. Expression (2.10) implies that the interaction index  $N$ of the flame is constant for all frequencies while the phase

$N$ of the flame is constant for all frequencies while the phase  $\unicode[STIX]{x1D711}=\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}$ changes linearly with frequency.

$\unicode[STIX]{x1D711}=\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}$ changes linearly with frequency.

This is only a crude approximation since flames are generally more sensitive to low-frequency disturbances and their response drops down as the frequency is increased, the flame acting like a low pass filter which rapidly damps high-frequency small wavelength disturbances. This essential feature may be taken into account by introducing a FTF in which the flame response is characterized in the Fourier space by a gain  $G$ and a phase lag

$G$ and a phase lag  $\unicode[STIX]{x1D711}$ that both depend on the angular frequency

$\unicode[STIX]{x1D711}$ that both depend on the angular frequency  $\unicode[STIX]{x1D714}$:

$\unicode[STIX]{x1D714}$:

$$\begin{eqnarray}{\mathcal{F}}(\unicode[STIX]{x1D714})=\frac{\widetilde{\dot{Q}}/\overline{\dot{Q}}}{\tilde{u} _{1}/\overline{u_{1}}}=G(\unicode[STIX]{x1D714})\exp [\text{i}\unicode[STIX]{x1D711}(\unicode[STIX]{x1D714})].\end{eqnarray}$$

$$\begin{eqnarray}{\mathcal{F}}(\unicode[STIX]{x1D714})=\frac{\widetilde{\dot{Q}}/\overline{\dot{Q}}}{\tilde{u} _{1}/\overline{u_{1}}}=G(\unicode[STIX]{x1D714})\exp [\text{i}\unicode[STIX]{x1D711}(\unicode[STIX]{x1D714})].\end{eqnarray}$$ The quantities  $\overline{\dot{Q}}$ and

$\overline{\dot{Q}}$ and  $\overline{u}_{1}$ denote the mean heat release rate and the bulk velocity at the injector outlet section.

$\overline{u}_{1}$ denote the mean heat release rate and the bulk velocity at the injector outlet section.

The FTF can be extended to accommodate nonlinear features into a FDF framework. The describing function is widely used in control systems theory to represent nonlinear systems by making use of a family of transfer functions depending on the amplitude of the input. This concept was used in a theoretical analysis of the dynamics of a ducted flame (Dowling Reference Dowling1999). Using a measured FDF  ${\mathcal{F}}(\unicode[STIX]{x1D714},|\tilde{u} _{1}|)$ it was shown by Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008) that many nonlinear features observed experimentally could be predicted theoretically. The FDF in combination with an acoustic analysis allowed predictions of limit cycle amplitudes, resonant frequency shifting, mode switching, instability triggering and hysteresis all in good agreement with experiments. The present analysis is here voluntarily restricted to the linear regime of vanishingly small perturbation levels

${\mathcal{F}}(\unicode[STIX]{x1D714},|\tilde{u} _{1}|)$ it was shown by Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008) that many nonlinear features observed experimentally could be predicted theoretically. The FDF in combination with an acoustic analysis allowed predictions of limit cycle amplitudes, resonant frequency shifting, mode switching, instability triggering and hysteresis all in good agreement with experiments. The present analysis is here voluntarily restricted to the linear regime of vanishingly small perturbation levels  $|\tilde{u} _{1}|$. Effects of finite levels of oscillation are documented for example in Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008), Palies et al. (Reference Palies, Durox, Schuller and Candel2011), Krebs et al. (Reference Krebs, Krediet, Portillo, Hermeth, Poinsot, Schimek and Paschereit2013), Ghirardo, Juniper & Moeck (Reference Ghirardo, Juniper and Moeck2016) and Larea et al. (Reference Larea, Schuller, Prieur, Durox, Camporeale and Candel2017).

$|\tilde{u} _{1}|$. Effects of finite levels of oscillation are documented for example in Noiray et al. (Reference Noiray, Durox, Schuller and Candel2008), Palies et al. (Reference Palies, Durox, Schuller and Candel2011), Krebs et al. (Reference Krebs, Krediet, Portillo, Hermeth, Poinsot, Schimek and Paschereit2013), Ghirardo, Juniper & Moeck (Reference Ghirardo, Juniper and Moeck2016) and Larea et al. (Reference Larea, Schuller, Prieur, Durox, Camporeale and Candel2017).

Two limits are useful to mention for the FTF or FDF gain  $G$. In the low-frequency limit, quasi-steady combustion takes place and the flame instantaneously converts the reactive mixture it receives (

$G$. In the low-frequency limit, quasi-steady combustion takes place and the flame instantaneously converts the reactive mixture it receives ( $\dot{Q}\propto u$). As a consequence

$\dot{Q}\propto u$). As a consequence  $G$ tends in this limit to unity (Polifke & Lawn Reference Polifke and Lawn2007)

$G$ tends in this limit to unity (Polifke & Lawn Reference Polifke and Lawn2007)

$$\begin{eqnarray}\displaystyle \text{lim}_{\unicode[STIX]{x1D714}\rightarrow 0}G=1. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{lim}_{\unicode[STIX]{x1D714}\rightarrow 0}G=1. & & \displaystyle\end{eqnarray}$$ This property is often used to verify the quality of FTF measurements or reconstruction from time series data. In the high-frequency limit,  $G$ drops to zero. Flames act as low-pass filters systems and high frequency modulations do not induce a finite response:

$G$ drops to zero. Flames act as low-pass filters systems and high frequency modulations do not induce a finite response:

$$\begin{eqnarray}\displaystyle \text{lim}_{\unicode[STIX]{x1D714}\rightarrow \infty }G=0. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{lim}_{\unicode[STIX]{x1D714}\rightarrow \infty }G=0. & & \displaystyle\end{eqnarray}$$ Between these two limits, the FTF gain  $G$ can take finite values. Maximum values of the order of 2–5 are observed in some laminar flame experiments (Durox et al. Reference Durox, Schuller, Noiray and Candel2009). One may then rewrite (2.7) in Fourier space:

$G$ can take finite values. Maximum values of the order of 2–5 are observed in some laminar flame experiments (Durox et al. Reference Durox, Schuller, Noiray and Candel2009). One may then rewrite (2.7) in Fourier space:

$$\begin{eqnarray}\tilde{u} _{2}=\tilde{u} _{1}(1+\unicode[STIX]{x1D703}{\mathcal{F}}(\unicode[STIX]{x1D714})).\end{eqnarray}$$

$$\begin{eqnarray}\tilde{u} _{2}=\tilde{u} _{1}(1+\unicode[STIX]{x1D703}{\mathcal{F}}(\unicode[STIX]{x1D714})).\end{eqnarray}$$ In the previous expression, use has been made of  $\widetilde{\dot{Q}}=(\overline{\dot{Q}}/\overline{u}_{1})\,{\mathcal{F}}(\unicode[STIX]{x1D714})\tilde{u} _{1}$. The parameter

$\widetilde{\dot{Q}}=(\overline{\dot{Q}}/\overline{u}_{1})\,{\mathcal{F}}(\unicode[STIX]{x1D714})\tilde{u} _{1}$. The parameter  $\unicode[STIX]{x1D703}$ in (2.14) stands for

$\unicode[STIX]{x1D703}$ in (2.14) stands for

$$\begin{eqnarray}\unicode[STIX]{x1D703}=\frac{\unicode[STIX]{x1D6FE}-1}{\unicode[STIX]{x1D6FE}}\frac{\overline{\dot{Q}}}{S\overline{p}\,\overline{u}_{1}}=\frac{Y_{f}(-\unicode[STIX]{x0394}h_{f}^{0})}{c_{p}T_{1}}=\frac{T_{2}}{T_{1}}-1\geqslant 0.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D703}=\frac{\unicode[STIX]{x1D6FE}-1}{\unicode[STIX]{x1D6FE}}\frac{\overline{\dot{Q}}}{S\overline{p}\,\overline{u}_{1}}=\frac{Y_{f}(-\unicode[STIX]{x0394}h_{f}^{0})}{c_{p}T_{1}}=\frac{T_{2}}{T_{1}}-1\geqslant 0.\end{eqnarray}$$ This dimensionless number depends on the ratio of the total heat release rate to the surface area  $\overline{\dot{Q}}/S$ indicating that the mean power flux essentially controls this relation. The mean pressure in the chamber also intervenes and

$\overline{\dot{Q}}/S$ indicating that the mean power flux essentially controls this relation. The mean pressure in the chamber also intervenes and  $\overline{\dot{Q}}/(\overline{p}S)$ has dimensions of a velocity that needs to be compared to the bulk velocity

$\overline{\dot{Q}}/(\overline{p}S)$ has dimensions of a velocity that needs to be compared to the bulk velocity  $\bar{u}_{1}$ of the flow feeding the combustion region. This quantity may alternatively be expressed as the ratio of the energy released by combustion and the sensible enthalpy of the incoming flow, where

$\bar{u}_{1}$ of the flow feeding the combustion region. This quantity may alternatively be expressed as the ratio of the energy released by combustion and the sensible enthalpy of the incoming flow, where  $Y_{f}$ is the fuel mass fraction,

$Y_{f}$ is the fuel mass fraction,  $-\unicode[STIX]{x0394}h_{f}^{0}$ the fuel heating value,

$-\unicode[STIX]{x0394}h_{f}^{0}$ the fuel heating value,  $c_{p}$ the specific heat and

$c_{p}$ the specific heat and  $T_{1}$ the temperature of the incoming flow. Finally, it may also be viewed as the relative heat produced by combustion

$T_{1}$ the temperature of the incoming flow. Finally, it may also be viewed as the relative heat produced by combustion  $\unicode[STIX]{x1D703}=T_{2}/T_{1}-1$.

$\unicode[STIX]{x1D703}=T_{2}/T_{1}-1$.

2.4 Approaches to study combustion instability and instability criteria

There are three main types of approaches used to analyse CI problems:

(i) Approach 1a consists in solving a set of linearized equations describing the system dynamics governing the perturbed combustion process and the coupled acoustic motion. Analytical solution is sometimes possible but in most cases the system is integrated in the time domain.

(ii) Approach 1b relies on the derivation of a dispersion relation in the frequency domain. Nonlinear terms may be treated by making use of describing function concepts and only retaining the first harmonic term. The complex roots of the dispersion relation are then sought to examine the stability of the system and see if a given acoustic mode will be amplified or damped.

(iii) Approach 2 is based on energy considerations that are used to derive stability criteria. This approach does not generally provide the full solution, but may be used to determine the growth rate of unstable modes as described later.

To illustrate these three approaches, it is instructive to begin by a simple mass/spring oscillator system where  $m$,

$m$,  $k$ and

$k$ and  $x$ are respectively the mass, spring strength and position of the oscillating mass. A force

$x$ are respectively the mass, spring strength and position of the oscillating mass. A force  $F$ is exerted on this system. In coupled systems this force depends on the position

$F$ is exerted on this system. In coupled systems this force depends on the position  $x$ and velocity

$x$ and velocity  ${\dot{x}}$ and we assume for simplicity that this relation is linear

${\dot{x}}$ and we assume for simplicity that this relation is linear

$$\begin{eqnarray}m\frac{\text{d}^{2}x}{\text{d}t^{2}}+kx=F(x,{\dot{x}}).\end{eqnarray}$$

$$\begin{eqnarray}m\frac{\text{d}^{2}x}{\text{d}t^{2}}+kx=F(x,{\dot{x}}).\end{eqnarray}$$ In approach 1a, (2.16) is solved analytically or numerically by integrating from an initial state  $x(0)=x_{0}$,

$x(0)=x_{0}$,  ${\dot{x}}(0)={\dot{x}}_{0}$. Under some conditions the system may be led to oscillate at an angular frequency

${\dot{x}}(0)={\dot{x}}_{0}$. Under some conditions the system may be led to oscillate at an angular frequency  $\unicode[STIX]{x1D714}$ that is close to the eigenfrequency

$\unicode[STIX]{x1D714}$ that is close to the eigenfrequency  $\unicode[STIX]{x1D714}_{0}=(k/m)^{1/2}$.

$\unicode[STIX]{x1D714}_{0}=(k/m)^{1/2}$.

In approach 1b, the system is described in frequency space. The time derivative is replaced by  $-\text{i}\unicode[STIX]{x1D714}$. This yields a dispersion relation of the form

$-\text{i}\unicode[STIX]{x1D714}$. This yields a dispersion relation of the form  $-m\unicode[STIX]{x1D714}^{2}+k=F(1,-\text{i}\unicode[STIX]{x1D714})$. The roots of this equation may then be determined numerically or by considering that

$-m\unicode[STIX]{x1D714}^{2}+k=F(1,-\text{i}\unicode[STIX]{x1D714})$. The roots of this equation may then be determined numerically or by considering that  $F$ is small and by making use of a perturbation expansion.

$F$ is small and by making use of a perturbation expansion.

In approach 2, one makes no attempt to obtain a solution. The objective is instead to derive a stability criterion by examining the total energy in the system. This is obtained by multiplying (2.16) by  ${\dot{x}}$ and integrating the result. One obtains

${\dot{x}}$ and integrating the result. One obtains

$$\begin{eqnarray}\displaystyle \frac{\text{d}E}{\text{d}t}=F{\dot{x}}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \frac{\text{d}E}{\text{d}t}=F{\dot{x}}, & & \displaystyle\end{eqnarray}$$ where  $E$ is the total energy in the system

$E$ is the total energy in the system

$$\begin{eqnarray}E={\textstyle \frac{1}{2}}m{\dot{x}}^{2}+{\textstyle \frac{1}{2}}kx^{2}.\end{eqnarray}$$

$$\begin{eqnarray}E={\textstyle \frac{1}{2}}m{\dot{x}}^{2}+{\textstyle \frac{1}{2}}kx^{2}.\end{eqnarray}$$ In the absence of external forcing  $F=0$, (2.17) indicates that the energy

$F=0$, (2.17) indicates that the energy  $E$ is constant. Oscillations will continue with the same energy. This result does not provide the position

$E$ is constant. Oscillations will continue with the same energy. This result does not provide the position  $x(t)$ but only expresses the conservation of energy. If there is a force

$x(t)$ but only expresses the conservation of energy. If there is a force  $F$ applied to the system approaches 1a or 1b cannot be used if details controlling the force

$F$ applied to the system approaches 1a or 1b cannot be used if details controlling the force  $F$ are not known. Approach 2, however, indicates that

$F$ are not known. Approach 2, however, indicates that

$$\begin{eqnarray}E(t)-E_{0}=\left[\frac{1}{2}m{\dot{x}}^{2}+\frac{1}{2}kx^{2}\right]_{0}^{t}=\int _{0}^{t}F{\dot{x}}\,\text{d}t,\end{eqnarray}$$

$$\begin{eqnarray}E(t)-E_{0}=\left[\frac{1}{2}m{\dot{x}}^{2}+\frac{1}{2}kx^{2}\right]_{0}^{t}=\int _{0}^{t}F{\dot{x}}\,\text{d}t,\end{eqnarray}$$ which shows that the energy  $E$ of the system will grow in time if the term

$E$ of the system will grow in time if the term  $\int F{\dot{x}}\,\text{d}t$ is positive or if the force

$\int F{\dot{x}}\,\text{d}t$ is positive or if the force  $F$ is in phase with the velocity

$F$ is in phase with the velocity  ${\dot{x}}$. This is an incomplete solution of the problem but it is useful because it provides a stability criterion. The details of the force

${\dot{x}}$. This is an incomplete solution of the problem but it is useful because it provides a stability criterion. The details of the force  $F$ are not needed to assess the stability of the system. This forced oscillator is stable if

$F$ are not needed to assess the stability of the system. This forced oscillator is stable if  $\int F{\dot{x}}\,\text{d}t$ remains negative. For a swing for example, this means that pushing the swing (

$\int F{\dot{x}}\,\text{d}t$ remains negative. For a swing for example, this means that pushing the swing ( $F>0$) when its velocity is positive (

$F>0$) when its velocity is positive ( ${\dot{x}}>0$) amplifies its oscillations and vice versa.

${\dot{x}}>0$) amplifies its oscillations and vice versa.

This simple example can be directly extrapolated to thermoacoustic problems. While the full solution following approach 1 of combustion oscillations is difficult to derive in many cases because the combustion response is not well known, it is still possible to construct a stability criterion similar to  $\int F{\dot{x}}\,\text{d}t<0$. This is often used to analyse the dynamic stability and determine possible control strategies.

$\int F{\dot{x}}\,\text{d}t<0$. This is often used to analyse the dynamic stability and determine possible control strategies.

Approach 1 is illustrated in § 2.5 in a simple case where a flame is stabilized in a duct. This is analysed by making use of a few simplifications. Section 2.6 shows how a stability criterion similar to that obtained previously can be derived for thermoacoustics and discusses two examples of application.

2.5 Approach 1: longitudinal thermoacoustics in a channel

The model problem illustrated in figure 6 is examined in what follows by making use of approach 1. A flame is stabilized in a duct at a sudden expansion of the cross-section separating the injection unit (length  $l_{1}$, section

$l_{1}$, section  $S_{1}$) from the combustion chamber (length

$S_{1}$) from the combustion chamber (length  $l_{2}$, section

$l_{2}$, section  $S_{2}$). The objective is to determine whether the flame can couple to longitudinal acoustic modes of the system. The analysis is limited to low-frequency acoustic waves for which the wavelength, typically of the order of a metre, is much greater than the flame length. The flame is ‘compact’ and can be treated as a discontinuity between fresh and burnt gases.

$S_{2}$). The objective is to determine whether the flame can couple to longitudinal acoustic modes of the system. The analysis is limited to low-frequency acoustic waves for which the wavelength, typically of the order of a metre, is much greater than the flame length. The flame is ‘compact’ and can be treated as a discontinuity between fresh and burnt gases.

Figure 6. A model for combustion instabilities: a laminar flame is stabilized at the plane  $x=0$ separating an injection duct (length

$x=0$ separating an injection duct (length  $l_{1}$) and a combustion chamber (length

$l_{1}$) and a combustion chamber (length  $l_{2}$). The field plotted in colour corresponds to the velocity modulus (Courtine, Selle & Poinsot Reference Courtine, Selle and Poinsot2015). Here

$l_{2}$). The field plotted in colour corresponds to the velocity modulus (Courtine, Selle & Poinsot Reference Courtine, Selle and Poinsot2015). Here  $A_{i}^{+}$ and

$A_{i}^{+}$ and  $A_{i}^{-}$ are the acoustic right- and left-going waves in duct

$A_{i}^{-}$ are the acoustic right- and left-going waves in duct  $i$, respectively.

$i$, respectively.

Under these assumptions, plane acoustic waves propagate in the injection tube and in the chamber, which are respectively numbered  $j=1$ and

$j=1$ and  $2$. The compact flame is located at

$2$. The compact flame is located at  $x=0$. The fluctuating acoustic pressures

$x=0$. The fluctuating acoustic pressures  $p_{j}^{\prime }$ and velocities

$p_{j}^{\prime }$ and velocities  $u_{j}^{\prime }$ in these two ducts are

$u_{j}^{\prime }$ in these two ducts are

$$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}_{j}c_{j}u_{j}^{\prime }(x,t)=\text{Re}([A_{j}^{+}\text{e}^{\text{i}k_{j}x}-A_{j}^{-}\text{e}^{-\text{i}k_{j}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}_{j}c_{j}u_{j}^{\prime }(x,t)=\text{Re}([A_{j}^{+}\text{e}^{\text{i}k_{j}x}-A_{j}^{-}\text{e}^{-\text{i}k_{j}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle p_{j}^{\prime }(x,t)=\text{Re}([A_{j}^{+}\text{e}^{\text{i}k_{j}x}+A_{j}^{-}\text{e}^{-\text{i}k_{j}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle p_{j}^{\prime }(x,t)=\text{Re}([A_{j}^{+}\text{e}^{\text{i}k_{j}x}+A_{j}^{-}\text{e}^{-\text{i}k_{j}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}), & \displaystyle\end{eqnarray}$$ where  $k_{j}=\unicode[STIX]{x1D714}/c_{j}$ is the wavenumber in duct

$k_{j}=\unicode[STIX]{x1D714}/c_{j}$ is the wavenumber in duct  $j$,

$j$,  $\unicode[STIX]{x1D714}$ the angular frequency and

$\unicode[STIX]{x1D714}$ the angular frequency and  $c_{j}$ the speed of sound in duct

$c_{j}$ the speed of sound in duct  $j$. Since the problem involves four unknown quantities, the wave amplitudes

$j$. Since the problem involves four unknown quantities, the wave amplitudes  $A_{1}^{+}$,

$A_{1}^{+}$,  $A_{2}^{+}$,

$A_{2}^{+}$,  $A_{1}^{-}$ and

$A_{1}^{-}$ and  $A_{2}^{-}$, four conditions are needed:

$A_{2}^{-}$, four conditions are needed:

(i) One boundary condition is given at the inlet at

$x=-l_{1}$ and one at the outlet at

$x=-l_{1}$ and one at the outlet at  $x=l_{2}$. Very often

$x=l_{2}$. Very often  $u_{1}^{\prime }=0$ is applied at

$u_{1}^{\prime }=0$ is applied at  $x=-l_{1}$ because one assumes that velocity is imposed at the inlet corresponding to an infinite impedance

$x=-l_{1}$ because one assumes that velocity is imposed at the inlet corresponding to an infinite impedance  $Z_{i}\rightarrow \infty$. The outlet is open to the ambient atmosphere and one may consider that

$Z_{i}\rightarrow \infty$. The outlet is open to the ambient atmosphere and one may consider that  $p^{\prime }=0$ at

$p^{\prime }=0$ at  $x=l_{2}$. This corresponds to a vanishing impedance

$x=l_{2}$. This corresponds to a vanishing impedance  $Z_{o}=0$ at the open end of the duct.

$Z_{o}=0$ at the open end of the duct.(ii) Two conditions are expressed across the flame itself. At the plane

$x=0$ where the flame is stabilized, jump conditions from one side of the flame to the other relate pressure and velocity perturbations, assuming that the flame is compact compared to the acoustic wavelength. Such conditions were introduced previously. They express the continuity of pressure and the change of acoustic volume flow rate due the unsteady heat release in the flame

$x=0$ where the flame is stabilized, jump conditions from one side of the flame to the other relate pressure and velocity perturbations, assuming that the flame is compact compared to the acoustic wavelength. Such conditions were introduced previously. They express the continuity of pressure and the change of acoustic volume flow rate due the unsteady heat release in the flame  $\dot{Q}^{\prime }$ (Crighton et al. Reference Crighton, Dowling, Ffowcs Williams, Heckl and Leppington1992; Poinsot & Veynante Reference Poinsot and Veynante2012): (2.22a,b)where

$\dot{Q}^{\prime }$ (Crighton et al. Reference Crighton, Dowling, Ffowcs Williams, Heckl and Leppington1992; Poinsot & Veynante Reference Poinsot and Veynante2012): (2.22a,b)where $$\begin{eqnarray}p_{2}^{\prime }(x=0,t)=p_{1}^{\prime }(x=0,t)\quad \text{and}\quad S_{2}u_{2}^{\prime }(x=0,t)=S_{1}u_{1}^{\prime }(x=0,t)+\frac{\unicode[STIX]{x1D6FE}-1}{\unicode[STIX]{x1D70C}_{1}c_{1}^{2}}\dot{Q}^{\prime },\end{eqnarray}$$

$$\begin{eqnarray}p_{2}^{\prime }(x=0,t)=p_{1}^{\prime }(x=0,t)\quad \text{and}\quad S_{2}u_{2}^{\prime }(x=0,t)=S_{1}u_{1}^{\prime }(x=0,t)+\frac{\unicode[STIX]{x1D6FE}-1}{\unicode[STIX]{x1D70C}_{1}c_{1}^{2}}\dot{Q}^{\prime },\end{eqnarray}$$ $\bar{\unicode[STIX]{x1D70C}}_{j}$ is the mean density in section

$\bar{\unicode[STIX]{x1D70C}}_{j}$ is the mean density in section  $j$ and

$j$ and  $\unicode[STIX]{x1D6FE}$ the ratio of specific heats. The construction of jump conditions at a compact flame front when the Mach number tends to zero, is actually an open topic which is beyond the objective of the present article. Readers are referred to recent papers by Bauerheim, Nicoud & Poinsot (Reference Bauerheim, Nicoud and Poinsot2015) and Chen et al. (Reference Chen, Bomberg and Polifke2016) on this subject.

$\unicode[STIX]{x1D6FE}$ the ratio of specific heats. The construction of jump conditions at a compact flame front when the Mach number tends to zero, is actually an open topic which is beyond the objective of the present article. Readers are referred to recent papers by Bauerheim, Nicoud & Poinsot (Reference Bauerheim, Nicoud and Poinsot2015) and Chen et al. (Reference Chen, Bomberg and Polifke2016) on this subject.

The unsteady heat release rate  $\dot{Q}^{\prime }$ is then expressed using the time-lag model defined in (2.10) in which

$\dot{Q}^{\prime }$ is then expressed using the time-lag model defined in (2.10) in which  $N$ and

$N$ and  $\unicode[STIX]{x1D70F}$ are assumed to be constant:

$\unicode[STIX]{x1D70F}$ are assumed to be constant:

$$\begin{eqnarray}\frac{\unicode[STIX]{x1D6FE}-1}{\bar{\unicode[STIX]{x1D70C}}_{1}c_{1}^{2}S_{1}}\dot{Q}^{\prime }=N(\unicode[STIX]{x1D703}-1)u_{1}^{\prime }(x=0,t-\unicode[STIX]{x1D70F}),\end{eqnarray}$$

$$\begin{eqnarray}\frac{\unicode[STIX]{x1D6FE}-1}{\bar{\unicode[STIX]{x1D70C}}_{1}c_{1}^{2}S_{1}}\dot{Q}^{\prime }=N(\unicode[STIX]{x1D703}-1)u_{1}^{\prime }(x=0,t-\unicode[STIX]{x1D70F}),\end{eqnarray}$$ where  $\unicode[STIX]{x1D703}=T_{2}/T_{1}-1$ measures the relative change in sensible enthalpy released within the flow by combustion. Assuming harmonic variations for all perturbations

$\unicode[STIX]{x1D703}=T_{2}/T_{1}-1$ measures the relative change in sensible enthalpy released within the flow by combustion. Assuming harmonic variations for all perturbations  $a^{\prime }=\tilde{a}\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}$, the jump conditions become

$a^{\prime }=\tilde{a}\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}$, the jump conditions become

$$\begin{eqnarray}\tilde{p}_{2}(x=0,t)=\tilde{p}_{1}(x=0,t)\quad \text{and}\quad S_{2}\tilde{u} _{2}(x=0,t)=S_{1}\tilde{u} _{1}(x=0,t)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}}).\end{eqnarray}$$

$$\begin{eqnarray}\tilde{p}_{2}(x=0,t)=\tilde{p}_{1}(x=0,t)\quad \text{and}\quad S_{2}\tilde{u} _{2}(x=0,t)=S_{1}\tilde{u} _{1}(x=0,t)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}}).\end{eqnarray}$$ Equation (2.23) links heat release rate fluctuations to the acoustic velocity at the chamber inlet  $x=0$. The previous jump conditions together with the boundary conditions expressing that the velocity and pressure, respectively, vanish at the inlet and outlet

$x=0$. The previous jump conditions together with the boundary conditions expressing that the velocity and pressure, respectively, vanish at the inlet and outlet

$$\begin{eqnarray}\displaystyle & \displaystyle A_{1}^{+}\text{e}^{-\text{i}k_{1}l_{1}}-A_{1}^{-}\text{e}^{\text{i}k_{1}l_{1}}=0, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle A_{1}^{+}\text{e}^{-\text{i}k_{1}l_{1}}-A_{1}^{-}\text{e}^{\text{i}k_{1}l_{1}}=0, & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle A_{2}^{+}\text{e}^{\text{i}k_{2}l_{2}}+A_{2}^{-}\text{e}^{-\text{i}k_{2}l_{2}}=0, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle A_{2}^{+}\text{e}^{\text{i}k_{2}l_{2}}+A_{2}^{-}\text{e}^{-\text{i}k_{2}l_{2}}=0, & \displaystyle\end{eqnarray}$$ lead to a homogeneous system of equations for the wave amplitudes  $A_{1}^{-}$,

$A_{1}^{-}$,  $A_{1}^{+}$,

$A_{1}^{+}$,  $A_{2}^{-}$ and

$A_{2}^{-}$ and  $A_{2}^{+}$, which has a non-zero solution only if

$A_{2}^{+}$, which has a non-zero solution only if

$$\begin{eqnarray}\cos \left(\unicode[STIX]{x1D714}\frac{l_{2}}{c_{2}}\right)\cos \left(\unicode[STIX]{x1D714}\frac{l_{1}}{c_{1}}\right)-\unicode[STIX]{x1D6EF}\sin \left(\unicode[STIX]{x1D714}\frac{l_{2}}{c_{2}}\right)\sin \left(\unicode[STIX]{x1D714}\frac{l_{1}}{c_{1}}\right)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}})=0,\end{eqnarray}$$

$$\begin{eqnarray}\cos \left(\unicode[STIX]{x1D714}\frac{l_{2}}{c_{2}}\right)\cos \left(\unicode[STIX]{x1D714}\frac{l_{1}}{c_{1}}\right)-\unicode[STIX]{x1D6EF}\sin \left(\unicode[STIX]{x1D714}\frac{l_{2}}{c_{2}}\right)\sin \left(\unicode[STIX]{x1D714}\frac{l_{1}}{c_{1}}\right)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}})=0,\end{eqnarray}$$ where  $\unicode[STIX]{x1D6EF}=(\bar{\unicode[STIX]{x1D70C}}_{2}c_{2})/(\bar{\unicode[STIX]{x1D70C}}_{1}c_{1})(S_{1}/S_{2})$ is a coupling index between cavities upstream and downstream of the flame (Schuller et al. Reference Schuller, Durox, Palies and Candel2012). The dispersion relation (2.27) gives the complex angular frequency

$\unicode[STIX]{x1D6EF}=(\bar{\unicode[STIX]{x1D70C}}_{2}c_{2})/(\bar{\unicode[STIX]{x1D70C}}_{1}c_{1})(S_{1}/S_{2})$ is a coupling index between cavities upstream and downstream of the flame (Schuller et al. Reference Schuller, Durox, Palies and Candel2012). The dispersion relation (2.27) gives the complex angular frequency  $\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{r}+\text{i}\unicode[STIX]{x1D714}_{i}$. The real part of

$\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{r}+\text{i}\unicode[STIX]{x1D714}_{i}$. The real part of  $\unicode[STIX]{x1D714}$ fixes the angular frequency

$\unicode[STIX]{x1D714}$ fixes the angular frequency  $\unicode[STIX]{x1D714}_{r}$ of the mode while its imaginary part provides the growth rate

$\unicode[STIX]{x1D714}_{r}$ of the mode while its imaginary part provides the growth rate  $\unicode[STIX]{x1D714}_{i}$. If this last quantity is positive, the mode will be linearly amplified, leading to CI.

$\unicode[STIX]{x1D714}_{i}$. If this last quantity is positive, the mode will be linearly amplified, leading to CI.

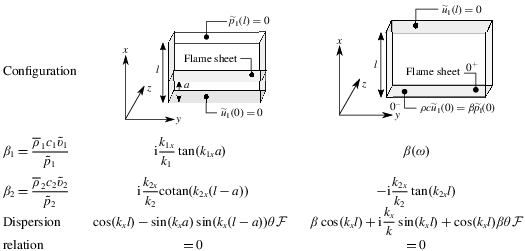

The general solution of (2.27) is difficult to formulate without additional simplifications. For example, an analytical expression can be obtained in a case where the two channels have equal sections  $S_{2}=S_{1}$ and lengths

$S_{2}=S_{1}$ and lengths  $l_{2}=l_{1}=a$ and the flame induces a negligible heat release so that

$l_{2}=l_{1}=a$ and the flame induces a negligible heat release so that  $\unicode[STIX]{x1D70C}_{2}\simeq \unicode[STIX]{x1D70C}_{1}$ and

$\unicode[STIX]{x1D70C}_{2}\simeq \unicode[STIX]{x1D70C}_{1}$ and  $c_{2}\simeq c_{1}\simeq c$. In this case,

$c_{2}\simeq c_{1}\simeq c$. In this case,  $\unicode[STIX]{x1D6EF}=1$ and

$\unicode[STIX]{x1D6EF}=1$ and  $\unicode[STIX]{x1D703}$ is a small number. The dispersion relation becomes

$\unicode[STIX]{x1D703}$ is a small number. The dispersion relation becomes

$$\begin{eqnarray}\cos ^{2}\left(\frac{\unicode[STIX]{x1D714}a}{c}\right)-\sin ^{2}\left(\frac{\unicode[STIX]{x1D714}a}{c}\right)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}})=0.\end{eqnarray}$$

$$\begin{eqnarray}\cos ^{2}\left(\frac{\unicode[STIX]{x1D714}a}{c}\right)-\sin ^{2}\left(\frac{\unicode[STIX]{x1D714}a}{c}\right)(1+\unicode[STIX]{x1D703}N\text{e}^{\text{i}\unicode[STIX]{x1D714}\unicode[STIX]{x1D70F}})=0.\end{eqnarray}$$ Without the flame,  $N=0$, the solution of the dispersion relation (2.28) corresponds to the acoustic eigenmodes of a duct of length

$N=0$, the solution of the dispersion relation (2.28) corresponds to the acoustic eigenmodes of a duct of length  $2a$. The first mode is such that

$2a$. The first mode is such that  $k_{0}a=\unicode[STIX]{x03C0}/4$ with

$k_{0}a=\unicode[STIX]{x03C0}/4$ with  $A_{1}^{+}=A_{2}^{+}$ and

$A_{1}^{+}=A_{2}^{+}$ and  $A_{1}^{-}=A_{2}^{-}$. It has a zero growth rate

$A_{1}^{-}=A_{2}^{-}$. It has a zero growth rate  $\text{Im}(k_{0})=0$ and a wavelength

$\text{Im}(k_{0})=0$ and a wavelength  $\unicode[STIX]{x1D706}_{0}=2\unicode[STIX]{x03C0}/k_{0}=8a$ which is four times the total length of the duct

$\unicode[STIX]{x1D706}_{0}=2\unicode[STIX]{x03C0}/k_{0}=8a$ which is four times the total length of the duct  $2a$. It is therefore designated as a ‘quarter-wave’ mode of the system. Its period is

$2a$. It is therefore designated as a ‘quarter-wave’ mode of the system. Its period is  $T_{0}=2\unicode[STIX]{x03C0}/\unicode[STIX]{x1D714}_{0}=8a/c$. The associated fields of unsteady velocity and pressure are

$T_{0}=2\unicode[STIX]{x03C0}/\unicode[STIX]{x1D714}_{0}=8a/c$. The associated fields of unsteady velocity and pressure are

$$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}_{j}c_{j}u_{j}^{\prime }(x,t)=A_{1}^{+}\text{Re}[\text{e}^{\text{i}k_{0}x}+\text{i}\text{e}^{-\text{i}k_{0}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \bar{\unicode[STIX]{x1D70C}}_{j}c_{j}u_{j}^{\prime }(x,t)=A_{1}^{+}\text{Re}[\text{e}^{\text{i}k_{0}x}+\text{i}\text{e}^{-\text{i}k_{0}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}, & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle p_{j}^{\prime }(x,t)=A_{1}^{+}\text{Re}[\text{e}^{\text{i}k_{0}x}-\text{i}\text{e}^{-\text{i}k_{0}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle p_{j}^{\prime }(x,t)=A_{1}^{+}\text{Re}[\text{e}^{\text{i}k_{0}x}-\text{i}\text{e}^{-\text{i}k_{0}x}]\text{e}^{-\text{i}\unicode[STIX]{x1D714}t}, & \displaystyle\end{eqnarray}$$ where  $A_{1}^{+}$ is the modal amplitude, which remains arbitrary as no information on amplitudes can be obtained in a linear framework. If the flame is present and the interaction index

$A_{1}^{+}$ is the modal amplitude, which remains arbitrary as no information on amplitudes can be obtained in a linear framework. If the flame is present and the interaction index  $N$ is non-zero but still small, the solution for

$N$ is non-zero but still small, the solution for  $k$ can be obtained using a small perturbation expansion around

$k$ can be obtained using a small perturbation expansion around  $k_{0}$ so that

$k_{0}$ so that  $k=k_{0}+k^{\prime }$ with

$k=k_{0}+k^{\prime }$ with

$$\begin{eqnarray}\text{Re}(k)=k_{0}+\text{Re}(k^{\prime })=\frac{\unicode[STIX]{x03C0}}{4a}-\frac{\unicode[STIX]{x1D703}N}{4a}\cos \!\left(\frac{2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}}{T_{0}}\!\right)\quad \text{and}\quad \text{Im}(k)=\text{Im}(k^{\prime })=-\frac{\unicode[STIX]{x1D703}N}{4a}\sin \!\left(\frac{2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}}{T_{0}}\!\right)\!.\end{eqnarray}$$

$$\begin{eqnarray}\text{Re}(k)=k_{0}+\text{Re}(k^{\prime })=\frac{\unicode[STIX]{x03C0}}{4a}-\frac{\unicode[STIX]{x1D703}N}{4a}\cos \!\left(\frac{2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}}{T_{0}}\!\right)\quad \text{and}\quad \text{Im}(k)=\text{Im}(k^{\prime })=-\frac{\unicode[STIX]{x1D703}N}{4a}\sin \!\left(\frac{2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}}{T_{0}}\!\right)\!.\end{eqnarray}$$ For small interaction index  $N$ values, the mode wavenumber

$N$ values, the mode wavenumber  $\text{Re}(k)$ is only weakly altered by the presence of the flame and remains close to its value

$\text{Re}(k)$ is only weakly altered by the presence of the flame and remains close to its value  $f_{0}=\unicode[STIX]{x03C0}/(4a)$ for the quarter-wave mode frequency without the flame. The flame response defined by a non-zero interaction index

$f_{0}=\unicode[STIX]{x03C0}/(4a)$ for the quarter-wave mode frequency without the flame. The flame response defined by a non-zero interaction index  $N\neq 0$, however, controls the growth rate of this mode. The combustor is unstable if

$N\neq 0$, however, controls the growth rate of this mode. The combustor is unstable if  $\text{Im}(k)>0$, which implies

$\text{Im}(k)>0$, which implies  $\sin (2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}/T_{0})<0$ that is obtained when

$\sin (2\unicode[STIX]{x03C0}\unicode[STIX]{x1D70F}/T_{0})<0$ that is obtained when

$$\begin{eqnarray}s+1/2<\frac{\unicode[STIX]{x1D70F}}{T_{0}}<s+1,\end{eqnarray}$$

$$\begin{eqnarray}s+1/2<\frac{\unicode[STIX]{x1D70F}}{T_{0}}<s+1,\end{eqnarray}$$ where  $s$ is an integer. Any flame with a time delay

$s$ is an integer. Any flame with a time delay  $\unicode[STIX]{x1D70F}$ such that

$\unicode[STIX]{x1D70F}$ such that  $(1/2+s)T_{0}<\unicode[STIX]{x1D70F}<(1+s)T_{0}$ will lead to CI in the absence of other damping mechanisms. Note also that this condition defines instability ‘bands’ for

$(1/2+s)T_{0}<\unicode[STIX]{x1D70F}<(1+s)T_{0}$ will lead to CI in the absence of other damping mechanisms. Note also that this condition defines instability ‘bands’ for  $\unicode[STIX]{x1D70F}$. Increasing

$\unicode[STIX]{x1D70F}$. Increasing  $\unicode[STIX]{x1D70F}$ from zero corresponds to a stable quarter-wave mode for

$\unicode[STIX]{x1D70F}$ from zero corresponds to a stable quarter-wave mode for  $\unicode[STIX]{x1D70F}<T_{0}/2$ followed by a band of instability when

$\unicode[STIX]{x1D70F}<T_{0}/2$ followed by a band of instability when  $T_{0}/2<\unicode[STIX]{x1D70F}<T_{0}$, followed by a new stability zone when

$T_{0}/2<\unicode[STIX]{x1D70F}<T_{0}$, followed by a new stability zone when  $\unicode[STIX]{x1D70F}$ exceeds

$\unicode[STIX]{x1D70F}$ exceeds  $T_{0}$ and so on… One may also note that this analysis needs to be repeated for higher-order modes. In the present case, the

$T_{0}$ and so on… One may also note that this analysis needs to be repeated for higher-order modes. In the present case, the  $3/4$,

$3/4$,  $5/4$,

$5/4$,  $7/4$ modes also have their own instability bands and the flame is stable only when

$7/4$ modes also have their own instability bands and the flame is stable only when  $\unicode[STIX]{x1D70F}$ falls outside of all these instability bands. This may seem a difficult condition to ensure but in practice, high-order modes are also rapidly damped by various dissipation mechanisms and energy losses at the system boundaries. These mechanisms are neglected in the present analysis. It is rare to see CIs coupled to high-order modes, except for high-frequency instabilities that are often coupled by transverse modes at frequencies in excess of 1 kHz. In that case the combustion region is no longer compact but each of the flames formed by the various injectors remains compact with respect to the acoustic wavelength. In practice, there are indeed values of

$\unicode[STIX]{x1D70F}$ falls outside of all these instability bands. This may seem a difficult condition to ensure but in practice, high-order modes are also rapidly damped by various dissipation mechanisms and energy losses at the system boundaries. These mechanisms are neglected in the present analysis. It is rare to see CIs coupled to high-order modes, except for high-frequency instabilities that are often coupled by transverse modes at frequencies in excess of 1 kHz. In that case the combustion region is no longer compact but each of the flames formed by the various injectors remains compact with respect to the acoustic wavelength. In practice, there are indeed values of  $\unicode[STIX]{x1D70F}$ which are stable for all modes.

$\unicode[STIX]{x1D70F}$ which are stable for all modes.

Even if the assumptions made to derive the stability criterion (2.32) are crude, this analysis contains all the ingredients of many low-order models used in thermoacoustics:

(i) It requires that all convective and chemistry effects be modelled as a function of a purely acoustic quantity, which is here, the inlet flow velocity. Models linking the unsteady heat release rate

$\dot{Q}^{\prime }$ to the acoustic inlet velocity

$\dot{Q}^{\prime }$ to the acoustic inlet velocity  $u_{1}^{\prime }(x=0,t)$ are ubiquitous. More advanced models may be found in the literature (Paschereit et al. Reference Paschereit, Polifke, Schuermans and Mattson2002; Truffin & Poinsot Reference Truffin and Poinsot2005; Taraneh et al. Reference Taraneh, Schmid, Richecoeur and Durox2015) and two of them need to be mentioned. The first extends the FTF concept by considering that the flame response may be represented by a FDF where the gain

$u_{1}^{\prime }(x=0,t)$ are ubiquitous. More advanced models may be found in the literature (Paschereit et al. Reference Paschereit, Polifke, Schuermans and Mattson2002; Truffin & Poinsot Reference Truffin and Poinsot2005; Taraneh et al. Reference Taraneh, Schmid, Richecoeur and Durox2015) and two of them need to be mentioned. The first extends the FTF concept by considering that the flame response may be represented by a FDF where the gain  $G$ and phase lag

$G$ and phase lag  $\unicode[STIX]{x1D711}$, not only depend on frequency but also on the forcing amplitude

$\unicode[STIX]{x1D711}$, not only depend on frequency but also on the forcing amplitude  $|u_{1}|$ (Noiray et al. Reference Noiray, Durox, Schuller and Candel2008; Durox et al. Reference Durox, Schuller, Noiray and Candel2009; Palies et al. Reference Palies, Durox, Schuller and Candel2011). A second extension of the flame transfer function concept was made to account for the fact that, in many systems, the fresh stream velocity may not be the only quantity inducing unsteady combustion. Fluctuations in equivalence ratio

$|u_{1}|$ (Noiray et al. Reference Noiray, Durox, Schuller and Candel2008; Durox et al. Reference Durox, Schuller, Noiray and Candel2009; Palies et al. Reference Palies, Durox, Schuller and Candel2011). A second extension of the flame transfer function concept was made to account for the fact that, in many systems, the fresh stream velocity may not be the only quantity inducing unsteady combustion. Fluctuations in equivalence ratio  $\unicode[STIX]{x1D719}$ have been identified as another important perturbation that may affect the combustion process (Lieuwen & Zinn Reference Lieuwen and Zinn1998; Sattelmayer Reference Sattelmayer2003; Birbaud et al. Reference Birbaud, Ducruix, Durox and Candel2008). These fluctuations may be caused for example by a difference in the response of the air and fuel injection devices to incident pressure waves. It is then important to consider the flame response to equivalence ratio disturbances and this may be represented by an FDF that accounts for the two types of incident perturbations (2.33)where