Article contents

Direct numerical simulation of Taylor–Couette flow with vertical asymmetric rough walls

Published online by Cambridge University Press: 16 November 2023

Abstract

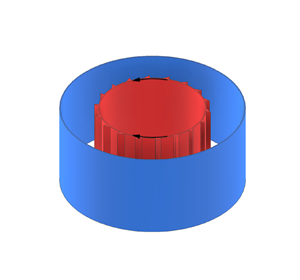

Direct numerical simulations are performed to explore the effects of the rotating direction of the vertically asymmetric rough wall on the transport properties of Taylor–Couette (TC) flow, up to a Taylor number of  ${Ta} = 2.39\times 10^{7}$. It is shown that, compared with the smooth wall, the rough wall with vertical asymmetric strips can enhance the dimensionless torque

${Ta} = 2.39\times 10^{7}$. It is shown that, compared with the smooth wall, the rough wall with vertical asymmetric strips can enhance the dimensionless torque  ${Nu}_{\omega }$. More importantly, at high Ta, clockwise rotation of the inner rough wall (where the fluid is sheared by the steeper slope side of the strips) results in a significantly greater torque enhancement compared to counter-clockwise rotation (where the fluid is sheared by the smaller slope side of the strips), due to the larger convective contribution to the angular velocity flux. However, the rotating direction has a negligible effect on the torque at low Ta. The larger torque enhancement caused by the clockwise rotation of the vertically asymmetric rough wall at high Ta is then explained by the stronger coupling between the rough wall and the bulk, attributed to the larger biased azimuthal velocity towards the rough wall at the mid-gap of the TC system, the increased turbulence intensity manifested by larger Reynolds stress and a thinner boundary layer, and the more significant contribution of the pressure force on the surface of the rough wall to the torque.

${Nu}_{\omega }$. More importantly, at high Ta, clockwise rotation of the inner rough wall (where the fluid is sheared by the steeper slope side of the strips) results in a significantly greater torque enhancement compared to counter-clockwise rotation (where the fluid is sheared by the smaller slope side of the strips), due to the larger convective contribution to the angular velocity flux. However, the rotating direction has a negligible effect on the torque at low Ta. The larger torque enhancement caused by the clockwise rotation of the vertically asymmetric rough wall at high Ta is then explained by the stronger coupling between the rough wall and the bulk, attributed to the larger biased azimuthal velocity towards the rough wall at the mid-gap of the TC system, the increased turbulence intensity manifested by larger Reynolds stress and a thinner boundary layer, and the more significant contribution of the pressure force on the surface of the rough wall to the torque.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2023. Published by Cambridge University Press

References

- 4

- Cited by