Impact Statement

Structural failures in aging ships and offshore installations often lead to catastrophic outcomes, including casualties, property damage, and marine pollution. The implementation of the digital healthcare engineering (DHE) system stands as a preventive measure against such incidents, leveraging emerging technologies in digitalization and communication. Comprising five modules, the DHE system incorporates a range of core technologies, some of which are still in development while others are mature for implementation. Notably, modern sensor-equipped devices enable the direct measurement and digitization of crucial health parameters—such as wave dynamics, wind patterns, currents, and in-service damages like corrosion wastage, fatigue cracking, or mechanical denting—on-site. These data streams are transmitted via low earth orbit (LEO) satellite, such as StarLink, to land-based data analytic centers equipped with digital twins. Furthermore, artificial intelligence algorithms powered by machine and deep learning facilitate accurate diagnosis and offer remedial action recommendations. This article contributes significantly to the advancement of DHE systems for ensuring the lifetime healthcare of aging ships and offshore structures, presenting recent breakthroughs in affordable, precise, and cost-effective technologies poised for integration into the DHE framework’s five modules.

1. Introduction

In an era marked by rapid technological advancement, the last coauthor introduced a groundbreaking concept and terminology: “digital healthcare engineering” (DHE), tailored specifically for marine applications (Paik, Reference Paik2022, Reference Paik2023, Reference Paik2024). DHE systems signify a profound innovation, leveraging communication and digital technologies to monitor and sustain both human health and the integrity of aging structures and infrastructure (Paik and Melchers, Reference Paik and Melchers2008). These systems establish a knowledge-based virtual model mirroring the real-time characteristics and properties of physical systems. By seamlessly integrating a continuously synchronized virtual representation with actual operating scenarios, DHE systems enable intelligent and timely interpretation of reality, crucial for decision-making, operational planning, and life extension (Semeraro et al., Reference Semeraro, Lezoche, Panetto and Dassisti2021). While digitization has found widespread application in the design, manufacturing, and lifetime healthcare of engineering structures, including ships and offshore installations (Fernandez and Cosma, Reference Fernandez and Cosma2020), its adoption in lifetime healthcare systems for human bodies is gaining prominence. The principles of lifetime healthcare exhibit remarkable parallels between human bodies and engineering structures, necessitating consistent care through ongoing health monitoring, periodic condition assessment, and predictions of future health conditions (Paik, Reference Paik2022), as illustrated in Figure 1. This article delves into the feasibility of deploying DHE systems for aging offshore structures, confronting numerous unresolved challenges, as underscored by Ciuriuc et al. (Reference Ciuriuc, Rapha, Guanche and Domínguez-García2022).

Figure 1. Lifetime healthcare processes for human bodies and engineering structures (Paik, Reference Paik2022).

Furthermore, this article conducts an exhaustive review of cutting-edge technologies employed in the key modules comprising the DHE system customized for aging ships and offshore structures, as illustrated in Figure 2. The primary objective of health monitoring is to capture physical parameters of actual structures governing structural safety and integrity, where direct factors such as in-service damages (e.g., corrosion, fatigue cracking, or local denting) or sea states (e.g., waves, wind, current) are directly measured. In scenarios where direct measurement of sea states poses challenges, indirect factors such as load effects or structural responses (e.g., stresses, strains) may be measured to derive environmental loads. Data collected from real structures situated remotely at sea are relayed to a land-based big data center for comprehensive analytics and visualization. Health condition assessment aims to ascertain the structural safety margin, defined as the ratio of residual ultimate strength to applied loads. Nonlinear structural analyses are employed to compute the residual ultimate strength, incorporating the measured age-related degradation effects. Additionally, computational fluid dynamics (CFD) simulations are utilized to estimate applied loads based on measured sea states. Health condition assessment entails highly nonlinear structural responses and ideally necessitates real-time execution, demanding approaches that are exceptionally swift, efficient, and accurate. As previously noted, indirect factors, recorded in the form of load effects or structural responses, must be translated into loads, such as axial forces, shearing forces, or bending moments. To ensure secure operation, the safety factor should not surpass critical values delineated by acceptance criteria (e.g., 0.9). Subsequent to health condition assessment, optimal strategies for remedial action, encompassing repair or renewal, are devised and recommended to operators, with a focus on minimizing downtime and costs. Predictions of probable future health conditions can also be formulated to devise effective lifetime healthcare schemes for future maintenance.

Figure 2. A prototype digital healthcare system of aging ships (Paik, Reference Paik2024).

A pivotal facet of DHE systems, deserving special attention, is their inevitable integration into the realm of autonomous ships. As the maritime industry advances toward heightened automation and autonomy, incorporating DHE systems becomes imperative for ensuring the operational health and safety of these sophisticated vessels. Raza et al. (Reference Raza, Prokopova, Huseynzade, Azimi and Lafond2022) underscore the substantial potential of integrated digital twins in autonomous maritime surface vessels (AMSVs) for tasks like autonomous obstacle detection and path planning, showcasing the agility and safety benefits of digital twins in AMSV design and development. Furthermore, Hasan et al. (Reference Hasan, Widyotriatmo, Fagerhaug and Osen2023) emphasize the crucial role of predictive digital twins in autonomous ship operations, particularly in fault diagnosis and predictive maintenance, demonstrating their value through field experiments and simulations in accurately predicting fault parameters in propulsion systems, thereby enhancing the safety and efficiency of autonomous maritime vessels. Thombre et al. (Reference Thombre, Zhao, Ramm-Schmidt, García, Malkamäki, Nikolskiy, Hammarberg, Nuortie, Bhuiyan, Särkkä and Lehtola2020) further bolster the importance of sensors and artificial intelligence (AI) in situational awareness in autonomous ships, illustrating how AI-driven sensor data fusion is pivotal for vessel localization and awareness. Collectively, these studies underscore the significance and indispensable role of DHE systems in the evolving domain of autonomous maritime vessels, particularly through the utilization of their key modules.

Despite recent advancements in individual technologies, certain ones may still be in their early stages of development or impractical for implementation within a real ship and offshore structure’s DHE system. Hence, we propose a prototype system that leverages practical technologies and approaches to ensure the lifetime healthcare of aging ships and offshore structures.

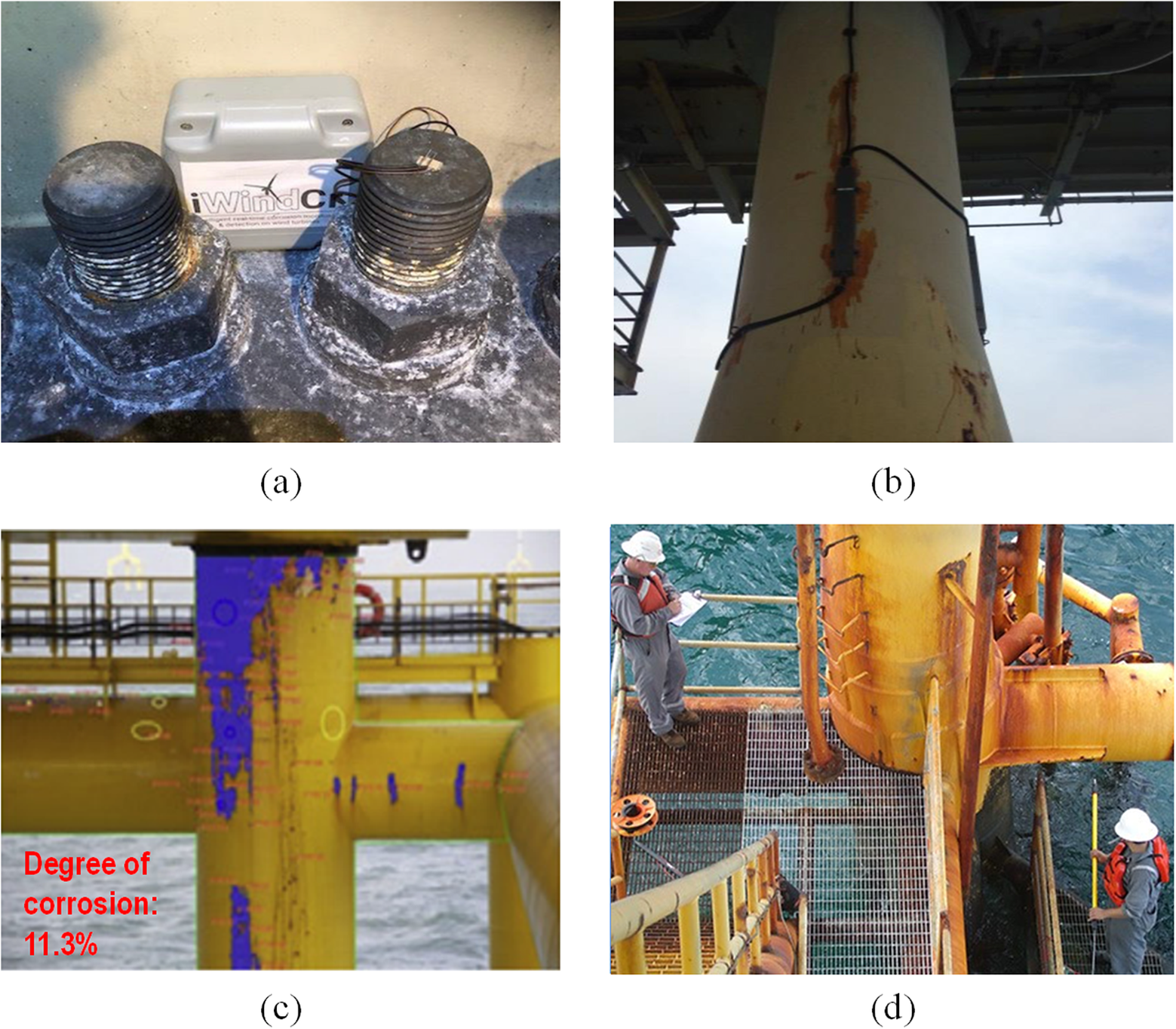

Figure 3. Photographs of a field trial for in situ monitoring on the existing offshore structures: (a) electrochemical sensor (Simandjuntak et al., Reference Simandjuntak, Bausch, Farrar, Ahuir-Torres, Thomas and Muna2021); (b) optical fiber strain sensor (Lee and Chung, Reference Lee and Chung2016); (c) image processing technology (Momber, Reference Momber2016); and (d) Visual inspection (DEEPWATER, 2022).

2. Module 1–1: On-site measurements of in-service damage

As ships and offshore structures undergo aging, in-service damages like corrosion wastage, fatigue cracking, or mechanical denting emerge as primary factors compromising structural safety and integrity. Hence, precise measurement of these damages is paramount. To accurately assess the structural health condition, especially regarding maximum load-carrying capacity or residual ultimate strength under damaged conditions, it is imperative to thoroughly define in-service damages. This definition should encompass the following factors (Paik and Melchers, Reference Paik and Melchers2008):

-

• type of damage;

-

• shape;

-

• size; and

-

• location.

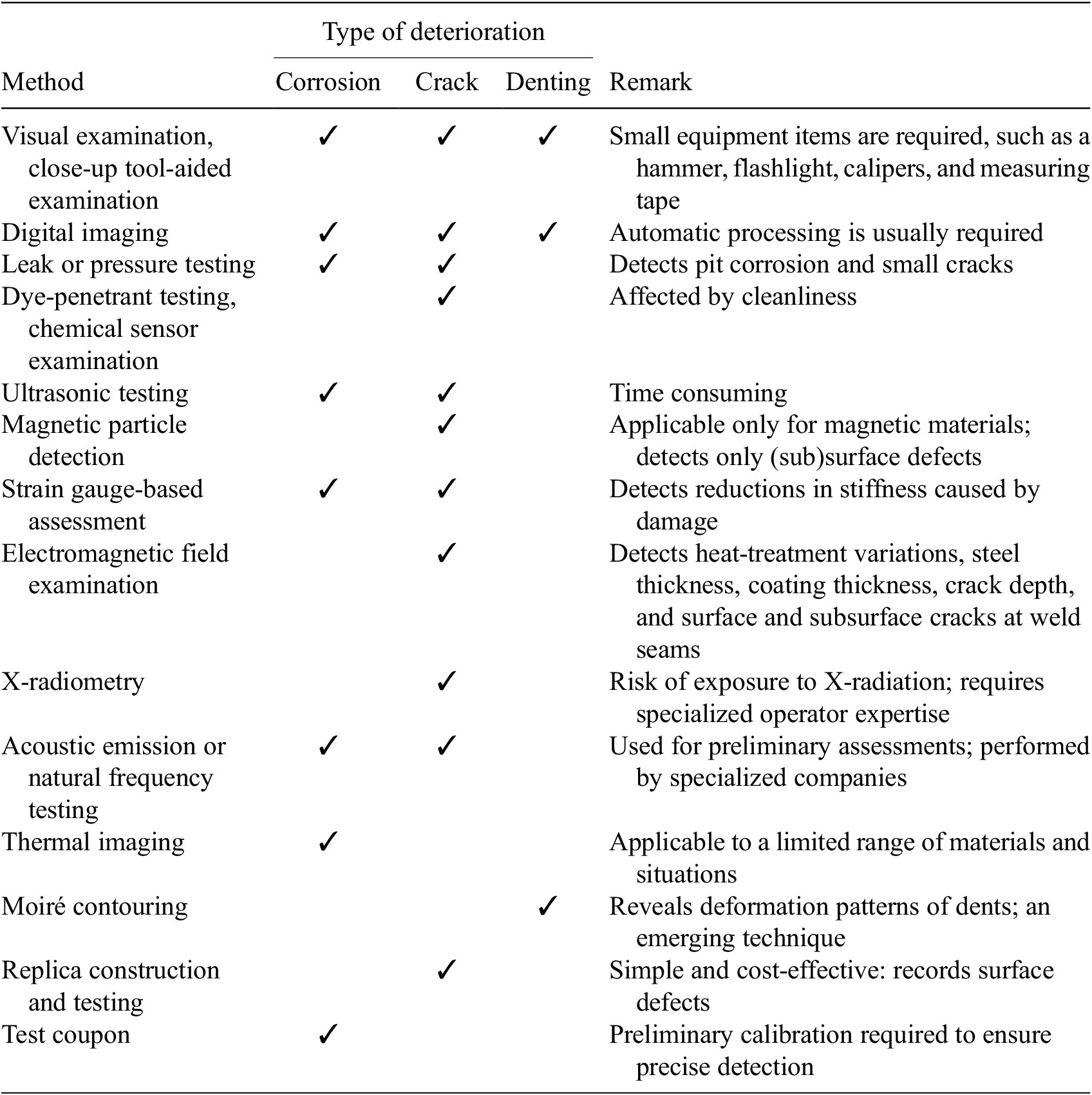

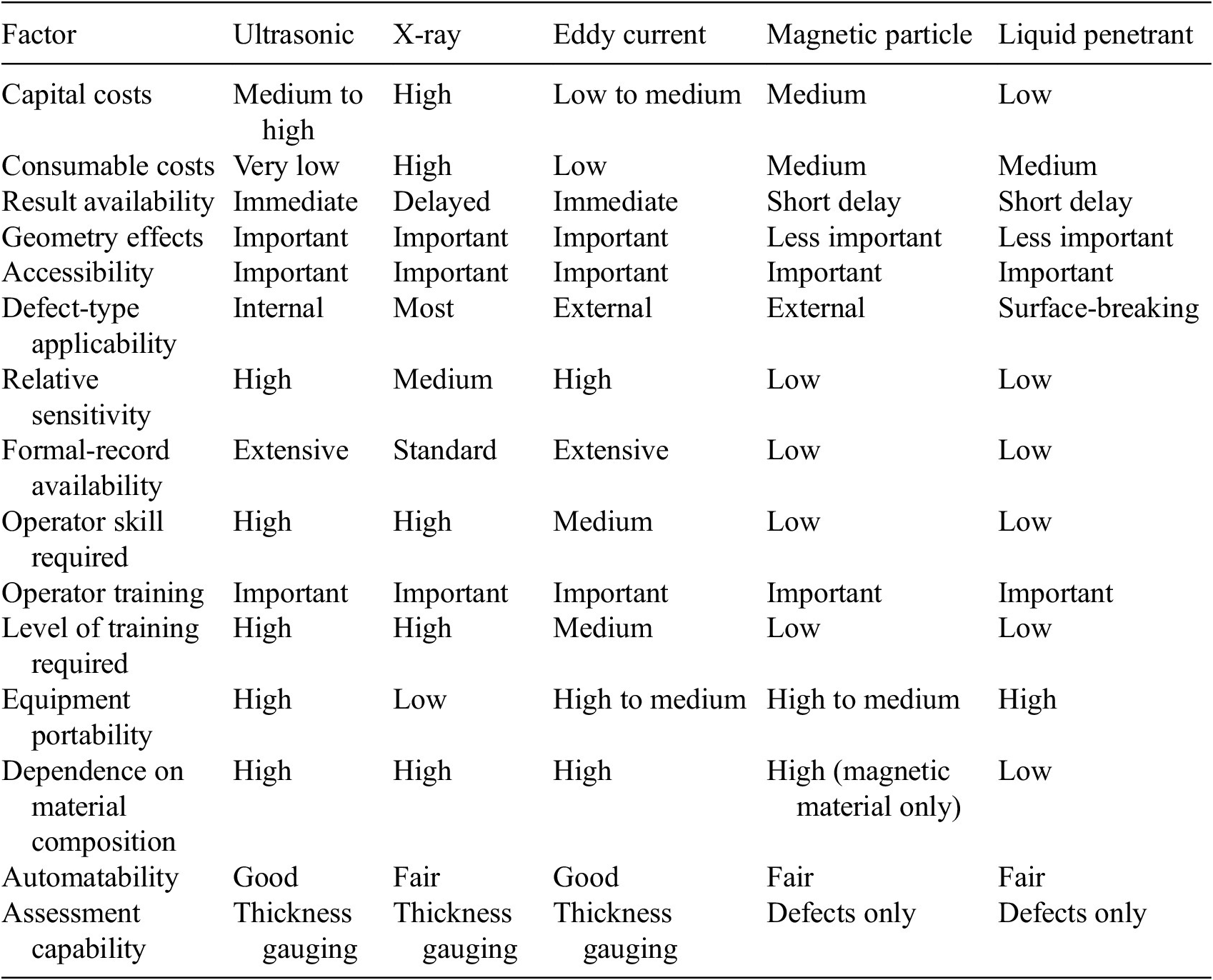

Traditionally, structural health monitoring (SHM) has centered on condition monitoring rather than direct measurements of structural damages. In condition monitoring approaches, the dynamic responses of structures are compared between intact and damaged conditions (Tian et al., Reference Tian, Liu, Gao, Chen and Mu2017; Kim et al., Reference Kim, Kim and Choe2019; Bao et al., Reference Bao, Fan, Shi and Yang2021a, Reference Bao, Fan, Shi and Yang2021b; Ciuriuc et al., Reference Ciuriuc, Rapha, Guanche and Domínguez-García2022). However, these methods often lack specificity in defining precise in-service damage factors. Nonetheless, condition-based monitoring approaches can still be valuable for qualitatively diagnosing damaged structures. A range of methods exist for the on-site measurement of in-service damage and deterioration, as outlined in Table 1 (Paik, Reference Paik2022).

Table 1. Methods for the detection of in-service damage and deterioration (Paik, Reference Paik2022)

2.1 Corrosion wastage

Corrosion wastage not only diminishes structural capacity but also poses risks such as oil/gas boundary leakages, leading to undesirable pollution, cargo mixing, or gas accumulation in enclosed spaces (Paik, Reference Paik2018, Reference Paik2020, Reference Paik2022). The corrosion process is dynamic and influenced by factors such as the integrity of protective coatings. Given that the health assessment of corroded structures relies on residual ultimate strength, it is crucial to precisely define corrosion wastage parameters such as depth, extent, and location in real-world scenarios. Conventionally, this assessment employs time-variant corrosion models which are utilized in evaluating the structural integrity of both ships and offshore structures. Tekgoz et al. (Reference Tekgoz, Garbatov and Guedes Soares2020) extensively reviewed corrosion wastage modeling and its applications in ship structures. Notably, ship structures share similarities with ship-shaped offshore installations such as floating, production, storage, and offloading (FPSO) units. However, there are notable uncertainties in corrosion prediction mathematical models owing to the highly nonlinear nature of corrosion degradation mechanisms.

On-site measurements of corrosion wastage offer a precise and intuitive means of monitoring corrosion in ships and offshore structures. Despite challenges in achieving real-time monitoring of corrosion factors due to technical constraints, the existing literature highlights advancements in methodologies for on-site measurements of corrosion wastage. Xia et al. (Reference Xia, Deng, Macdonald, Jamali, Mills, Luo, Strebl, Amiri, Jin, Song and Hu2022) extensively reviewed recent progress in electrochemical techniques, instrumentation (based on virtual instrumentation), and advanced sensor/probe methodologies for on-site corrosion measurements. However, the large size of ships and offshore structures presents challenges, particularly with active sensors that require an independent energy source for operation, necessitating both an emitter and a receiver. Nonetheless, these advanced sensors prove effective in detecting corrosion degradation in specific regions prone to high corrosion rates. Other sensors such as electrical resistance and linear polarization resistance sensors find application in corrosion monitoring within the industry, albeit with limitations confined to specific modules (Soh et al., Reference Soh, Lee, Kim and Kim2016; Tacq, Reference Tacq2021). It is worth noting that the most recent technologies for monitoring ships and offshore structures are still in experimental and theoretical stages, primarily due to the myriad challenges inherent in industrial applications. These challenges include the large size and complex geometry of ships and offshore structures, operation in harsh environments, uncertain reliability of sensors, and remote and inaccessible locations. Meribout et al. (Reference Meribout, Mekid, Kharoua and Khezzar2021) conducted a comprehensive review of primary unmanned on-site techniques for monitoring corrosion wastage, highlighting passive sensors like fiber Bragg gratings (FBGs) as an alternative approach. They observed that while these sensors can function collectively, offering a potential solution for remote and unmanned corrosion monitoring, they suffer from notably low sensitivity and limited coverage area.

Recent studies on full-scale ship and offshore structure corrosion monitoring have revealed notable methodologies. Simandjuntak et al. (Reference Simandjuntak, Bausch, Farrar, Ahuir-Torres, Thomas and Muna2021) applied electrochemical sensors in their monitoring application for offshore wind turbines in the United Kingdom. Their research delves into the reliability of electrochemical sensors in estimating corrosion rates in offshore environments. Further exploration of the technical challenges encountered could potentially elevate their approach to an industry-standard level. Meanwhile, Lee and Chung (Reference Lee and Chung2016) utilized optical fiber strain sensors in a structural integrity monitoring system, detecting corrosion wastage by measuring stiffness reduction. Although their technique necessitates a substantial number of sensors to overcome the limitation of measuring strain at a single point, it offers real-time monitoring capabilities—an advantage of their approach.

Visual inspection techniques serve as routine condition assessments for ships and offshore structures but come with inherent limitations. Chandrasekaran (Reference Chandrasekaran2019) highlighted in their overview on SHM that recent findings suggest visual inspections are imprecise and unreliable. The large size and partial submersion of ships and offshore structures make it challenging to conduct visual inspections comprehensively. Automated systems employing sensors emerge as effective tools for assessing offshore structures and ensuring safe operability. Momber (Reference Momber2016) employed AI to process images for locating and defining the extent of corrosion in a jacket platform installed in the North Sea. However, the image processing method for corrosion monitoring struggles to accurately identify the depth of corrosion and lacks mobility for operation on full-scale structures (Yao et al., Reference Yao, Yang, Wang and Zhao2019; Khayatazad et al., Reference Khayatazad, Pue and Waele2020). Moreover, the method faces difficulties in detecting hidden degradation and non-visible spaces.

The introduction of robotic-based corrosion monitoring has been spurred by rapid advancements in cutting-edge technology, leading to numerous recent investigations. A state-of-the-art review on robotic-based damage assessments for fixed offshore structures by Liu et al. (Reference Liu, Hajj and Bao2022) showcases various approaches, including the utilization of X-ray, thermography, and photography techniques, tested with mobile robots such as unmanned aerial vehicles and climbing robots. However, it is worth noting that motion control techniques for robotic-based assessments are still in the developmental phase.

Chapter 15 of Paik (Reference Paik2022) elucidates advanced techniques for on-site measurements of corrosion wastage alongside the challenges they entail. Among these methods, ultrasonic sensors emerge as valuable tools for measuring corrosion wastage. However, they necessitate surface and coupling medium preparation and a meticulous point-by-point examination, particularly where heavy rust removal is required from structures with numerous corrosion pits to obtain accurate thickness measurements. Nondestructive examination may be feasible when the existing coating is insignificant. Additionally, acoustic emission and natural-frequency measurements present themselves as promising methods, offering inexpensive and reliable means of detecting significant changes in structural responses. Nonetheless, they encounter difficulties in precisely quantifying essential corrosion wastage factors for residual ultimate strength analysis. Galvanic thin-film microsensors offer the potential for in situ monitoring of coating durability and hidden corrosion. On the other hand, dye-penetrant methods employing chemical sensors detect corrosion through fluorescence or color changes, but their practicality for widespread corrosion detection remains unproven. Lastly, methods utilizing strain gauges have proven impractical due to the challenges in converting strain measurements to corrosion wastage.

2.2 Fatigue cracking

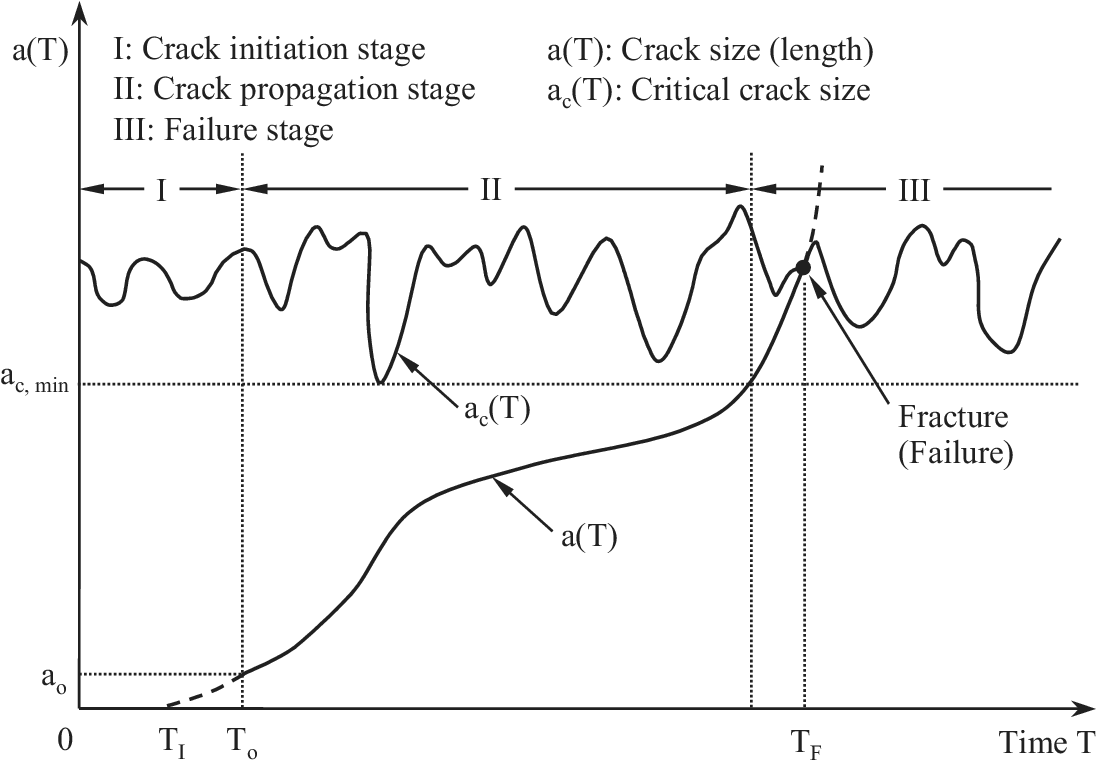

Fatigue cracking often initiates at areas of structural stress concentration due to repeated cyclic loading. Recent technological advancements have facilitated the precise identification of suspicious areas prone to fatigue cracking before its initiation through detailed stress and fatigue analysis. These cracks may propagate under repeated loading or even under monotonically increasing extreme loads, potentially leading to catastrophic structural failure, especially in scenarios where rapid and uncontrolled crack extension occurs without arrest. As the crack lengthens and significantly degrades the structural capacity, the risk intensifies (Paik, Reference Paik2018). Fatigue cracking exhibits variations over time, as depicted in Figure 4, illustrating the schematic of fatigue crack progression categorized into three stages: initiation (stage I), propagation (stage II), and failure (stage III). For the health condition assessment of aging structures through residual ultimate strength analysis, in situ measurement of fatigue cracking is imperative.

Figure 4. A schematic of crack initiation and growth for a structure with time (Paik, Reference Paik2018).

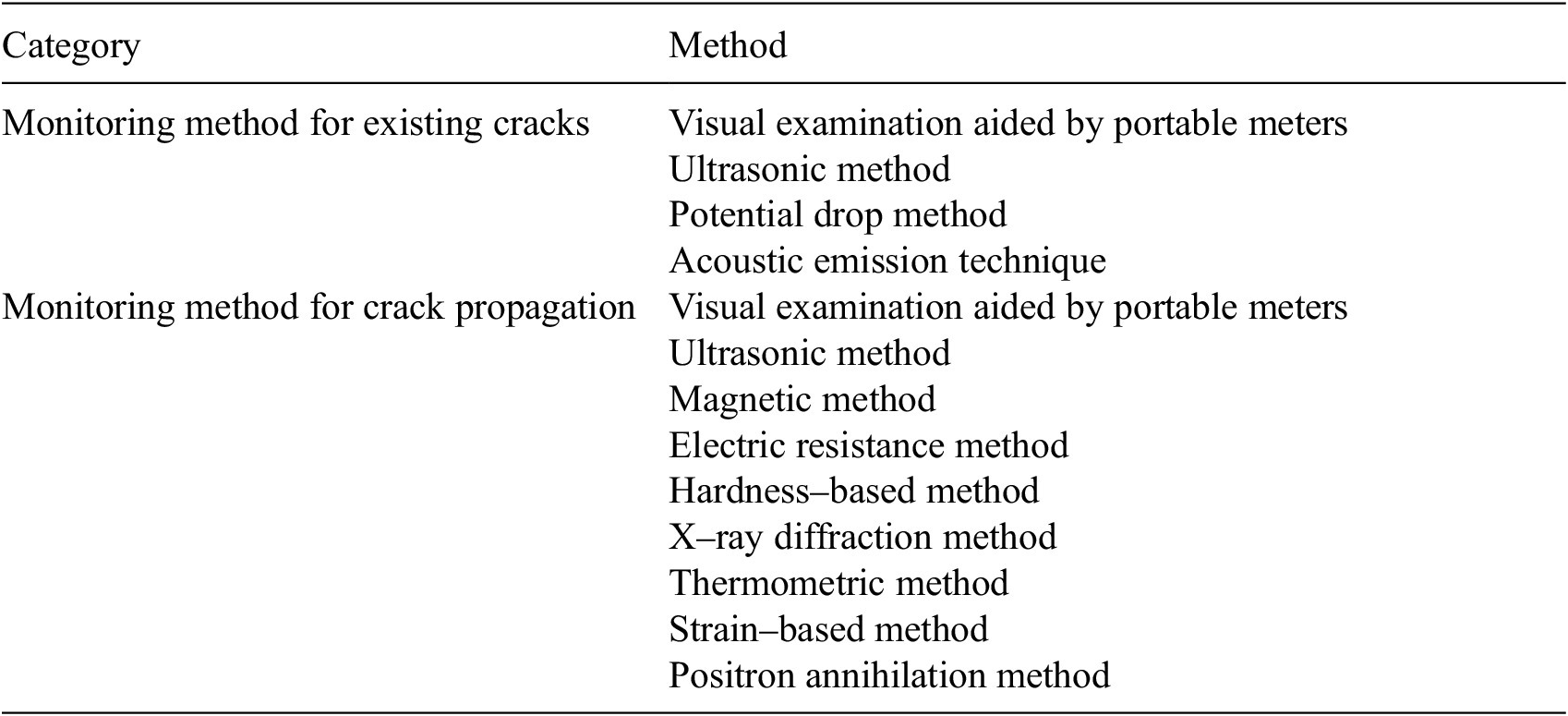

Numerous studies in the literature delve into on-site measurements of fatigue cracking in ships and offshore structures. Bjørheim et al. (Reference Bjørheim, Siriwardane and Pavlou2022) conducted a review of methods for monitoring fatigue cracking and categorized them into two groups: “fatigue crack monitoring” and “fatigue damage monitoring.” The former entails detecting and monitoring cracks after their initiation, while the latter focuses on identifying early signs of material degradation before cracks form. On-site measurements of cracks in steel structures can be conducted using acoustic emission, hardness, ultrasonic, magnetic, and potential drop methods. For fatigue crack monitoring in composite structures, methods such as acoustic emissions, X-ray diffraction, ultrasonic, strain-based, and thermometric techniques are employed. Table 2 outlines the methods for conducting on-site measurements of existing cracks or their propagation, where visual examination supported by portable gauges or meters emerges as a practical solution.

Table 2. Methods for in situ measurements of existing fatigue cracks and their propagation

May et al. (Reference May, Mendy, Tallett, Sanderson and Sharp2009) provided a comprehensive review of fatigue crack monitoring methods, showcasing the diverse technologies employed for offshore platform applications. Given the array of approaches available for fatigue monitoring in ships and offshore structures, their study meticulously evaluates each technique’s sensitivity/effectiveness, health and safety benefits, and cost reduction potential, offering a comparative criterion (as also delineated in Table 2). While many real-time fatigue crack monitoring techniques and technologies presented thus far remain in the research and development stage, similar to corrosion wastage monitoring for ships and offshore structures, the existing literature on on-site fatigue crack monitoring methods offers valuable insights for the development of a lifetime healthcare digital twin for ships and offshore structures, elucidating the reliability and applicability of each approach. Despite the predominance of active techniques, the incorporation of naturally passive methods like acoustic emissions for damage detection presents distinct advantages, including simple implementation, no requirement for energy input for detection, early flaw detection, precise monitoring of crack occurrences, and real-time monitoring capabilities (Gholizadeh et al., Reference Gholizadeh, Leman and Baharudin2015; Tziavos et al., Reference Tziavos, Hemida, Dirar, Papaelias, Metje and Baniotopoulos2020). Furthermore, Mitra and Gopalakrishnan (Reference Mitra and Gopalakrishnan2016) reviewed various ultrasonic-guided wave methods for SHM, highlighting their potential to develop high-fidelity schemes capable of detecting minute damages such as fatigue cracking during inspection. As noted by Min et al. (Reference Min, Liu, Pereira, Yang, Sui and Marques2021), the FBG approach is categorized into point and distributed sensing technologies in the marine environment. Moreover, Aalberts et al. (Reference Aalberts, Ibekwe, Hageman, Oguntola, Izuchukwu, Sorensen, Nadathur and van Vliet2019) demonstrated the sustained effectiveness of using strain gauges to measure in-service damages such as fatigue cracking on an FPSO unit’s hull over several years.

Tang et al. (Reference Tang, Soua, Mares and Gan2016) implemented a method to monitor fatigue cracks in a full-scale offshore wind turbine structure utilizing acoustic emission sensors. These sensors were internally mounted on the blade and effectively detected localized damages in their nascent stages over a 21-day period under realistic fatigue loading conditions. However, their study revealed that noise in the vicinity of ships and offshore structures influenced the results, necessitating further investigation to address this issue. In a separate experiment, Mieloszyk and Ostachowicz (Reference Mieloszyk and Ostachowicz2017) tested the feasibility of using FBG sensors to detect fatigue cracks on ships and offshore structures. Their experimental setup involved wind turbine models—one intact and the other containing a crack—immersed in a wave tank to replicate oceanic environmental conditions, with FBG sensors affixed to the models. Their findings demonstrated the effectiveness of the FBG sensor approach in detecting crack presence and location. However, it is worth noting that FBG sensors, due to their limited coverage area, may not adequately monitor fatigue crack parameters across entire structural members.

Chapter 15 of Paik (Reference Paik2022) further discusses advanced techniques for conducting on-site measurements of fatigue cracking in aging ships and offshore structures. Visual examination supplemented by portable meters remains a common approach for detecting fatigue cracking. Surface cracks can be assessed using dye-penetrant and magnetic-particle testing, although these methods cannot measure crack depth beyond the removed material. Nondestructive examination methods outlined in Table 3 offer alternatives for measuring fatigue cracking, each with its own set of advantages and disadvantages. Selection of appropriate methods should be based on thorough cost–benefit analyses.

Table 3. Comparison of nondestructive examination methods used for crack detection (Paik, Reference Paik2022)

2.3 Mechanical damage

Mechanical damage, such as local denting, often results from impacts by falling objects during craning operations on deck plates. This denting can lead to cracking, residual stresses or strains due to plastic deformation, or coating damage. The presence of mechanical damage diminishes the ultimate strength of the structure, necessitating its consideration in residual ultimate strength analysis. Close-up tool-aided examination stands as the most practical method for measuring mechanical damage. Although advanced techniques like guided wave techniques and magnetic flux leakage inspection have been developed, they pose challenges for in situ measurements of local denting in ships and offshore structures.

2.4 Challenges and practical solutions

Three methods for on-site measurements of in-service damage applicable to DHE of aging ships and offshore structures are outlined below:

-

• unmanned detection approach via remote sensing in real time;

-

• manned detection approach in specific intervals (e.g., months, quarters, or years) and

-

• hybrid approach of both unmanned and manned approaches.

The first approach is ideally suited for the real-time monitoring of structural health. However, it faces significant challenges due to the large size and complex geometry of ships and offshore structures. Despite recent advancements in traditional real-time sensing methods such as distributed optical fiber sensors, FBGs, strain gauges, and acoustic emission sensors, these techniques have not yet been effectively scaled for large-scale structural monitoring (Martinez-Luengo et al., Reference Martinez-Luengo, Kolios and Wang2016; Min et al., 2021; Yang et al., Reference Yang, Tao, Guo, Yang and Liu2023). Consequently, determining the location and number of health sensors to embed becomes challenging, especially considering the uncertainties surrounding in-service damage formation. Furthermore, emerging unconventional methods, such as the use of remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), and specifically drones for structural monitoring, hold promise but have not fully realized their potential for large-scale inspections of ships and offshore structures (Shafiee et al., Reference Shafiee, Zhou, Mei, Dinmohammadi, Karama and Flynn2021; Benzon et al., Reference Benzon, Chen, Belcher, Castro, Branner and Smit2022). Given these challenges, the second approach may prove more practical, as it enables direct measurement of physical in-service damage parameters, albeit without real-time capability. The third approach is particularly advantageous for addressing critical and sensitive regions prone to in-service damages.

For the prototype DHE system proposed in this paper, employing visual examination aided by advanced equipment is deemed appropriate. This visual examination or close-up survey can be conducted by inspectors visiting ships and offshore installations or operators utilizing advanced equipment to quantify damage and transmit data. While this approach may not facilitate real-time monitoring every second, such close-up surveys can be scheduled at periodic intervals. Current inspection practices and classification societies’ standards stipulate that essential structural elements should undergo inspection at least once a year, with a strong recommendation to inspect all elements at least once every five years or depending on their exposure level (ISO, 2007, 2019; DNV GL, 2014, 2016, 2018; Vázquez et al., Reference Vázquez, Rodríguez and Esteban2023). However, the prototype DHE system aims to extend the service life of ships and offshore assets and prevent failures, necessitating more frequent inspections and maintenance (Soliman et al., Reference Soliman, Frangopol and Mondoro2016; Abbas and Shafiee, Reference Abbas and Shafiee2020). Therefore, it is suggested that in-service damages be measured on a weekly, monthly, or quarterly basis rather than annually or bi-annually. Additionally, suspicious areas that are critical and vulnerable to significant impacts of structural failures may be monitored by health sensors in real time.

Nevertheless, underwater and confined spaces often pose challenges for human accessibility, necessitating specialized monitoring techniques. Historically, inspection services were conducted by divers, and with the advancement of ROVs, the latter gained popularity (Rocha and De Tomi, Reference Rocha and De Tomi2015). Visual inspection underwater by divers offers the advantage of human judgment, enabling coverage of large areas where ROVs may easily become disoriented. Moreover, it is considered the most maintenance-free and least breakdown-prone inspection method (Hughes, Reference Hughes1972; Faulds, Reference Faulds1982), thus playing a pivotal role in determining the success or inadequacy of an inspection program. ROVs provide a versatile platform for comprehensive underwater inspections, offering high-definition visual assessments and advanced sensor modalities. They prove invaluable for ships and offshore structure operations, particularly at depths beyond diver reach (Capocci et al., Reference Capocci, Dooly, Omerdić, Coleman, Newe and Toal2017). Their capabilities range from visual examinations in turbid waters to 3D sonar mapping and scour estimation, and they can be operated remotely from secure locations, making them ideal for subsea inspection, maintenance, and repair (Chemisky et al., Reference Chemisky, Menna, Nocerino and Drap2021). However, ROVs require tethering to a large surface vessel for power and control, incurring significant operational costs (Bogue, Reference Bogue2015). AUVs are a newer breed of self-driven underwater robots, untethered and powered and directed by internal computers. They are primarily utilized for seafloor mapping and inspecting underwater structures. However, they suffer from limitations such as a restricted mission duration, inability to provide continuous surveillance/inspection, and high costs (Bogue, Reference Bogue2015; Capocci et al., Reference Capocci, Dooly, Omerdić, Coleman, Newe and Toal2017). Therefore, for the prototype DHE system, underwater inspections are suggested to be undertaken by divers due to their efficiency and adequacy in assessment.

3. Module 1–2: On-site measurements of ocean environmental conditions

In assessing the health condition of aging ships and offshore structures, which relies on the ratio of residual ultimate strength to applied loads, it is imperative to define ocean environmental conditions that induce environmental loads. These loads can be calculated through CFD simulations, given the measurement of parameters associated with ocean environmental conditions. Various types of ocean environmental conditions are pertinent to this assessment (Paik, Reference Paik2022):

-

• wind;

-

• waves and swell;

-

• current;

-

• tide;

-

• sea surface temperature;

-

• rain and squall;

-

• humidity;

-

• snow;

-

• ice;

-

• marine growth and

-

• seafloor earthquakes and tsunamis.

In the prototype DHE system for ships and offshore structures presented in this paper, we focus solely on primary types of ocean environmental conditions, including waves, wind, and icebergs. Although extreme events such as earthquakes and tsunamis can have significant impacts, they are rare incidents for which safety measures are typically implemented in advance. Therefore, we have opted to exclude them from our assessments.

3.1 Waves

Wave loads represent the primary structural loading on both local components and global systems. To compute wave loads accurately, the following wave parameters need to be statistically defined:

-

• significant wave height;

-

• modal wave period;

-

• wave direction and spreading.

Wave parameters in the surrounding environment of ships and offshore structures can be measured using various methods, including visual observation, on-site instrumentation, and remote sensing techniques. Visual observation, historically relied upon, involves estimating wave information based on the crew’s experience. This method is commonly employed during sea trials for ships (ISO, 2015). Guedes Soares (Reference Guedes Soares1986) compared visual observations with hindcast predictions and found them to be of comparable quality, with visual observations even preferred for long-term predictions of ship response during transiting. Pitman and Lee (Reference Pitman and Lee2019) analyzed the accuracy of lifeguards’ visual observations of wave heights and identified significant variations between coasts. Specifically, east-coast lifeguards underestimated wave heights by approximately 0.12 m, while their west-coast counterparts underestimated by a larger margin of 0.39 m. Plant and Griggs (Reference Plant and Griggs1992) discovered that observers tended to underestimate high wave heights (greater than 2.0 meters) by 33 ± 28 cm to 1.01 ± 35 cm, while periods of short waves (less than 11 seconds) were overestimated by up to 5 ± 4 seconds. These findings underscore the substantial deviations in human visual estimations compared to instrumental measurements.

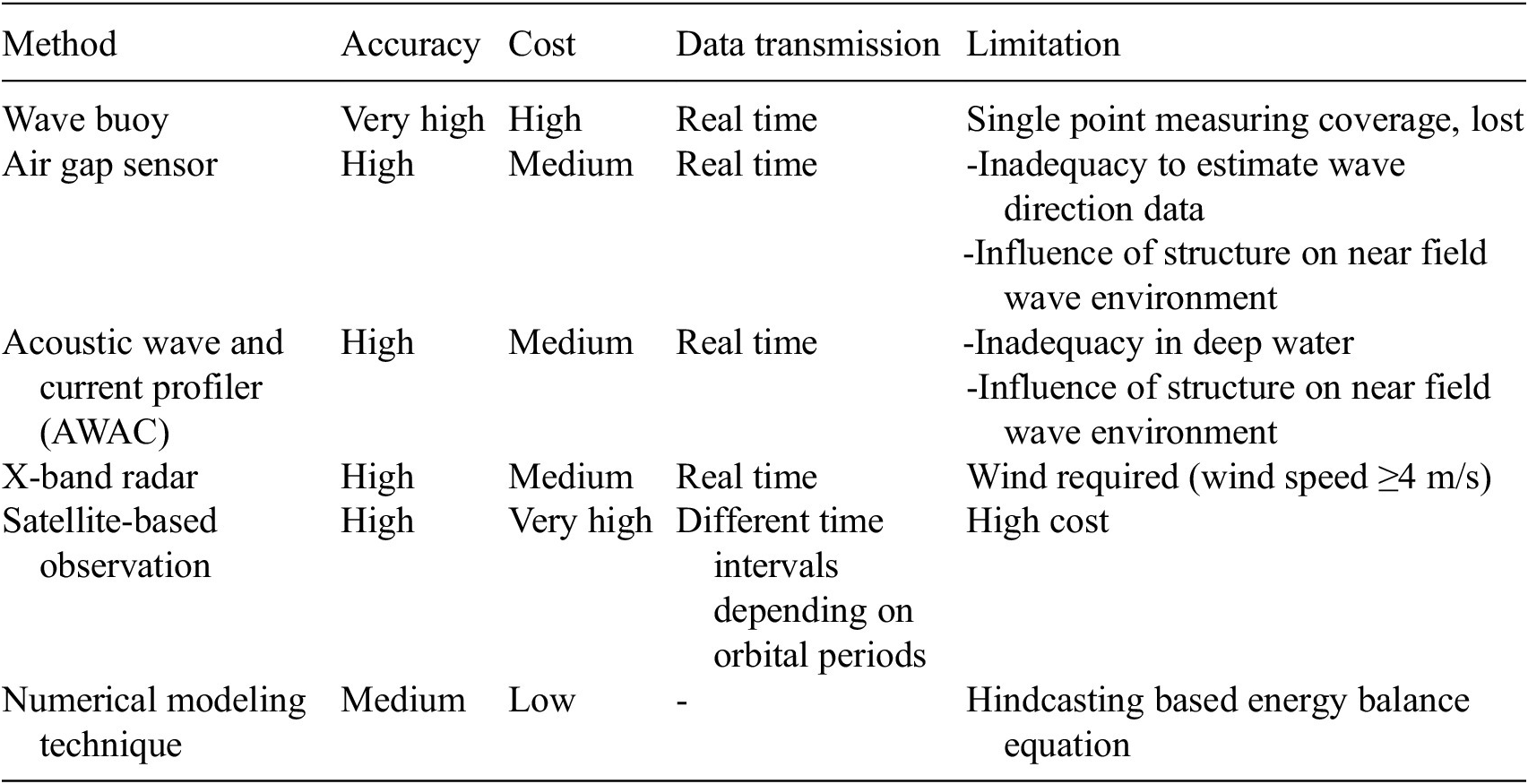

Wave measurement directly on a platform offers the highest accuracy, with measurement data transmitted in real-time to a land-based analytic center. In the DHE system, the data analytic center aims to model wave environmental conditions to compute loads on the ships and offshore structures. Several widely used modeling techniques for hindcasting long-term wave characteristics using energy balance equations include Wavewatch 3, SWAN, and MIIKE21 (Tolman, Reference Tolman2009; Akpınar et al., Reference Akpınar, van Vledder, Kömürcü and Özger2012; Kim et al., Reference Kim, Dinh, Sung, Kim, Choi, Graber, Yu and Park2022). However, hindcast data are not as accurate as measurements taken directly on a platform, making it less ideal for wave load computations. Ocean wave measurement methods can be categorized based on installation methods and contact with water into on-site and remote sensing techniques. On-site approaches involve measuring specific points, typically using devices such as wave buoys, air gap sensors (sea level monitors), pressure sensors, or acoustic Doppler current profilers (ADCPs). Remote sensing techniques, on the other hand, capture the spatial characteristics of the wave surface using tools like X-band marine radar (ship-borne) and synthetic aperture radar (SAR) on satellites. Additionally, numerical modeling techniques are available for estimating wave parameters. Further details on these methods are provided in Table 4.

Table 4. Summary of methods and their characteristics for estimation of the wave parameters

Wave buoys represent the most reliable on-site measurement method for estimating sea state in the surrounding environment of ships and offshore structures (Raghukumar et al., Reference Raghukumar, Chang, Spada, Jones, Janssen and Gans2019; Lin et al., Reference Lin, Huang and Chen2020a). However, for large areas such as wind farms, wave buoys are not suitable due to their measurements being confined to a single point. Alternatively, air gap sensors can be employed for fixed and/or floating offshore platforms to estimate wave height and period by measuring the elevation of the water surface (Anokhin and Ewans, Reference Anokhin and Ewans2018). Although air gap sensors cannot directly measure wave direction as they are installed on the structure, they can provide information on ocean waves distorted by the column. While impractical in deep water, recent advancements in acoustic wave and current sensors (AWAC) combine an ADCP with a directional wave gauge, allowing for the measurement of wave parameters near coastal structures (Mendelsohn et al., Reference Mendelsohn, Fratantonio, Hanson, Bangs, Withall and Crosby2017, Reference Mendelsohn, Zarate, Kurrus, Leung and Røstad2019).

X-band radars installed on ships or offshore platforms offer the capability to measure wave parameters on-site, providing real-time estimates within a range of several kilometers from their location (Wang et al., Reference Wang, Tian, Peng and Luo2018). Moreover, these radars offer additional advantages such as the ability to measure the surface wave field in real time and distinguish between wind, waves, and swell (Chernyshov et al., Reference Chernyshov, Hessner, Zavadsky and Toledo2022). Since swell acts as an external force on offshore structures, it is crucial to separate its measurement from that of wind and waves. The measurement principle involves computing the spatial–temporal radar image by applying three-dimensional fast Fourier transform to the intensity of the signal reflected from the sea level. X-band radar provides a means to determine the profile of incident waves in real time, which can be pivotal in predicting the motion of floating bodies. Satellite-borne SAR systems also utilize X-band frequencies; however, they utilize the Doppler effect to measure the ocean’s surface wave field. While SAR systems can measure a wide area exceeding tens of kilometers, they face challenges such as high cost and difficulties in providing real-time responses. In contrast, C-band radar is widely used on offshore platforms to measure wave parameters and surface currents effectively. However, it relies on the Doppler effect and only provides statistical characteristics of the waves rather than enabling direct wave field measurement. Additionally, high frequency radar, typically installed along coastlines, is specifically designed to measure surface currents. Jiao et al. (Reference Jiao, Ren and Guedes Soares2021) conducted a comprehensive review of on-site methods for measuring hydrodynamic and structural loads on large-scale floating structures, highlighting ongoing advancements in large-scale model measurements. Figure 5 depicts the installation of various on-site instruments.

Figure 5. Photographs of in situ instruments (Zwick, Reference Zwick2022): (a) wave buoy; (b) air gap sensor; (c) acoustic wave and current profiler (AWAC); (d) X-band radar; (e) C-band radar (Salcon Petroleum, n.d.); (f) SAR radar; (g) HF radar; and (h) pressure sensor.

3.2 Wind

Wind loads exert significant forces on ships and offshore structures, posing potential risks of catastrophic damage, particularly during severe storms. Consequently, they demand careful consideration both during the design phase and in ongoing structural health assessments. These loads are characterized by several parameters, necessitating measurement at the structure’s site (Paik, Reference Paik2022):

-

• windage area;

-

• wind speed at the standard World Meteorological Office height of 10 m above mean sea level for its known suitable estimates (McQueen and Watson, Reference McQueen and Watson2006; Jimenez et al., Reference Jimenez, Durante, Lange, Kreutzer and Tambke2007);

-

• wind direction.

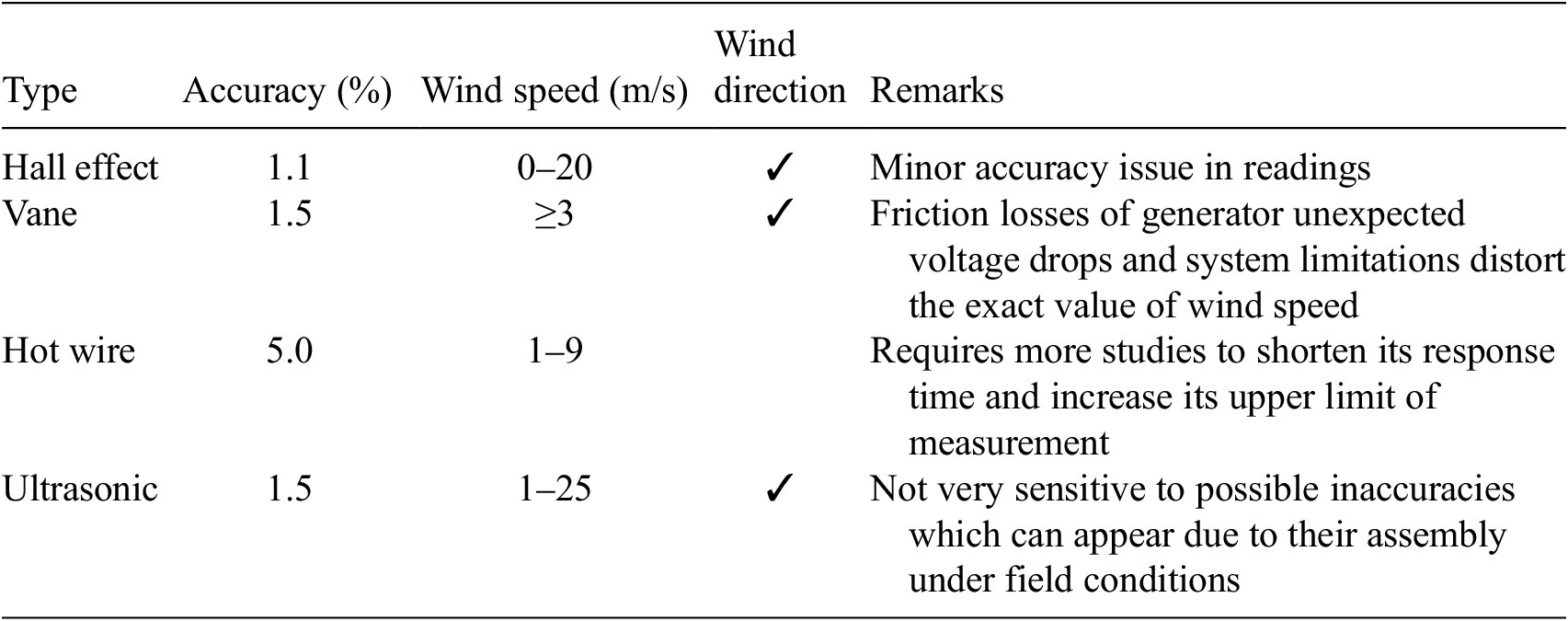

Wind sensors, particularly anemometers, offer valuable on-site measurements of wind parameters. Anemometers, categorized by their working principles such as effect, hot wire, and ultrasonic, are among the most common and accurate instruments for this purpose. Table 5 provides a detailed overview of the various types of anemometers and their properties (Wang et al., Reference Wang, Tian, Peng and Luo2018). However, a common challenge with all types of anemometers is the potential distortion of wind flow, often caused by superstructures or mounting arrangements (Moat et al., Reference Moat, Yelland and Molland2005). In recent methodologies aimed at estimating wind parameters on-site, emerging technologies like satellite-based methods and X-band radar have gained traction, addressing some of the limitations associated with traditional anemometers. Satellite-based methods offer the significant advantage of measuring extensive areas. Nonetheless, studies by Chen et al. (Reference Chen, Huang and Yao2018) and Majidi Nezhad et al. (Reference Majidi Nezhad, Neshat, Heydari, Razmjoo, Piras and Astiaso Garcia2021) suggest that these methods may exhibit relatively lower accuracy compared to on-site measurements.

Table 5. Summary of different anemometers and their characteristics

Offshore wind turbines are continually increasing in size, necessitating the placement of anemometers on taller masts to accurately capture wind parameters. However, traditional mast installations face both technical and economic challenges, particularly regarding their height. In response to this, light detection and ranging (LiDAR) systems, which are remote sensing technologies with fewer height limitations, have gained popularity for estimating wind parameters in offshore settings. Research by Shu et al. (Reference Shu, Li, He and Chan2016) explored the wind characteristics of offshore wind turbines using both LiDAR systems and traditional meteorological masts. Their study revealed that LiDAR measurements closely correlated with mast anemometer readings in terms of wind direction and speed. However, notable deviations were observed at higher altitudes when comparing LiDAR-derived profiles with standard wind profiles. Figure 6 illustrates the different LiDAR and anemometer installations on offshore structures.

Figure 6. Various instruments for the wind parameters: (a) Hall effect anemometer (Rutledge et al., Reference Rutledge, McDaniel, Teng, Hall, Ramroop, Sprout, Hunt, Boudreau and Costa2022); (b) vane anemometer; (c) ultrasonic anemometer; and (d) LiDAR (Shu et al., Reference Shu, Li, He and Chan2016).

3.3 Moving iceberg

Ships and offshore structures operating in Arctic environments may encounter infrequent but potentially significant external forces resulting from collisions with drifting icebergs, as depicted in Figure 7. The acceleration of climate change has heightened the occurrence of drifting icebergs in open waters, thereby posing a notable threat to ships and offshore structures in Arctic regions. In conducting structural health condition assessments, calculations of iceberg-induced loads rely on measured parameters of the moving iceberg, which encompass:

-

• iceberg mass;

-

• iceberg shape;

-

• moving speed; and

-

• moving direction.

Figure 7. A moving iceberg at sea.

Predictive analytical models aimed at forecasting drifting iceberg collisions with ships and offshore structures have been put forth, as delineated by Wagner et al. (Reference Wagner, Dell and Eisenman2017). These models hinge on precise, on-site measurements of waves, currents, and wind to ensure accurate predictions of iceberg drift trajectories. However, inaccuracies in the measured parameters, especially concerning current direction, can markedly diminish the reliability of the predictive model, as evidenced by Turnbull et al. (Reference Turnbull, Fournier, Stolwijk, Fosnaes and McGonigal2015) in their study.

Visual examination by operators serves as an effective means to relay measured parameters of moving icebergs to the data center of the digital healthcare system for calculating iceberg loads. Advanced technologies, such as SAR and marine radar, have been developed for unmanned iceberg monitoring applications. Marine radars have gained widespread adoption for iceberg detection and size measurement, often deployed on ships and offshore platforms for such purposes. This application is evident in Lund et al. (Reference Lund, Graber, Persson, Smith, Doble, Thomson and Wadhams2018), where drifting icebergs were monitored, and their speed and direction were measured using a marine radar installed on a vessel. Similarly, Long et al. (Reference Long, Chen, Wang, Liu and Ji2021) characterized drifting iceberg parameters using a marine radar mounted on an offshore platform. However, it is important to note, as highlighted in Lee and Park’s (Reference Lee and Park2021) review, that detecting large icebergs using marine radar can present challenges. SAR has emerged as a highly effective satellite-based method for detecting and monitoring icebergs, as underscored in various research studies and in Hannevik’s (Reference Hannevik2017) review. Among its notable advantages over other iceberg detection methods is its capability to measure iceberg parameters regardless of weather conditions, cloud cover, and day-night cycles. However, the relatively large sensor size of SAR systems poses a limitation to their effectiveness, resulting in lower resolution compared to on-site measurements obtained from instruments mounted on offshore platforms (Kaspersen, Reference Kaspersen2017). Additionally, satellite technologies often entail significant time intervals between measured data points due to the orbital period of satellites (AMEC et al., 2007).

3.4 Challenges and practical solutions

On-site measurement methods for ocean environmental conditions provide real-time data through sensors or visual examination, enabling the immediate calculation of ocean environmental loads. Given the intricate nonlinear dynamics between ocean environments and structures, CFD remains indispensable for accurately determining these loads. However, the current computational demands of CFD pose challenges in processing real-time simulations directly from transmitted on-site data. As computational technologies advance, the prospect of real-time CFD simulations may become more attainable in the future. Meanwhile, periodic assessments based on average values of measured parameters over weeks or months intervals can be conducted, with real-time measurement reserved for significant storm conditions or iceberg collision events. Depending on the sensitivity of the outputs to collected data, this approach proves both adequate and cost-effective. Furthermore, weather forecasts or previous examinations can complement this strategy.

4. Module 2: Data transmission and communication

4.1 Data digitalization and transmission

Connectivity and data sharing pose significant challenges to the advancement of Maritime 4.0, encompassing factors such as speed, capacity, reliability, and security (de la Peña Zarzuelo et al., Reference de la Peña Zarzuelo, Soeane and Bermúdez2020). To facilitate the transmission of digitized environmental and in-service damage parameters, data must be sent to a land-based data center for computations related to offshore structure loads and strength evaluation. For fixed offshore structures, especially those near shorelines, Wi-Fi broadband offers a viable option for data transmission. However, in remote areas where ships and floating offshore installations are prevalent, satellite communication becomes essential. Yang et al. (Reference Yang, Zhong, Yao, Yu, Fu and Postolache2018) compared various transmission methods (ZigBee, Wi-Fi, radio frequency [RF], 4G, and 5G), highlighting Wi-Fi as the preferred choice for automated ports due to its wide coverage and broadband bandwidth advantages. RF communication is typically utilized for ships and offshore structures within a 20 km range from the port. Meanwhile, 4G and 5G technologies offer lower infrastructure costs, improved coverage, and enhanced flexibility compared to earlier methods. Notably, 5G, with its capacity for evolution, adaptation, and growth, emerges as the preferred solution in scenarios requiring higher speeds, stronger security, and greater reliability (Capela et al., Reference Capela, Low and Bastos2021; Zmysłowski et al., Reference Zmysłowski, Skokowski, Malon, Maślanka and Kelner2023). In a case study by Loughney et al. (Reference Loughney, Wang, Matellini and Nguyen2021) focusing on offshore gas turbines, four wireless sensor network (WSN) designs were evaluated: Single-hop transmission (WSN 1), Single-hop transmission with cluster head nodes (WSN 2), Multi-hop transmission with a small sensor node radius (WSN 3), and multi-hop transmission with a large sensor node radius (WSN 4). Their findings indicated that WSN 3 represents the optimal solution for structural integrity monitoring driven by electrical generators.

Terrestrial communication systems, including broadband cellular networks, low power wide area networks (LPWANs), and massive machine type communication (mMTC) technologies, present viable options for offshore structures, albeit with limitations primarily confined to coastal regions. Parri et al. (Reference Parri, Parrino, Peruzzi and Pozzebon2020) advocate for advanced LPWAN solutions tailored for marine industry monitoring systems, emphasizing their ability to achieve significant operational ranges while addressing challenges related to packet losses and power consumption. Meanwhile, mMTC technology offers specialized connectivity for large-scale machine-to-machine interactions, crucial for Internet of Things (IoT) applications. These systems provide extensive and energy-efficient wireless connectivity, making them well-suited for applications such as remote data collection in environments like wind farms (Ullah et al., Reference Ullah, Mikhaylov and Alves2021).

Satellite communication stands as the predominant data transmission method in maritime and offshore environments, boasting expansive coverage capabilities, particularly when contrasted with conventional techniques. Satellite systems are typically classified into three primary types: low-earth orbit (LEO), positioned below 2000 km; medium earth orbit, spanning distances from 2000 to 35,786 km; and geostationary earth orbit, situated at 35,786 km. LEO satellites, in particular, offer improved communication efficiency with reduced propagation attenuation and faster transmission times, albeit necessitating constellations for continuous coverage. Recent technological strides have underscored the significance of free-space optical communication technology in LEO constellations, heralding fiber-like data rates. This advancement holds pivotal importance for broad maritime connectivity, as evidenced by initiatives like SpaceX’s Starlink, Telesat Lightspeed, and OneWeb constellation (Guan et al., Reference Guan, Wang, Jiang, Duan, Ren and Quek2021; Alqurashi et al., Reference Alqurashi, Trichili, Saeed, Ooi and Alouini2022). Moreover, the integration of mMTC and LPWAN technologies with satellites facilitates direct device communication and extends coverage to remote areas, thereby suggesting the potential for more efficient and widespread connectivity solutions (Liu et al., Reference Liu, Gao, Wu, Ng, Gao, Wong, Chatzinotas and Ottersten2021; Ullah et al., Reference Ullah, Mikhaylov and Alves2021, 2022).

4.2 Satellite-assisted health data management

Following the transmission and reception of health parameters at the data analytic center, thorough analysis ensues to compute loads and assess structural integrity. Visualization emerges as a pivotal tool in scrutinizing the characteristics of these conditions and delineating their trends over time. Fang et al. (Reference Fang, Wang, Li, Liu and Cai2022) pioneered the development of a digital twin system tailored for fatigue monitoring in marine structures, harnessing advanced data visualization techniques within a virtual model. Renowned for its high-fidelity representation, this model faithfully captures physical attributes such as geometry, boundary conditions, and damage, effectively crafting a cyber-counterpart to the physical system. Moreover, emerging methodologies for modeling ships and offshore structures incorporate virtual reality visualization, offering an immersive virtual onboard experience. This approach encompasses diverse functionalities, including equipment handling simulations, a dynamic positioning system simulator for platform motion control, walk-through simulations enabling monitoring from a worker’s perspective on the platform, and more (Park et al., Reference Park, Ahn, Oh and Chang2020).

Through simulation-based monitoring, the structural characteristics are virtually rendered in real-time, facilitating diagnosis, prognosis, and health management. Fang et al. (Reference Fang, Wang, Li, Liu and Cai2022) emphasize the necessity of exploring multi-scale and multi-physical field modeling methods, given the large size of ships and offshore structures and the localized nature of damages. A recent illustration of this approach is provided by Augustyn et al. (Reference Augustyn, Ulriksen and Sørensen2021), who delved into digital twin modeling and visualization by crafting a simulated numerical model of a jacket support structure. Leveraging advanced modeling techniques for ships and offshore structures, Augustyn et al. (Reference Augustyn, Ulriksen and Sørensen2021) achieved remarkable precision in representing structural dynamics. Their meticulous methodology comprised several key steps:

-

1. Adopting Craig-Bampton (Craig and Bampton, Reference Craig and Bampton1968) as a reduced model for wave loading.

-

2. Conducting aeroelastic computations for wind loading.

-

3. Retrieving the substructure response and extracting pertinent measurements for force recovery, following the guidelines set by Nielsen et al. (Reference Nielsen, Jensen, Augustyn and Pedersen2016).

Nonetheless, there remains an imperative for more extensive investigations into real-time simulation approaches tailored specifically for ships and offshore structures, particularly as real-time computing of the reduced order models (ROMs) continues to pose challenges (Zheng et al., Reference Zheng, Jiang, Jia, Wang, Zhang, Brumercik and Li2023). Zhao et al. (Reference Zhao, Dao and Le2023) demonstrate how ROMs can achieve real-time predictions with exceptional efficiency, enabling swift structural health assessments of offshore wind turbines at speeds up to 650 times faster than conventional models, with an accuracy level of less than 0.2% error.

4.3 Challenges and practical solutions

The virtual model relies on the aggregation of both sensor and historical data (Uhlemann et al., Reference Uhlemann, Schock, Lehmann, Freiberger and Steinhilper2017; Wang et al., Reference Wang, Wang, Hnydiuk-Stefan, Feng, Incesik and Li2021), necessitating substantial data volumes for the on-site measurements across different locations, time variants, and parameters. Thus, periodic time-variant data analytics might be contemplated at certain intervals, utilizing average parameter values for health condition assessment over time. Data fusion, ideally, encompasses data preprocessing, mining, and optimization (Tao et al., Reference Tao, Zhang, Liu and Nee2018b), facilitating timely information exchange between the digital twin’s system modules to achieve seamless information sharing. The overarching objective of the digital twin is to operate as a service system, prioritizing intelligent control and task optimization of the physical model (Wang et al., Reference Wang, Wang, Hnydiuk-Stefan, Feng, Incesik and Li2021). Technologies such as IoT, big data driving, status monitoring of the virtual model, and feedback to the physical model are continuously updated in real time to realize the service goal (Tao et al., Reference Tao, Cheng, Qi, Zhang, Zhang and Sui2018a).

With adequate data transfer rates, real-time continuous monitoring, data collection, and transmission of structural damage and environmental loads can be assured. Sensors can be deployed for continuous online data gathering and transmission, enabling the estimation of damage severity and identification of affected structure locations (Wang et al., Reference Wang, Tian, Peng and Luo2018). While the DHE system predominantly relies on periodic visual examinations with advanced equipment due to computational demands and efficiency considerations, integrating real-time monitoring for critical areas ensures prompt detection and response to vulnerabilities. Additionally, to comprehensively characterize the load and damage of support structures, it is imperative to integrate online monitoring with nondestructive testing, given the discrete nature of nondestructive testing data (Wang et al., Reference Wang, Wang, Hnydiuk-Stefan, Feng, Incesik and Li2021).

5. Module 3: Data analytics and visualization with digital twin

5.1 Residual ultimate strength-based safety criteria

Progressive collapse, stemming from a loss of structural stiffness and strength due to factors like buckling, plasticity, and fracture (Paik, Reference Paik2018, Reference Paik2020, Reference Paik2022), can lead to the failure of a specific structural member or an entire structure. Such failures may have dire consequences, including human casualties, structural collapse, and environmental damage. Thus, conducting a health condition assessment of offshore structures based on their ultimate strength is imperative.

This paper adopts a deterministic approach, employing CFD and finite element analysis (FEA) to compute ocean environmental and operational loads, along with their effects on the structure. This method offers a straightforward and tangible assessment, enabling prompt decision-making, which is crucial for operators and engineers during emergent situations. The criteria for conducting health condition assessments based on ultimate strength are outlined as follows (Hughes and Paik, Reference Hughes and Paik2010; Paik, Reference Paik2018):

where

![]() $ C $

is the ultimate strength or maximum load-carrying capacity,

$ C $

is the ultimate strength or maximum load-carrying capacity,

![]() $ D $

is the applied loads,

$ D $

is the applied loads,

![]() $ \eta $

is the safety factor, and

$ \eta $

is the safety factor, and

![]() $ {\eta}_{cr} $

is the critical safety factor. To be safe, the computed safety factor,

$ {\eta}_{cr} $

is the critical safety factor. To be safe, the computed safety factor,

![]() $ \eta $

should always be greater than the critical safety factor,

$ \eta $

should always be greater than the critical safety factor,

![]() $ {\eta}_{cr} $

, despite in-service damage and ocean environmental conditions.

$ {\eta}_{cr} $

, despite in-service damage and ocean environmental conditions.

While probabilistic methods provide valuable insights into uncertainties and risk factors, the deterministic approach better aligns with the real-time decision-making framework of the proposed DHE system. Jiang et al. (Reference Jiang, Hu, Dong, Gao and Ren2017) conducted a comprehensive review of reliability analysis methods for offshore wind turbines, underscoring the significant role of probabilistic methods and the challenges in quantifying uncertainties for novel structures. Traditional probabilistic methods such as the first-order reliability method (FORM) and second-order reliability method (SORM) are commonly utilized. SORM is known for its potential accuracy, albeit being computationally expensive compared to FORM (Lee and Kim, Reference Lee and Kim2019). In their investigation of offshore wind turbine support structures, Kim and Lee (Reference Kim and Lee2015) introduced a static analysis-based reliability method that estimates dynamic response by multiplying the static response and peak response factor, thereby significantly reducing computational efforts. However, they noted a limitation concerning the approach’s potential inaccuracy for structures with high nonlinear properties. Abaei et al. (Reference Abaei, Abbassi, Garaniya, Chai and Khan2018) employed a Bayesian network for probabilistic hydrodynamic analysis to assess the safety of floating structures, successfully identifying critical design points associated with hydrodynamic responses in various sea states. Their methodology not only demonstrated the effectiveness of Bayesian networks for their specific study but also suggested their applicability to diverse failure modes with appropriate modifications.

5.2 Calculations of ocean environmental loads

The applied loads in Equation (1) can be determined through analytical, numerical, or experimental approaches. Traditionally, experimental and analytical methods were the primary means of calculating applied loads, especially in aero-hydrodynamic analysis. However, with the introduction of CFD simulations utilizing Reynolds-averaged Navier–Stokes equations, a more comprehensive approach has emerged for computing complex wave and wind-induced loads, particularly considering the combined effects of these forces. The prevalent methods for conducting CFD simulations of combined wind and wave loads on offshore structures typically involve the utilization of advanced industrial-grade software packages such as ANSYS Fluent, STAR-CCM+, and OpenFOAM.

For instance, Figure 8 showcases a CFD model depicting wave-induced hull girder load computations for FPSO hull structures, as demonstrated in the research by Paik (Reference Paik2022). Additionally, it presents the intricate dynamics of wind, wave, and rotor-induced loads on an offshore wind turbine. These visual representations elucidate the multifaceted factors influencing the calculation of environmental loads, which significantly affect the structural integrity and durability of these engineering marvels.

Figure 8. CFD models for environmental load computations on ship-shaped offshore structures and offshore wind turbines.

There has been a notable surge in research publications focusing on wind and wave simulation employing these computational tools. For instance, Temarel et al. (Reference Temarel, Bai, Bruns, Derbanne, Dessi, Dhavalikar, Fonseca, Fukasawa, Gu, Nestegård, Papanikolaou, Parunov, Song and Wang2016) provided a review on evaluation methods for wave-induced loads, offering a comparative analysis of CFD methods against analytical and experimental approaches. Similarly, Liu et al. (Reference Liu, Sun, Zhong, Xie, Incecik and Li2020) conducted a review on practical methods for calculating wind-induced loads acting on offshore platforms, classifying these methods into numerical simulation, experimentation, and on-site measurement. Although published experimental studies, including wave tank and wind tunnel test analyses, are often deemed unsuitable for industrial applications within a lifetime healthcare digital twin monitoring system. This limitation stems primarily from the high costs and lengthy preparation periods associated with their implementation (Xie et al., Reference Xie, Chen, Liu, Jian and Shi2021). Nevertheless, these studies offer valuable insights guiding the further development of the proposed approach toward achieving industrial applicability. Hence, based on the current state-of-the-art literature, the most viable solution appears to be the utilization of CFD simulations based on measured environmental conditions.

Throughout their operational lifespan, ships and offshore structures endure the relentless forces of waves and winds, which combine to influence their structural responses. However, these responses are not merely a simple summation of wave-induced and wind-induced effects; rather, they are influenced by nonlinear coupling effects (Inoue et al., Reference Inoue, Adilah, Iijima, Sho and Suzuki2020). Recent studies that account for such coupling effects in CFD simulations offer valuable insights into advanced techniques for calculating environmental loads. Notably, advancements highlighted by Wang and Wan (Reference Wang and Wan2020) underscore the increasing preference for CFD in predicting complex viscous flows across various domains of ship and ocean engineering. Specifically, they emphasize the significance of coupled CFD analysis for floating offshore wind turbines under combined wind and wave conditions, positioning it as a superior method for aero-hydrodynamic analysis compared to traditional numerical methods like blade element momentum and vortex methods.

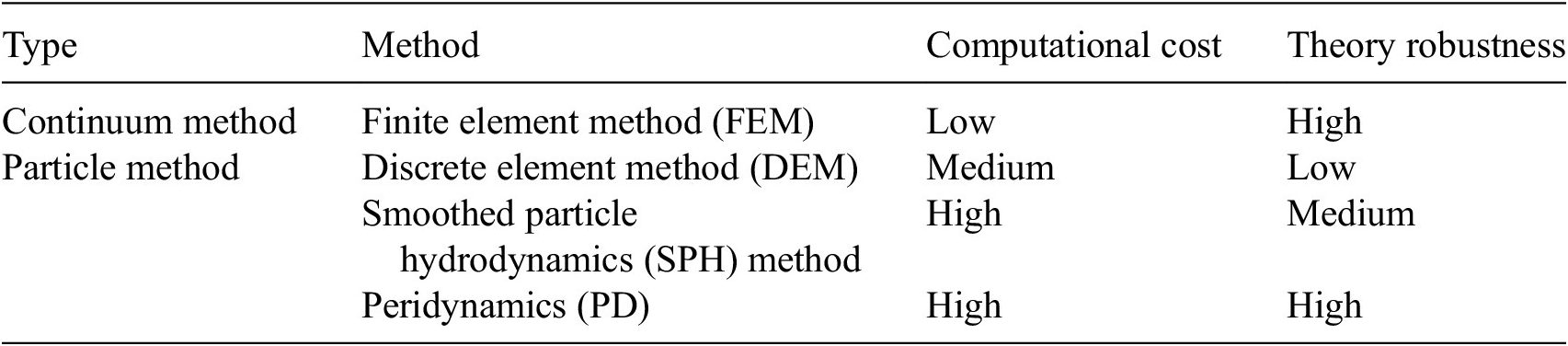

To assess the impacts of iceberg-induced forces on ships and offshore structures, numerical dynamic structural analysis methods are employed. Xue et al. (Reference Xue, Liu, Li and Han2020) provide a comprehensive review detailing the primary numerical methods for computing ice-induced loads on hull structures, as summarized in Table 6. Utilizing FEA simulation software such as LS-DYNA proves effective due to its robust theoretical foundation in simulating collisions, large deformations, and dynamic fractures induced by icebergs.

Table 6. Numerical methods used in the previous studies for iceberg induced forces analysis(Xue et al., Reference Xue, Liu, Li and Han2020)

Fluid–structure interaction (FSI) methods have been introduced to integrate wind and wave effects into simulations, particularly by researchers focused on dynamic structural and aero-hydrodynamic interaction analyses. In a study by Song et al. (Reference Song, Kim, Amdahl, Ma and Huang2016), a comparative analysis of the FSI method to the constant added mass (CAM) methods using LS-DYNA software for an iceberg-floating structure collision analysis was conducted, validating their results against ice tank tests. Their study revealed that while the FSI method, coupled with a specific ice material model, yielded significantly more accurate results aligned with potential theory, it required an order of magnitude greater CPU power consumption compared to the CAM method. Therefore, a carefully calibrated CAM approach remains a desirable option.

In Guo et al. (Reference Guo, Zhang, Tian, Li and Zhao2018), a numerical and experimental investigation of ice-induced forces on an ice-going ship utilized the FSI method for numerical analysis and compared the results with towing tank test outcomes. The findings indicated good agreement between the numerical simulation and the experiments, both in observed phenomena and resistance values, suggesting the promise of their numerical simulation approach for future related studies. Furthermore, Sayeed et al. (Reference Sayeed, Colbourne, Quinton, Molyneux, Peng and Spencer2017), in their state-of-the-art literature review on iceberg-induced impact forces on offshore structures, with a focus on hydrodynamic interaction, highlighted that the accurate prediction of these forces is currently limited by understanding of hydrodynamic effects near the icebergs.

5.3 Calculations of residual ultimate strength

The ultimate strength, as defined in Equation (1), is derived from a function incorporating nine parameters (Paik, Reference Paik2018, Reference Paik2020, Reference Paik2022). This relationship can be expressed as follows:

where

![]() $ {X}_1 $

is the parameter associated with geometric properties,

$ {X}_1 $

is the parameter associated with geometric properties,

![]() $ {X}_2 $

is the parameter associated with material properties,

$ {X}_2 $

is the parameter associated with material properties,

![]() $ {X}_3 $

is the parameter associated with fabrication-related initial imperfections,

$ {X}_3 $

is the parameter associated with fabrication-related initial imperfections,

![]() $ {X}_4 $

is the parameter associated with the loads on various types of components,

$ {X}_4 $

is the parameter associated with the loads on various types of components,

![]() $ {X}_5 $

is the parameter associated with loading speed,

$ {X}_5 $

is the parameter associated with loading speed,

![]() $ {X}_6 $

is the parameter associated with temperature,

$ {X}_6 $

is the parameter associated with temperature,

![]() $ {X}_7 $

is the parameter associated with age-related degradation,

$ {X}_7 $

is the parameter associated with age-related degradation,

![]() $ {X}_8 $

is the parameter associated with accident-induced damage, and

$ {X}_8 $

is the parameter associated with accident-induced damage, and

![]() $ {X}_9 $

is the parameter associated with human error.

$ {X}_9 $

is the parameter associated with human error.

Nonlinear finite element methods (FEMs), or advanced large-scale FEMs as proposed by Paik (Reference Paik2018), are utilized to compute the residual ultimate strength under damaged conditions. Finite element (FE) models, established prior to the deployment of offshore installations, undergo regular updates using in-service damage parameters. This iterative process is illustrated in the approach outlined by Lampe and Hamann (Reference Lampe and Hamann2018), which entails model refinement through incorporation of fresh measurements derived from inspection data.

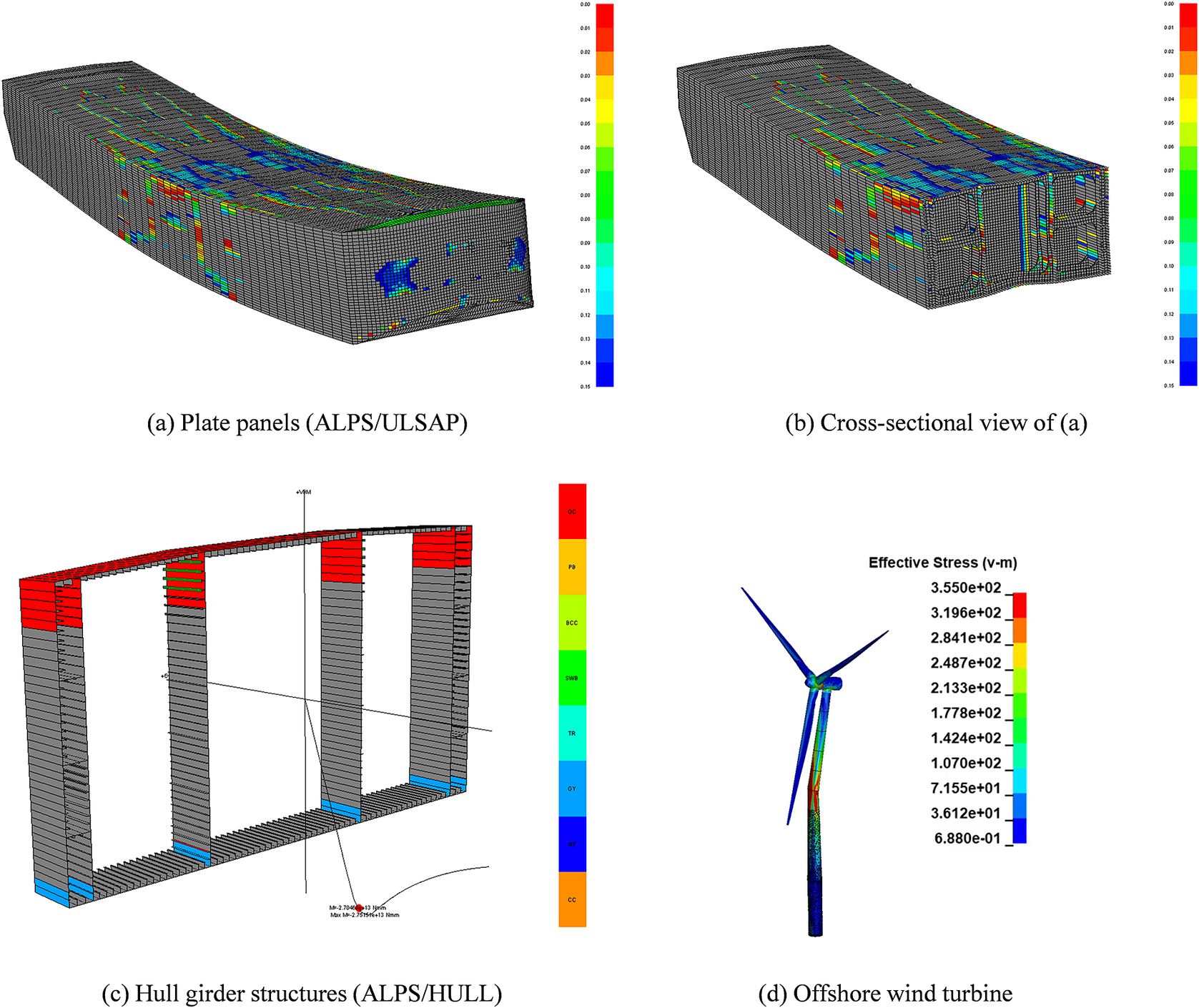

The computational modeling depicted in Figure 9 displays a nonlinear FE model employed for progressive collapse analysis of aging FPSO hull structures in wave conditions and aging offshore wind turbines subjected to wind, wave, and rotor-induced loads, as presented by Sindi et al. (Reference Sindi, Kim, Chaves and Paik2023). Specifically, ALPS/ULSAP and ALPS/HULL are software modules integrated within the MAESTRO platform for ultimate strength analysis of plate panels and hull girder structures (ALPS/HULL, 2023; ALPS/ULSAP, 2023; MAESTRO, 2023). This visualization underscores the intricate interplay of various factors and the meticulousness required in their modeling to ensure an accurate evaluation of the structural integrity of these expansive engineering systems.

Figure 9. Nonlinear finite element models for progressive collapse analysis illustrating the calculation of the ultimate strength.

Tekgoz et al. (Reference Tekgoz, Garbatov and Guedes Soares2020) provide an exhaustive review of current methodologies for computing the residual ultimate strength of aging ships and offshore structures, with a specific focus on steel-plated structures such as plates, stiffened panels, box girders, and hull girder structures. Their work comprehensively examines these structures’ responses to in-service damages, encompassing corrosion wastage, fatigue cracking, and mechanical damages. In alignment with Wang et al. (Reference Wang, Wharton and Shenoi2014), Babazadeh and Khedmati (Reference Babazadeh and Khedmati2018) and Tekgoz et al. (Reference Tekgoz, Garbatov and Guedes Soares2020) have also contributed reviews, with Wang et al. (Reference Wang, Wharton and Shenoi2014) emphasizing corrosion wastage and fatigue cracking in steel-plated structures. Together, these studies underscore the breadth of research in modeling residual ultimate strength under diverse loading conditions. However, they collectively suggest the need for further investigation to refine the accuracy of conventional prediction methods for load-bearing capacity.

Recent advancements in evaluating the residual ultimate strength of aging ships and offshore structures include the work of Ji et al. (Reference Ji, Xue, Shi and Gaidai2016), which combines numerical and experimental investigations. Their study focuses on corroded or cracked jacket structures under a 50-year service life assumption, employing a time-dependent mathematical model to characterize crack size and volume loss in the target structure. The results reveal that corrosion and fatigue cracks not only reduce the ultimate strength of the aged jacket structure but also shift its failure mode from global yielding to local tearing. Moreover, their research indicates that models incorporating both corrosion and cracks exhibit lower residual ultimate strength compared to those with corrosion alone. This suggests that in real-world structures where corrosion and cracks coexist, the ultimate strength of the existing jacket structures in operation may exceed the findings of this study. Additionally, Nouri and Khedmati (Reference Nouri and Khedmati2020) delve into the progressive collapse behaviors of corroded FPSO hull structures using four different corrosion models: uniform, random, pitting, and tanker pattern corrosion. Their analysis reveals that hull structures with pitting and tanker pattern corrosion models exhibit significantly lower residual ultimate strength compared to other corrosion models.

Through extensive physical testing, Ahn et al. (Reference Ahn, Choi, Jeon, Kim and Kim2016) examined the effects of pit corrosion on the ultimate compressive strength of steel tubular members, which constitute a fundamental structural element of jacket platforms. They derived an empirical formula that correlates the ultimate strength with parameters obtained from material testing and the extent of the damaged area. Given the prevalence of pitting corrosion in marine structures, the insights gleaned from these large-scale physical tests are invaluable. However, it is important to acknowledge that the practical applicability of the empirical formula warrants further investigation, particularly due to the limited test data and the utilization of a simple linear regression technique.

In the realm of digital twin modeling for the lifelong healthcare monitoring of aging ships and offshore structures, it is imperative to consider the collective impact of all in-service damages to accurately replicate the structure’s real condition. This holistic approach not only enhances the reliability of diagnostic and prognostic analyses conducted by the digital twin but also underscores the necessity of investigating the effects of each type of in-service damage while considering all other damages. This significance is vividly portrayed in Kim et al.’s (Reference Kim, Zalaya, Mohd, Choi and Park2017) examination of various corrosion models applied to steel-plated structures. In their research, they explored the residual ultimate strength of corroded jacket structures using FEM, aiming to gauge their service life under distinct environmental conditions. Opting for a uniform corrosion model to minimize modeling expenses, they observed a notable disparity in service life between benign and harsh environments such as the North Sea, suggesting a potential difference of at least 15 years. Consequently, there is a pressing need for further exploration incorporating the combined effects of all in-service damages to refine the existing methodology.

Additionally, Li et al., Reference Li, Feng, Huang, Shi and Wang2021b delved into the synergistic impact of pitting corrosion and cracks on the residual ultimate strength of stiffened box girders subjected to vertical bending moments. Their numerical investigation unveiled that the cumulative reduction in ultimate strength stemming from a solitary pit corrosion or crack closely resembled that induced by the combined damage. Leveraging their findings, they proposed an empirical formula, dependent on volume loss and crack length, to predict the residual ultimate strength of stiffened box girders afflicted with concurrent damages.

5.4 Challenges and practical solutions

Calculating ocean environmental loads and residual ultimate strength demands considerable time and computational resources, underscoring the quest for efficient methodologies to facilitate prompt health condition assessments and timely interventions. Particularly, CFD simulations conducted in the time domain entail extensive computational efforts and time investments. A viable alternative is the utilization of CFD simulations in the frequency domain, offering superior efficiency, as exemplified by Pegalajar-Jurado et al.’s (Reference Pegalajar-Jurado, Borg and Bredmose2018) comparative study, which delineated notable time disparities between the two approaches.

Conversely, while analytical solutions present themselves as potential tools for determining characteristic values of strength or loads, their applicability often entails increased complexity. Furthermore, ROMs emerge as a promising avenue to circumvent computational limitations, facilitating real-time health monitoring of intricate systems such as ships and offshore structures. This attribute renders ROMs particularly attractive for integration within digital twins, as highlighted by Lin et al. (Reference Lin, Cevasco and Collu2020b).

6. Module 4: AI-driven diagnosis and remedial action recommendations

6.1 AI-driven diagnosis with machine and deep learning

After acquiring detailed on-site measurements of health parameters and computing environmental loads and residual ultimate strength, a pivotal component of the DHE system for aging ships and offshore structures involves timely data interpretation, ideally in real-time or within short intervals (e.g., weekly, monthly, or quarterly rather than annually or biannually). This capability, crucial for precise health diagnostics, harnesses the capabilities of AI, particularly machine learning (ML) and deep learning algorithms.

AI not only demonstrates proficiency in approximating data output but, more significantly, excels at deciphering complex patterns within the measured data and computed outputs from CFD and FEA. The integration of AI-driven diagnoses within the DHE system, notably in the framework of digital twins, substantially enhances the efficiency and viability of real-time health condition assessments and recommendations for remedial actions across various critical aspects of aging offshore structures.

AI technology is currently experiencing a stage of rapid development (Kuang et al., Reference Kuang, He, Yili, Kai, Mingyu, Jian and Xin2021). Numerous studies have delved into the application of AI in evaluating offshore structures. Richmond et al. (Reference Richmond, Sobey, Pandit and Kolios2020) underscore the effectiveness of AI in analyzing offshore wind farms, employing CFD for flow field estimation. Their research conducted a comparative assessment of various ML models, including artificial neural network (ANN), Gaussian process, and radial basis function, among others, revealing that radial basis function and ANNs emerged as the most efficient methods.

Conversely, Häfele et al. (Reference Häfele, Gebhardt and Rolfes2019) employed the openFAST simulation tool, coupled with Gaussian process regression-based ML, to optimize jacket substructures for offshore wind turbines. This approach, tested on the NREL 5 MW turbine under FINO3 conditions, demonstrates the effectiveness of AI in managing intricate simulations and a diverse array of design parameters. These instances showcase AI’s capability to integrate field measurements and simulation data for ML analyses of offshore structures.

Literature also showcases applications more focused on fault detection. Okenyi et al. (Reference Okenyi, Bodaghi, Mansfield, Afazov and Siegkas2022) delve into the application of ANN within digital twin systems for offshore wind turbines, particularly highlighting their efficacy in fault detection. They emphasize that ANN, alongside other ML techniques, excels in tracing patterns in fault diagnosis, crucial for addressing challenges in corrosion fatigue assessment. This application not only enhances accuracy in assessing the state of horizontal-axis offshore wind turbine structures but also contributes to reducing computational costs.