1. Introduction

Turbulent flows over walls with spatially varying roughness patterns are ubiquitous in nature and technical applications alike (Colombini & Parker Reference Colombini and Parker1995; Bons Reference Bons2002). In particular, lateral (spanwise) inhomogeneity of the roughness distribution can lead to the formation of secondary flows; i.e. non-zero mean values of the transverse velocity components.

Hinze (Reference Hinze1967, Reference Hinze1973) first studied flows through rectangular ducts with longitudinal roughness strips. He noted that upwelling occurred over the low friction patches, and explained these secondary flows by means of the balance of turbulent kinetic energy. In the near-wall region fluid is transported out of regions where production exceeds dissipation and into regions with production deficit, i.e. from the rough towards the smooth surface regions. In consequence, low momentum fluid is transported from the wall towards the channel centre above the smooth wall region generating what has later been referred to as a low momentum pathway (LMP) in the literature (Mejia-Alvarez, Barros & Christensen Reference Mejia-Alvarez, Barros and Christensen2013); i.e. the mean flow speed above the smooth patches is smaller than above the rough ones. The direction of the secondary motion that generates this counter-intuitive mean flow distribution has been repeatedly reproduced in later experiments with roughness strips (Studerus Reference Studerus1982; Nezu & Nakagawa Reference Nezu and Nakagawa1984; Wang & Cheng Reference Wang and Cheng2006; Wangsawijaya et al. Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020), where the strongest secondary motions are found when the roughness strip spacing is of the order of the boundary layer thickness.

In many literature studies the representation of heterogeneous surface roughness through streamwise oriented roughness strips has been further simplified to two model problems which are referred to as strip-type and ridge-type roughness (Colombini & Parker Reference Colombini and Parker1995; Wang & Cheng Reference Wang and Cheng2006). The former is especially attractive for numerical approaches and corresponds to longitudinal strips of laterally alternating wall shear stress conditions (Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015; Chung, Monty & Hutchins Reference Chung, Monty and Hutchins2018). The latter, employed in experiments and simulations, is given by a series of protruding longitudinal ridges, see e.g. Vanderwel et al. (Reference Vanderwel, Stroh, Kriegseis, Frohnapfel and Ganapathisubramani2019). While strip-type roughness assumes a large scale separation between roughness height and boundary layer thickness and therefore negligible influence of surface elevation differences between smooth and rough surface areas, ridge-type roughness places the elevation of (deposition-type) roughness strips in the focus. The fact that these two simplified surface configurations lead to different rotational directions of the secondary flow and in consequence also to different LMP locations was repeatedly addressed in the literature (Wang & Cheng Reference Wang and Cheng2006; Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015; Hwang & Lee Reference Hwang and Lee2018). Based on roughness resolving direct numerical simulation (DNS) it has recently been shown that rough surface strips can produce both types of secondary flow depending on the relative roughness elevation (Stroh et al. Reference Stroh, Schäfer, Frohnapfel and Forooghi2020). The particular secondary flow of (canonical) strip-type roughness is found for non-elevated roughness strips in this case.

The secondary flow above strip-type roughness corresponds to the more intriguing configuration with high momentum pathways (HMP) located over rough surface patches and LMP over the smooth area, if the spanwise wavelength is less than or of the order of the channel height (Chung et al. Reference Chung, Monty and Hutchins2018). In order to study the underlying physical mechanisms in detail, the simplified numerical treatment through prescribed shear stress boundary conditions, as employed by Anderson et al. (Reference Anderson, Barros, Christensen and Awasthi2015) in large eddy simulation (LES) and Chung et al. (Reference Chung, Monty and Hutchins2018) in DNS, is a sensible approach, since it avoids the need to numerically resolve any roughness features and condenses the roughness effect in a boundary condition. The reduced resolution requirements enable DNS or LES at higher Reynolds numbers, required, for example, to numerically address the connection between secondary motions and very large-scale structures (Zampiron, Cameron & Nikora Reference Zampiron, Cameron and Nikora2020) through parametric studies in turbulent boundary layers. In addition, the use of a modified wall boundary condition has the advantage that any blockage effects due to roughness elevation are avoided.

As already pointed out by Chung et al. (Reference Chung, Monty and Hutchins2018), the prescription of a shear stress distribution at the wall is a very strong simplification especially suited to study of the outer flow behaviour. In the present work, we therefore suggest employing a slip-length approach to model heterogeneous roughness. This combines the advantage and simplicity of the shear stress boundary condition, i.e. no influence of protruding or recessed surface parts, with a less intrusive modification of the flow field through the introduction of an artificial boundary condition. In particular, the slip-length boundary condition can be formulated in such a way that it impacts turbulent flow fields only. This is an important characteristic of ‘proper’ roughness since the classical definition of rough surfaces includes the fact that those surfaces do not influence the flow resistance of laminar flow (Nikuradse Reference Nikuradse1933; Schlichting Reference Schlichting1979).

Slip lengths (or protrusion heights) have been used as a model for textured surfaces for the investigation of turbulent flow over drag reducing riblets (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991) and for the modelling of superhydrophobic surfaces (Min & Kim Reference Min and Kim2004). As discussed by Luchini (Reference Luchini2013), slip lengths are also a natural boundary condition for the modelling of rough surfaces. Multiple approaches exist to estimate the tensor of slip lengths (also called mobility tensor) from a description of the rough surface, typically by solving the Stokes equations near the wall (Kamrin, Bazant & Stone Reference Kamrin, Bazant and Stone2010; Luchini Reference Luchini2013). The present study employs a simple slip-length approach restricted to the prescription of a spanwise slip length to model strip-type roughness.

In order to clearly identify the turbulence driven flow field modifications for both types of boundary conditions, the shear stress boundary condition is considered under laminar flow conditions in addition. This allows us to identify whether the occurrence of secondary flows can be traced back to a linear process triggered by small disturbances in the modified laminar base flow. In the case of the slip-length boundary condition this laminar reference case is the standard laminar channel flow.

Besides elucidating relevant differences in the two model approaches and the related secondary motions, the present study aims at understanding the relevance of the spanwise gradient in the boundary condition for the formation of secondary flow. On the one hand, secondary flows are known to displace sediments in a riverbed in such a way that the roughness distribution and secondary flow form a positive feedback loop (Studerus Reference Studerus1982; Scherer et al. Reference Scherer, Uhlmann, Kidanemariam and Krayer2022), which suggests that an instantaneous jump between ‘rough’ and ‘smooth’ regions is not required. A similar conclusion can be drawn from the observation of secondary flows over a damaged turbine blade (Mejia-Alvarez et al. Reference Mejia-Alvarez, Barros and Christensen2013). On the other hand, most available literature studies consider sharp jumps between low and high shear stress regions.

The slip-length and shear stress boundary conditions along with the employed numerical method are introduced in § 2. Section 3 addresses the effect of the shear stress boundary condition in laminar flows. The application of a spanwise-varying boundary condition results in a velocity distribution with large spanwise gradients. It is shown that the introduction of a small disturbance in this laminar base flow results in the generation of large scale flow structures with resemblance to turbulent secondary flow. Consecutively, the shear stress boundary condition is analysed under turbulent flow conditions in § 4. We reproduce the results previously reported by Chung et al. (Reference Chung, Monty and Hutchins2018) and discuss those in light of the laminar flow observations of § 3, including the difference between sudden and gradual changes of the boundary condition. Section 5 first presents a short discussion about the possibility and limits of using a spanwise slip length as roughness model in general before its particular application as a model for streamwise aligned roughness strips is addressed. A discussion of important differences between the two numerical modelling approaches for roughness strips is presented in § 6 before we conclude with final remarks in § 7.

2. Procedure

2.1. Numerical set-up

We consider the turbulent flow within a doubly periodic channel as sketched in figure 1 by means of DNS. Streamwise, wall-normal and spanwise directions are denoted through ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$, whereas

$z$, whereas ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$ are the respective velocity components. While most aspects of the present numerical experiment are standard for this flow geometry, the peculiarity of the present work is the wall boundary condition with a spanwise inhomogeneity, which is described in detail in § 2.2. For the time being, it is sufficient to know that the wall boundary condition, applied symmetrically to both walls, periodically varies in the spanwise direction with a period

$w$ are the respective velocity components. While most aspects of the present numerical experiment are standard for this flow geometry, the peculiarity of the present work is the wall boundary condition with a spanwise inhomogeneity, which is described in detail in § 2.2. For the time being, it is sufficient to know that the wall boundary condition, applied symmetrically to both walls, periodically varies in the spanwise direction with a period ![]() $2s$.

$2s$.

Figure 1. A sketch of the channel with piecewise constant, spanwise variable roughness. For both SSBC and SLBC cases, the displayed shading is used to identify smooth and rough surface patches. In case of SSBC the grey shading indicates enhanced wall shear stress, in case of SLBC the grey patch corresponds to a region with spanwise slip.

The DNS in this work are performed using the open-source solver XCompact3D (Laizet & Lamballais Reference Laizet and Lamballais2009; Laizet & Li Reference Laizet and Li2010; Bartholomew et al. Reference Bartholomew, Deskos, Frantz, Schuch, Lamballais and Laizet2020), which adopts sixth-order compact finite differences for computing spatial derivatives. In the streamwise and spanwise directions, the mesh is homogeneous; in the wall-normal direction stretching is used to refine the mesh towards the wall such that the first node is placed at ![]() $y^{+}=1$. The discretisation parameters for all simulations are given in tables 1 and 2.

$y^{+}=1$. The discretisation parameters for all simulations are given in tables 1 and 2.

Table 1. Grid properties.

Table 2. Metadata of the simulations used for this paper. Abbreviations: NSBC: no-slip boundary condition, SSBC: shear stress boundary condition, SLBC: slip-length boundary condition, ![]() $T$ denotes the averaging time, — means ‘not applicable’.

$T$ denotes the averaging time, — means ‘not applicable’.

All turbulent properties denoted with ![]() $\langle \cdot \rangle$ are averaged along directions of statistical homogeneity, namely the

$\langle \cdot \rangle$ are averaged along directions of statistical homogeneity, namely the ![]() $x$-direction and time, for a time interval given in table 2. Moreover, all available symmetries of the problem are exploited in computing

$x$-direction and time, for a time interval given in table 2. Moreover, all available symmetries of the problem are exploited in computing ![]() $\langle \cdot \rangle$, i.e. the symmetry about the channel centreplane (

$\langle \cdot \rangle$, i.e. the symmetry about the channel centreplane (![]() $y=\delta$) and the statistical periodicity of the flow above the likewise periodic wall boundary condition. Therefore, besides its dependency on

$y=\delta$) and the statistical periodicity of the flow above the likewise periodic wall boundary condition. Therefore, besides its dependency on ![]() $y$,

$y$, ![]() $\langle \cdot \rangle$ depends upon

$\langle \cdot \rangle$ depends upon ![]() $z$ only through the relative position

$z$ only through the relative position ![]() $-1\leq z/s \leq 1$ above the spanwise periodic boundary condition. Additionally,

$-1\leq z/s \leq 1$ above the spanwise periodic boundary condition. Additionally, ![]() $\overline \phi$ denotes quantities that are also averaged in the spanwise direction, e.g.

$\overline \phi$ denotes quantities that are also averaged in the spanwise direction, e.g. ![]() $\bar {u}(y) = \frac {1}{2}\int _{-1}^{1} \langle u \rangle (y, z/s) \,{{\,\mathrm {d}}} (z/s)$.

$\bar {u}(y) = \frac {1}{2}\int _{-1}^{1} \langle u \rangle (y, z/s) \,{{\,\mathrm {d}}} (z/s)$.

The flow is advanced in time with an explicit third-order Runge–Kutta scheme and driven by a constant pressure gradient (CPG), so that the average wall shear stress ![]() $\overline {\tau _w}= \rho \overline {u_\tau }^{2}$, where

$\overline {\tau _w}= \rho \overline {u_\tau }^{2}$, where ![]() $\rho$ is the fluid density and

$\rho$ is the fluid density and ![]() $\overline {u_\tau }$, the average friction velocity, is also prescribed. This amounts to prescribing the friction Reynolds number

$\overline {u_\tau }$, the average friction velocity, is also prescribed. This amounts to prescribing the friction Reynolds number ![]() $Re_\tau = \delta \overline {u_\tau } / \nu$, where

$Re_\tau = \delta \overline {u_\tau } / \nu$, where ![]() $\delta$ is the channel half-height and

$\delta$ is the channel half-height and ![]() $\nu$ the kinematic viscosity of the fluid. Analogous to field quantities, local

$\nu$ the kinematic viscosity of the fluid. Analogous to field quantities, local ![]() $u_\tau$ and local

$u_\tau$ and local ![]() $\tau _w$ are phase averaged and a function of

$\tau _w$ are phase averaged and a function of ![]() $z/s$. The non-dimensionalisation in viscous units, denoted through a

$z/s$. The non-dimensionalisation in viscous units, denoted through a ![]() $+$-sign is based on

$+$-sign is based on ![]() $\overline {u_\tau }$ unless stated otherwise (e.g.

$\overline {u_\tau }$ unless stated otherwise (e.g. ![]() $\langle u\rangle ^{+} = \langle u\rangle / \overline {u_\tau }$).

$\langle u\rangle ^{+} = \langle u\rangle / \overline {u_\tau }$).

2.2. Considered boundary conditions

Two kinds of boundary conditions are employed to model strip-type roughness: a shear stress boundary condition (SSBC) and a slip-length boundary condition (SLBC). As can be seen in figure 1, we consider spanwise alternating strips of width ![]() $s$.

$s$.

The SSBC, already adopted e.g. by Chung, Monty & Ooi (Reference Chung, Monty and Ooi2014); Chung et al. (Reference Chung, Monty and Hutchins2018), prescribes a fixed wall-normal (instantaneous) derivative of the streamwise velocity. Naturally, a high wall shear stress is associated with rough wall regions, while a low wall shear stress represents a smooth wall. The boundary conditions on bottom (![]() $y=0$) and top (

$y=0$) and top (![]() $y=2\delta$) wall are defined by

$y=2\delta$) wall are defined by

where ![]() $\tau _w$ can be varied depending on the spanwise location

$\tau _w$ can be varied depending on the spanwise location ![]() $z$. At both walls impermeability

$z$. At both walls impermeability ![]() $v=0$ holds and a free-slip boundary condition

$v=0$ holds and a free-slip boundary condition ![]() $\partial w / \partial y = 0$ is applied for the spanwise velocity component. We confirm the statement of Chung et al. (Reference Chung, Monty and Hutchins2018) that the alternative use of a no-slip condition for

$\partial w / \partial y = 0$ is applied for the spanwise velocity component. We confirm the statement of Chung et al. (Reference Chung, Monty and Hutchins2018) that the alternative use of a no-slip condition for ![]() $w$ does not significantly affect the results. The spanwise profile of

$w$ does not significantly affect the results. The spanwise profile of ![]() $\tau _w(z)$ is directly imposed with SSBC, thus particular care needs to be taken so that its mean value

$\tau _w(z)$ is directly imposed with SSBC, thus particular care needs to be taken so that its mean value ![]() $\overline {\tau }_w$ matches the prescribed pressure gradient. Since only Neumann boundary conditions are imposed for

$\overline {\tau }_w$ matches the prescribed pressure gradient. Since only Neumann boundary conditions are imposed for ![]() $u$ at the wall, the mean velocity profile becomes undefined up to a constant additive value and so does the flow rate. A unique solution

$u$ at the wall, the mean velocity profile becomes undefined up to a constant additive value and so does the flow rate. A unique solution ![]() $\langle \tilde {u}\rangle (y,z/s)$ is found without losing generality by constraining the flow rate to a constant arbitrary value, chosen here to be zero. Henceforth, the streamwise velocity is plotted relative to the mean velocity at the wall, i.e.

$\langle \tilde {u}\rangle (y,z/s)$ is found without losing generality by constraining the flow rate to a constant arbitrary value, chosen here to be zero. Henceforth, the streamwise velocity is plotted relative to the mean velocity at the wall, i.e. ![]() $\langle u\rangle (y,z/s)= \langle \tilde {u} \rangle (y,z/s) - \bar {\tilde {u}}(y=0)$.

$\langle u\rangle (y,z/s)= \langle \tilde {u} \rangle (y,z/s) - \bar {\tilde {u}}(y=0)$.

A piecewise constant boundary condition with periodicity ![]() $2s$ is considered, as also employed by Chung et al. (Reference Chung, Monty and Hutchins2018). In the present study, we prescribe

$2s$ is considered, as also employed by Chung et al. (Reference Chung, Monty and Hutchins2018). In the present study, we prescribe

i.e. strips of width ![]() $s$, a shear stress ratio of

$s$, a shear stress ratio of ![]() $3$ and where

$3$ and where ![]() $z=0$ is the centre of the low shear stress region. In addition, a sigmoid transition of the patch interfaces between high (

$z=0$ is the centre of the low shear stress region. In addition, a sigmoid transition of the patch interfaces between high (![]() $\tau _h$) and low (

$\tau _h$) and low (![]() $\tau _l$) wall shear stress is defined by

$\tau _l$) wall shear stress is defined by

\begin{equation} \tau_w(z) = \begin{cases} \dfrac{\tau_h - \tau_l}{1+\exp\left(4\dfrac{z - s/2}{\Delta}\right)} + \tau_l, & \text{for } z \in [0, s],\\ \dfrac{\tau_h - \tau_l}{1+\exp\left(4\dfrac{-z - s/2}{\Delta}\right)} + \tau_l, & \text{for } z \in [{-}s, 0), \end{cases} \end{equation}

\begin{equation} \tau_w(z) = \begin{cases} \dfrac{\tau_h - \tau_l}{1+\exp\left(4\dfrac{z - s/2}{\Delta}\right)} + \tau_l, & \text{for } z \in [0, s],\\ \dfrac{\tau_h - \tau_l}{1+\exp\left(4\dfrac{-z - s/2}{\Delta}\right)} + \tau_l, & \text{for } z \in [{-}s, 0), \end{cases} \end{equation}

for ![]() $z \in [-s, s]$; the function may be periodically repeated as needed. This formulation is used to investigate the influence of a gradual change in wall shear stress on the flow. The parameter

$z \in [-s, s]$; the function may be periodically repeated as needed. This formulation is used to investigate the influence of a gradual change in wall shear stress on the flow. The parameter ![]() $\Delta$ describes the transition length, with larger values resulting in a less steep transition between

$\Delta$ describes the transition length, with larger values resulting in a less steep transition between ![]() $\tau _h$ and

$\tau _h$ and ![]() $\tau _l$. For

$\tau _l$. For ![]() $\Delta \rightarrow \infty$, (2.2) is recovered. While the transition function is not differentiable at whole-number multiples of

$\Delta \rightarrow \infty$, (2.2) is recovered. While the transition function is not differentiable at whole-number multiples of ![]() $s$, the exponential decay of the derivatives ensures that this is negligible in a numerical context. When the influence of the prescribed wall shear stress distribution on the obtained results is discussed in the following sections, the actual distribution of

$s$, the exponential decay of the derivatives ensures that this is negligible in a numerical context. When the influence of the prescribed wall shear stress distribution on the obtained results is discussed in the following sections, the actual distribution of ![]() $\tau _w$ is included in the lower part of the corresponding figures for reference, see e.g. figure 3 or figure 7.

$\tau _w$ is included in the lower part of the corresponding figures for reference, see e.g. figure 3 or figure 7.

The SLBC employs a spanwise-varying slip length for the spanwise velocity component as a numerical model for roughness strips. A slip length (Navier Reference Navier1823) relates the wall slip velocity with the wall-normal velocity gradient at the wall. It can be understood as the distance between a virtual wall, where no slip is thought to apply, and the actual wall, which then has a non-zero velocity. For spanwise slip the boundary conditions are given by

where ![]() $l_{s,w}(z)$ denotes the spanwise slip length, which is the quantity that can vary along the spanwise direction. We note that a slip in streamwise direction can be inserted in an analogous way with

$l_{s,w}(z)$ denotes the spanwise slip length, which is the quantity that can vary along the spanwise direction. We note that a slip in streamwise direction can be inserted in an analogous way with ![]() $l_{s,u}$ as streamwise slip length. It was confirmed that the present implementation of the slip lengths reproduces the data presented in Min & Kim (Reference Min and Kim2004).

$l_{s,u}$ as streamwise slip length. It was confirmed that the present implementation of the slip lengths reproduces the data presented in Min & Kim (Reference Min and Kim2004).

Following the suggestion by Luchini (Reference Luchini2013) we employ a spanwise slip length to model the drag increasing effect of small roughness on the turbulent flow field. Especially from research on turbulent drag reduction via riblets, it is established knowledge that the change in drag is related to the difference ![]() $\Delta l = l_{s,u} - l_{s,w}$ between the streamwise and spanwise slip lengths, so that drag is reduced when

$\Delta l = l_{s,u} - l_{s,w}$ between the streamwise and spanwise slip lengths, so that drag is reduced when ![]() $\Delta l$ is positive. In this context, the slip length is typically referred to as the ‘protrusion height’ and

$\Delta l$ is positive. In this context, the slip length is typically referred to as the ‘protrusion height’ and ![]() $\Delta l$ for streamwise and spanwise flow can be used to predict the achievable drag reduction rate for small riblets (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Luchini et al. Reference Luchini, Manzo and Pozzi1991). In contrast, an increase of the spanwise slip length leads to enhanced near-wall turbulence and thus drag increase (Min & Kim Reference Min and Kim2004; Fukagata, Kasagi & Koumoutsakos Reference Fukagata, Kasagi and Koumoutsakos2006; Busse & Sandham Reference Busse and Sandham2012; Gómez-de Segura & García-Mayoral Reference Gómez-de Segura and García-Mayoral2020). In § 5, we employ

$\Delta l$ for streamwise and spanwise flow can be used to predict the achievable drag reduction rate for small riblets (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Luchini et al. Reference Luchini, Manzo and Pozzi1991). In contrast, an increase of the spanwise slip length leads to enhanced near-wall turbulence and thus drag increase (Min & Kim Reference Min and Kim2004; Fukagata, Kasagi & Koumoutsakos Reference Fukagata, Kasagi and Koumoutsakos2006; Busse & Sandham Reference Busse and Sandham2012; Gómez-de Segura & García-Mayoral Reference Gómez-de Segura and García-Mayoral2020). In § 5, we employ ![]() $l_{s,u} = 0$ and

$l_{s,u} = 0$ and ![]() $l_{s,w} > 0$ (and therefore a negative

$l_{s,w} > 0$ (and therefore a negative ![]() $\Delta l$) as a simple model for a rough surface. Standard no-slip

$\Delta l$) as a simple model for a rough surface. Standard no-slip ![]() $(u=0)$ and impermeability (

$(u=0)$ and impermeability (![]() $v=0$) conditions are applied for the streamwise and wall-normal velocity components at both walls. The boundary condition is discussed for a homogeneous rough surface before

$v=0$) conditions are applied for the streamwise and wall-normal velocity components at both walls. The boundary condition is discussed for a homogeneous rough surface before ![]() $l_{s,w} > 0$ is prescribed as a function of

$l_{s,w} > 0$ is prescribed as a function of ![]() $z$ in order to model strip-type roughness. The coordinates are again chosen in such a way that

$z$ in order to model strip-type roughness. The coordinates are again chosen in such a way that ![]() $z=0$ is at the centre of a low shear stress patch which corresponds to a patch with standard no-slip conditions for

$z=0$ is at the centre of a low shear stress patch which corresponds to a patch with standard no-slip conditions for ![]() $w$. The present formulation ensures that the boundary condition does not have any influence on laminar flow conditions but leads to enhanced drag for turbulent flow only. Note that under CPG conditions this drag enhancement corresponds to a reduction of the flow rate. Again, a piecewise constant slip length and a sigmoid transition between patches are considered; the definitions are analogous to (2.2) and (2.3).

$w$. The present formulation ensures that the boundary condition does not have any influence on laminar flow conditions but leads to enhanced drag for turbulent flow only. Note that under CPG conditions this drag enhancement corresponds to a reduction of the flow rate. Again, a piecewise constant slip length and a sigmoid transition between patches are considered; the definitions are analogous to (2.2) and (2.3).

Different from the SSBC, the use of a spanwise slip length to define roughness regions does not cause an undefined flow rate. Therefore, it is possible to evaluate the relative change of the bulk velocity ![]() $U_b$ with respect to a standard no-slip channel at the same pressure gradient. This change in

$U_b$ with respect to a standard no-slip channel at the same pressure gradient. This change in ![]() $U_b$ can be used to evaluate the corresponding overall drag increase through the modification of the skin-friction coefficient

$U_b$ can be used to evaluate the corresponding overall drag increase through the modification of the skin-friction coefficient ![]() $C_f = 2 \overline {u_\tau }^{2}/{U_b}^{2}$.

$C_f = 2 \overline {u_\tau }^{2}/{U_b}^{2}$.

3. Heterogeneous shear-stress boundary condition in laminar flow

In this section, the effect of the SSBC on a fully developed laminar channel flow is addressed in order to verify whether aspects of the occurrence and character of secondary flows are visible in this simplified setting and can be traced back to the properties of the laminar solution. In particular, we will first utilise the laminar solution to assess the effect of the smoothness of the transition between strips of high and low shear stress on the streamwise velocity profile. Then, the emergence of a secondary flow is observed in the linear response of the laminar base profile with SSBC boundary condition to a specific small disturbance.

A laminar, steady, fully developed parallel flow along a channel of constant cross-section is described by the streamwise momentum equation:

where the pressure gradient ![]() ${{\rm d}p}/{{\rm d}x}$ is constant and independent of

${{\rm d}p}/{{\rm d}x}$ is constant and independent of ![]() $y$ and

$y$ and ![]() $z$. Without loss of generality,

$z$. Without loss of generality, ![]() ${{\rm d}p}/{{\rm d}x}=-1$ and

${{\rm d}p}/{{\rm d}x}=-1$ and ![]() $\delta =1$ are assumed. This is a Stokes flow in the two dimensions

$\delta =1$ are assumed. This is a Stokes flow in the two dimensions ![]() $y \in [0, 2\delta ]$ and

$y \in [0, 2\delta ]$ and ![]() $z\in [-\infty, \infty ]$ with

$z\in [-\infty, \infty ]$ with ![]() $2s$-periodicity in

$2s$-periodicity in ![]() $z$.

$z$.

How much the smoothness of the transition region between strips of ![]() $\tau _h$ and

$\tau _h$ and ![]() $\tau _l$ influences the streamwise velocity profile can be easily assessed by exploiting the linearity of (3.1), which allows us to express the Stokes solution as sum of elemental solutions. The periodic SSBC boundary condition can thus be transformed into Fourier space and the Stokes problem can be solved for each separate spanwise wavenumber

$\tau _l$ influences the streamwise velocity profile can be easily assessed by exploiting the linearity of (3.1), which allows us to express the Stokes solution as sum of elemental solutions. The periodic SSBC boundary condition can thus be transformed into Fourier space and the Stokes problem can be solved for each separate spanwise wavenumber ![]() $\kappa$, knowing that high wavenumber content relates to a steep transition.

$\kappa$, knowing that high wavenumber content relates to a steep transition.

We consider an SSBC with piecewise constant shear stress with periodicity ![]() $2s$, i.e.

$2s$, i.e.

Its Fourier transform is given by

\begin{equation} \tau_w(z) = 1 + \frac{2}{\rm \pi} \sum_{n=0}^{\infty} \frac{\sin((2n+1) z\frac{\rm \pi}{s})}{2n+1}, \end{equation}

\begin{equation} \tau_w(z) = 1 + \frac{2}{\rm \pi} \sum_{n=0}^{\infty} \frac{\sin((2n+1) z\frac{\rm \pi}{s})}{2n+1}, \end{equation}which is displayed in figure 2. Thanks to the linearity of equation (3.1), the solution is given as

\begin{equation} u(y, z) ={-} \frac{(y - 1)^{2}}{2} - 2 \sum_{n=0}^{\infty} \frac{\sin(\kappa z) \cosh(\kappa(y - 1))}{s\kappa^{2}\sinh(\kappa)} \end{equation}

\begin{equation} u(y, z) ={-} \frac{(y - 1)^{2}}{2} - 2 \sum_{n=0}^{\infty} \frac{\sin(\kappa z) \cosh(\kappa(y - 1))}{s\kappa^{2}\sinh(\kappa)} \end{equation}

(with ![]() $\kappa = (2n+1) ({{\rm \pi} }/{s})$). It is clearly visible that lower wavenumbers in the boundary condition dominate the solution. In fact, their contribution to the solution scales as

$\kappa = (2n+1) ({{\rm \pi} }/{s})$). It is clearly visible that lower wavenumbers in the boundary condition dominate the solution. In fact, their contribution to the solution scales as ![]() $\kappa ^{-2}$ at the wall and as

$\kappa ^{-2}$ at the wall and as ![]() $\kappa ^{-2} \exp (-\kappa )$ at the centreline. This means that higher wavenumbers not only contribute less to the solution, but that their contribution is limited to a thinner and thinner layer in the vicinity of the wall. Therefore, we can conclude that the details of the transition region for a given patch size play a secondary role in determining the flow solution, particularly farther from the wall, since these details are contained only in the high wavenumber part of the spectrum.

$\kappa ^{-2} \exp (-\kappa )$ at the centreline. This means that higher wavenumbers not only contribute less to the solution, but that their contribution is limited to a thinner and thinner layer in the vicinity of the wall. Therefore, we can conclude that the details of the transition region for a given patch size play a secondary role in determining the flow solution, particularly farther from the wall, since these details are contained only in the high wavenumber part of the spectrum.

The solution of (3.4) also indicates that increasing the patch size ![]() $s$, which corresponds to a decrease of the lowest allowed wavenumber for

$s$, which corresponds to a decrease of the lowest allowed wavenumber for ![]() $n=0$, yields an overall larger velocity difference between the regions of high and low wall shear stress. In the

$n=0$, yields an overall larger velocity difference between the regions of high and low wall shear stress. In the ![]() $s \rightarrow \infty$ limit, the parabolic velocity profile is recovered everywhere; while the absolute values of the velocity tend to

$s \rightarrow \infty$ limit, the parabolic velocity profile is recovered everywhere; while the absolute values of the velocity tend to ![]() $\pm \infty$.

$\pm \infty$.

The first two main results of this section are visualised in figure 3, which shows the solution of the Stokes problem for different transition functions at different patch sizes. (The spanwise coordinate of the figure has been translated to match the remaining figures of this paper.) First, it can be seen that the spanwise inhomogeneous boundary condition affects the longitudinal flow in the channel centre for large patch sizes only, here, ![]() $s/\delta =1$ (i.e. larger base wavelengths). For

$s/\delta =1$ (i.e. larger base wavelengths). For ![]() $s/\delta =0.25$ the depicted isolines of

$s/\delta =0.25$ the depicted isolines of ![]() $u$ (referred to as isovels in the following) do not reveal any variation in spanwise direction for

$u$ (referred to as isovels in the following) do not reveal any variation in spanwise direction for ![]() $y/\delta > 0.2$. With increasing strip width, the presence of HMP over the low stress region thus becomes more pronounced and is present up to larger wall distances. In addition, figure 3 includes results generated with either a sharp (solid black lines, (2.2)) or a smooth transition (dashed red lines, (2.3)) from high stress to low stress in the boundary condition. It is clearly visible that these different boundary conditions have only minor influence on the resulting momentum distribution under laminar flow conditions.

$y/\delta > 0.2$. With increasing strip width, the presence of HMP over the low stress region thus becomes more pronounced and is present up to larger wall distances. In addition, figure 3 includes results generated with either a sharp (solid black lines, (2.2)) or a smooth transition (dashed red lines, (2.3)) from high stress to low stress in the boundary condition. It is clearly visible that these different boundary conditions have only minor influence on the resulting momentum distribution under laminar flow conditions.

Figure 3. Isolines of the laminar streamwise velocity for (a) ![]() $s/\delta =0.25$ and (b)

$s/\delta =0.25$ and (b) ![]() $s/\delta =1$ for

$s/\delta =1$ for ![]() $\tau _h = 3 \tau _l$. The colour code refers to different transitions between

$\tau _h = 3 \tau _l$. The colour code refers to different transitions between ![]() $\tau _h$ and

$\tau _h$ and ![]() $\tau _l$: stepwise (solid black lines) and sigmoid with

$\tau _l$: stepwise (solid black lines) and sigmoid with ![]() $\Delta /s = 0.5$ (dashed red lines). The upper part of the figure shows equidistant isolines (in arbitrary units), the lower part depicts the prescribed spanwise distribution of

$\Delta /s = 0.5$ (dashed red lines). The upper part of the figure shows equidistant isolines (in arbitrary units), the lower part depicts the prescribed spanwise distribution of ![]() $\tau _w$.

$\tau _w$.

In the following, the linear response of a laminar flow to infinitesimal perturbations is studied at ![]() $Re_\tau =180$ with SSBC boundary condition

$Re_\tau =180$ with SSBC boundary condition ![]() $\tau _h / \tau _l=3$ and

$\tau _h / \tau _l=3$ and ![]() $s/\delta =1$. The intention of this numerical experiment is to assess whether the linear response to such perturbation contains features that resemble the secondary flows which occur for the same boundary conditions and turbulent flow. A comprehensive analysis of the linear transient growth of optimal perturbations (Schmid & Henningson Reference Schmid and Henningson2001) is out of the scope of the present manuscript. Instead, we limit the consideration to a simple class of perturbations, which represents an extremely simplified model of spanwise velocity fluctuations as they may occur in the vicinity of a wall of a turbulent channel. An initial perturbation is added to the streamwise base flow

$s/\delta =1$. The intention of this numerical experiment is to assess whether the linear response to such perturbation contains features that resemble the secondary flows which occur for the same boundary conditions and turbulent flow. A comprehensive analysis of the linear transient growth of optimal perturbations (Schmid & Henningson Reference Schmid and Henningson2001) is out of the scope of the present manuscript. Instead, we limit the consideration to a simple class of perturbations, which represents an extremely simplified model of spanwise velocity fluctuations as they may occur in the vicinity of a wall of a turbulent channel. An initial perturbation is added to the streamwise base flow ![]() $u(y,z)$ defined by (3.4) and shown in figure 3(b). This spanwise-homogeneous initial perturbation is prescribed as a spanwise velocity of the form

$u(y,z)$ defined by (3.4) and shown in figure 3(b). This spanwise-homogeneous initial perturbation is prescribed as a spanwise velocity of the form

where ![]() $c = 10^{-10}$ is a constant determining the amplitude of the perturbation, while

$c = 10^{-10}$ is a constant determining the amplitude of the perturbation, while ![]() $w_x(x)$ and

$w_x(x)$ and ![]() $w_y(y)$ are streamwise and spanwise shape functions, respectively. These are defined as

$w_y(y)$ are streamwise and spanwise shape functions, respectively. These are defined as

$$\begin{gather} w_x(x) = (x/\delta-\mu_x) \exp\left({-\frac{(x/\delta-\mu_x)^{2}}{2\sigma_x^{2}}}\right), \nonumber\\ w_y(y) = \frac{1}{y/\delta} \sigma_y \sqrt{2{\rm \pi}} \exp\Bigg({-\frac{(\ln(1 - |y/\delta-1|)-\mu_y)^{2}}{2\sigma_y^{2}}}\Bigg), \end{gather}$$

$$\begin{gather} w_x(x) = (x/\delta-\mu_x) \exp\left({-\frac{(x/\delta-\mu_x)^{2}}{2\sigma_x^{2}}}\right), \nonumber\\ w_y(y) = \frac{1}{y/\delta} \sigma_y \sqrt{2{\rm \pi}} \exp\Bigg({-\frac{(\ln(1 - |y/\delta-1|)-\mu_y)^{2}}{2\sigma_y^{2}}}\Bigg), \end{gather}$$

which resemble a normal and a log-normal distribution, respectively, so that the disturbance is localised in space, has zero streamwise average ![]() $\langle w\rangle _x$, is symmetric about the channel centre and fulfils the boundary conditions. The coefficients in (3.6a,b) are

$\langle w\rangle _x$, is symmetric about the channel centre and fulfils the boundary conditions. The coefficients in (3.6a,b) are ![]() $\mu _x=4\delta$,

$\mu _x=4\delta$, ![]() $\sigma _x= \sigma _y=0.2$ and

$\sigma _x= \sigma _y=0.2$ and ![]() $\mu _y=\ln (0.08)+\sigma _y^{2}$, i.e. the disturbance is centred about

$\mu _y=\ln (0.08)+\sigma _y^{2}$, i.e. the disturbance is centred about ![]() $x/ \delta =4$ and

$x/ \delta =4$ and ![]() $y/\delta = 0.08$. These parameters result in the initial disturbance distribution shown in figure 4.

$y/\delta = 0.08$. These parameters result in the initial disturbance distribution shown in figure 4.

Figure 4. (a) Initial disturbance and its shape functions. (b) Temporal evolution of the initial disturbance at ![]() $t=0$,

$t=0$, ![]() $tu_\tau /\delta =0.0127$ and

$tu_\tau /\delta =0.0127$ and ![]() $tu_\tau /\delta =0.0254$; isosurfaces of

$tu_\tau /\delta =0.0254$; isosurfaces of ![]() $w = \text {const.} = 1/4 \max (w(x,y,t=0))$. The isosurfaces are displayed as viewed by an observer moving with constant

$w = \text {const.} = 1/4 \max (w(x,y,t=0))$. The isosurfaces are displayed as viewed by an observer moving with constant ![]() $x$ velocity to avoid overlap.

$x$ velocity to avoid overlap.

Applied to a flow with homogeneous wall boundary condition, for which the mean velocity profile is ![]() $u=u(y)$, the initial disturbance would only be sheared apart due to the effect of mean shear

$u=u(y)$, the initial disturbance would only be sheared apart due to the effect of mean shear ![]() $\mathrm {d} u / \mathrm {d}y$ while retaining the spanwise homogeneity, and eventually vanish by viscosity without the generation of additional velocity components. On the other hand, the spanwise inhomogeneity of the velocity profile

$\mathrm {d} u / \mathrm {d}y$ while retaining the spanwise homogeneity, and eventually vanish by viscosity without the generation of additional velocity components. On the other hand, the spanwise inhomogeneity of the velocity profile ![]() $u=u(y,z)$ over the SSBC strips will deform the original spanwise alignment of the disturbance, since its convection speed will generally be larger in region of

$u=u(y,z)$ over the SSBC strips will deform the original spanwise alignment of the disturbance, since its convection speed will generally be larger in region of ![]() $\tau _l$, as shown in figure 4(b). The loss of spanwise homogeneity, which is largest across the interface between strips, causes

$\tau _l$, as shown in figure 4(b). The loss of spanwise homogeneity, which is largest across the interface between strips, causes ![]() $\partial w / \partial z$ to become non-zero and thus implies the generation of further velocity components via continuity and yields a linear exponential growth of the disturbance. The linearity has been tested by progressive reduction of the

$\partial w / \partial z$ to become non-zero and thus implies the generation of further velocity components via continuity and yields a linear exponential growth of the disturbance. The linearity has been tested by progressive reduction of the ![]() $c$ constant, which showed an invariant solution once rescaled with the norm of the initial disturbance. If the flow is averaged in the streamwise direction during this exponential growth phase, the velocity field (shown in figure 5) exhibits non-zero streamwise-average velocity components

$c$ constant, which showed an invariant solution once rescaled with the norm of the initial disturbance. If the flow is averaged in the streamwise direction during this exponential growth phase, the velocity field (shown in figure 5) exhibits non-zero streamwise-average velocity components ![]() $\langle v \rangle$ and

$\langle v \rangle$ and ![]() $\langle w \rangle$ compatible with the secondary flows occurring in a turbulent channel. Region of upwelling motions are located above strips of

$\langle w \rangle$ compatible with the secondary flows occurring in a turbulent channel. Region of upwelling motions are located above strips of ![]() $\tau _l$, while downwelling fluid is found over regions of

$\tau _l$, while downwelling fluid is found over regions of ![]() $\tau _h$. This mechanism, that involves the shearing of spanwise velocity fluctuations and the consequent effect of continuity, is likely to occur also in fully developed turbulent channel flows and to be a contributor to the generation of secondary motions above strips of SSBC, as it will be discussed also in § 4. Qualitatively similar results are achieved for a number of different disturbances (not shown here), such as different wall-normal locations, asymmetric shape functions

$\tau _h$. This mechanism, that involves the shearing of spanwise velocity fluctuations and the consequent effect of continuity, is likely to occur also in fully developed turbulent channel flows and to be a contributor to the generation of secondary motions above strips of SSBC, as it will be discussed also in § 4. Qualitatively similar results are achieved for a number of different disturbances (not shown here), such as different wall-normal locations, asymmetric shape functions ![]() $w_y(x)$ or non-zero streamwise mean

$w_y(x)$ or non-zero streamwise mean ![]() $\langle w(x)\rangle _x$. The result also generalises to other spanwise wavelengths

$\langle w(x)\rangle _x$. The result also generalises to other spanwise wavelengths ![]() $s$.

$s$.

Figure 5. The dominant mode after ![]() $tu_\tau /\delta =1.27$, the pointwise cross-stream velocity of this mode grows exponentially.

$tu_\tau /\delta =1.27$, the pointwise cross-stream velocity of this mode grows exponentially.

4. Heterogeneous SSBC in turbulent flow

We now employ the same SSBC as used in § 3 to a turbulent channel flow. The SSBC with the sharp jump from low to high stress values corresponds to the configuration studied by Chung et al. (Reference Chung, Monty and Hutchins2018). The main results of that study have been replicated and are discussed in comparison with the laminar result of the previous section in the following.

In contrast to the unperturbed laminar flow conditions, a vortical secondary flow is observed for turbulent flow conditions after averaging the resulting instantaneous velocity fields in time, streamwise direction and phase. This vortical motion induces downwelling over the patches with high shear stress and upwelling over patches with low shear stress. The corresponding results are visualised in figure 6(a) for ![]() $s/\delta = 1$. The secondary flow resembles the large-scale flow structures generated in the perturbed laminar flow at the same

$s/\delta = 1$. The secondary flow resembles the large-scale flow structures generated in the perturbed laminar flow at the same ![]() $s/\delta$ (cf. figure 5)

$s/\delta$ (cf. figure 5)

Figure 6. (a,c) Time- and phase-averaged streamwise velocity contours in the channel cross-section, centred on the low shear stress region, for (a,b) ![]() $s/\delta =1$ and (c,d)

$s/\delta =1$ and (c,d) ![]() $s/\delta =4$. Here

$s/\delta =4$. Here ![]() $\tau _h = 3 \tau _l$,

$\tau _h = 3 \tau _l$, ![]() ${Re}_{\tau } = 180$, piecewise constant shear stress. The secondary flow

${Re}_{\tau } = 180$, piecewise constant shear stress. The secondary flow ![]() $[\langle v \rangle, \langle w \rangle ] / \overline {u_\tau }$ in the plane is indicated with streamlines, with equally scaled width among the plots. (b,d) In-plane Reynolds stress

$[\langle v \rangle, \langle w \rangle ] / \overline {u_\tau }$ in the plane is indicated with streamlines, with equally scaled width among the plots. (b,d) In-plane Reynolds stress ![]() $\langle v'w' \rangle ^{+}$.

$\langle v'w' \rangle ^{+}$.

Opposite to the unperturbed laminar flow, a HMP is present over the high stress (rough) region, whereas a LMP is found over the low stress (smooth) region. For larger ![]() $s/\delta$, a different distribution of streamwise mean velocity is found, as can be seen in figure 6(c). The secondary motion has the same rotational direction as in the case of

$s/\delta$, a different distribution of streamwise mean velocity is found, as can be seen in figure 6(c). The secondary motion has the same rotational direction as in the case of ![]() $s/\delta = 1$. However, the flow conditions at the channel centreline reveal a HMP over the low stress region and a LMP over the high stress region. In particular, above the high stress region the downward motion of the secondary flow is located in a clearly pronounced LMP visualised through upward bulging isovels (isolines of longitudinal mean velocity).

$s/\delta = 1$. However, the flow conditions at the channel centreline reveal a HMP over the low stress region and a LMP over the high stress region. In particular, above the high stress region the downward motion of the secondary flow is located in a clearly pronounced LMP visualised through upward bulging isovels (isolines of longitudinal mean velocity).

Comparing the bulging of isovels between unperturbed laminar and turbulent flow conditions at the same ![]() $s/\delta =1$ (cf. figures 3b and 6a) reveals that the location of HMP and LMP differs between laminar and turbulent flow conditions, the difference obviously being caused by the secondary flow. In turbulent flow with heterogeneous SSBC, the secondary flow motion counteracts the tendency of the longitudinal flow to follow the path of lower resistance. This results in the flow phenomenon that the turbulent flow rate above the low stress (smooth) surface patches is smaller than the one over high stress (rough) patches, which is in agreement with the original experimental results by Hinze (Reference Hinze1967). The consideration of Hinze (Reference Hinze1967, Reference Hinze1973), that local overproduction of turbulent kinetic energy (TKE) is linked to the presence of secondary motions, also holds true for the present data. In the near-wall region the secondary motion carries fluid from high TKE regions (above the ‘rough’ patches) to low TKE ones.

$s/\delta =1$ (cf. figures 3b and 6a) reveals that the location of HMP and LMP differs between laminar and turbulent flow conditions, the difference obviously being caused by the secondary flow. In turbulent flow with heterogeneous SSBC, the secondary flow motion counteracts the tendency of the longitudinal flow to follow the path of lower resistance. This results in the flow phenomenon that the turbulent flow rate above the low stress (smooth) surface patches is smaller than the one over high stress (rough) patches, which is in agreement with the original experimental results by Hinze (Reference Hinze1967). The consideration of Hinze (Reference Hinze1967, Reference Hinze1973), that local overproduction of turbulent kinetic energy (TKE) is linked to the presence of secondary motions, also holds true for the present data. In the near-wall region the secondary motion carries fluid from high TKE regions (above the ‘rough’ patches) to low TKE ones.

For the present case of SSBC with ![]() $s/\delta =1$ (figure 6a), the downward bulging isovels of the laminar flow (figure 3b) are straightened by the secondary flow near the wall (

$s/\delta =1$ (figure 6a), the downward bulging isovels of the laminar flow (figure 3b) are straightened by the secondary flow near the wall (![]() $z=0, y/\delta \approx 0.05$) while the bulging direction is reversed at larger wall distance (

$z=0, y/\delta \approx 0.05$) while the bulging direction is reversed at larger wall distance (![]() $z=0, y/\delta \approx 0.2$). In the direct vicinity of the wall the distribution of the mean streamwise velocity is prescribed by the boundary condition, such that lower streamwise velocity prevails above the high shear region, similar to the laminar case (see zoomed in region of figure 6a). For larger

$z=0, y/\delta \approx 0.2$). In the direct vicinity of the wall the distribution of the mean streamwise velocity is prescribed by the boundary condition, such that lower streamwise velocity prevails above the high shear region, similar to the laminar case (see zoomed in region of figure 6a). For larger ![]() $s/\delta$, the secondary flow also counteracts the laminar velocity distribution, but its visible impact is limited to a central region above the low shear stress strip. The upwelling in this region induces a local HMP above the intersection between high and low shear stress clearly visible around

$s/\delta$, the secondary flow also counteracts the laminar velocity distribution, but its visible impact is limited to a central region above the low shear stress strip. The upwelling in this region induces a local HMP above the intersection between high and low shear stress clearly visible around ![]() $y/\delta \approx 0.6$,

$y/\delta \approx 0.6$, ![]() $z/s\approx \pm 0.4$ in figure 6(c). Note that the isovels are very dense directly above the high shear stress region, indicating the anticipated large velocity gradients. As a direct consequence of the SSBC (see § 3), the simulations produce artificially large wall velocity differences where the difference

$z/s\approx \pm 0.4$ in figure 6(c). Note that the isovels are very dense directly above the high shear stress region, indicating the anticipated large velocity gradients. As a direct consequence of the SSBC (see § 3), the simulations produce artificially large wall velocity differences where the difference ![]() $\langle u \rangle (y=0, z=0) - \langle u \rangle (y=0, z=-s)$ between patches increases with

$\langle u \rangle (y=0, z=0) - \langle u \rangle (y=0, z=-s)$ between patches increases with ![]() $s$. For

$s$. For ![]() $s/\delta = 4$, this difference is approximately

$s/\delta = 4$, this difference is approximately ![]() $10.9 \overline {u_\tau }$; for

$10.9 \overline {u_\tau }$; for ![]() $s/\delta =8$ it increases to

$s/\delta =8$ it increases to ![]() $20.8 \overline {u_\tau }$ and is thus larger than the bulk mean velocity in a standard turbulent channel flow at the same

$20.8 \overline {u_\tau }$ and is thus larger than the bulk mean velocity in a standard turbulent channel flow at the same ![]() ${Re}_\tau$. It is thus not surprising that the secondary flow is not able to invert the isovel bulging for large strip widths. As noted before, the reference velocity in the figure is chosen such that

${Re}_\tau$. It is thus not surprising that the secondary flow is not able to invert the isovel bulging for large strip widths. As noted before, the reference velocity in the figure is chosen such that ![]() $\bar {u}(0)=0$. Therefore, the colour scale for

$\bar {u}(0)=0$. Therefore, the colour scale for ![]() $(\langle u \rangle - \langle u \rangle (0))/\overline {u_\tau }$ in figure 6 contains negative values. Those are limited to the direct vicinity of the high shear stress region and can thus only be identified in the enlargement provided for figure 6(a).

$(\langle u \rangle - \langle u \rangle (0))/\overline {u_\tau }$ in figure 6 contains negative values. Those are limited to the direct vicinity of the high shear stress region and can thus only be identified in the enlargement provided for figure 6(a).

It is interesting to note that, contrary to turbulent secondary flows in non-circular ducts (or as observed over streamwise ridges), the secondary motions obtained with SSBC do not enhance but counteract the local curvature of the isolines of the streamwise velocity of the corresponding laminar flow. A possible explanation of this observation might be the mechanism described in § 3, where it was shown that near-wall spanwise perturbations in the laminar base flow with spanwise gradients of the (streamwise) velocity can induce large-scale vortical motions even in a linearised setting. This suggests that the secondary flow structures might not require the existence of the complex nonlinear scale interaction of turbulent flows for their initial generation.

The cross-stream motion is oriented from the high to the low shear stress region near the wall. Under laminar flow conditions these regions correspond to low and high streamwise velocity, respectively (see figure 3b). The turbulent secondary motion is thus expected to reduce the spanwise gradients of ![]() $\langle u \rangle$ near the wall compared with the laminar case, as indicated by the straightened isovels in this region. The related redistribution of streamwise momentum can induce a reversal of the isovel curvature (in the turbulent flow compared with its laminar counterpart) at larger wall distance (

$\langle u \rangle$ near the wall compared with the laminar case, as indicated by the straightened isovels in this region. The related redistribution of streamwise momentum can induce a reversal of the isovel curvature (in the turbulent flow compared with its laminar counterpart) at larger wall distance (![]() $y/\delta >0.5$) as observed for

$y/\delta >0.5$) as observed for ![]() $s/\delta = 1$ and above the low shear stress region for

$s/\delta = 1$ and above the low shear stress region for ![]() $s/\delta = 4$.

$s/\delta = 4$.

Secondary motions above roughness strips are usually categorised as secondary motions of Prandtl's second kind (Wang & Cheng Reference Wang and Cheng2006). In the following, we discuss to which extent the secondary motions in turbulent flow over SSBC are in agreement with the original descriptions by Prandtl for this flow phenomenon. The driving mechanism of turbulent secondary flows originally proposed by Prandtl (Reference Prandtl1926) is based on the hypothesis that turbulent velocity fluctuations along isovels are larger than normal to their orientation. For isovels with inclined orientation in the present coordinate system, this suggests the presence of a correlation between ![]() $v$ and

$v$ and ![]() $w$. For curved isovels, this motion along the isovel induces forces directed to the convex side of the isovels. These forces, which are only present under turbulent flow conditions, increase with increasing curvature and induce a net transport of mean streamwise momentum (Prandtl Reference Prandtl1926).

$w$. For curved isovels, this motion along the isovel induces forces directed to the convex side of the isovels. These forces, which are only present under turbulent flow conditions, increase with increasing curvature and induce a net transport of mean streamwise momentum (Prandtl Reference Prandtl1926).

Figure 6(b,d) shows the spatial distribution of ![]() $\langle v'w' \rangle$ for

$\langle v'w' \rangle$ for ![]() $s/\delta =1$ and

$s/\delta =1$ and ![]() $s/\delta =4$. Indeed, the correlation of

$s/\delta =4$. Indeed, the correlation of ![]() $v$ and

$v$ and ![]() $w$ fluctuations is overall in very good agreement with the direction of the isovels depicted in figure 6(a,c). The enlargement provided for the near-wall region around the step change in boundary condition for figure 6(a) allows us to better identify the local isovel shape near the wall. In both cases a negative slope of the isoline corresponds to

$w$ fluctuations is overall in very good agreement with the direction of the isovels depicted in figure 6(a,c). The enlargement provided for the near-wall region around the step change in boundary condition for figure 6(a) allows us to better identify the local isovel shape near the wall. In both cases a negative slope of the isoline corresponds to ![]() $\langle v'w' \rangle <0$, i.e. a negative correlation between

$\langle v'w' \rangle <0$, i.e. a negative correlation between ![]() $v'$ and

$v'$ and ![]() $w'$, and vice versa. The hypothesis of Prandtl that in-plane velocity fluctuations are largest along isovels is thus confirmed for the present data. Also, the isovel curvature largely agrees with the direction of the secondary motion. However, we note that the distribution of

$w'$, and vice versa. The hypothesis of Prandtl that in-plane velocity fluctuations are largest along isovels is thus confirmed for the present data. Also, the isovel curvature largely agrees with the direction of the secondary motion. However, we note that the distribution of ![]() $\langle v'w' \rangle$ is not in qualitative agreement with the one observed in DNS of immersed boundary method (IBM) resolved roughness strips (see figure 8 of Schäfer et al. (Reference Schäfer, Stroh, Forooghi and Frohnapfel2022) and the Appendix). We will return to the discussion of

$\langle v'w' \rangle$ is not in qualitative agreement with the one observed in DNS of immersed boundary method (IBM) resolved roughness strips (see figure 8 of Schäfer et al. (Reference Schäfer, Stroh, Forooghi and Frohnapfel2022) and the Appendix). We will return to the discussion of ![]() $\langle v'w' \rangle$ in comparison with the SLBC in § 5.2.

$\langle v'w' \rangle$ in comparison with the SLBC in § 5.2.

Finally, we address the influence of gradual vs sudden transition of the boundary condition for turbulent flow. It was shown in § 3 that a gradual instead of a step-change transition between high and low stress regions does not alter the laminar flow field except for the very near-wall region. Figure 7 shows a ![]() $y$–

$y$–![]() $z$ cross-section of the phase-averaged mean flow quantities for turbulent flow conditions at

$z$ cross-section of the phase-averaged mean flow quantities for turbulent flow conditions at ![]() $s/\delta =1$ and different sigmoid transitions. For

$s/\delta =1$ and different sigmoid transitions. For ![]() $\Delta /s=1/{16}, 1/8, 1/4$, a very similar secondary flow to the case of the piecewise constant reference case is observed. The secondary flow magnitude is slightly reduced for gradual wall shear stress changes. This also reflects in the bulging of the isovels, which are shown in direct comparison for

$\Delta /s=1/{16}, 1/8, 1/4$, a very similar secondary flow to the case of the piecewise constant reference case is observed. The secondary flow magnitude is slightly reduced for gradual wall shear stress changes. This also reflects in the bulging of the isovels, which are shown in direct comparison for ![]() $\Delta /s=0$ and

$\Delta /s=0$ and ![]() $\Delta /s={1}/{4}$ for strip width

$\Delta /s={1}/{4}$ for strip width ![]() $s/\delta =1$ and

$s/\delta =1$ and ![]() $s/\delta =4$ in figure 8. The dashed red line corresponds to the gradual change in the boundary condition. This sigmoid transition apparently leads to a slightly reduced spanwise inhomogeneity of the mean flow field, especially visible for

$s/\delta =4$ in figure 8. The dashed red line corresponds to the gradual change in the boundary condition. This sigmoid transition apparently leads to a slightly reduced spanwise inhomogeneity of the mean flow field, especially visible for ![]() $s/\delta =4$, which is in agreement with the presence of a slightly weaker secondary motion. However, the overall impact of the gradual change in boundary condition is very small.

$s/\delta =4$, which is in agreement with the presence of a slightly weaker secondary motion. However, the overall impact of the gradual change in boundary condition is very small.

Figure 7. Time- and phase-averaged streamwise velocity contours in the channel cross-section, centred on the low shear stress region, for the different transitions with ![]() $\tau _h = 3 \tau _l$,

$\tau _h = 3 \tau _l$, ![]() ${Re}_{\tau } = 180$ and

${Re}_{\tau } = 180$ and ![]() $s/\delta =1$. The secondary flow

$s/\delta =1$. The secondary flow ![]() $[\langle v \rangle, \langle w \rangle ] / \overline {u_\tau }$ in the plane is indicated with vectors, with equally scaled length among the plots. The prescribed wall shear stress as a function of the spanwise coordinate

$[\langle v \rangle, \langle w \rangle ] / \overline {u_\tau }$ in the plane is indicated with vectors, with equally scaled length among the plots. The prescribed wall shear stress as a function of the spanwise coordinate ![]() $z$ is shown below each panel; (a)

$z$ is shown below each panel; (a) ![]() $\Delta /s = 0$, (b)

$\Delta /s = 0$, (b) ![]() $\Delta /s = 1/16$, (c)

$\Delta /s = 1/16$, (c) ![]() $\Delta /s = 1/8$, (d)

$\Delta /s = 1/8$, (d) ![]() $\Delta /s = 1/4$.

$\Delta /s = 1/4$.

Figure 8. Isolines of the time- and phase-averaged streamwise velocity for (a) ![]() $s/\delta =1$ and (b)

$s/\delta =1$ and (b) ![]() $s/\delta =4$ at

$s/\delta =4$ at ![]() $\tau _h = 3 \tau _l$. The colour code refers to different transitions between

$\tau _h = 3 \tau _l$. The colour code refers to different transitions between ![]() $\tau _h$ and

$\tau _h$ and ![]() $\tau _l$: stepwise (solid black lines) and sigmoid with

$\tau _l$: stepwise (solid black lines) and sigmoid with ![]() $\Delta /s = 1/4$ (dashed red lines).

$\Delta /s = 1/4$ (dashed red lines).

5. Spanwise slip-length boundary condition in turbulent flow

5.1. Modelling homogeneous roughness

As introduced in § 2.2, we employ a transversal slip length to model the effect of a rough surface on a turbulent flow field. It has been established that a transversal slip increases near-wall turbulence and thus skin-friction drag; while a longitudinal slip leads to drag reduction (Min & Kim Reference Min and Kim2004). Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006) and Busse & Sandham (Reference Busse and Sandham2012) suggested a relation between the dimensionless spanwise slip length and the resulting drag increase. Assuming only minor modifications to the shape of the turbulent velocity profile due to the imposed boundary condition, the corresponding reduction of ![]() $U_b^{+}$ can be translated into the Hama roughness function

$U_b^{+}$ can be translated into the Hama roughness function ![]() $\Delta U^{+}$, which is widely used to characterise turbulent flow over rough surfaces. Figure 9(a) shows the correlation proposed by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006) translated into

$\Delta U^{+}$, which is widely used to characterise turbulent flow over rough surfaces. Figure 9(a) shows the correlation proposed by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006) translated into ![]() $\Delta U^{+}$ for the present CPG conditions in comparison with simulation results. They are in excellent agreement. As noted by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006), the observed changes in

$\Delta U^{+}$ for the present CPG conditions in comparison with simulation results. They are in excellent agreement. As noted by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006), the observed changes in ![]() $\Delta U^{+}$ are almost independent of Reynolds number, which we confirmed with additional simulations at

$\Delta U^{+}$ are almost independent of Reynolds number, which we confirmed with additional simulations at ![]() $Re_\tau =540$ (not shown here). For a rough surface,

$Re_\tau =540$ (not shown here). For a rough surface, ![]() $\Delta U^{+}$ is expected to increase with Reynolds number. Therefore, it should be noted that simulations with constant

$\Delta U^{+}$ is expected to increase with Reynolds number. Therefore, it should be noted that simulations with constant ![]() $l_s^{+}$ at different Reynolds number do not mimic the Reynolds number dependence of real rough surfaces. For such a study the prescription of a Reynolds number dependent

$l_s^{+}$ at different Reynolds number do not mimic the Reynolds number dependence of real rough surfaces. For such a study the prescription of a Reynolds number dependent ![]() $l_{s,w}^{+}$ would be required. In figure 9(a) it can be seen that the relationship between

$l_{s,w}^{+}$ would be required. In figure 9(a) it can be seen that the relationship between ![]() $\Delta U^{+}$ and the spanwise slip length is nonlinear. This saturation effect was previously reported by Gómez-de Segura & García-Mayoral (Reference Gómez-de Segura and García-Mayoral2020) and is in agreement with the finding of Luchini (Reference Luchini2013) that this type of boundary condition is suited for the representation of small roughness only. Nevertheless, a roughness function of the present order of magnitude corresponds to a significant drag increase. The related increase of

$\Delta U^{+}$ and the spanwise slip length is nonlinear. This saturation effect was previously reported by Gómez-de Segura & García-Mayoral (Reference Gómez-de Segura and García-Mayoral2020) and is in agreement with the finding of Luchini (Reference Luchini2013) that this type of boundary condition is suited for the representation of small roughness only. Nevertheless, a roughness function of the present order of magnitude corresponds to a significant drag increase. The related increase of ![]() $C_f$ under CPG conditions is of the order of

$C_f$ under CPG conditions is of the order of ![]() $50\,\%$ for

$50\,\%$ for ![]() $l_{s,w}^{+} \approx 10$ (

$l_{s,w}^{+} \approx 10$ (![]() $\Delta U^{+} \approx 3$) at

$\Delta U^{+} \approx 3$) at ![]() $Re_\tau =180$, as shown in figure 9(b). An increase in Reynolds number leads to a smaller change in skin-friction drag coefficient for a fixed

$Re_\tau =180$, as shown in figure 9(b). An increase in Reynolds number leads to a smaller change in skin-friction drag coefficient for a fixed ![]() $\Delta U^{+}$, as discussed by Gatti & Quadrio (Reference Gatti and Quadrio2016). This is confirmed for the present boundary condition at

$\Delta U^{+}$, as discussed by Gatti & Quadrio (Reference Gatti and Quadrio2016). This is confirmed for the present boundary condition at ![]() $Re_\tau =540$ where

$Re_\tau =540$ where ![]() $l_{s,w}^{+} \approx 10$ corresponds to a drag increase of approximately

$l_{s,w}^{+} \approx 10$ corresponds to a drag increase of approximately ![]() $45\,\%$.

$45\,\%$.

Figure 9. (a) Relative velocity deficit ![]() $\Delta U^{+} = \langle u \rangle ^{+}|_\delta - \langle u \rangle ^{+}|_{\delta,{NSBC}}$ for

$\Delta U^{+} = \langle u \rangle ^{+}|_\delta - \langle u \rangle ^{+}|_{\delta,{NSBC}}$ for ![]() ${Re}_\tau =180$ and (solid line) Relationship suggested by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006), adapted. (b) Relative change in skin-friction coefficient

${Re}_\tau =180$ and (solid line) Relationship suggested by Fukagata et al. (Reference Fukagata, Kasagi and Koumoutsakos2006), adapted. (b) Relative change in skin-friction coefficient ![]() $C_f$ compared with the no-slip reference case (denoted by index 0) at the same

$C_f$ compared with the no-slip reference case (denoted by index 0) at the same ![]() $Re_\tau$ evaluated for

$Re_\tau$ evaluated for ![]() $Re_\tau =180$ and

$Re_\tau =180$ and ![]() $Re_\tau =540$.

$Re_\tau =540$.

The prescription of a spanwise slip length can thus reproduce the mean velocity profile of a turbulent flow over rough surfaces with roughness functions of the order of ![]() $\Delta U^{+} < 4$ (Fukagata et al. Reference Fukagata, Kasagi and Koumoutsakos2006). We note that the spanwise slip length has no direct relation to the roughness topography and cannot reproduce the specific flow signatures of a roughness sublayer (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is also the case for other roughness models employed in DNS, see e.g. Busse & Sandham (Reference Busse and Sandham2012). While a SLBC based roughness model has the advantage of replicating the roughness effect of not influencing the drag of laminar flows, the model requires a priori knowledge about the main flow direction as slip is prescribed for the transversal velocity component only.

$\Delta U^{+} < 4$ (Fukagata et al. Reference Fukagata, Kasagi and Koumoutsakos2006). We note that the spanwise slip length has no direct relation to the roughness topography and cannot reproduce the specific flow signatures of a roughness sublayer (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is also the case for other roughness models employed in DNS, see e.g. Busse & Sandham (Reference Busse and Sandham2012). While a SLBC based roughness model has the advantage of replicating the roughness effect of not influencing the drag of laminar flows, the model requires a priori knowledge about the main flow direction as slip is prescribed for the transversal velocity component only.

5.2. Modelling heterogeneous roughness

In order to model alternating strips of rough and smooth surfaces, the SLBC is applied in the same configuration as in § 4; i.e. ![]() $Re_{\tau } = 180$,

$Re_{\tau } = 180$, ![]() $s/\delta = 0.25, 1, 4$. We choose a slip length of

$s/\delta = 0.25, 1, 4$. We choose a slip length of ![]() $l_{s,w} = 0.05 \delta$ (

$l_{s,w} = 0.05 \delta$ (![]() $l_{s,w}^{+} = 9$), which corresponds to a roughness function of

$l_{s,w}^{+} = 9$), which corresponds to a roughness function of ![]() $\Delta U^{+} \approx 3$ for a homogeneously rough surface at

$\Delta U^{+} \approx 3$ for a homogeneously rough surface at ![]() $Re_{\tau } = 180$. The resulting velocity profiles for the heterogeneous case are presented in figure 10. The left column of plots is scaled with the global friction velocity

$Re_{\tau } = 180$. The resulting velocity profiles for the heterogeneous case are presented in figure 10. The left column of plots is scaled with the global friction velocity ![]() $\overline {u_\tau }$, which is defined by the prescribed pressure gradient. Since the pressure gradient is equal in all considered cases, the plots in this column allow us to deduce statements on the flow rate in a given section of the inhomogeneous channel. The plots in the right column are scaled with the local friction velocity

$\overline {u_\tau }$, which is defined by the prescribed pressure gradient. Since the pressure gradient is equal in all considered cases, the plots in this column allow us to deduce statements on the flow rate in a given section of the inhomogeneous channel. The plots in the right column are scaled with the local friction velocity ![]() $u_\tau (z)$, which makes it possible to compare local flow conditions with the homogeneous reference cases.

$u_\tau (z)$, which makes it possible to compare local flow conditions with the homogeneous reference cases.

Figure 10. Velocity profile for different ![]() $z$ positions, scaled with (a,c,e) the mean friction velocity

$z$ positions, scaled with (a,c,e) the mean friction velocity ![]() $\overline {u_\tau }$ and (b,d, f) the local friction velocity

$\overline {u_\tau }$ and (b,d, f) the local friction velocity ![]() $u_\tau (z)$. (a,b)

$u_\tau (z)$. (a,b) ![]() $s/\delta = 0.25$, (c,d)

$s/\delta = 0.25$, (c,d) ![]() $s/\delta = 1$, (e, f)

$s/\delta = 1$, (e, f) ![]() $s/\delta = 4$.

$s/\delta = 4$.

For ![]() $s \ll \delta$, the change in the boundary condition only affects the near-wall region; Townsend's outer layer similarity hypothesis holds (Townsend Reference Townsend1976). For

$s \ll \delta$, the change in the boundary condition only affects the near-wall region; Townsend's outer layer similarity hypothesis holds (Townsend Reference Townsend1976). For ![]() $y > s$, the mean velocity profiles at different

$y > s$, the mean velocity profiles at different ![]() $z$ positions collapse when scaled with the global friction velocity

$z$ positions collapse when scaled with the global friction velocity ![]() $u_{\bar \tau }$ (figure 10a), suggesting spanwise homogeneity. The velocity profile in the outer layer falls between the limiting homogeneous cases. For

$u_{\bar \tau }$ (figure 10a), suggesting spanwise homogeneity. The velocity profile in the outer layer falls between the limiting homogeneous cases. For ![]() $s \gg \delta$, the flow in each patch centre is barely affected by the change in the boundary condition. Above the two patches the flow conditions are relatively independent from each other. As a consequence, the local velocity profile agrees well with the respective homogeneous cases when scaled with the local friction velocity (which is higher in the

$s \gg \delta$, the flow in each patch centre is barely affected by the change in the boundary condition. Above the two patches the flow conditions are relatively independent from each other. As a consequence, the local velocity profile agrees well with the respective homogeneous cases when scaled with the local friction velocity (which is higher in the ![]() $l_{s, w} > 0$ region), see figure 10( f). This suggests that the flow above the patches is in near equilibrium with the respective boundary condition which is not the case for the narrower strips, see figure 10(b,d). Since scaling the velocity profile with the local friction velocity

$l_{s, w} > 0$ region), see figure 10( f). This suggests that the flow above the patches is in near equilibrium with the respective boundary condition which is not the case for the narrower strips, see figure 10(b,d). Since scaling the velocity profile with the local friction velocity ![]() $u_\tau (z)$ represents normalisation with the actual near-wall gradients of these profiles, the observed near-wall collapse of the profiles is expected.

$u_\tau (z)$ represents normalisation with the actual near-wall gradients of these profiles, the observed near-wall collapse of the profiles is expected.

As indicated in figure 10(e), the no-slip region provides a preferred pathway to the flow for ![]() $s \gg \delta$ due to the (relatively) lower skin friction. Therefore, a HMP is located above the no-slip region; i.e. the blue curve is located above the red one. For

$s \gg \delta$ due to the (relatively) lower skin friction. Therefore, a HMP is located above the no-slip region; i.e. the blue curve is located above the red one. For ![]() $s \approx \delta$, the opposite is observed, and the blue curve is located below the red one in figure 10(c). The redistribution of momentum due to the secondary motion obviously dominates over the effect of locally lower skin-friction drag and a LMP is located over the no-slip region.

$s \approx \delta$, the opposite is observed, and the blue curve is located below the red one in figure 10(c). The redistribution of momentum due to the secondary motion obviously dominates over the effect of locally lower skin-friction drag and a LMP is located over the no-slip region.

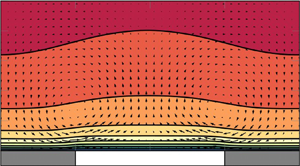

The corresponding mean momentum distribution and secondary flow are presented in figure 11. As expected, for ![]() $s/\delta = 0.25$, the secondary motions are restricted to a region close to the wall. For

$s/\delta = 0.25$, the secondary motions are restricted to a region close to the wall. For ![]() $s=\delta$, the secondary vortices expand towards the channel centre and give rise to a high momentum pathway over the rough region. For