1. Introduction

A turbulent boundary layer over a streamwise change in wall roughness can be considered to be a distillation of flows commonly observed in nature and industry, examples of which include a surface layer where a forest terrain changes to a prairie, and a turbulent boundary layer developing on a ship's hull with patchy biofouling. Understanding the behaviour of the flow downstream of a step-change in roughness and the ability to model the flow evolution are beneficial to atmospheric forecasting, as well as drag estimation for better fuel efficiency.

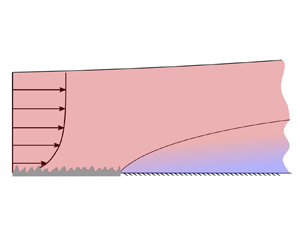

A schematic of the flow configuration is shown in figure 1. A turbulent boundary layer develops on a wall, the roughness of which abruptly changes at ![]() $x=x_0$. Here,

$x=x_0$. Here, ![]() $x$ represents the streamwise direction and

$x$ represents the streamwise direction and ![]() $z$ represents the wall-normal direction. The fetch on the downstream surface is then denoted as

$z$ represents the wall-normal direction. The fetch on the downstream surface is then denoted as ![]() $\hat {x} = x-x_0$. The flow adapts to the new wall condition firstly close to the wall, and the affected region (light blue shaded region) widens farther downstream. This region, where the flow is modified by the new wall condition, is usually referred to as the internal layer or internal boundary layer (IBL), and its thickness is denoted by

$\hat {x} = x-x_0$. The flow adapts to the new wall condition firstly close to the wall, and the affected region (light blue shaded region) widens farther downstream. This region, where the flow is modified by the new wall condition, is usually referred to as the internal layer or internal boundary layer (IBL), and its thickness is denoted by ![]() $\delta _i$. The topic has been reviewed by Garratt (Reference Garratt1990), and the application in meteorology has recently been reviewed by Bou-Zeid et al. (Reference Bou-Zeid, Anderson, Katul and Mahrt2020). The flow structures with characteristics of the upstream roughness are considered to persist above the IBL. An equilibrium layer (EL) can also be defined as the near-wall region where the flow has fully adapted to the new surface condition, and its thickness is denoted by

$\delta _i$. The topic has been reviewed by Garratt (Reference Garratt1990), and the application in meteorology has recently been reviewed by Bou-Zeid et al. (Reference Bou-Zeid, Anderson, Katul and Mahrt2020). The flow structures with characteristics of the upstream roughness are considered to persist above the IBL. An equilibrium layer (EL) can also be defined as the near-wall region where the flow has fully adapted to the new surface condition, and its thickness is denoted by ![]() $\delta _e$. Traditionally,

$\delta _e$. Traditionally, ![]() $\delta _e$ has been assessed by comparing the mean streamwise velocity profile or shear stress profile scaled by the local friction velocity with the corresponding profile of the downstream surface (Rao, Wyngaard & Coté Reference Rao, Wyngaard and Coté1974). In this study, we define both IBL and EL using the mean velocity profile.

$\delta _e$ has been assessed by comparing the mean streamwise velocity profile or shear stress profile scaled by the local friction velocity with the corresponding profile of the downstream surface (Rao, Wyngaard & Coté Reference Rao, Wyngaard and Coté1974). In this study, we define both IBL and EL using the mean velocity profile.

Figure 1. Schematic of a turbulent boundary layer over a step change in surface roughness condition. The roughness transition occurs at ![]() $x_0$, and

$x_0$, and ![]() $\hat {x} = x-x_0$ denotes the fetch downstream of the transition.

$\hat {x} = x-x_0$ denotes the fetch downstream of the transition.

Predicting the evolution of the flow downstream of a roughness step change, given the surface and upstream flow conditions, has attracted great interest in the past few decades. It has important applications in the site selection of a meteorology measurement tower, where it is desirable to choose a location at a sufficient distance away from the change in surface condition to avoid the ‘leading-edge effects’. The tower should also be submerged in the EL in order to sample the quantities associated with the local wall condition rather than the remnant of upstream structures. A detailed summary of various modelling attempts can be found in the work by Savelyev & Taylor (Reference Savelyev and Taylor2005). A crude rule of thumb to estimate the IBL thickness is ![]() $\delta _i/\hat {x}\approx 1/10$ and

$\delta _i/\hat {x}\approx 1/10$ and ![]() $\delta _e/\hat {x}\approx 1/200$ (Rao et al. Reference Rao, Wyngaard and Coté1974). Power-law relationships with a form of

$\delta _e/\hat {x}\approx 1/200$ (Rao et al. Reference Rao, Wyngaard and Coté1974). Power-law relationships with a form of ![]() $\delta _i\propto \hat {x}^{\alpha }$ are obtained by empirically fitting to experimentally or numerically generated data, and the exponent varies from 0.2 to 1 across studies (Rouhi, Chung & Hutchins Reference Rouhi, Chung and Hutchins2019). Although these relationships are easy to implement, they are usually obtained from a particular set of surface and flow conditions and cannot be generalised to others.

$\delta _i\propto \hat {x}^{\alpha }$ are obtained by empirically fitting to experimentally or numerically generated data, and the exponent varies from 0.2 to 1 across studies (Rouhi, Chung & Hutchins Reference Rouhi, Chung and Hutchins2019). Although these relationships are easy to implement, they are usually obtained from a particular set of surface and flow conditions and cannot be generalised to others.

There are considerable attempts in the literature to theoretically model the flow response to a step change in the wall condition, and they can be classified into two major categories based on the assumptions made. Most of these models are developed in the context of atmospheric surface layers where the canonical mean velocity profile can be approximated by a log-law. The first category of theoretical models is established on the diffusion analogy, which was introduced by Miyake (Reference Miyake1965). In this approach, the IBL is assumed to propagate in the same manner as a passive contaminant, and the growth rate of ![]() $\delta _i$ is proportional to

$\delta _i$ is proportional to ![]() $w_{rms}(\delta _i) = (\overline {w^2})^{1/2}$, the vertical diffusion intensity at the interface. That is,

$w_{rms}(\delta _i) = (\overline {w^2})^{1/2}$, the vertical diffusion intensity at the interface. That is,

where ![]() $A$ is a constant and

$A$ is a constant and ![]() ${\rm d}(\,{\cdot }\,)/{\rm d}(\,{\cdot}\,)$ denotes the total derivative. Using the chain rule, the left-hand side of the equation can be rewritten as

${\rm d}(\,{\cdot }\,)/{\rm d}(\,{\cdot}\,)$ denotes the total derivative. Using the chain rule, the left-hand side of the equation can be rewritten as ![]() $\mathrm {d}\delta _i/\mathrm {d}t =(\partial \delta _i/\partial x)({\mathrm{d}\kern0.7pt x}/\mathrm {d}t)$ for a steady state (

$\mathrm {d}\delta _i/\mathrm {d}t =(\partial \delta _i/\partial x)({\mathrm{d}\kern0.7pt x}/\mathrm {d}t)$ for a steady state (![]() $\partial \delta _i/\partial t = 0$). Assuming

$\partial \delta _i/\partial t = 0$). Assuming ![]() $\mathrm{d}\kern0.7pt x/\mathrm {d}t = U(\delta _i)$, which is the mean velocity at the interface, the equation above can be rewritten as

$\mathrm{d}\kern0.7pt x/\mathrm {d}t = U(\delta _i)$, which is the mean velocity at the interface, the equation above can be rewritten as

After relating the ![]() $w_{rms}$ term to the friction velocity (upstream or downstream) through an assumed proportionality in neutrally stratified flow,

$w_{rms}$ term to the friction velocity (upstream or downstream) through an assumed proportionality in neutrally stratified flow, ![]() $w_{rms} = C U_{\tau }$ (

$w_{rms} = C U_{\tau }$ (![]() $C$ is also a constant), determining the velocity at the interface

$C$ is also a constant), determining the velocity at the interface ![]() $U(\delta _i)$ from a logarithmic profile and prescribing an initial condition of

$U(\delta _i)$ from a logarithmic profile and prescribing an initial condition of ![]() $\delta _i|_{\hat {x} = 0}$, (1.2) can be integrated to obtain the final expression of the IBL growth. Models with various expressions of the

$\delta _i|_{\hat {x} = 0}$, (1.2) can be integrated to obtain the final expression of the IBL growth. Models with various expressions of the ![]() $w_{rms}$ and

$w_{rms}$ and ![]() $U(\delta _i)$ terms were developed (Jackson Reference Jackson1976; Panofsky & Dutton Reference Panofsky and Dutton1984; Savelyev & Taylor Reference Savelyev and Taylor2001; Bou-Zeid, Meneveau & Parlange Reference Bou-Zeid, Meneveau and Parlange2004; Yang Reference Yang2016), and it was also extended to non-neutral stability conditions (Savelyev & Taylor Reference Savelyev and Taylor2005).

$U(\delta _i)$ terms were developed (Jackson Reference Jackson1976; Panofsky & Dutton Reference Panofsky and Dutton1984; Savelyev & Taylor Reference Savelyev and Taylor2001; Bou-Zeid, Meneveau & Parlange Reference Bou-Zeid, Meneveau and Parlange2004; Yang Reference Yang2016), and it was also extended to non-neutral stability conditions (Savelyev & Taylor Reference Savelyev and Taylor2005).

A second group of models assume a form of the recovering mean velocity profile, and then relate the local wall-shear stress to the growth of the IBL through the streamwise momentum equation. This approach was established in the seminal study of Elliott (Reference Elliott1958), where a piecewise logarithmic velocity profile with a change in slope across the edge of the IBL was used. Shear stress, as derived from the slope of the log-law profile through a ‘mixing-length’ relation, takes the form of a step function, and attempts were made to eliminate the discontinuity at the edge of the IBL by using a velocity profile integrated from a shear-stress profile that linearly changes from the downstream value to the upstream one across the IBL (Panofsky & Townsend Reference Panofsky and Townsend1964). So far in both mean velocity profile models described, the flow above the IBL remains unmodified from that upstream of the step change and no streamwise development of the flow in this region is considered. That is to say, if we denote the upstream velocity profile as ![]() $U_1(z)$ (where

$U_1(z)$ (where ![]() $z$ is the wall-normal position), then

$z$ is the wall-normal position), then ![]() $U(z)=U_1(z)$ will hold for all

$U(z)=U_1(z)$ will hold for all ![]() $z>\delta _i$. Another way of modelling the flow is to assume that the mean velocity remains constant along a streamline above the IBL, while within the IBL the acceleration of the mean velocity along the same streamline is self-similar (Townsend Reference Townsend1965a,Reference Townsendb, Reference Townsend1966). The mean velocity profiles constructed by Elliott (Reference Elliott1958) and Panofsky & Townsend (Reference Panofsky and Townsend1964) can be incorporated into the Townsend self-similar framework with streamline displacement.

$z>\delta _i$. Another way of modelling the flow is to assume that the mean velocity remains constant along a streamline above the IBL, while within the IBL the acceleration of the mean velocity along the same streamline is self-similar (Townsend Reference Townsend1965a,Reference Townsendb, Reference Townsend1966). The mean velocity profiles constructed by Elliott (Reference Elliott1958) and Panofsky & Townsend (Reference Panofsky and Townsend1964) can be incorporated into the Townsend self-similar framework with streamline displacement.

More recently, it has been recognised that the flow in the IBL has not fully adapted to the local wall condition, questioning the applicability of an equilibrium log-law profile, as well as the corresponding mixing-length relation (Antonia & Luxton Reference Antonia and Luxton1972; Shir Reference Shir1972; Rao et al. Reference Rao, Wyngaard and Coté1974; Ismail, Zaki & Durbin Reference Ismail, Zaki and Durbin2018; Rouhi et al. Reference Rouhi, Chung and Hutchins2019). Chamorro & Porté-Agel (Reference Chamorro and Porté-Agel2009) proposed a semiempirical blending model of the recovering mean velocity profile without further incorporating the streamwise evolution. They considered that after a rough-to-smooth transition, the mean velocity profile asymptotes to the new smooth-wall log law at the wall and the upstream rough-wall log law at the edge of the IBL. These two limiting cases are then blended by a log-linear weight function, representing the gradual transition from the local smooth-wall log law to the upstream rough-wall counterpart as ![]() $z/\delta _i$ increases. This model of the velocity profile does not assume a constant or linear distribution of the shear stress in the IBL (as did Elliott (Reference Elliott1958) and Panofsky & Townsend (Reference Panofsky and Townsend1964)). The agreement with measurements in the near-wall region is further improved by prescribing a finite thickness of the EL (Abkar & Porté-Agel Reference Abkar and Porté-Agel2012; Ghaisas Reference Ghaisas2020), or using a log-normal blending function that gives more weight to the smooth-wall profile close to the wall (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$z/\delta _i$ increases. This model of the velocity profile does not assume a constant or linear distribution of the shear stress in the IBL (as did Elliott (Reference Elliott1958) and Panofsky & Townsend (Reference Panofsky and Townsend1964)). The agreement with measurements in the near-wall region is further improved by prescribing a finite thickness of the EL (Abkar & Porté-Agel Reference Abkar and Porté-Agel2012; Ghaisas Reference Ghaisas2020), or using a log-normal blending function that gives more weight to the smooth-wall profile close to the wall (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

In addition to the two major categories as discussed above, there have also been other attempts in modelling the flow response to a roughness change. Wood (Reference Wood1982) developed a simple correlation for the IBL thickness from dimensional analysis. Peterson (Reference Peterson1969) adopted a closure of the turbulent shear stress and solved the continuity, momentum and turbulent-energy equations numerically. Van Buren et al. (Reference Van Buren, Floryan, Ding, Hellström and Smits2020) performed a perturbation analysis on the mean-momentum equation and Reynolds stress transport equation of a rough-to-smooth change in a pipe flow, and successfully captured the second-order response in the experimental data.

To summarise, Elliott's original model was formulated for an atmospheric surface layer with no consideration of the gradual adjustment of the flow in the IBL to the new wall condition. In this study, we incorporate modifications that make Elliott's approach valid for a turbulent boundary layer with finite thickness. The inherent difference between the current model and Elliott's original formulation is that we consider a finite thickness of the total boundary layer, and introduce an additional momentum equation to describe its spatial growth. The new model is useful for a wide range of engineering applications where a finite-thickness boundary layer is concerned, such as the flow over patches of biofouling roughness on a ship's hull. A series of refinements will be discussed, including reassessing the assumptions originally made concerning a deep surface layer where ![]() $\delta _i/\delta _{99}$ is small, as well as incorporating the blending velocity profile as detailed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$\delta _i/\delta _{99}$ is small, as well as incorporating the blending velocity profile as detailed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

The streamwise, spanwise and wall-normal directions are represented by ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$. The corresponding time-averaged and fluctuation velocity components are denoted by

$z$. The corresponding time-averaged and fluctuation velocity components are denoted by ![]() $U$,

$U$, ![]() $V$,

$V$, ![]() $W$ and

$W$ and ![]() $u$,

$u$, ![]() $v$,

$v$, ![]() $w$, respectively. Quantities upstream and downstream of the rough-to-smooth transition are distinguished by a subscript

$w$, respectively. Quantities upstream and downstream of the rough-to-smooth transition are distinguished by a subscript ![]() $(\,{\cdot}\,)_1$ and

$(\,{\cdot}\,)_1$ and ![]() $(\,{\cdot }\,)_2$, respectively, and the subscript

$(\,{\cdot }\,)_2$, respectively, and the subscript ![]() $(\,{\cdot }\,)_0$ represents quantities at the roughness transition (

$(\,{\cdot }\,)_0$ represents quantities at the roughness transition (![]() $x = x_0$ or just prior to it if there is a jump of that quantity across the roughness transition, see figure 1).

$x = x_0$ or just prior to it if there is a jump of that quantity across the roughness transition, see figure 1).

This paper is structured as follows. First, Elliott's original model is summarised in § 2, and its numerical implementation is presented in § 3. The model is then evaluated utilising an experimental dataset covering a wide range of flow parameters (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021) in § 3.1. Refinements including considering a wake profile, the streamwise growth of the entire boundary layer, a ![]() $z$-dependent shear stress profile, and the blending velocity profile in the IBL (as discussed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021)), are added and compared with the original model in § 4. The performance of the new model is assessed in § 5.

$z$-dependent shear stress profile, and the blending velocity profile in the IBL (as discussed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021)), are added and compared with the original model in § 4. The performance of the new model is assessed in § 5.

2. A brief review of Elliott's model

In the seminal study of Elliott (Reference Elliott1958), a theoretical model predicting the flow recovery from a step change in the surface roughness was established. The flow condition is illustrated in figure 2(a). The incoming flow can be fully described by the roughness length ![]() $z_{01}$ and friction velocity

$z_{01}$ and friction velocity ![]() $U_{\tau 1}$ of the upstream surface, while the only information about the downstream surface is the roughness length

$U_{\tau 1}$ of the upstream surface, while the only information about the downstream surface is the roughness length ![]() $z_{02}$. Both upstream and downstream surfaces are assumed to be in the fully rough regime, and the roughness length can be related to the equivalent sand grain roughness

$z_{02}$. Both upstream and downstream surfaces are assumed to be in the fully rough regime, and the roughness length can be related to the equivalent sand grain roughness ![]() $k_s$ by

$k_s$ by

where ![]() $A'_{fr}=8.5$ is the fully rough intercept for sand grain roughness (Nikuradse Reference Nikuradse1950). An extension of the model is to consider that either the upstream or downstream surface is fully smooth, and the roughness length will then be related to the viscous wall unit through

$A'_{fr}=8.5$ is the fully rough intercept for sand grain roughness (Nikuradse Reference Nikuradse1950). An extension of the model is to consider that either the upstream or downstream surface is fully smooth, and the roughness length will then be related to the viscous wall unit through

where ![]() $B$ is the smooth-wall intercept,

$B$ is the smooth-wall intercept, ![]() $U_{\tau }$ is the local friction velocity and

$U_{\tau }$ is the local friction velocity and ![]() $\nu$ is the kinematic viscosity of air. Here, the constant values are chosen as

$\nu$ is the kinematic viscosity of air. Here, the constant values are chosen as ![]() $\kappa = 0.384$,

$\kappa = 0.384$, ![]() $B = 4.17$ (Chauhan, Monkewitz & Nagib Reference Chauhan, Monkewitz and Nagib2009). In the scenario of a rough-to-smooth transition, the downstream roughness length

$B = 4.17$ (Chauhan, Monkewitz & Nagib Reference Chauhan, Monkewitz and Nagib2009). In the scenario of a rough-to-smooth transition, the downstream roughness length ![]() $z_{02}$ is directly related to the local friction velocity, which can vary significantly with

$z_{02}$ is directly related to the local friction velocity, which can vary significantly with ![]() $\hat {x}$, particularly for

$\hat {x}$, particularly for ![]() $\hat {x}/\delta _0 \lesssim 2$ (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$\hat {x}/\delta _0 \lesssim 2$ (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

Figure 2. (a) Sketch of the flow over a roughness change in the streamwise direction. The IBL is shown by blue, and the outer layer is shown by red. The control volume used to obtain (2.5) is bounded by the dashed line. (b) Sketch of the mean velocity profile in Elliott's model corresponding to the flow condition in (a). The local inner log-law profile is shown by blue, and the outer log-law profile is shown by red, and a rough-to-smooth transition (![]() $z_{01}>z_{02}$) is assumed in the plot.

$z_{01}>z_{02}$) is assumed in the plot.

After the roughness transition at ![]() $x = x_0$ (i.e.

$x = x_0$ (i.e. ![]() $\hat {x} = 0$), an IBL containing the modified flow develops on the downstream surface and a local friction velocity

$\hat {x} = 0$), an IBL containing the modified flow develops on the downstream surface and a local friction velocity ![]() $U_{\tau 2}$ evolves with the growth of the IBL. In this system, the roughness lengths

$U_{\tau 2}$ evolves with the growth of the IBL. In this system, the roughness lengths ![]() $z_{01}$ and

$z_{01}$ and ![]() $z_{02}$ are known. Here,

$z_{02}$ are known. Here, ![]() $U_{\tau 1}$ is also given and assumed to be constant, therefore, we have

$U_{\tau 1}$ is also given and assumed to be constant, therefore, we have ![]() $U_{\tau 1}(\hat {x}) = U_{\tau 1}(0) \equiv U_{\tau 0}$, to be consistent with previous notations. This leaves two unknowns,

$U_{\tau 1}(\hat {x}) = U_{\tau 1}(0) \equiv U_{\tau 0}$, to be consistent with previous notations. This leaves two unknowns, ![]() $\delta _i(\hat {x})$ and

$\delta _i(\hat {x})$ and ![]() $U_{\tau 2}(\hat {x})$, as functions of

$U_{\tau 2}(\hat {x})$, as functions of ![]() $\hat {x}$, the fetch on the downstream surface. Therefore, two equations are required to close the system and provide solutions of

$\hat {x}$, the fetch on the downstream surface. Therefore, two equations are required to close the system and provide solutions of ![]() $\delta _i$ and

$\delta _i$ and ![]() $U_{\tau 2}$.

$U_{\tau 2}$.

Elliott approximated the recovering mean velocity profile with a piecewise logarithmic function (illustrated in figure 2b),

\begin{equation} U(z) = \begin{cases}

\dfrac{U_{\tau 1}}{\kappa} \ln(z/z_{01}), &

z\geqslant\delta_i\\ \dfrac{U_{\tau 2}}{\kappa}

\ln(z/z_{02}), & z<\delta_i,\\

\end{cases}\end{equation}

\begin{equation} U(z) = \begin{cases}

\dfrac{U_{\tau 1}}{\kappa} \ln(z/z_{01}), &

z\geqslant\delta_i\\ \dfrac{U_{\tau 2}}{\kappa}

\ln(z/z_{02}), & z<\delta_i,\\

\end{cases}\end{equation}

which implicitly assumes that the mean velocity profile within the IBL immediately adapts to the local wall condition (i.e. that ![]() $\delta _i = \delta _e$). From this expression of the mean velocity profile, the first equation to close the system rises naturally as the matching condition, i.e. the two log laws intersecting at

$\delta _i = \delta _e$). From this expression of the mean velocity profile, the first equation to close the system rises naturally as the matching condition, i.e. the two log laws intersecting at ![]() $z = \delta _i$:

$z = \delta _i$:

A series of the velocity profiles with various ![]() $\delta _i$ values are shown in figure 3.

$\delta _i$ values are shown in figure 3.

Figure 3. An illustration of the mean velocity profile (2.3) for (a) ![]() $z_{01}>z_{02}$ (rough-to-smooth) and (b)

$z_{01}>z_{02}$ (rough-to-smooth) and (b) ![]() $z_{01}< z_{02}$ (smooth-to-rough). The red lines in both panels are the upstream velocity profile, and the blue line is the velocity profile within the IBL at

$z_{01}< z_{02}$ (smooth-to-rough). The red lines in both panels are the upstream velocity profile, and the blue line is the velocity profile within the IBL at ![]() $\hat {x} = 0$. The black dots are a few representative locations of

$\hat {x} = 0$. The black dots are a few representative locations of ![]() $\delta _i$ farther downstream and the black dashed lines are the velocity profile within the IBL corresponding to these

$\delta _i$ farther downstream and the black dashed lines are the velocity profile within the IBL corresponding to these ![]() $\delta _i$ values.

$\delta _i$ values.

Considering a control volume which has a streamwise width of ![]() ${\rm d}\kern0.7pt x$ and is bounded by the wall and the IBL height (shown by the dashed line in figure 2a), and balancing the streamwise momentum fluxes across the control surface with the net shear stress applied on the top and bottom surfaces, a second equation can be obtained,

${\rm d}\kern0.7pt x$ and is bounded by the wall and the IBL height (shown by the dashed line in figure 2a), and balancing the streamwise momentum fluxes across the control surface with the net shear stress applied on the top and bottom surfaces, a second equation can be obtained,

where ![]() $\Delta \tau (\hat {x}) = \tau (\hat {x},\delta _i(\hat {x}))-\tau (\hat {x},0)$. The shear stress at the wall is

$\Delta \tau (\hat {x}) = \tau (\hat {x},\delta _i(\hat {x}))-\tau (\hat {x},0)$. The shear stress at the wall is ![]() $\tau (\hat {x},0) = \rho U^2_{\tau 2}(\hat {x})$ by definition, while Elliott assumed that the upper boundary of the control volume resides within the constant-stress layer which preserves the shear stress of the upstream surface, i.e.

$\tau (\hat {x},0) = \rho U^2_{\tau 2}(\hat {x})$ by definition, while Elliott assumed that the upper boundary of the control volume resides within the constant-stress layer which preserves the shear stress of the upstream surface, i.e. ![]() $\tau (\hat {x},\delta _i) = \rho U^2_{\tau 1}$. Therefore, the net shear stress term can be expressed as

$\tau (\hat {x},\delta _i) = \rho U^2_{\tau 1}$. Therefore, the net shear stress term can be expressed as ![]() $\Delta \tau (\hat {x}) = \rho U_{\tau 1}^2- \rho U_{\tau 2}^2(\hat {x})$. The lower bound of the integral,

$\Delta \tau (\hat {x}) = \rho U_{\tau 1}^2- \rho U_{\tau 2}^2(\hat {x})$. The lower bound of the integral, ![]() $z_{02}$, is chosen as the lowest wall-normal position where the logarithmic

$z_{02}$, is chosen as the lowest wall-normal position where the logarithmic ![]() $U$ profile is negative according to the mean velocity profile in (2.3). To simplify the notation, we denote the mean velocity at

$U$ profile is negative according to the mean velocity profile in (2.3). To simplify the notation, we denote the mean velocity at ![]() $z = \delta _i$ as

$z = \delta _i$ as ![]() $U_i$, i.e.

$U_i$, i.e. ![]() $U_i(\hat {x})\equiv U(\hat {x},\delta _i)$.

$U_i(\hat {x})\equiv U(\hat {x},\delta _i)$.

With these two equations (2.4) and (2.5), the system will be closed and the evolution of ![]() $U_{\tau 2}$ and

$U_{\tau 2}$ and ![]() $\delta _i$ can be solved. The growth of

$\delta _i$ can be solved. The growth of ![]() $\delta _i$ is driven by the source term,

$\delta _i$ is driven by the source term, ![]() $\Delta \tau (\hat {x})/\rho$, which is essentially the difference in the shear stress between the lower and upper control surfaces. The recovering downstream friction velocity

$\Delta \tau (\hat {x})/\rho$, which is essentially the difference in the shear stress between the lower and upper control surfaces. The recovering downstream friction velocity ![]() $U_{\tau 2}(\hat {x})$ asymptotes to

$U_{\tau 2}(\hat {x})$ asymptotes to ![]() $U_{\tau 1}$. In fact, the streamwise evolution of the flow will only terminate when

$U_{\tau 1}$. In fact, the streamwise evolution of the flow will only terminate when ![]() $U_{\tau 2}=U_{\tau 1}$, which is expected at an infinitely long fetch where

$U_{\tau 2}=U_{\tau 1}$, which is expected at an infinitely long fetch where ![]() $\delta _i\gg \max (z_{01},z_{02})$. That is to say, when

$\delta _i\gg \max (z_{01},z_{02})$. That is to say, when ![]() $\delta _i$ is infinitely large, in figure 2(b) the velocity profile in the IBL (blue line) will eventually be parallel with the upstream velocity profile (red line), thus

$\delta _i$ is infinitely large, in figure 2(b) the velocity profile in the IBL (blue line) will eventually be parallel with the upstream velocity profile (red line), thus ![]() $U_{\tau 2} = U_{\tau 1}$.

$U_{\tau 2} = U_{\tau 1}$.

3. Numerical implementation of Elliott's 1958 model

Elliott (Reference Elliott1958) solved the ordinary differential equation (ODE) (2.5) analytically. This approach is highly dependent on the analytical form of the mean velocity profile and it can be tedious or even impossible to find an algebraic solution when the functional form of the mean velocity profile changes. Alternatively, we may consider the integral form of (2.5). We first consider a change of variable with ![]() $\delta _i$ replacing

$\delta _i$ replacing ![]() $\hat {x}$ as the independent variable, and apply substitutions

$\hat {x}$ as the independent variable, and apply substitutions

to (2.5), resulting in

Multiplying both sides of the equation by ![]() $\mathrm{d}\kern0.7pt x(\delta _i)$ and integrating with respect to

$\mathrm{d}\kern0.7pt x(\delta _i)$ and integrating with respect to ![]() $G_1$ and

$G_1$ and ![]() $G_2$ on the left-hand side, and

$G_2$ on the left-hand side, and ![]() $x$ on the right-hand side gives

$x$ on the right-hand side gives

\begin{equation} \hat{x}(\delta_i) = \int_{G_2(\delta_i(0))}^{G_2(\delta_i)} \frac{\rho}{\Delta \tau(\delta_i)}\mathrm{d}G_2(\delta_i)-\int_{G_1(\delta_i(0))}^{G_1(\delta_i)} \frac{\rho U_i(\delta_i)}{\Delta \tau(\delta_i)}\mathrm{d}G_1(\delta_i) , \end{equation}

\begin{equation} \hat{x}(\delta_i) = \int_{G_2(\delta_i(0))}^{G_2(\delta_i)} \frac{\rho}{\Delta \tau(\delta_i)}\mathrm{d}G_2(\delta_i)-\int_{G_1(\delta_i(0))}^{G_1(\delta_i)} \frac{\rho U_i(\delta_i)}{\Delta \tau(\delta_i)}\mathrm{d}G_1(\delta_i) , \end{equation}

which is equivalent to (2.5) when ![]() $\Delta \tau$ is non-zero.

$\Delta \tau$ is non-zero.

Here in the integral form (3.3), ![]() $\delta _i$ rather than

$\delta _i$ rather than ![]() $\hat {x}$ is considered as the independent variable for computational convenience, provided that

$\hat {x}$ is considered as the independent variable for computational convenience, provided that ![]() $\mathrm {d} \delta _i/\mathrm {d}\hat {x}\neq 0$. Thus,

$\mathrm {d} \delta _i/\mathrm {d}\hat {x}\neq 0$. Thus, ![]() $U_i$ will be a function of

$U_i$ will be a function of ![]() $\delta _i$ and the two-dimensional mean velocity field

$\delta _i$ and the two-dimensional mean velocity field ![]() $U(\hat {x},z)$ will be a function of

$U(\hat {x},z)$ will be a function of ![]() $\delta _i$ and

$\delta _i$ and ![]() $z$ instead. The initial condition of the IBL evolution is

$z$ instead. The initial condition of the IBL evolution is ![]() $\delta _{i}(0)$, i.e.

$\delta _{i}(0)$, i.e. ![]() $\delta _i(0) = \delta _i$ at

$\delta _i(0) = \delta _i$ at ![]() $\hat {x} = 0$. The choice of

$\hat {x} = 0$. The choice of ![]() $\delta _i(0)$, provided small, will only lead to a constant displacement in

$\delta _i(0)$, provided small, will only lead to a constant displacement in ![]() $\hat {x}$ without changing the shape of the predicted

$\hat {x}$ without changing the shape of the predicted ![]() $\delta _i$ trajectories (see Appendix C). In practice, an array of

$\delta _i$ trajectories (see Appendix C). In practice, an array of ![]() $\delta _i$ locations is first generated, which subsequently determines

$\delta _i$ locations is first generated, which subsequently determines ![]() $U_{\tau 2}(\delta _i)$ and the mean velocity profile

$U_{\tau 2}(\delta _i)$ and the mean velocity profile ![]() $U(\delta _i,z)$ using (2.4), the relation from matching the mean velocity profile at

$U(\delta _i,z)$ using (2.4), the relation from matching the mean velocity profile at ![]() $\delta _i$. The fetch

$\delta _i$. The fetch ![]() $\hat {x}$ corresponding to each

$\hat {x}$ corresponding to each ![]() $\delta _i$ will then be computed from (3.3) numerically. Compared with the original solution of Elliott (Reference Elliott1958), this approach can easily accommodate velocity profiles with more complicated functional forms, which will largely serve our intention in refining the model assumptions. We also note that when presenting the model predictions graphically, we revert to the previous convention of plotting physical quantities against

$\delta _i$ will then be computed from (3.3) numerically. Compared with the original solution of Elliott (Reference Elliott1958), this approach can easily accommodate velocity profiles with more complicated functional forms, which will largely serve our intention in refining the model assumptions. We also note that when presenting the model predictions graphically, we revert to the previous convention of plotting physical quantities against ![]() $\hat {x}$ to be consistent with the literature. From here on, this model will be referred to as the E58 model.

$\hat {x}$ to be consistent with the literature. From here on, this model will be referred to as the E58 model.

3.1. Evaluating the E58 model

We first evaluate the E58 model by comparing the experimental data (Li et al. Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021) with predictions at matched flow conditions. Two groups of wind tunnel experiments are designed to separately examine the effect of friction Reynolds number and roughness Reynolds number on the flow recovery from a rough-to-smooth change. The friction and roughness Reynolds numbers are defined as ![]() $Re_{\tau 0}\equiv U_{\tau 0}\delta _0/\nu$ and

$Re_{\tau 0}\equiv U_{\tau 0}\delta _0/\nu$ and ![]() $k_{s0}^+\equiv U_{\tau 0}k_s/\nu$, respectively, and are both evaluated based on conditions over the rough surface just upstream of the roughness transition. The Group-Re consists of measurements with varying

$k_{s0}^+\equiv U_{\tau 0}k_s/\nu$, respectively, and are both evaluated based on conditions over the rough surface just upstream of the roughness transition. The Group-Re consists of measurements with varying ![]() $Re_{\tau 0}$ while holding

$Re_{\tau 0}$ while holding ![]() $k_{s0}^+$ constant, while Group-ks measurements vary

$k_{s0}^+$ constant, while Group-ks measurements vary ![]() $k_{s0}^+$ while holding

$k_{s0}^+$ while holding ![]() $Re_{\tau 0}$ constant. The same P24 grit sandpaper is used in all cases, ensuring a constant

$Re_{\tau 0}$ constant. The same P24 grit sandpaper is used in all cases, ensuring a constant ![]() $k_s$, and the variation in

$k_s$, and the variation in ![]() $Re_{\tau 0}$ and

$Re_{\tau 0}$ and ![]() $k_{s0}^+$ is achieved by adjusting

$k_{s0}^+$ is achieved by adjusting ![]() $U_{\infty }$, the free stream velocity, and

$U_{\infty }$, the free stream velocity, and ![]() $x_0$, the streamwise length of the sandpaper patch. The magnitude of the surface roughness change is denoted by

$x_0$, the streamwise length of the sandpaper patch. The magnitude of the surface roughness change is denoted by ![]() $M\equiv \ln (z_{02}/z_{01})$, where

$M\equiv \ln (z_{02}/z_{01})$, where ![]() $z_{02}$ is calculated from the maximum

$z_{02}$ is calculated from the maximum ![]() $U_{\tau 2}$ measured downstream of the transition. Legends and flow conditions of the cases are summarised in table 1 and the

$U_{\tau 2}$ measured downstream of the transition. Legends and flow conditions of the cases are summarised in table 1 and the ![]() $Re_{\tau 0}$–

$Re_{\tau 0}$–![]() $k_{s0}^+$ parameter space is shown in figure 4. For further experimental details of these cases, readers are referred to the paper by Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$k_{s0}^+$ parameter space is shown in figure 4. For further experimental details of these cases, readers are referred to the paper by Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

Figure 4. Flow conditions (![]() $Re_{\tau 0}$ and

$Re_{\tau 0}$ and ![]() $k_{s0}^+$) at the immediate upstream of the roughness transition of all cases. All symbols are defined in table 1. The horizontal line is at

$k_{s0}^+$) at the immediate upstream of the roughness transition of all cases. All symbols are defined in table 1. The horizontal line is at ![]() $k_{s0}^+ = 160$, and the vertical line is at

$k_{s0}^+ = 160$, and the vertical line is at ![]() $Re_{\tau 0} = 14\,500$. The two dashed lines show the cases with matched

$Re_{\tau 0} = 14\,500$. The two dashed lines show the cases with matched ![]() $\delta _{0}/k_s$ of 64 and 133. Adapted from Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$\delta _{0}/k_s$ of 64 and 133. Adapted from Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

Table 1. Summary of the experimental cases. The friction velocity ![]() $U_{\tau 0}$ employed in calculating

$U_{\tau 0}$ employed in calculating ![]() $Re_{\tau 0}$ and

$Re_{\tau 0}$ and ![]() $k^+_{s0}$ is obtained over the rough fetch just upstream of the rough-to-smooth transition. Note that case Re14ks16 is shared between Group-Re and Group-ks, therefore its symbol can take either pink or blue colour in the corresponding group. Adapted from Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

$k^+_{s0}$ is obtained over the rough fetch just upstream of the rough-to-smooth transition. Note that case Re14ks16 is shared between Group-Re and Group-ks, therefore its symbol can take either pink or blue colour in the corresponding group. Adapted from Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021).

In the original formulation of Elliott's model, the incoming flow is a deep surface layer where neither ![]() $\delta _0$ nor

$\delta _0$ nor ![]() $U_{\infty }$ (therefore

$U_{\infty }$ (therefore ![]() $C_f$) is defined. It is also applicable to a flat plate boundary layer with a finite thickness where

$C_f$) is defined. It is also applicable to a flat plate boundary layer with a finite thickness where ![]() $\delta _i$ is only a small fraction of the entire boundary layer. Based on the dimensional argument, the flow should be independent of

$\delta _i$ is only a small fraction of the entire boundary layer. Based on the dimensional argument, the flow should be independent of ![]() $\delta _0$ in the limit of small

$\delta _0$ in the limit of small ![]() $\delta _i/\delta _0$. For a smooth downstream surface, the piecewise mean velocity profile (2.3) can be rewritten as

$\delta _i/\delta _0$. For a smooth downstream surface, the piecewise mean velocity profile (2.3) can be rewritten as

\begin{equation} U(z) = \begin{cases}

\dfrac{U_{\tau 1}}{\kappa} \ln(z/z_{01}), &

z\geqslant\delta_i\\ U_{\tau 2}\left(\dfrac{1}{\kappa}

\ln(zU_{\tau 2}/\nu)+B\right), & z<\delta_i,

\end{cases}\end{equation}

\begin{equation} U(z) = \begin{cases}

\dfrac{U_{\tau 1}}{\kappa} \ln(z/z_{01}), &

z\geqslant\delta_i\\ U_{\tau 2}\left(\dfrac{1}{\kappa}

\ln(zU_{\tau 2}/\nu)+B\right), & z<\delta_i,

\end{cases}\end{equation}

and the kinematic viscosity of the fluid ![]() $\nu$ instead of a roughness length

$\nu$ instead of a roughness length ![]() $z_{02}$ is introduced to the problem. When choosing

$z_{02}$ is introduced to the problem. When choosing ![]() $U_{\tau 0}$ as the velocity scale and

$U_{\tau 0}$ as the velocity scale and ![]() $\nu /U_{\tau 0}$ as the length scale, the incoming flow condition can be fully described by a non-dimensional number

$\nu /U_{\tau 0}$ as the length scale, the incoming flow condition can be fully described by a non-dimensional number ![]() $k_{s0}^+$, provided that

$k_{s0}^+$, provided that ![]() $\delta _0$ is large so it does not enter the problem. This implies that for the E58 model, both

$\delta _0$ is large so it does not enter the problem. This implies that for the E58 model, both ![]() $U_{\tau 2}/U_{\tau 0}$ and

$U_{\tau 2}/U_{\tau 0}$ and ![]() $\delta _i U_{\tau 0}/\nu$ in Group-Re, where

$\delta _i U_{\tau 0}/\nu$ in Group-Re, where ![]() $k_{s0}^+$ is held constant, should collapse to a single trend despite the changes in

$k_{s0}^+$ is held constant, should collapse to a single trend despite the changes in ![]() $Re_{\tau 0}$. The comparison of these theoretical results with experimental data is discussed below.

$Re_{\tau 0}$. The comparison of these theoretical results with experimental data is discussed below.

3.2. Friction velocity  $U_{\tau 2}$

$U_{\tau 2}$

The measured and predicted recovering friction velocity ![]() $U_{\tau 2}$ on the downstream surface is plotted against fetch

$U_{\tau 2}$ on the downstream surface is plotted against fetch ![]() $\hat {x}$ in figure 5, using

$\hat {x}$ in figure 5, using ![]() $U_{\tau 0}$ and

$U_{\tau 0}$ and ![]() $\nu /U_{\tau 0}$ as the velocity and length scales, respectively. The Group-Re results are shown in figure 5(a), where a single curve represents the prediction of the E58 model for all four cases, since

$\nu /U_{\tau 0}$ as the velocity and length scales, respectively. The Group-Re results are shown in figure 5(a), where a single curve represents the prediction of the E58 model for all four cases, since ![]() $Re_{\tau 0}$ (essentially the outer length scale) was not a parameter in the original model. Over a limited range of

$Re_{\tau 0}$ (essentially the outer length scale) was not a parameter in the original model. Over a limited range of ![]() $\hat {x}U_{\tau 0}/\nu <1\times 10^5$, the measurements follow the prediction closely with no distinguishable trend with

$\hat {x}U_{\tau 0}/\nu <1\times 10^5$, the measurements follow the prediction closely with no distinguishable trend with ![]() $Re_{\tau 0}$. The Group-ks data are presented in figure 5(b), where a greater drop in the friction velocity downstream is observed with a higher

$Re_{\tau 0}$. The Group-ks data are presented in figure 5(b), where a greater drop in the friction velocity downstream is observed with a higher ![]() $k_{s0}^+$. The good agreement between the data points and the model prediction indicates that such a dependence on

$k_{s0}^+$. The good agreement between the data points and the model prediction indicates that such a dependence on ![]() $k_{s0}^+$ is generally well captured by the E58 model.

$k_{s0}^+$ is generally well captured by the E58 model.

Figure 5. Friction velocities on the smooth surface normalised by ![]() $U_{\tau 0}$, the friction velocity on the rough surface versus the viscous-scaled fetch

$U_{\tau 0}$, the friction velocity on the rough surface versus the viscous-scaled fetch ![]() $\hat {x} U_{\tau 0}/\nu$ for (a) Group-Re and (b) Group-ks. Panels (c) and (d) are the corresponding magnified view in the near field. The solid lines in all figures are predictions using the E58 model with

$\hat {x} U_{\tau 0}/\nu$ for (a) Group-Re and (b) Group-ks. Panels (c) and (d) are the corresponding magnified view in the near field. The solid lines in all figures are predictions using the E58 model with ![]() $k_{s0}^+ = 160$, while the dashed and dash-dotted lines in (b) and (d) are with

$k_{s0}^+ = 160$, while the dashed and dash-dotted lines in (b) and (d) are with ![]() $k_{s0}^+ = 110$ and

$k_{s0}^+ = 110$ and ![]() $k_{s0}^+ = 230$, respectively. Data points with

$k_{s0}^+ = 230$, respectively. Data points with ![]() $\delta _i/\delta _{99}<0.15$ are shown by solid symbols, while the rest are shown by open symbols. Symbols with a thick black outline are at

$\delta _i/\delta _{99}<0.15$ are shown by solid symbols, while the rest are shown by open symbols. Symbols with a thick black outline are at ![]() $\delta _i/\delta _{99}\approx 0.6$.

$\delta _i/\delta _{99}\approx 0.6$.

However, the zoomed views as shown in figures 5(c) and 5(d) reveal the under-estimation of the E58 model in the near field (![]() $0<\hat {x}U_{\tau 0}/\nu <0.05\times 10^5$). Since the mean velocity within and above the IBL are modelled by two logarithmic laws, the flow recovery in the near vicinity of the step change will not be captured correctly by the E58 model due to the deviation from a canonical smooth-wall mean velocity profile as detailed in Li et al. (Reference Li, de Silva, Baidya, Rouhi, Chung, Marusic and Hutchins2019, Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021). In addition, the adequacy of the model is also expected to drop when

$0<\hat {x}U_{\tau 0}/\nu <0.05\times 10^5$). Since the mean velocity within and above the IBL are modelled by two logarithmic laws, the flow recovery in the near vicinity of the step change will not be captured correctly by the E58 model due to the deviation from a canonical smooth-wall mean velocity profile as detailed in Li et al. (Reference Li, de Silva, Baidya, Rouhi, Chung, Marusic and Hutchins2019, Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021). In addition, the adequacy of the model is also expected to drop when ![]() $\delta _i$ exceeds the upper limit of the logarithmic layer (chosen as

$\delta _i$ exceeds the upper limit of the logarithmic layer (chosen as ![]() $z/\delta _{99}=0.15$ in this study), as the E58 model fails to capture the wake region. In figure 5, the data points with

$z/\delta _{99}=0.15$ in this study), as the E58 model fails to capture the wake region. In figure 5, the data points with ![]() $\delta _i/\delta _{99}<0.15$ are shown by solid symbols, while the rest are shown by open symbols. For all solid symbols, the model prediction follows the measured results closely (excluding the near field). This good agreement still exists even after

$\delta _i/\delta _{99}<0.15$ are shown by solid symbols, while the rest are shown by open symbols. For all solid symbols, the model prediction follows the measured results closely (excluding the near field). This good agreement still exists even after ![]() $\delta _i$ exceeds

$\delta _i$ exceeds ![]() $0.15\delta _{99}$, until it reaches approximately

$0.15\delta _{99}$, until it reaches approximately ![]() $0.6\delta _{99}$ (shown by the symbols with a thick black outline). The model appears valid for a wider range of

$0.6\delta _{99}$ (shown by the symbols with a thick black outline). The model appears valid for a wider range of ![]() $\delta _i/\delta _{99}$ than would be expected. One possible explanation is that the effects from those factors which are not accounted for in the E58 model, such as the inclusion of a wake function or the growth of the outer layer downstream, tend to cancel out. This will be discussed in more detail in § 4. It is also noticed in figure 5(a) that cases with a higher

$\delta _i/\delta _{99}$ than would be expected. One possible explanation is that the effects from those factors which are not accounted for in the E58 model, such as the inclusion of a wake function or the growth of the outer layer downstream, tend to cancel out. This will be discussed in more detail in § 4. It is also noticed in figure 5(a) that cases with a higher ![]() $Re_{\tau 0}$ in Group-Re follow the model prediction for a longer

$Re_{\tau 0}$ in Group-Re follow the model prediction for a longer ![]() $\hat {x}U_{\tau 0}/\nu$, as a longer

$\hat {x}U_{\tau 0}/\nu$, as a longer ![]() $\hat {x}U_{\tau 0}/\nu$ is required before

$\hat {x}U_{\tau 0}/\nu$ is required before ![]() $\delta _i/\delta _{99}$ reaches 0.6. After

$\delta _i/\delta _{99}$ reaches 0.6. After ![]() $\delta _i$ exceeds

$\delta _i$ exceeds ![]() $0.6\delta _{99}$, the experimentally determined

$0.6\delta _{99}$, the experimentally determined ![]() $U_{\tau 2}/U_{\tau 0}$ starts to decrease with

$U_{\tau 2}/U_{\tau 0}$ starts to decrease with ![]() $\hat {x}U_{\tau 0}/\nu$ in both groups, in contrast to the model predictions. For cases in Group-Re,

$\hat {x}U_{\tau 0}/\nu$ in both groups, in contrast to the model predictions. For cases in Group-Re, ![]() $U_{\tau 2}/U_{\tau 0}$ is observed to fan out and increase with

$U_{\tau 2}/U_{\tau 0}$ is observed to fan out and increase with ![]() $Re_{\tau 0}$ at

$Re_{\tau 0}$ at ![]() $\hat {x}U_{\tau 0}/\nu \gtrsim 1\times 10^5$, which can be broadly explained as follows. Neglecting the growth in

$\hat {x}U_{\tau 0}/\nu \gtrsim 1\times 10^5$, which can be broadly explained as follows. Neglecting the growth in ![]() $\delta _{99}$, the asymptotic value of fully recovered

$\delta _{99}$, the asymptotic value of fully recovered ![]() $U_{\tau 2}/U_{\tau 0}$ can be written as

$U_{\tau 2}/U_{\tau 0}$ can be written as

\begin{equation} U_{\tau 2}/U_{\tau 0} = \frac{\sqrt{2/C_f}-\Delta U^+}{\sqrt{2/C_f}}. \end{equation}

\begin{equation} U_{\tau 2}/U_{\tau 0} = \frac{\sqrt{2/C_f}-\Delta U^+}{\sqrt{2/C_f}}. \end{equation}

Since ![]() $k_{s0}^+$ is constant in Group-Re,

$k_{s0}^+$ is constant in Group-Re, ![]() $\Delta U^+$ will also be a constant, while

$\Delta U^+$ will also be a constant, while ![]() $\sqrt {2/C_f}$ increases with an increasing

$\sqrt {2/C_f}$ increases with an increasing ![]() $Re_{\tau 0}$. Therefore, the ratio

$Re_{\tau 0}$. Therefore, the ratio ![]() $U_{\tau 2}/U_{\tau 0}$ also increases with

$U_{\tau 2}/U_{\tau 0}$ also increases with ![]() $Re_{\tau 0}$. A rigorous theoretical proof of this is detailed in Appendix A.

$Re_{\tau 0}$. A rigorous theoretical proof of this is detailed in Appendix A.

3.3. The IBL height  $\delta _i$

$\delta _i$

As mentioned in § 2, ![]() $U_{\tau 2}$ and

$U_{\tau 2}$ and ![]() $\delta _i$ are coupled through the assumed mean velocity profile in Elliott's model. The mean velocity profile is modelled by a piecewise logarithmic function, with a slope proportional to

$\delta _i$ are coupled through the assumed mean velocity profile in Elliott's model. The mean velocity profile is modelled by a piecewise logarithmic function, with a slope proportional to ![]() $U_{\tau 2}$ below

$U_{\tau 2}$ below ![]() $\delta _i$, and

$\delta _i$, and ![]() $U_{\tau 0}$ above

$U_{\tau 0}$ above ![]() $\delta _i$. Here we examine the validity of this assumption by reconstructing the inner logarithmic profile as

$\delta _i$. Here we examine the validity of this assumption by reconstructing the inner logarithmic profile as ![]() $U_{log}^+ = ({1}/{\kappa })\ln (z^+)+B$, where

$U_{log}^+ = ({1}/{\kappa })\ln (z^+)+B$, where ![]() $^+$ denotes an inner normalisation with the local

$^+$ denotes an inner normalisation with the local ![]() $U_{\tau 2}$. The comparison between the experimentally measured

$U_{\tau 2}$. The comparison between the experimentally measured ![]() $U^+$ and predicted inner log region

$U^+$ and predicted inner log region ![]() $U_{log}^+$ is shown in figure 6. Elliott's IBL height

$U_{log}^+$ is shown in figure 6. Elliott's IBL height ![]() $\delta _i$ is defined as the wall-normal location where

$\delta _i$ is defined as the wall-normal location where ![]() $U^+-U_{log}^+=0$, or where the smooth-wall logarithmic profiles intersect the measured mean velocity profile, as represented by the black crosses, and we will denote it by

$U^+-U_{log}^+=0$, or where the smooth-wall logarithmic profiles intersect the measured mean velocity profile, as represented by the black crosses, and we will denote it by ![]() $\delta _{i,log}$. This definition is essentially dependent on the local

$\delta _{i,log}$. This definition is essentially dependent on the local ![]() $U_{\tau 2}$ value rather than the shape of the measured mean velocity profiles below

$U_{\tau 2}$ value rather than the shape of the measured mean velocity profiles below ![]() $\delta _i$. If the mean velocity profile is the same as assumed by Elliott, then

$\delta _i$. If the mean velocity profile is the same as assumed by Elliott, then ![]() $\delta _{i,log}$ should coincide with the profile-based

$\delta _{i,log}$ should coincide with the profile-based ![]() $\delta _{i}$ results. Figure 6 shows two additional profiles based estimates of

$\delta _{i}$ results. Figure 6 shows two additional profiles based estimates of ![]() $\delta _i$. The circles show

$\delta _i$. The circles show ![]() $\delta _i$ determined from the variance profiles following the approach in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), while the solid pink symbol with the black outline shows

$\delta _i$ determined from the variance profiles following the approach in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), while the solid pink symbol with the black outline shows ![]() $\delta _i$ estimated from

$\delta _i$ estimated from ![]() $U$ versus

$U$ versus ![]() $z^{1/2}$ profile following Antonia & Luxton (Reference Antonia and Luxton1971). Both profile-based estimates are in good agreement with each other (despite a small systematic difference), while both are much lower than

$z^{1/2}$ profile following Antonia & Luxton (Reference Antonia and Luxton1971). Both profile-based estimates are in good agreement with each other (despite a small systematic difference), while both are much lower than ![]() $\delta _{i,log}$ which is shown by the open pink symbol. A comparison of the

$\delta _{i,log}$ which is shown by the open pink symbol. A comparison of the ![]() $\delta _i$ values within the logarithmic region is shown in figure 7. Note that the method to compute Elliott's

$\delta _i$ values within the logarithmic region is shown in figure 7. Note that the method to compute Elliott's ![]() $\delta _{i,log}$ is only expected to perform well within the logarithmic region: when

$\delta _{i,log}$ is only expected to perform well within the logarithmic region: when ![]() $\delta _{i,log}$ enters the wake region, the intersecting location will remain as the upper limit of the logarithmic region regardless of the shape of the profile. Therefore, only

$\delta _{i,log}$ enters the wake region, the intersecting location will remain as the upper limit of the logarithmic region regardless of the shape of the profile. Therefore, only ![]() $\delta _{i,log}<0.15\delta _{99}$ are shown in figure 7. In both Group-Re and Group-ks,

$\delta _{i,log}<0.15\delta _{99}$ are shown in figure 7. In both Group-Re and Group-ks, ![]() $\delta _{i,log}$ is systematically higher than the

$\delta _{i,log}$ is systematically higher than the ![]() $\delta _i$ calculated following our current approach. This observation reiterates our previous conclusion that the mean flow within the IBL has not yet fully recovered to a canonical smooth-wall profile, and it also provides some useful clues in refining Elliott's original model. In fact,

$\delta _i$ calculated following our current approach. This observation reiterates our previous conclusion that the mean flow within the IBL has not yet fully recovered to a canonical smooth-wall profile, and it also provides some useful clues in refining Elliott's original model. In fact, ![]() $\delta _{i,log}$ can be approximated by the following empirical equation at least in the near field:

$\delta _{i,log}$ can be approximated by the following empirical equation at least in the near field:

The additive constant ![]() $\Delta \delta _i^+ \approx 500$ is obtained based on empirical observation, and it appears to apply within the range of

$\Delta \delta _i^+ \approx 500$ is obtained based on empirical observation, and it appears to apply within the range of ![]() $Re_{\tau 0}$ and

$Re_{\tau 0}$ and ![]() $k_{s0}^+$ available in this study, which may be interpreted as a constant level of deviation from the canonical smooth-wall state. It is not clear whether this additive constant will change in the case of extreme

$k_{s0}^+$ available in this study, which may be interpreted as a constant level of deviation from the canonical smooth-wall state. It is not clear whether this additive constant will change in the case of extreme ![]() $Re_{\tau 0}$ or

$Re_{\tau 0}$ or ![]() $k_{s0}^+$ values. Future work is required to fully address this question. The predicted IBL thickness is also included in figure 7. The E58 model predicts that the viscous-scaled IBL thickness

$k_{s0}^+$ values. Future work is required to fully address this question. The predicted IBL thickness is also included in figure 7. The E58 model predicts that the viscous-scaled IBL thickness ![]() $\delta _i U_{\tau 0}/\nu$ will grow slightly faster with a higher upstream

$\delta _i U_{\tau 0}/\nu$ will grow slightly faster with a higher upstream ![]() $k_{s0}^+$, as shown in figure 7(b). The comparison with the E58 model suggests that for the range of

$k_{s0}^+$, as shown in figure 7(b). The comparison with the E58 model suggests that for the range of ![]() $k_{s0}^+$ investigated here, we would struggle (within experimental error) to see any difference in the development of

$k_{s0}^+$ investigated here, we would struggle (within experimental error) to see any difference in the development of ![]() $\delta _i$ in the Group-ks experimental data. If

$\delta _i$ in the Group-ks experimental data. If ![]() $k_{s0}^+$ effects on the growth rate of

$k_{s0}^+$ effects on the growth rate of ![]() $\delta _i$ are to be investigated, a much larger variation of

$\delta _i$ are to be investigated, a much larger variation of ![]() $k_{s0}^+$, or perturbation strength

$k_{s0}^+$, or perturbation strength ![]() $M$ will be required. As shown in figure 7, the E58 model under-predicts

$M$ will be required. As shown in figure 7, the E58 model under-predicts ![]() $\delta _{i,log}$, suggesting the necessity in improving the assumptions in the E58 model. However, it is noted that the model predictions are closer to the

$\delta _{i,log}$, suggesting the necessity in improving the assumptions in the E58 model. However, it is noted that the model predictions are closer to the ![]() $\delta _i$ values determined from variance profiles, although these two quantities have different physical meaning.

$\delta _i$ values determined from variance profiles, although these two quantities have different physical meaning.

Figure 6. (a,c,e) Comparison between ![]() $U^+$ (empty triangles), the viscous-scaled mean velocity profile downstream of the step change, inner logarithmic profile

$U^+$ (empty triangles), the viscous-scaled mean velocity profile downstream of the step change, inner logarithmic profile ![]() $U_{log}^+ = ({1}/{\kappa })\ln (z^+)+B$ (solid blue line) and outer logarithmic profile (solid red line) for case Re07ks16. Panels (b,d, f) show the difference between

$U_{log}^+ = ({1}/{\kappa })\ln (z^+)+B$ (solid blue line) and outer logarithmic profile (solid red line) for case Re07ks16. Panels (b,d, f) show the difference between ![]() $U^+$ and

$U^+$ and ![]() $U_{log}^+$ at streamwise locations corresponding to (a,c,e), respectively. Black ‘

$U_{log}^+$ at streamwise locations corresponding to (a,c,e), respectively. Black ‘![]() $+$’ symbols represent the wall-normal position where

$+$’ symbols represent the wall-normal position where ![]() $U^+-U_{log}^+ = 0$, circles represent

$U^+-U_{log}^+ = 0$, circles represent ![]() $\delta _i$ computed using the variance-profile-based approach detailed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), and the triangles with a thick black outline represent

$\delta _i$ computed using the variance-profile-based approach detailed in Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), and the triangles with a thick black outline represent ![]() $\delta _i$ defined as the inflection point in the

$\delta _i$ defined as the inflection point in the ![]() $U$ versus

$U$ versus ![]() $z^{1/2}$ profile (Antonia & Luxton Reference Antonia and Luxton1971).

$z^{1/2}$ profile (Antonia & Luxton Reference Antonia and Luxton1971).

Figure 7. Comparison of ![]() $\delta _i$ determined using the current variance-profile-based approach (solid symbols) and

$\delta _i$ determined using the current variance-profile-based approach (solid symbols) and ![]() $\delta _{i,log}$, the wall-normal position where

$\delta _{i,log}$, the wall-normal position where ![]() $U^+-U_{log}^+ = 0$ (empty symbols) for (a) Group-Re and (b) Group-ks cases. The solid lines in both columns are predictions using the E58 model with

$U^+-U_{log}^+ = 0$ (empty symbols) for (a) Group-Re and (b) Group-ks cases. The solid lines in both columns are predictions using the E58 model with ![]() $k_{s0}^+ = 160$, while the dashed and dash-dotted lines in (b) are with

$k_{s0}^+ = 160$, while the dashed and dash-dotted lines in (b) are with ![]() $k_{s0}^+ = 110$ and

$k_{s0}^+ = 110$ and ![]() $k_{s0}^+ = 230$, respectively.

$k_{s0}^+ = 230$, respectively.

4. Finite-thickness boundary layer: a refined model

Elliott (Reference Elliott1958) originally considered a thick surface layer where the total boundary layer thickness is irrelevant in the problem and the mean velocity profile can be modelled by a logarithmic law over the entire range of ![]() $z$ to predict the quantities of interest. In most engineering applications, however, the boundary layers have a finite thickness and the growth of the IBL may be affected when it exceeds the logarithmic layer and enters the wake region (figure 8). In this section, we adapt the E58 model to accommodate such scenarios with a focus on the outer layer behaviour.

$z$ to predict the quantities of interest. In most engineering applications, however, the boundary layers have a finite thickness and the growth of the IBL may be affected when it exceeds the logarithmic layer and enters the wake region (figure 8). In this section, we adapt the E58 model to accommodate such scenarios with a focus on the outer layer behaviour.

Figure 8. Schematic of the IBL with a finite outer layer height ![]() $\delta _c(\hat {x})$ that grows in the streamwise direction. The flow direction is from left to right. A step change from rough to smooth is currently depicted in the figure, but the FTBL model is also applicable to other scenarios (e.g. smooth-to-rough or rough-to-rougher). The control volumes are delineated by thick dashed borderlines.

$\delta _c(\hat {x})$ that grows in the streamwise direction. The flow direction is from left to right. A step change from rough to smooth is currently depicted in the figure, but the FTBL model is also applicable to other scenarios (e.g. smooth-to-rough or rough-to-rougher). The control volumes are delineated by thick dashed borderlines.

In particular, we continue within the framework of Elliott, which is to satisfy the streamwise momentum equation by adjusting the local length and velocity scales in an assumed velocity profile. However, the form of the assumed velocity profile and momentum equation(s) need to be modified for a finite-thickness boundary layer (FTBL). First, the mean velocity profile deviates from the logarithmic law in the outer layer, which can be modelled by a wake function (§ 4.1). Second, alongside the growth of the IBL, the thickness of whole boundary layer also increases spatially, modifying ![]() $U_{\tau 1}$, the local friction velocity scale of the outer layer (§ 4.2). Finally, the constant-stress layer assumption is not applicable beyond the logarithmic layer, and in § 4.3 we replace it with a more realistic wall-normal shear-stress distribution which decreases to 0 at the edge of the boundary layer. This model will be denoted as FTBL. Further, the deviation of the mean velocity profile from the log-law in a recovering internal layer can be modelled by the blending function, as introduced by Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), and this variation of the model (introduced in § 4.4) will be denoted as FTBL-B.

$U_{\tau 1}$, the local friction velocity scale of the outer layer (§ 4.2). Finally, the constant-stress layer assumption is not applicable beyond the logarithmic layer, and in § 4.3 we replace it with a more realistic wall-normal shear-stress distribution which decreases to 0 at the edge of the boundary layer. This model will be denoted as FTBL. Further, the deviation of the mean velocity profile from the log-law in a recovering internal layer can be modelled by the blending function, as introduced by Li et al. (Reference Li, de Silva, Chung, Pullin, Marusic and Hutchins2021), and this variation of the model (introduced in § 4.4) will be denoted as FTBL-B.

4.1. Wake function

We first introduce an additional variable, ![]() $\delta _c$, as a representation of the boundary layer thickness, and adopt the expression of the wake function given by Jones, Marusic & Perry (Reference Jones, Marusic and Perry2001),

$\delta _c$, as a representation of the boundary layer thickness, and adopt the expression of the wake function given by Jones, Marusic & Perry (Reference Jones, Marusic and Perry2001),

where ![]() $\eta \equiv z/\delta _{c}$. The mean velocity profile has zero gradient at

$\eta \equiv z/\delta _{c}$. The mean velocity profile has zero gradient at ![]() $z=\delta _c$, and typically

$z=\delta _c$, and typically ![]() $\delta _c\approx 1.2\delta _{99}$ for a smooth-wall turbulent boundary layer at a moderate Reynolds number. Here,

$\delta _c\approx 1.2\delta _{99}$ for a smooth-wall turbulent boundary layer at a moderate Reynolds number. Here, ![]() $\varPi = 0.56$ (corresponding to a Coles wake strength of

$\varPi = 0.56$ (corresponding to a Coles wake strength of ![]() $\varPi _c = 0.42$, as reported by Marusic et al. (Reference Marusic, Chauhan, Kulandaivelu and Hutchins2015) from data obtained in the Melbourne High Reynolds Number Wind Tunnel). To summarise, the mean velocity profile is modified as

$\varPi _c = 0.42$, as reported by Marusic et al. (Reference Marusic, Chauhan, Kulandaivelu and Hutchins2015) from data obtained in the Melbourne High Reynolds Number Wind Tunnel). To summarise, the mean velocity profile is modified as

\begin{equation} U(z)=\begin{cases}

\dfrac{U_{\tau 1}}{\kappa}\ln\left(\dfrac{z}{z_{01}}\right)

+ U_{\tau 1}\mathcal{W} \left(\dfrac{z}{\delta_c}\right), &

\text{for } z\geqslant\delta_i,\\ \dfrac{U_{\tau

2}}{\kappa}\ln\left(\dfrac{z}{z_{02}}\right) + U_{\tau

2}\mathcal{W} \left(\dfrac{z}{\delta_c}\right), & \text{for

} z<\delta_i. \end{cases}

\end{equation}

\begin{equation} U(z)=\begin{cases}

\dfrac{U_{\tau 1}}{\kappa}\ln\left(\dfrac{z}{z_{01}}\right)

+ U_{\tau 1}\mathcal{W} \left(\dfrac{z}{\delta_c}\right), &

\text{for } z\geqslant\delta_i,\\ \dfrac{U_{\tau

2}}{\kappa}\ln\left(\dfrac{z}{z_{02}}\right) + U_{\tau

2}\mathcal{W} \left(\dfrac{z}{\delta_c}\right), & \text{for

} z<\delta_i. \end{cases}

\end{equation}

Here we assume that the internal and outer boundary layers (below and above ![]() $\delta _i$) perceive the same overall boundary layer thickness

$\delta _i$) perceive the same overall boundary layer thickness ![]() $\delta _c$, and the mixing of both logarithmic profiles in (4.2) with the free stream flow occur at the same distance from the wall (approximately

$\delta _c$, and the mixing of both logarithmic profiles in (4.2) with the free stream flow occur at the same distance from the wall (approximately ![]() $0.15\delta _c$). This can be justified, at least in the limits: close to the roughness change where

$0.15\delta _c$). This can be justified, at least in the limits: close to the roughness change where ![]() $\delta _i\rightarrow 0$, the contribution from the wake function to the internal velocity profile is negligible, and the outer layer remains unchanged from the incoming boundary layer. Very far downstream of the roughness change where

$\delta _i\rightarrow 0$, the contribution from the wake function to the internal velocity profile is negligible, and the outer layer remains unchanged from the incoming boundary layer. Very far downstream of the roughness change where ![]() $\delta _i\rightarrow \delta _c$, the boundary layer has almost fully adapted to the new surface condition, and the expression (4.2) reduces to a profile in equilibrium with the local wall conditions.

$\delta _i\rightarrow \delta _c$, the boundary layer has almost fully adapted to the new surface condition, and the expression (4.2) reduces to a profile in equilibrium with the local wall conditions.

The velocity matching condition at ![]() $z = \delta _i$ consequently becomes

$z = \delta _i$ consequently becomes

4.2. Streamwise evolution of the outer layer

In contrast to the E58 model, we introduce ![]() $\delta _c$, the thickness of the entire boundary layer (§ 4.1), which grows with

$\delta _c$, the thickness of the entire boundary layer (§ 4.1), which grows with ![]() $\hat {x}$, and

$\hat {x}$, and ![]() $U_{\tau 1}$ is no longer treated as a constant. Therefore, two more unknowns

$U_{\tau 1}$ is no longer treated as a constant. Therefore, two more unknowns ![]() $\delta _c(\hat {x})$ and

$\delta _c(\hat {x})$ and ![]() $U_{\tau 1}(\hat {x})$ are added to the problem, and two more equations are required to close the system. A refined schematic of the problem is shown in figure 8.

$U_{\tau 1}(\hat {x})$ are added to the problem, and two more equations are required to close the system. A refined schematic of the problem is shown in figure 8.

We assume that the evolution of the outer layer is not directly affected by the presence of the IBL. The outer-layer friction velocity ![]() $U_{\tau 1}(\hat {x})$ can be determined by ensuring that the mean velocity profile satisfies the boundary condition of

$U_{\tau 1}(\hat {x})$ can be determined by ensuring that the mean velocity profile satisfies the boundary condition of ![]() $U = U_{\infty }$ at

$U = U_{\infty }$ at ![]() $z = \delta _c$:

$z = \delta _c$:

Note that now both ![]() $U_{\tau 1}$ and

$U_{\tau 1}$ and ![]() $\delta _c$ are functions of

$\delta _c$ are functions of ![]() $\hat {x}$ and their values will change in the streamwise direction as the outer layer evolves. We can also introduce the von Kármán momentum integral equation of the entire boundary layer (control volume

$\hat {x}$ and their values will change in the streamwise direction as the outer layer evolves. We can also introduce the von Kármán momentum integral equation of the entire boundary layer (control volume ![]() ${\unicode{x2460}}$ in figure 8),

${\unicode{x2460}}$ in figure 8),

where ![]() $\theta = \int _{z_{02}}^{\delta _c}(U_{\infty }-U)U/U^2_{\infty }\,\mathrm {d}z$ is the momentum thickness of the entire boundary layer. The momentum integral equation can be rearranged and further integrated with respect to

$\theta = \int _{z_{02}}^{\delta _c}(U_{\infty }-U)U/U^2_{\infty }\,\mathrm {d}z$ is the momentum thickness of the entire boundary layer. The momentum integral equation can be rearranged and further integrated with respect to ![]() $\theta$ as

$\theta$ as

\begin{equation} \hat{x} = \int_{\theta(\delta_i(0))}^{\theta(\delta_i)}\frac{U_{\infty}^2}{U_{\tau 2}^2}\mathrm{d} \theta. \end{equation}

\begin{equation} \hat{x} = \int_{\theta(\delta_i(0))}^{\theta(\delta_i)}\frac{U_{\infty}^2}{U_{\tau 2}^2}\mathrm{d} \theta. \end{equation}

These two equations (4.4) and (4.6), together with (2.4) and (3.3) which govern the flow within the IBL, can fully determine the four unknowns (![]() $U_{\tau 2}$,

$U_{\tau 2}$, ![]() $\delta _i$,

$\delta _i$, ![]() $U_{\tau 1}$ and

$U_{\tau 1}$ and ![]() $\delta _c$) of the system.

$\delta _c$) of the system.

4.3. Shear-stress correction

In a turbulent boundary layer, the total shear stress ![]() $\tau$ is contributed by the wall-normal gradient in the mean flow and the Reynolds shear stress:

$\tau$ is contributed by the wall-normal gradient in the mean flow and the Reynolds shear stress:

The first term only dominates in the viscous sublayer, and the contribution is mainly from the Reynolds shear stress (the second term) above the buffer region. In the limit of asymptotically high Reynolds numbers, a constant-stress layer forms in the logarithmic region with ![]() $\tau ^+$ remaining at unity as determined by the equations of motion (Tennekes & Lumley Reference Tennekes and Lumley1972, p. 54). This assumption is adequate in the E58 model, posed for the atmospheric surface layer, because

$\tau ^+$ remaining at unity as determined by the equations of motion (Tennekes & Lumley Reference Tennekes and Lumley1972, p. 54). This assumption is adequate in the E58 model, posed for the atmospheric surface layer, because ![]() $\delta _i$ remains in the logarithmic layer throughout the evolution and Reynolds numbers are typically very high. However, the validity of this assumption diminishes when a finite-thickness turbulent boundary layer is considered. In the wake region, the Reynolds shear stress is observed to decrease significantly to

$\delta _i$ remains in the logarithmic layer throughout the evolution and Reynolds numbers are typically very high. However, the validity of this assumption diminishes when a finite-thickness turbulent boundary layer is considered. In the wake region, the Reynolds shear stress is observed to decrease significantly to ![]() $0.5\tau _w$ at

$0.5\tau _w$ at ![]() $z\approx 0.5\delta _c$ (Antonia & Luxton Reference Antonia and Luxton1972; Schlatter & Örlü Reference Schlatter and Örlü2010; Morrill-Winter et al. Reference Morrill-Winter, Squire, Klewicki, Hutchins, Schultz and Marusic2017). Shear stress data from both experiments and DNS of spatially developing canonical boundary layers are summarised in figure 9. Both rough-wall and smooth-wall boundary layer data with a wide range of

$z\approx 0.5\delta _c$ (Antonia & Luxton Reference Antonia and Luxton1972; Schlatter & Örlü Reference Schlatter and Örlü2010; Morrill-Winter et al. Reference Morrill-Winter, Squire, Klewicki, Hutchins, Schultz and Marusic2017). Shear stress data from both experiments and DNS of spatially developing canonical boundary layers are summarised in figure 9. Both rough-wall and smooth-wall boundary layer data with a wide range of ![]() $Re_{\tau }$ and

$Re_{\tau }$ and ![]() $k_s^+$ are included. Here

$k_s^+$ are included. Here ![]() $\tau ^+$ decreases steadily from 1 in the near-wall region to 0 in the free stream. The approximation of a constant stress, i.e.

$\tau ^+$ decreases steadily from 1 in the near-wall region to 0 in the free stream. The approximation of a constant stress, i.e. ![]() $\tau ^+ = 1$, is reasonable for

$\tau ^+ = 1$, is reasonable for ![]() $z/\delta _c<0.15$, while the deviation from this approximation is significant above the logarithmic region. A good collapse of the data at various Reynolds numbers is observed under the current scaling. We then fit a third-order polynomial

$z/\delta _c<0.15$, while the deviation from this approximation is significant above the logarithmic region. A good collapse of the data at various Reynolds numbers is observed under the current scaling. We then fit a third-order polynomial

(which is constrained to ![]() $\tau ^+ = 1$ at

$\tau ^+ = 1$ at ![]() $z = 0$ and

$z = 0$ and ![]() $\tau ^+ = 0$ at

$\tau ^+ = 0$ at ![]() $z/\delta _c = 1$) to the data in the range of

$z/\delta _c = 1$) to the data in the range of ![]() $0.1< z/\delta _c<1$, and the fitting parameters are found to be

$0.1< z/\delta _c<1$, and the fitting parameters are found to be ![]() $p_1 = 1.9971$ and

$p_1 = 1.9971$ and ![]() $p_2 = -3.0789$.

$p_2 = -3.0789$.

Figure 9. Shear stress normalised by the friction velocity at the wall and plotted against the wall position normalised by Jones’ boundary layer thickness. The coloured symbols are multiwire hot-wire data obtained from turbulent boundary layers developed on a sandpaper roughness (Morrill-Winter et al. Reference Morrill-Winter, Squire, Klewicki, Hutchins, Schultz and Marusic2017). The black empty symbols are direct numerical simulation (DNS) data of a smooth-wall boundary layer (Schlatter & Örlü Reference Schlatter and Örlü2010). The thick blue line is (4.8) and the horizontal dashed line is at ![]() $\tau ^+ = 1$.

$\tau ^+ = 1$.

Here we propose a modification of the term ![]() $\Delta \tau _2$, which is the difference between the shear stress at the top and bottom surfaces of control volume

$\Delta \tau _2$, which is the difference between the shear stress at the top and bottom surfaces of control volume ![]() ${\unicode{x2461}}$ in figure 8, by replacing the stress at

${\unicode{x2461}}$ in figure 8, by replacing the stress at ![]() $z = \delta _i$ with the aforementioned empirical fit (4.8) that captures the decrease of the shear stress in the wake region. The shear-stress difference

$z = \delta _i$ with the aforementioned empirical fit (4.8) that captures the decrease of the shear stress in the wake region. The shear-stress difference ![]() $\Delta \tau _2$ becomes

$\Delta \tau _2$ becomes