Introduction

Bronze casting techniques in ancient China have long been an important field of study. Mysteries and questions regarding techniques for model replicating have puzzled many scholars, and reliable records of these techniques are very scarce. There are no replicated bronzes that share the same size, shape, and decorative patterns in the Early and Middle Bronze Age (1500–600 b.c.e.); rather, they emerged as late as 500 b.c.e. How the replication of bronzes was practiced and developed, then, is the focus of this article. The process of replication required that bronze workshops produce decorated models, conduct many transfers between models and molds, slice and assemble molds, and insert spacers and clay cores. The techniques involved will illustrate how an assembly line of bronze industrial production operated in 500 b.c.e. China.

Definition of replicated bronze objects

When we use the term “replicated bronze objects,” we mean that the objects are identical in terms of size, shape, and decorative patterns, implying that they probably originated from the same decorated model. This article treats the words “identical” and “the same” seriously and distinguishes them from “highly similar” and “similar.” An object being “identical” to another means that their size, shape, and decorative patterns are the same, as demonstrated in the group of identical bronze quadrupeds shown in Figures 1–3. Sammy Li proposes to compare the size and shape of these objects carefully;Footnote 1 their decorative patterns in particular are inspected inch by inch to determine whether they are truly identical. “Highly similar” bronzes resemble each other in a high degree but with variations in detail.

Figure 1 Bronze quadruped. Freer (FR) Gallery collection. Accession no. F1948.24. L. (from the nose to the tail) 20.5 cm, ca. 500 b.c.e. Freer Gallery of Art, Smithsonian Institution, Washington, DC: Purchase – Charles Lang Freer Endowment, F1948.24. Photo by Kin Sum (Sammy) LI (hereafter “KSL”).

Figure 2 Bronze quadruped. British Museum (BM) collection. Accession no. 1947.0712.333. L. 20.5 cm, ca. 500 b.c.e. Photo credit: © The Trustees of the British Museum. All rights reserved.

Figure 3 Bronze quadruped (animal-shaped object). Asian Art Museum of San Francisco (SF), the Avery Brundage collection. Accession no. B60B1000. L. 20.5 cm, ca. 500 b.c.e. Photo by KSL.

The model-replicating method

Robert Bagley has described the model-replicating method, which occurred as early as the Erligang 二里崗 period (1400–1300 b.c.e.).Footnote 2 He concludes that ancient Chinese casters would first create a clay model—the “decorated model”—bearing the shape and decorative patterns of the final bronze object. Casters invested the decorated model with clay and formed a clay mold around the model. They then sliced the mold into sections and removed them from the model. The model was removed or scraped down to a core. The mold sections were then re-assembled around the scraped model or a new clay core. In between the core and the re-assembled mold sections was a cavity in the shape of the desired bronze. To stabilize the positions of the core and the outer mold sections, casters might insert spacers or chaplets to sustain them.Footnote 3 Without these spacers or chaplets, the outer mold might easily shift or join with the core, leading to defects in the final bronze. A sprue and gate were created on the outer mold, allowing casters to pour molten bronze into the cavity in the mold. They broke the mold when the molten bronze had solidified and thereby obtained the final bronze in the desired shape with all its decorative patterns. The mold often could not be re-used because the decorative patterns were usually damaged during the casting.

The success of ancient Chinese bronze casters relied on three important skills: in the use of mold sections, in multiple pours of molten bronze, and in the placing of spacers/chaplets.Footnote 4 There is a consensus that the section-mold casting method was widely practiced in ancient China, as evidenced by the presence of mold join lines on extant bronzes.Footnote 5 To cast bronze objects of complicated structure and shape, composite casting and multiple pours might have been adopted.Footnote 6 Pre-cast and/or cast-on techniques were thus included in the technical corpus in respect of multiple pours. The traces of pre-cast and cast-on techniques can be found at the joints between the separately cast parts. Some of the spacers have left marks on the outer surface of the bronze. Spacers and bronzes were made of different alloy composition, hence traces of spacers appear in a color different from the neighboring bronze in the long-term corrosion.Footnote 7

Theoretically, these casting techniques allowed for the widespread phenomenon of replicating bronzes from decorated models. If the model was not scraped down to a core, it could actually have been re-used. As long as the decorated model did not become deformed in the process of making molds, casters could have formed molds in sections on the models multiple times. After removal from the model, the mold sections could be re-assembled in the same manner time after time. The size, shape, and decorative patterns of the final bronzes, cast from these identical molds, should appear the same. This is one of the advantages of using the model-replicating method as it saved the model maker's chores of repeatedly decorating new models.Footnote 8 The model maker could also decorate directly on the model, thereby avoiding the need to decorate new molds again and again (and always in reverse). He simply adopted visually straightforward designs and did not need to worry about decorating mirror-reversed patterns on the mold.

We have to note that surmoulage bronzes are not counted as identical bronzes in this article. Surmoulage bronzes are cast from molds replicated from an existing bronze, which implies that a surmoulage does not share the same decorated model with that of the existing bronze. Moreover, surmoulage bronzes tend to be smaller than the bronzes that they took the mold from because bronze shrinks during cooling.

It is, however, very strange that we have not, as yet, found groups of identical bronzes from before about 500 b.c.e. The reasons for this are unknown.Footnote 9 Perhaps all models were scraped down to cores, and therefore they were never used to form more than one mold.Footnote 10 Or perhaps instead such groups have just not yet been identified or excavated. There have been some attempts to find such groups but only within a single archaeological context, that is to say, the same tomb or hoard.Footnote 11 Given that identical bronzes might over time have been traded to distant places, such limited searches are inadequate. Only a large and systematic search for groups of identical bronzes would be sufficient and conclusive for our research purposes.

Methodology

There are, in practice, three particular problems that make it extremely difficult to identify replicated bronze objects. First of all, numerous bronze objects of simpler structure, such as bronze blades, and disks without any decorative patterns, might have been replicated from the same model or cast from re-usable molds. It is quite difficult, if not impossible, to identify such replicas. Thus this article will focus on bronzes of complicated structure and shape, which provide more clues for comparison. Second, the prevailing publication format for three-dimensional bronzes is a two-dimensional photograph, which is quite insufficient to compare whether the bronzes are identical. Identical bronzes are best put on the same table for close examination. But most of the identical bronzes are now scattered in museums and other collections around the world and it is too troublesome to gather them for detailed comparison. Third, to compare three-dimensional bronzes is extremely difficult even if they are put on the same table, because they cannot be fitted together. Bronzes that are essentially two-dimensional, such as mirrors, are easier to compare: a photograph will reveal enough detail for decorative patterns to be fitted together.Footnote 12

In order to address the second and third of those problems, Sammy Li obtained funds to travel to various museums around the world in 2017 and scan these bronzes on site into freely rotatable 3D models.Footnote 13 He first theorizes that the 3D models of the bronzes can be placed together in the computer for detailed comparison, and then fitted together to determine if they share the same size, shape, and decorative patterns. The detection of spacers and clay core inside a bronze object cannot be done with the naked eye. Instead, scholars conduct X-ray photography and computerized tomography (CT) scan of the bronzes in order to detect the use and positions of the spacers and core applied during casting.Footnote 14 Sammy Li thus proposes to investigate whether casters of identical bronzes would have shared the same method of applying and positioning the spacers. Clues to the existence of section-mold casting and mold lines can occasionally be examined with the naked eye.Footnote 15 Next we analyze whether these identical bronzes had shared the same or similar alloy composition. Through these investigations we will be able to glean information regarding the individual stages and formation of an assembly line in ancient Chinese industrial production.Footnote 16 Production of identical bronzes, or at least identical bronze components, is an essential indicator of the existence of an assembly line in an industrial context.

Identical bronzes: three quadrupeds plus a highly similar one

Previous scholars have hunted for identical bronzes but failed to find them. For instance, in 1986 Chen Zhida 陳志達 concluded, after examining clay molds and bronzes found in Yinxu 殷墟, that Anyang 安陽 casters used a single clay model for a single object.Footnote 17 Chen failed to locate any identical bronzes. Yue Hongbin 岳洪彬 and Yue Zhanwei 岳占偉 conducted another hunt in 2014, still limited to the corpus of Yinxu bronzes.Footnote 18 They hypothesized that one model might have been used for multiple objects. But their only evidence was the observation that some bronze objects share a “highly similar” shape. They admit that they had not located any bronze object that was identical to others in terms of decorative patterns. Minor variations in decorative patterns testify to the likelihood that these “highly similar” bronzes did not share the same decorated models. The “identical” bronzes, in the eyes of the two authors, were replicated from models of rough shape, meaning that the final bronzes appear to be of a roughly similar shape. This is not, however, evidence of identical bronzes such as those we focus on in this article; our identical bronzes must share the same size, shape, and decorative patterns.

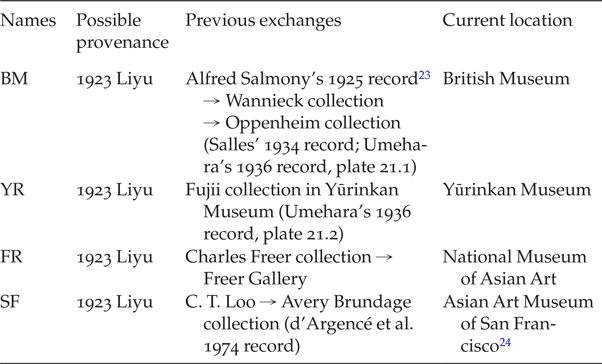

The earliest group of identical bronzes that we can identify to date consists of at least three quadrupeds (four-legged animals) housed in three museums. It is highly likely that they came from Liyu 李峪 village, Hunyuan 渾源 county in Shanxi 山西 Province and were cast in foundries at Shanxi Houma 侯馬 in around 500 b.c.e.Footnote 19 The three identical quadrupeds are listed in Table 1 and shown in Figures 1–3.Footnote 20

Table 1 Measurement data of three quadrupeds (Sammy Li measured each quadruped himself; measurement data of YR not available)

For convenience, we call the quadruped stored in the Freer Gallery “FR,” the one in British Museum “BM,” and the one in Asian Art Museum of San Francisco “SF.” There is one more quadruped, which appears partially identical to these three, but with some decorative patterns that are different to those of the others. It belongs to the Fujii 藤井 collection and is held in the Yūrinkan 有隣館 Museum in Kyōto 京都 (Figure 4). We call it “YR” in the following sections. Sammy Li has examined the former three quadrupeds in person and measured them in a consistent way; but he has not handled YR and thus cannot provide detailed measurement data.

Figure 4 Bronze quadruped. Yūrinkan (YR) Museum collection. Accession no. unknown. H. 11 cm (not the authors’ measurement), l. unknown. ca. 500 b.c.e. Photo by KSL.

Here is a brief history of the identification of this group of identical bronzes. Georges Salles and Shang Chengzuo, in 1934 and 1936 respectively, noted that four such quadrupeds may be extant in various locations.Footnote 21 Umehara Sueji in 1936 published a catalog featuring objects from the 1923 find at Hunyuan Liyu. Three of those bronzes, for which Umehara provides black-and-white photographs (Umehara's catalog, plate nos. 20.2, 21.1, and 21.2), are the quadrupeds mentioned here. Umehara claims that the plate 20.2 object is from somewhere in Taiyuan 太原 county, Shanxi Province; the plate 21.1 one is in the Oppenheim Collection in London, while the plate 21.2 one is the one in the Fujii Collection in Kyōto. Thomas Lawton adds more details and gives a comprehensive summary.Footnote 22 Therefore, we can provide a brief list of how the quadrupeds came to different collections:

Table 2 History of collecting the quadrupeds

Lawton is still not certain whether they are identical, and he simply uses “almost identical” and “similar” to describe their relationship. Bagley embraces a firmer stance that FR, SF, and BM are identical; namely they “were almost certainly made from a single decorated model.”Footnote 25

The quadrupeds are actually the earliest examples of identical bronzes that we have identified to date. Since all of the quadrupeds were likely cast in around 500 b.c.e. at Houma, we can state that we have not identified any groups of identical bronzes before 500 b.c.e.. We will take the discoveries and observations of the scholars cited above as our basis for exploring a long-ignored story of metallurgy in ancient China.

We notice that FR, BM, and SF are of an almost identical size (Table 1). Their current appearance, color, patina, and weight have been affected by corrosion and other damage. Therefore, we will have to compare their shape and decorative patterns carefully. Tiny curls, spirals, and minute lines constitute the majority of the patterns, which were executed in millimeter ranges. From Figure 5 and Figure 6, viewers can conclude that FR, BM, and SF share the same decorative patterns; but, while most parts of the decorative patterns on YR are identical to that of the former three, the patterns around its belly are different. We will discuss this phenomenon in the later sections. Thus far we can conclude that the former three quadrupeds originated from the same decorated model; no caster would have devoted so much effort into making every detail match.

Figure 5 Comparison of the details of the left sides of the four quadrupeds. Top left: FR; top right: BM; bottom left: SF, and bottom right: YR.

Figure 6. Comparison of the details of the right sides of the four quadrupeds. Top left: FR; top right: BM; bottom left: SF; bottom right: YR (from Umehara, Sengoku shiki dōki, pl. 21.2, n.p.).

Section-mold casting and mold lines

FR, BM, and SF were cast with the section-mold method. A model maker first carved every fine detail on a clay model. Next, his colleague the mold maker formed one mold on this decorated model. The mold maker then sliced the mold into sections and carefully detached them from the model. Putting the model aside, he next created a clay core, which was then placed inside the cavity formed by re-assembling the mold sections. So as to ensure that the core will hold exactly the right position in relation to the outer mold sections during casting, he used more than fifteen spacers to stabilize the core and outer mold sections. Once he had this mold prepared for casting, his colleagues were then ready to create another mold on the same model. The mold maker then sliced this new mold as before. Repeating the same steps, the second and third molds were formed and made ready for casting. Based on the evidence set out below, this description accurately delineates the process that should have been followed in the casting of FR, BM, and SF.

We will use FR as the first example to illustrate this process, basing our analysis on the evidence of the mold lines found on all three quadrupeds. Figures 7–10 show the locations (indicated by arrows and drawn lines) of the mold lines on FR. When mold sections were re-assembled, no matter how tightly they were joined together, a tiny gap would inevitably have been left between two neighboring mold sections. This gap, which was sunken in the mold, appears in the form of a raised line on the final object where molten bronze has filled the tiny gap.

Figure 7 Mold lines, indicated by arrows, on the right side of FR. Photo by KSL.

Figure 8 Mold lines, indicated by arrows, on the left side and neck of FR. Photo by KSL.

Figure 9 Mold lines indicated by arrows and spacers are circled on the bottom of FR. Photo by KSL.

Figure 10 Reconstructed mold lines indicated by lines drawn on FR. Photo by KSL.

We can see these raised lines around the neck, on the right and left bumps, and at the bottom/underbelly of FR. In Figure 7, a mold line begins from the right rump, cuts through some decorative patterns, and continues to the right side of the neck. In the three sub-images in Figure 8, we can see a mold line running along the spine of FR and then across the top of its neck; another mold line begins from the left rump; and three more beneath its neck. In Figure 9, there is a bold line at the underbelly of FR, running from the rump to the neck. Vertical to this bold line is a thinner line separating the rump from the belly. At the joints between the decorative patterns on the left and right sides and the smooth and plain underbelly of the bottom, and also on the bottom of the feet, there are vague mold lines running across. A certain proportion of the raised/mold lines were removed during the polishing of the bronze; but there are enough remains to clearly reveal the original positions and continuance of the lines. We illustrate the positions of the reconstructed mold lines in Figure 10 and deduce that there were at least seven mold lines on FR, which in turn implies that there were at least seven mold sections re-assembled to form the outer mold for casting of FR. These “at least seven mold sections” are an estimation and there may have been more; but we cannot now discern any more from the evidence of mold lines that remains.

We can readily imagine just how the casters would have wanted to slice the mold formed on the decorated model, once the mold had absorbed all decorative patterns. They would have wanted to cut off two mold sections from the top—one section adhering to one side of an ear. Two more sections of mold corresponded to the two sides—each section adhering to the other side of each ear. The left side section extended to the underbelly and one side of the two left legs; so did the right side section. At least three separate sections were subsequently rejoined to form the underbelly: one for the rump, one for the left part of the underbelly and the other side of the left legs, and one for the right part of the underbelly and the right legs. It would have been very difficult to remove an intact mold from a long protrusion, e.g. the ears and legs. A better way would have been to slice the mold formed on the protrusion into sections and then remove these sections one by one. This was applicable to the removal of mold sections relating to the ears and legs.

We are able to find mold lines on corresponding positions on BM and SF although, but due to the corrosion and polishing, some lines were too obscure to be discerned. In Figure 11, mold lines on the left and right rumps are revealed on SF. Figure 12 reveals the three mold lines beneath the neck of SF and two lines on the underbelly and rump. BM displays fewer lines as corrosion still covers the decorative patterns. But we can discern the same three mold lines beneath the neck and a further two on the underbelly of BM in Figure 13. Since Sammy Li has not handled YR in person, all we can say for certain, as seen in Figure 14, is that it is possible to distinguish two mold lines beneath the neck. The casters of YR might have adopted a similar number of mold sections as was used in casting FR, BM, and SF.

Figure 11 Mold lines, indicated by arrows, on SF. Photo by KSL

Figure 12 Mold lines indicated by arrows and spacers circled on the bottom of SF. Photo by KSL.

Figure 13 Mold lines indicated by arrows and possible sprue and gate circled on BM.

Figure 14 Mold lines indicated by arrows on YR. Photo by KSL.

The circled parts in Figure 13 indicate the possible positions of the sprue and gate. Molten bronze was poured into the mold through the sprue. When the cavity inside the mold was filled, any excess of molten bronze would come out through the gate. Experienced casters would stop pouring at just this moment. The bronze protrusions on the sprue and gate were then removed during final polishing; as a result, we can see directly into the clay core in Figure 13.

Spacers and clay cores

Occasionally we can see the spacers on the bronze surface, as the corrosion degrees and colors of the spacers and neighboring substance are different. We can see the rectangular-shaped spacers on FR (Figure 9) and SF (Figure 12), some of which are circled in the images. Many other spacers, however, are hidden inside the molten bronze during casting; as a result, we can only use X-ray photographs and CT scanned images to illustrate their positions.Footnote 26 CT scanned images are similar to X-ray photographs; but we can obtain a more comprehensive picture of how the spacers were positioned in CT scanned images because we can change our points of views. An X-ray photograph yields a static point of view, while CT scanned images are like numerous X-ray photographs providing different perspectives. We have obtained some X-ray photographs of FR and SF, and CT scanned images of BM (Figure 15). Since the point of view of an X-ray photograph is limited, the spacers hidden on both sides of a quadruped would be revealed on the same image; however, we cannot clearly distinguish their exact positions. As for the CT scanned images of BM, on the other hand, we can keep changing our points of view and distinguish the exact locations of the spacers. We point out the spacers on the left side of BM with arrows (see the top left sub-image of Figure 15). Readers are welcome to discern the other spacers on the right side of BM in the bottom left sub-image of Figure 15. In Figure 16 we can view the quadrupeds from the top or the bottom. The arrows in Figure 16 indicate the presence of possible spacers. We can just barely compare the use of the spacers on the three quadrupeds.

Figure 15 X-ray photographs of the left sides of the three quadrupeds: BM (top left and bottom left; as it is done with CT scans, we can rotate the quadruped a little to see its x-ray photographs in different views); SF (top right), and FR (bottom right). Arrows indicate the positions of spacers at the left side of BM. Image credit: © The Trustees of the British Museum, all rights reserved; the Asian Art Museum of San Francisco; and Freer Gallery of Art/Department of Conservation and Scientific Research.

Figure 16 X-ray photographs of the bottom and backs of three quadrupeds: SF (first; viewing from the bottom), FR (second; viewing from the top), and BM (third, viewing from the top). Arrows indicate the positions of spacers. Image credit: the Asian Art Museum of San Francisco; Freer Gallery of Art/Department of Conservation and Scientific Research; and © The Trustees of the British Museum, all rights reserved.

In this way, we can ascertain that the casters of the three quadrupeds utilized numerous spacers. For example, the casters of BM adopted more than fifteen spacers. Furthermore, the casters positioned the spacers around the neck, front legs, belly, and the rump; in other words, almost every part of each quadruped. This makes sense as, on the one hand, these parts were the weak links where the clay core might adhere to the outer mold sections, thereby bringing about defects on the finished piece. And, on the other hand, we can understand that the casters were not confident in stabilizing the clay core and outer mold sections. It is not surprising to find this lack of confidence as we can see from Figure 7 to Figure 14 that the clusters of spacers were distributed in areas where we can discern multiple mold lines, which means that these were the joints between multiple mold sections. Joints between mold sections were the weak links that might not bear the pressure and striking force of the molten bronze. The use of spacers helped consolidate the joints. Finally, we can observe that the casters of the three quadrupeds shared a very similar method of positioning the spacers. The positions and shapes of the spacers are highly similar. It seems more than possible that all of this work was carried out by the same group of casters.

The shapes of the clay cores of the three quadrupeds were remarkably well formed.Footnote 27 From Figure 15 we can see that the clay cores bear almost the complete shapes of the quadrupeds, but with slightly smaller dimensions, which means that their cores are not merely rough clay trunks. For example, the core of BM includes the head, torso, and four legs.Footnote 28 The contour of the torso part of the core develops with regard to the shape of the final bronze. The bronze substance is, as a result, very thin and just robust enough to sustain the entire structure of the quadruped.

These very sophisticated cores hint at the practice of scraping of decorated models. But given that the three identical quadrupeds have already proven themselves to be from the same decorated model, where then did the models that were to be scraped come from? One hypothesis is that the original decorated model could have been replicated. After the model maker finished decorating the original model, the mold makers then made multiple identical molds from the original decorated model in order to produce identical quadrupeds. Out of the multiple identical molds, they somehow also retained one mold to replicate a clay decorated model. They poured soft clay into the re-assembled mold and waited until the soft clay hardened. Then they scraped the retrieved model, which bore the complete shape and size of the original model, to the shape of a core. That means they removed the surface decoration and large protruding parts including the ears. The scraped core is the one we see in the X-ray photograph of BM. This explains how the mold makers made the core to a shape very close to that of the final bronze.

Did the mold makers replicate the scraped core and produce identical clay cores? This is possible but we do not have evidence to further test this hypothesis. We may be able to prove this in the future if we can compare clearly the shapes of the cores of SF and FR to that of BM. Replicating the clay cores saved the mold makers’ efforts in scraping down the models and simultaneously conforming to the complex shape of the outer mold sections. This would protect the original model and mold from being replicated too many times. Excessive replication would very easily lead to the deformation of the original. A deformed or damaged model or mold could no longer provide the fine source for replication, meaning that casters would then need to either repair the deformed or damaged model or mold, or start with a new one.

We can thus reconstruct a complete assembly line of production based on the evidence we have cited. At least one model maker was in charge of decorating the model. After he carved all decorative patterns on the model, mold makers invested the model with clay, formed a mold, and sliced this mold into sections. They repeated this investing and slicing many times and obtained multiple identical molds. During the re-assembly of the mold sections, spacers were inserted into the mold for casting and they helped to stabilize the gap between the clay core and mold sections. Clay cores were of course prepared in advance, whilst the insertion and placing of spacers were probably done by one single specialist.

Superimposition of 3D models of the quadrupeds

Even in modern engineering, errors, variations, or discrepancies generally exist in replicated components. Engineers have to reduce the discrepancies of replicated car doors, for example, in order for the doors to fit precisely into every replicated car shell. The fewer the discrepancies, the easier it is to fit the door into the shell. The doors and shells are mass produced, thus individual discrepancies are reduced to the smallest possible number.Footnote 29 The ability to produce numerous components of identical size, shape, and decorative patterns is critical to the success of mass production. If errors, variations, or discrepancies of individual components cannot be adequately minimized, the entire mass production assembly line will collapse.

With this perspective in mind, we will now consider the discrepancies between the identical quadrupeds, which were supposedly made by the same group of casters in the same assembly line of production. In today's engineering projects, engineers can use 3D scanned models of the components to compare discrepancies. The three quadrupeds are compared using this method. First of all, in order to establish the reliability, consistency, and precision level of this 3D comparison method, we must guarantee that every 3D scanned model will accurately and precisely represent the size and shape of the original object.Footnote 30 We prove this by 3D scanning a pottery camel twice (Figure 17). The first scanned model is compared to the second scanned model in Figures 17–18. Corresponding points of the two 3D models are selected in Figure 17 for automatic alignment in a 3D processing software called “3D Reshaper.” This means that the two 3D models will be superimposed on each other. If they do not fit perfectly, it means the 3D comparison method is not reliable because after all the two 3D models were scanned from the same camel. Figure 18 displays the superimposed results in two formats. The left sub-image shows that the two colored 3D models fit perfectly; there is no extending part. The right sub-image reveals the two scanned models in point-cloud format. A 3D scanned model is actually composed of hundreds of millions of points; their cluster is called a “cloud.” The two sets of point cloud of the two models also fit perfectly. The comparison of the two 3D models scanned from the same camel shows that our method is consistent, precise, and reliable. A 3D scanned model precisely and accurately represents the size and shape of the original object.

Figure 17 (Left) pottery camel. Collection of the Department of History, Hong Kong Baptist University. (Center and right) two 3D models scanned from the same camel. Photo and images by KSL.

Figure 18 (Left) superimposing the two camel 3D models altogether. They perfectly match with each other. (Right) matched point clouds of the two superimposed camel 3D models. Images by KSL

We then start the 3D comparisons of the three quadrupeds. Since it is very hard to compare all three at one time, Sammy Li proposes instead to compare them two at a time.Footnote 31 In Figures 19–20, we start with the superimposition and comparison of BM and SF. Corresponding points on the left sides of the two quadrupeds are selected in Figure 19 for automatic alignment, and we see the interesting results in Figure 20 showing that they do not fit perfectly. Parts of BM, including the right belly, head, and feet are revealed on the body of SF, which means that parts of BM extend beyond the body of SF. Should they not instead be identical in terms of shape and size?

Figure 19 Selecting corresponding points, aligning the left sides, and superimposing the BM (left) and SF (right) 3D models. Images by KSL.

Figure 20 Different views of the BM and SF 3D models after superimposition. Alignment based on the left sides of the quadrupeds. Images by KSL.

Assembling mold sections

The discrepancies in their shapes and sizes are due to variations in the slicing and re-assembly of the mold sections. BM and SF do indeed derive from the same decorated model; but this does not necessarily imply that their mold sections were sliced and assembled in the same way. Although the positions of their mold lines are similar, which means that their mold sections were sliced in a similar way, variations did occur. When assembling the relatively soft mold sections in the shape of long slabs (Figure 10), different degrees of assembling force and starting points of assembly would have led to minor variations of shape and size. How can we justify this hypothesis?

Figure 21 reveals the clues. We attempted different alignment points of BM and SF. In Figure 19, we chose to align according to the corresponding points on the left sides of the two quadrupeds. This yielded the superimposition result of the top left sub-image in Figure 21. We then chose to align according to the corresponding points on the heads (top right), right sides (bottom left), and tails (bottom right) of the two quadrupeds. The first three superimposition results demonstrate that most of their parts match, although extending parts do occur. Two important indicators in determining the degree of matching are revealed on the heads and feet. We can see that there is very little deviation in terms of the heads and feet themselves. But when we align them by their tails, their heads, bodies, and feet deviate substantially. This means that when the mold makers were re-assembling the mold sections, they apparently preferred to assemble the head and body parts first. This has meant that the heads and bodies of BM and SF match to a high degree. But the mold makers could have easily exerted some force during the assembly of the long clay slabs of mold sections; when assembling the tail parts, in particular, they might have used relatively heavier force and thereby twisted the orientation of the tails. Therefore, alignment by the tails yields a relatively poor match.

Figure 21 Bottom views of the BM and SF 3D models after superimposition. Online version of this article: BM (red) and SF (blue); print verions: BM (lighter color) and SF (darker color). Alignment based on the left sides (top left), heads (top right), right sides (bottom left), and tails (bottom right) of the quadrupeds. Images by KSL.

Figure 22 and Figure 23 demonstrate the superimposition results between FR and SF, and FR and BM. It is difficult to conclude which parts were taken up first when assembling the mold section; however, given the significant deviation in tail superimpositions, it seems safe to postulate that they did not start with the tails. In Figure 22, the left side alignment between FR and SF deviates to a larger extent.

Figure 22 Bottom views of the FR and SF 3D models after superimposition. Online version of this article: FR (red) and SF (blue); print version: FR (lighter color) and SF (darker color). Alignment based on the left sides (top left), heads (top right), right sides (bottom left), and tails (bottom right) of the quadrupeds. Images by KSL.

Figure 23 Bottom views of the FR and BM 3D models after superimposition. Online version of this article: FR (red) and BM (blue); print version: FR (lighter color) and BM (darker color). Alignment based on the left sides (top left), heads (top right), right sides (bottom left), and tails (bottom right) of the quadrupeds. Images by KSL.

Comparing the results displayed from Figure 21 to Figure 23, alignment of the right sides and heads of the three quadrupeds deviate to the least degree. We may surmise that the mold makers probably assembled the mold sections by joining the long slabs at the head position and using the right side as the point of departure. After joining the several slabs of mold sections, they added the tail section. Every joint was added with a certain degree of force, and it appears to have been this application of force that led to the final twist of the tails.

Minor touch-ups

What if the original decorated model became deformed or damaged? These intelligent casters would repair the damaged parts and keep using the model for as long as possible. Figure 5 reveals a part of YR that is not found on the other three quadrupeds. This different part exists only around the frontal part of the torso of YR; in all other parts, YR is identical to the other three quadrupeds. We hypothesize that the difference in the frontal part of the torso of YR is the consequence of damage to the model from multiple replications. The model maker scraped away the undesired part and carved new patterns onto this area of the model.Footnote 32 He did not abandon the previous style of the pattern and kept using spirals and curls to fill the empty area. One of his concerns was to hide this change in order to keep the end user from noticing it.

We have a later set of examples to further illustrate this practice: three identical bronze mirrors (Figure 24). One of them was archaeologically excavated from a tomb at Yunmeng Shuihudi 雲夢睡虎地 in Hubei 湖北 Province; the second one is in the Winthrop collection in the Harvard University Art Museum (HUAM); and the third is in the Cotsen collection in the Shanghai 上海 Museum.Footnote 33 Their size, shape, and decorative patterns demonstrate that they originated from the same decorated model. The main motifs of each mirror consist of two warriors, one tiger, and one anthropomorphic monster. Careful readers will find that the head of the tiger on the Winthrop mirror is missing (Figure 25). Replacing the head of the tiger are granules and striations. These are not the repairs of a later period, but rather the result of touch-ups on the damaged decorated model. To keep using the damaged model as long as possible, the model maker scraped the damaged part and carved striations and granules similar to those of the neighboring areas, but somehow he did this in a rougher manner. Mold makers kept using this repaired model and replicated a new mold for casting the Winthrop mirror as we see it today. The Yunmeng and Cotsen mirrors, on the other hand, were cast with fine molds replicated from the previously undamaged decorated model. Along this line of thought, we can, therefore, deduce that the production time of YR was slightly later than that of SF, FR, and BM.

Figure 24 Three identical bronze mirrors. Top left: from Hubei Yunmeng Shuihudi M9. Report no. M9: 60. D. 10.4 cm, ca. 300 b.c.e. After Zhongguo qingtongqi quanji bianji weiyuanhui 《中國青銅器全集》編輯委員會, ed., Zhongguo qingtongqi quanji 中國青銅器全集, vol. 16 (Beijing: Wenwu, 1998), 35, plate 35. Top right: Grenville L. Winthrop purchased from Yamanaka & Co., New York. Harvard Art Museums/Arthur M. Sackler Museum, Bequest of Grenville L. Winthrop. Accession no.: 1943.52.139. D. 10.5 cm, ca. 300 b.c.e. Photo: ©President and Fellows of Harvard College. Bottom: formerly in the Lloyd Cotsen collection, now housed in the Shanghai Museum. The Cotsen collection no.: O-0460. D. 10.2 cm, ca. 300 b.c.e. After Lothar von Falkenhausen (ed.), The Lloyd Cotsen Study Collection of Chinese Bronze Mirrors, vol. 1 (Los Angeles: Cotsen Occasional Press, UCLA Cotsen Institute of Archaeology Press, 2011), 145, plate 56.

Figure 25 Detail of the Winthrop mirror. The tiger has lost its head, which is replaced by striations and granules. Photo: ©President and Fellows of Harvard College.

Possibilities for multiple replications

Careful readers will observe a minor difference on the backs of SF, FR, and BM (Figure 26); Sammy Li was not able to see the back of YR when he examined it. He finds intact patterns on SF and FR, but surprisingly a hole on BM. This hole might have led us to postulate that BM had been used as a stand or support for a table or a lamp.Footnote 34 But the reality is more complicated than we might imagine. Indeed BM might have been used as one of the stands; but SF and FR obviously did not belong to this BM group.

Figure 26 Backs of the three quadrupeds: SF (left), FR (center), and BM (right).

One possibility is that more than four quadrupeds were replicated from the one original decorated model.Footnote 35 It could be that BM and other quadrupeds with a hole on their backs were used as groups of stands for tables; or, alternatively, each of them could have supported a lamp pole. But the owners of SF, FR, and others probably used the quadrupeds as display items in order to show off their wealth, status, and ability to commission the most sophisticated craftsmanship. The patterns and shapes of the models and molds were transferrable; indeed, multiple decorated models and molds could have been replicated, the better to preserve the originals. We thus postulate that there might have been more than four such quadrupeds produced. This was the production power of the assembly line. But the fact remains not many of them have yet been found, either in existing collections or through more recent excavation.Footnote 36

Alloy composition

It will be interesting to investigate whether the casters adopted the same crucible of molten bronze to cast the four quadrupeds: if their alloy compositions—the proportions of their major, minor, and trace elements—are the same, it is likely that they were cast with the same crucible of molten bronze; if not, then the single production assembly line might have involved several castings. In other words, some quadrupeds might have been cast in one batch, and others in other batches. We will focus on the three quadrupeds again.

We have encountered numerous problems in conducting experiments to investigate this matter. First of all, since the quadrupeds are in three different museums, it is next to impossible to test them with the same machine using the same settings and calibration. Therefore, we have not been able to apply a consistent and reliable method to test the three quadrupeds. Second, corrosion on the quadrupeds may have affected the test results. Third, even if we choose to analyze only the uncorroded parts, different parts of the same quadruped may nonetheless have different alloy compositions. This is very likely to be the case for a leaded bronze (as shown in Table 3) because of segregation of some of the lead content. Despite these difficulties, we still have some interesting data, which may serve as a reference point for future analyses.

Table 3 Alloy compositions of FR, SF, and BM.

The 1973 and 1984 Freer Gallery tests were done with different methods: wet chemical analysis on the one hand and spectrographic analysis on the other; but these methods can yield reliable quantitative data of the major and minor elements of FR. At least we know the percentages of the major elements and the fact that FR contains iron as a minor element. But the test provided no data about trace elements, except for the fact that zinc had not been detected. The 2017 San Francisco and 2018 British Museum tests were conducted with two different X-ray fluorescence (XRF) machines with different settings. The conservators have not provided any quantitative data from their tests, but merely qualitative data of how many major, minor, and trace elements were found.Footnote 41 Interestingly SF and BM contain a very similar combination of elements. Copper, tin, and lead are the major elements, as would be expected; iron is a minor element in both quadrupeds. The two quadrupeds share the same set of trace elements, including nickel, zinc, arsenic, silver, and antimony; except that zirconium was found only on SF and not on BM. Since the signal in detecting zirconium is very weak, and zirconium can also be a consequence of contamination from burial soil, we may consider that the possibility of SF and BM sharing the same crucible of molten bronze is relatively high. No zinc has been detected on FR, but it has been detected on SF and BM.Footnote 42 Does this point to the possibility that SF and BM were cast in the same batch while FR was cast separately? This remains a possibility and a reference point awaiting more reliable and consistent analyses in the future.

The pattern-block technique in 500 b.c.e. Houma

There were at least two major casting methods being used in the Houma foundries in around 500 b.c.e. Barbara Keyser and Robert Bagley have illustrated one of the prevailing methods at Houma, and Bagley calls it the “pattern-block technique.”Footnote 43 The pattern-block method differs from the model-replicating method inasmuch as the decorative patterns were largely done on the mold, rather than on the models. Casters first created a rough and undecorated model. A mold was replicated from this model, bearing no decorative pattern but just a rough shape. Casters then carved a re-usable pattern block and replicated multiple small unit molds from this pattern block. These small unit molds were pasted onto the inner walls of the rough mold. Soon the rough mold was decorated with mirror-reversed patterns composed of multiple unit molds. Casters poured molten bronze into the decorated mold and obtained a unique bronze that would not have an identical counterpart. Casters might produce another bronze that appeared similar to the previous one. But since the pasting of the unit molds was not to be repeated, minor variations in the pasting process and subtle differences in joining the unit molds would lead to a different bronze.

Conclusion

The model-replicating method illustrated in this article is different from the pattern-block method. The four quadrupeds from Houma testify to this different method. They are also the earliest evidence of the use of the potential industrial power of the model-replicating method. Although some questions remain unanswered, at least we can reconstruct a more comprehensive picture of the assembly line of production at Houma for casting the quadrupeds. We have investigated the use of decorated models, mold sections, cores, and spacers. Ephemeral processes such as the production of identical bronzes, varied assembly of mold sections, and minor touch-ups are examined in new lights with new technologies. Social and economic change in China around 500 b.c.e. have provided the context and impetus for such a substantial advance in the contemporary bronze industry. Once the Houma bronze producers had successfully operated this assembly line production for quadrupeds and other bronzes, the new potential for development of the industry would have been clear for all producers to see.Footnote 44

Acknowledgments and notes

The work described in this paper was partially supported by grants from the Research Grants Council of the Hong Kong Special Administrative Region (HKSAR), China (Project No. HKBU 12604017, 12625716, 14600118, and 22601019); the Quality Education Fund, Government of the HKSAR (no. 2018/1337); and the HKBU Equipment Matching Fund (RC-EMF 07/17–18); Sammy Li is the principal investigator of all of these projects.

Quanyu Wang, Keith Wilson, and Fan Jeremy Zhang generously provided museum access and technical assistance; they commented on the second draft of this article. Kin San Lee, Tsz Hin Chun, Sum Lam, Mingyong Pang, Haoran Xie, and Mingqiang Wei were the 3D scanning advisors and Jody Ho Yee Cheung performed the 3D model superimposition experiments. Sammy Li is responsible for all other tasks and the errors that are found herein are his alone.