Researchers from Imperial College London and The University of Sheffield have demonstrated that concepts borrowed from metallurgy can be used to strengthen architected metamaterials made by three-dimensional (3D) printing. By introducing “meta grains,” the research team showed that many of the staple ideas from alloy strengthening such as higher yield strength due to smaller grains, toughening due to high-angle grain boundaries, as well as precipitation and phase hardening mechanisms could be translated to 3D printed lattices made of stainless steel. This opens the door to substantial improvements in additive manufactured components through macrostructure modification at no increased cost. As an accompanying editorial in Nature noted, “The parameter space for future exploration is large.”

Except for a few notable exceptions, most metal parts used for engineering applications are composed of smaller crystals (grains) that stick together like bricks in a wall. These grains can be anywhere from a few nanometers in size to a few millimeters, depending on the processing conditions. By breaking the monotony of the crystal lattice, the grain boundaries are obstacles to the motion of dislocations. All hardening mechanisms in metals rely on ways to impede or modify the flow of dislocations. While grain boundaries act as barriers that prevent a dislocation from entering a new grain, precipitates and phase modifications slow down, deflect, or even stop a dislocation altogether. The empirical Hall–Petch equation expresses this relationship mathematically by tying the yield strength to the inverse square root of grain size.

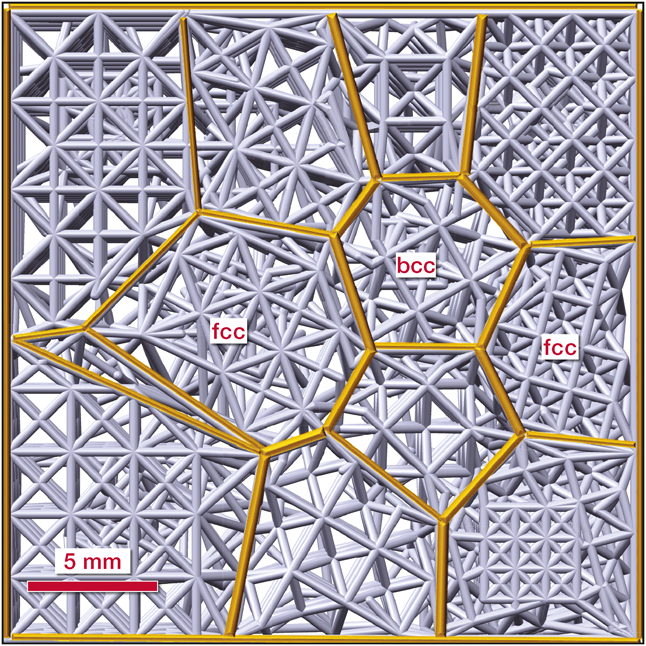

An engineered meta structure with face-centered embedding in body-centered lattices. This mesostructure that simulates the benefits of precipitation hardening in metals can be used for making high-strength lightweight alloys. Credit: Nature.

As reported in a recent issue of Nature (doi:10.1038/s41586-018-0850-3), the research team first showed that a 3D printed lattice—made of nodes for atoms and struts for chemical bonds—does indeed behave like a crystal under the action of stress. An appropriately applied stress created shear bands in the meta lattice, breaking down struts along a diagonal. Notably, single crystals show the same behavior along the exact direction. The next step was to introduce a twin boundary along a 3D printed lattice—aligning struts and nodes so that they are mirror images of each other across a plane. The shear bands across the twin boundary were not only symmetric as would be expected for a crystal, but by increasing the number of twin boundaries the yield strength of the printed lattice increased as well. This result confirmed that an effect similar to the Hall–Petch relationship exists for architected materials.

The team incorporated precipitation hardening by introducing embedded lattice domains with parameters different from those of the matrix. Face-centered (fcc) “meta precipitates,” for example, were introduced into body-centered (bcc) lattices. Not only did the overall strength and stability go up, but the shear bands were found to bow or stop around the meta precipitate interface. Finally, nonidentical lattice architectures were stacked on top of each other to generate multiscale hierarchical structures such as alternating fcc–bcc structures. The interfaces between the metaphases formed incoherent boundaries non-traversable to slip while combining the benefits of precipitation hardening. These mesostructures show that by tailoring architechted materials, lightweight components that can better withstand external loads can be designed.

María Teresa Pérez-Prado, head of the Physical Metallurgy Group at IMDEA Materials Institute, Spain, told MRS Bulletin that “this is one of the most creative recent works related to metallurgical research, which opens up new avenues to engineer lattice structures (metamaterials) with unprecedented properties.” She added that the “authors demonstrate a very strong resemblance between the behavior of architected lattices and metals, which is very striking. In particular, the parallelism shown in the paper between shear band propagation in lattices and slip bands in metals, as well as between the strengthening via a reduction in the size of meta-grains and the well-known Hall–Petch behavior are very surprising.”

Christian Leinenbach, head of Alloy Design for Advanced Processing Technologies at Empa—Swiss Federal Laboratories for Materials Science and Technology, echoed Pérez-Prado’s sentiments. “This approach opens up new space of controlling the properties of 3D printed products and offers a new way to make hierarchically structured parts with exceptional properties, e.g., lightweight and high damage tolerance. It seems to be possible to apply the idea to a variety of different materials or even combine materials to create novel architected ‘meta-composites.’” Both Pérez-Prado and Leinenbach are unrelated to the work reported in the publication.