1. Introduction

The invasion of a wetting liquid against gravity into a narrow vertical conduit, called capillary rise, is a classical illustration of the effects of capillarity (de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2004). Historically, the phenomenon was a recurring subject of experimentation and speculation (e.g. Hooke Reference Hooke1661; Hauksbee Reference Hauksbee1706; Jurin Reference Jurin1717; Laplace Reference Laplace1806), before it was finally attributed to the capillary pressure that arises due to the curvature induced by the contact angle formed by the liquid with the interior surface of the conduit. A viscous liquid driven by capillary effects into a tube of uniform cross-section experiences a constant driving pressure and increasing viscous dissipation, and thus advances diffusively as ![]() $t^{1/2}$ (see Bell & Cameron Reference Bell and Cameron1906; Lucas Reference Lucas1918; Washburn Reference Washburn1921). Different dynamics are observed when the tube cross-section, which affects the capillary pressure and viscous dissipation, varies axially; for example, the advancement of the meniscus into a tube with an expanding conical geometry exhibits a

$t^{1/2}$ (see Bell & Cameron Reference Bell and Cameron1906; Lucas Reference Lucas1918; Washburn Reference Washburn1921). Different dynamics are observed when the tube cross-section, which affects the capillary pressure and viscous dissipation, varies axially; for example, the advancement of the meniscus into a tube with an expanding conical geometry exhibits a ![]() $t^{1/4}$ power law for the meniscus position as a function of time (Reyssat et al. Reference Reyssat, Courbin, Reyssat and Stone2008).

$t^{1/4}$ power law for the meniscus position as a function of time (Reyssat et al. Reference Reyssat, Courbin, Reyssat and Stone2008).

Flow into open channel geometries differs from flow into closed conduits due to the replacement of a solid boundary by a free interface. The geometry of the flow conduit is no longer fixed, and consequently the curvature of the liquid–air interface, the cross-sectional area and the flow rate are no longer determined fully by the geometry of the solid surfaces. Instead, these quantities vary both axially and with time. In the simplest cases, the flow can be modelled by a one-dimensional partial differential equation (PDE). For example, analyses of low-Reynolds-number, unidirectional flow in a sharp triangular corner have been based on the Poisson equation (e.g. Ayyaswamy, Catton & Edwards Reference Ayyaswamy, Catton and Edwards1974; Ransohoff & Radke Reference Ransohoff and Radke1988), and the continuity equation relating the axial derivative of flow rate to the time derivative of the cross-sectional area of the conduit then is used to obtain the dynamics (e.g. Lenormand & Zarcone Reference Lenormand and Zarcone1984). For cases in which the geometry of the conduit changes with time due to elastocapillary deformations, additional power laws for capillary rise have been identified by Duprat, Aristoff & Stone (Reference Duprat, Aristoff and Stone2011) and Di, Xu & Doi (Reference Di, Xu and Doi2016).

When a liquid partially filling a triangular corner of interior angle ![]() $\theta _i$ has a contact angle

$\theta _i$ has a contact angle ![]() $\theta$ with the adjacent solid walls such that

$\theta$ with the adjacent solid walls such that ![]() $\theta < ({\rm \pi} -\theta _i)/2$ (the condition identified by Concus & Finn Reference Concus and Finn1969), the liquid spontaneously spreads along the corner due to capillarity. For such flows in the absence of gravity, Romero & Yost (Reference Romero and Yost1996) and Weislogel & Lichter (Reference Weislogel and Lichter1998) analyse the dynamics and identify a similarity solution, which reveals that the meniscus advances as

$\theta < ({\rm \pi} -\theta _i)/2$ (the condition identified by Concus & Finn Reference Concus and Finn1969), the liquid spontaneously spreads along the corner due to capillarity. For such flows in the absence of gravity, Romero & Yost (Reference Romero and Yost1996) and Weislogel & Lichter (Reference Weislogel and Lichter1998) analyse the dynamics and identify a similarity solution, which reveals that the meniscus advances as ![]() $t^{1/2}$. Warren (Reference Warren2004) identifies different power laws for the spreading of a liquid drop of fixed volume into triangular corner. When the Concus–Finn condition is satisfied, liquid will rise in triangular corners against gravity and approach a hyperbolic equilibrium profile, as documented originally by Taylor (Reference Taylor1710) and Hauksbee (Reference Hauksbee1712). Under such circumstances, the tip of the liquid in the corner rises to a theoretically infinite height as

$t^{1/2}$. Warren (Reference Warren2004) identifies different power laws for the spreading of a liquid drop of fixed volume into triangular corner. When the Concus–Finn condition is satisfied, liquid will rise in triangular corners against gravity and approach a hyperbolic equilibrium profile, as documented originally by Taylor (Reference Taylor1710) and Hauksbee (Reference Hauksbee1712). Under such circumstances, the tip of the liquid in the corner rises to a theoretically infinite height as ![]() $t^{1/3}$ according to a similarity transformation presented by Tang & Tang (Reference Tang and Tang1994) and Higuera, Medina & Linan (Reference Higuera, Medina and Linan2008). This power law for capillary rise applies to corners whose shapes are described by arbitrary power laws

$t^{1/3}$ according to a similarity transformation presented by Tang & Tang (Reference Tang and Tang1994) and Higuera, Medina & Linan (Reference Higuera, Medina and Linan2008). This power law for capillary rise applies to corners whose shapes are described by arbitrary power laws ![]() $h(x) \propto x^n$, with

$h(x) \propto x^n$, with ![]() $n\geq 1$, and not just to corners with straight walls (

$n\geq 1$, and not just to corners with straight walls (![]() $n=1$, linear corners), as shown experimentally and argued theoretically by Ponomarenko, Quéré & Clanet (Reference Ponomarenko, Quéré and Clanet2011). The universality of this power law was corroborated later by Zhou & Doi (Reference Zhou and Doi2020) using a PDE derived using the Onsager principle to describe capillary rise into symmetric power-law-shaped corners. Table 1 summarizes the contributions of prior investigations to the understanding of the dynamics of capillary rise in sharp power-law corners.

$n=1$, linear corners), as shown experimentally and argued theoretically by Ponomarenko, Quéré & Clanet (Reference Ponomarenko, Quéré and Clanet2011). The universality of this power law was corroborated later by Zhou & Doi (Reference Zhou and Doi2020) using a PDE derived using the Onsager principle to describe capillary rise into symmetric power-law-shaped corners. Table 1 summarizes the contributions of prior investigations to the understanding of the dynamics of capillary rise in sharp power-law corners.

Table 1. Contributions to the understanding of the universality of capillary rise of a liquid into a sharp corner whose geometry is described by a power law ![]() $h(x) \propto x^n$. In the references listed in this table, the self-similarity of the phenomenon and the

$h(x) \propto x^n$. In the references listed in this table, the self-similarity of the phenomenon and the ![]() $t^{1/3}$ rate of rise of the meniscus are reported. It is indicated whether the reference presented a time evolution equation describing capillary rise in a corner, and whether confirmation of the power law for capillary rise and the shape of the liquid column were provided. The powers

$t^{1/3}$ rate of rise of the meniscus are reported. It is indicated whether the reference presented a time evolution equation describing capillary rise in a corner, and whether confirmation of the power law for capillary rise and the shape of the liquid column were provided. The powers ![]() $n$ of each of the contributions are listed, in addition to whether those contributions consisted of experimental measurements (Exp) or numerical results (Num) obtained by solving the governing PDE.

$n$ of each of the contributions are listed, in addition to whether those contributions consisted of experimental measurements (Exp) or numerical results (Num) obtained by solving the governing PDE.

The initial study of capillary flow in sharp corners by Tang & Tang (Reference Tang and Tang1994) was motivated by the practical need to eliminate air bubbles when filling thin tubes, and since then there has been continued interest in the design of both open and closed channels with sharp interior corners to leverage capillary action for precise flow control (e.g. Weislogel & Lichter Reference Weislogel and Lichter1998; Gurumurthy et al. Reference Gurumurthy, Rettenmaier, Roisman, Tropea and Garoff2018; Berthier et al. Reference Berthier, Dostie, Lee, Berthier and Theberge2019). Studies of capillary flow in confined geometries also aid in the understanding of imbibition in porous media (e.g. Cai et al. Reference Cai, Chen, Liu, Li and Sun2022) and wicking in textiles (e.g. Duprat Reference Duprat2022), which are often characterized by irregularly shaped conduits with a wide range of length scales.

Our aim is to present a derivation using the lubrication approximation of a model of capillary rise in power-law-shaped corners, discuss how self-similarity arises in the phenomenon, and highlight those aspects of the phenomenon that are universal, i.e. independent of the corner geometry, while pointing out those that are not. The paper is organized as follows. In § 2, we describe the geometry of the corner and of the liquid cross-section in horizontal planes. In § 3, we introduce equations that model the flow of a liquid in a narrow channel, and we specialize the equations for the case of capillary rise in § 4. In § 5, we scale variables to render the problem dimensionless, present a similarity transformation that reduces the PDE to an ordinary differential equation (ODE), and discuss briefly the universal and self-similar aspects of the problem. The time evolution of the rising meniscus at early times is modelled in § 6. Section 7 describes the experimental set-up and compares experimental measurements with theoretical predictions. Section 8 concludes the paper.

2. Geometry

2.1. Power-law corners

We consider the flow of a liquid into a sharp corner created by two surfaces of possibly different geometries. The surfaces are in contact along the ![]() $z$-axis, which is oriented such that the acceleration due to gravity is

$z$-axis, which is oriented such that the acceleration due to gravity is ![]() $-g \boldsymbol {e}_z$, as depicted in figure 1(a). A schematic of the horizontal cross-sectional geometry is shown in figure 1(b). In the cross-section, the surfaces make contact at

$-g \boldsymbol {e}_z$, as depicted in figure 1(a). A schematic of the horizontal cross-sectional geometry is shown in figure 1(b). In the cross-section, the surfaces make contact at ![]() $x = y = 0$, and their locations are given by

$x = y = 0$, and their locations are given by

and the geometric parameters ![]() $c_i$ have dimensions [Length]

$c_i$ have dimensions [Length]![]() $^{-(n-1)}$. We impose the condition

$^{-(n-1)}$. We impose the condition ![]() $c_2 > c_1$, where the inequality is necessary so that the surfaces do not coincide, but the

$c_2 > c_1$, where the inequality is necessary so that the surfaces do not coincide, but the ![]() $c_i$ may have the same sign. The thickness of the gap formed by the surfaces is

$c_i$ may have the same sign. The thickness of the gap formed by the surfaces is

where ![]() $c = c_2-c_1$.

$c = c_2-c_1$.

Figure 1. Geometry of a power-law corner. (a) Fluid column in the gap formed by two surfaces that meet in a vertical line. Grey lines indicate the liquid–solid and liquid–air interfaces. (b) Diagram of a planar cross-section. The corner is located at the origin, and it is formed by two surfaces that are located at ![]() $h_2(x)$ and

$h_2(x)$ and ![]() $h_1(x)$. The width of the liquid column is

$h_1(x)$. The width of the liquid column is ![]() $w(z,t)$, and the radius of the liquid–air interface is

$w(z,t)$, and the radius of the liquid–air interface is ![]() $s(z,t)$.

$s(z,t)$.

Before moving forward, we discuss the applicability of this simple corner geometry, i.e. corners formed by power-law surfaces with a single exponent ![]() $n$, to understanding corners with more varied and complex geometries. One may consider the case in which each surface has a different power,

$n$, to understanding corners with more varied and complex geometries. One may consider the case in which each surface has a different power, ![]() $h_i(x) = c_i x^{n_i}$, e.g. with

$h_i(x) = c_i x^{n_i}$, e.g. with ![]() $n_2 > n_1$. However, this case reduces to

$n_2 > n_1$. However, this case reduces to ![]() $h(x) = h_1(x) = c_1 x^{n_1}$ as

$h(x) = h_1(x) = c_1 x^{n_1}$ as ![]() $x \to 0$ since

$x \to 0$ since ![]() $x^{n_2}\ll x^{n_1}$. Furthermore, any arbitrary (smooth) surface profile may be approximated by a Taylor series expansion near

$x^{n_2}\ll x^{n_1}$. Furthermore, any arbitrary (smooth) surface profile may be approximated by a Taylor series expansion near ![]() $x=0$, which yields a power series. Taking the limit as we approach the corner, we may keep only the leading-order term and thus use a power law to describe the surface geometry. Therefore, we focus our investigations on power-law corners with a single exponent,

$x=0$, which yields a power series. Taking the limit as we approach the corner, we may keep only the leading-order term and thus use a power law to describe the surface geometry. Therefore, we focus our investigations on power-law corners with a single exponent, ![]() $n_1 = n_2 = n$, so that we may capture the essential features of the phenomenon while maintaining brevity.

$n_1 = n_2 = n$, so that we may capture the essential features of the phenomenon while maintaining brevity.

2.2. Scaling of the dimensions of the liquid cross-section

In this subsection, we examine the geometry of the liquid cross-section to identify scaling relationships between its various geometrical descriptors. The width of the column ![]() $w(z,t)$ is the minimal value of

$w(z,t)$ is the minimal value of ![]() $x$ of the liquid–air interface, and it is a function of the altitude

$x$ of the liquid–air interface, and it is a function of the altitude ![]() $z$ (figure 1). The liquid–air interface in the cross-section can assumed to be a circular arc with radius

$z$ (figure 1). The liquid–air interface in the cross-section can assumed to be a circular arc with radius ![]() $s(z,t)$. The use and justification of this assumption in the context of capillary rise will be discussed in greater detail in § 4. We anticipate that the liquid column is long and narrow such that the triple line at which the liquid, solid and air meet is nearly parallel to the

$s(z,t)$. The use and justification of this assumption in the context of capillary rise will be discussed in greater detail in § 4. We anticipate that the liquid column is long and narrow such that the triple line at which the liquid, solid and air meet is nearly parallel to the ![]() $z$-axis. Therefore, the angle made by the liquid–air interface and the solid surface in the horizontal cross-section is approximated to be the equilibrium contact angle

$z$-axis. Therefore, the angle made by the liquid–air interface and the solid surface in the horizontal cross-section is approximated to be the equilibrium contact angle ![]() $\theta$ of the liquid, which is assumed to be constant.

$\theta$ of the liquid, which is assumed to be constant.

In the remainder of this section, we will identify the relationship between the interface radius ![]() $s(z,t)$, the width

$s(z,t)$, the width ![]() $w(z,t)$, and the equilibrium contact angle

$w(z,t)$, and the equilibrium contact angle ![]() $\theta$. In particular, we show below that, in certain limits, the radius and width scale as

$\theta$. In particular, we show below that, in certain limits, the radius and width scale as

and ![]() $s(z,t) \ll w(z,t)$, which will enable the use of lubrication theory in § 3.

$s(z,t) \ll w(z,t)$, which will enable the use of lubrication theory in § 3.

By defining the horizontal positions of the triple lines on the upper and lower surfaces as ![]() $x_2(z,t)$ and

$x_2(z,t)$ and ![]() $x_1(z,t)$, respectively (see figure 1b), we find that

$x_1(z,t)$, respectively (see figure 1b), we find that

where ![]() $\beta _i(x) = \tan ^{-1}(h_i'(x))$, with

$\beta _i(x) = \tan ^{-1}(h_i'(x))$, with ![]() $h_i'(x)=\mathrm {d}h_i/\mathrm {d} x$, are the angles measured from the

$h_i'(x)=\mathrm {d}h_i/\mathrm {d} x$, are the angles measured from the ![]() $x$-axis to the lines tangent to the solid surfaces. Then, by defining the centre of the circular arc of the interface as

$x$-axis to the lines tangent to the solid surfaces. Then, by defining the centre of the circular arc of the interface as ![]() $(x_c(z,t), y_c(z,t))$, we can write

$(x_c(z,t), y_c(z,t))$, we can write

Subtracting the two preceding equations yields the geometrical relationship

For the case ![]() $n=1$, in which case

$n=1$, in which case ![]() $c$ is dimensionless, we can take the

$c$ is dimensionless, we can take the ![]() $xz$-plane to be the symmetry plane of the corner without loss of generality, such that

$xz$-plane to be the symmetry plane of the corner without loss of generality, such that ![]() $h_2'(x)=-h_1'(x)=c/2$,

$h_2'(x)=-h_1'(x)=c/2$, ![]() $\beta _2(x) = -\beta _1(x) = \tan ^{-1}(c/2)$ and

$\beta _2(x) = -\beta _1(x) = \tan ^{-1}(c/2)$ and

Then (2.6) becomes

By using the definition in (2.2), we obtain

Rearranging and considering the limit ![]() $c \ll 1$, we find

$c \ll 1$, we find

For the case ![]() $n>1$, the surfaces are tangent to the

$n>1$, the surfaces are tangent to the ![]() $xz$-plane at

$xz$-plane at ![]() $x = 0$, and

$x = 0$, and ![]() $\lim _{x\to 0}\beta _i(x) = 0$. As

$\lim _{x\to 0}\beta _i(x) = 0$. As ![]() $x_i(z,t)\to 0$ for

$x_i(z,t)\to 0$ for ![]() $i = 1,2$, we find that

$i = 1,2$, we find that ![]() $x_2(z,t) \sim x_1(z,t) \sim w(z,t) + s(z,t)$

$x_2(z,t) \sim x_1(z,t) \sim w(z,t) + s(z,t)$ ![]() $(1-\sin \theta )$, and (2.6) simplifies to

$(1-\sin \theta )$, and (2.6) simplifies to

where the last equality comes from applying the definition of ![]() $h(x)$ in (2.2). Since both

$h(x)$ in (2.2). Since both ![]() $s(z,t) \to 0$ and

$s(z,t) \to 0$ and ![]() $w(z,t)\to 0$, we anticipate that terms on the right-hand side of (2.11) with powers

$w(z,t)\to 0$, we anticipate that terms on the right-hand side of (2.11) with powers ![]() $s^2(z,t)$ or greater are insignificant compared to the

$s^2(z,t)$ or greater are insignificant compared to the ![]() $s(z,t)$ term on the left-hand side, and thus consider the balance

$s(z,t)$ term on the left-hand side, and thus consider the balance

By rearranging terms, we find that in the limit ![]() $cn\,w^{n-1}(z,t) \ll 1$,

$cn\,w^{n-1}(z,t) \ll 1$,

Therefore, in the limit as ![]() $x_i(z,t)\to 0$ for

$x_i(z,t)\to 0$ for ![]() $i = 1,2$,

$i = 1,2$, ![]() $s(z,t)/w(z,t) \to 0$. Due to the results (2.10) obtained for

$s(z,t)/w(z,t) \to 0$. Due to the results (2.10) obtained for ![]() $n=1$ and (2.13) for

$n=1$ and (2.13) for ![]() $n>1$, we may use the relation in (2.3) stated at the start of this subsection for

$n>1$, we may use the relation in (2.3) stated at the start of this subsection for ![]() $n\geq 1$ when

$n\geq 1$ when ![]() $cn\, w^{n-1}(z,t) \ll 1$. In the

$cn\, w^{n-1}(z,t) \ll 1$. In the ![]() $n=1$ case, certain conditions on the corner geometry (i.e. a small interior angle) must be satisfied. In the

$n=1$ case, certain conditions on the corner geometry (i.e. a small interior angle) must be satisfied. In the ![]() $n>1$ case,

$n>1$ case, ![]() $c$ may vary, but for a given value of

$c$ may vary, but for a given value of ![]() $c$, we require the dimension of the liquid cross-section to be sufficiently small.

$c$, we require the dimension of the liquid cross-section to be sufficiently small.

The results derived in this section may be understood through the context of geometric similarity. When two shapes are geometrically similar, corresponding angles and dimensionless ratios between linear dimensions are identical, so that the shapes are scaled versions of each other. Geometric similarity of the liquid cross-sections holds only for ![]() $n=1$. When

$n=1$. When ![]() $n>1$,

$n>1$, ![]() $s(z,t)$ and

$s(z,t)$ and ![]() $w(z,t)$ are not directly proportional (see (2.3)), and the ratio

$w(z,t)$ are not directly proportional (see (2.3)), and the ratio ![]() $s(z,t)/w(z,t)$ tends to

$s(z,t)/w(z,t)$ tends to ![]() $0$ as the cross-section shrinks to a point. Geometric similarity is also closely tied to the nature of the constant parameters

$0$ as the cross-section shrinks to a point. Geometric similarity is also closely tied to the nature of the constant parameters ![]() $c_i$ (and

$c_i$ (and ![]() $c$). When

$c$). When ![]() $n=1$, the cross-sections are geometrically similar because the

$n=1$, the cross-sections are geometrically similar because the ![]() $c_i$, which are dimensionless descriptors of the geometry, are constant. However, when

$c_i$, which are dimensionless descriptors of the geometry, are constant. However, when ![]() $n>1$, the definition of geometric similarity is no longer met because there are constant quantities

$n>1$, the definition of geometric similarity is no longer met because there are constant quantities ![]() $c_i^{-1/(n-1)}$ with units of [Length], which leads to dimensionless parameters that vary with the size of the cross-section. Perhaps surprisingly, the introduction of parameters

$c_i^{-1/(n-1)}$ with units of [Length], which leads to dimensionless parameters that vary with the size of the cross-section. Perhaps surprisingly, the introduction of parameters ![]() $c_i$ with physical dimensions when

$c_i$ with physical dimensions when ![]() $n>1$ does not preclude the presence of self-similarity in the phenomenon of capillary rise in sharp corners. This result will be discussed in greater detail in § 5.

$n>1$ does not preclude the presence of self-similarity in the phenomenon of capillary rise in sharp corners. This result will be discussed in greater detail in § 5.

Finally, we note that by assuming a cross-section of the form in figure 1(b), we implicitly assume that if the liquid does not extend to ![]() $z\to \infty$, then the location of the maximum height of the fluid is located on the

$z\to \infty$, then the location of the maximum height of the fluid is located on the ![]() $z$-axis (

$z$-axis (![]() $x=y=0$), where the two surfaces make contact. However, this is not necessarily true at early times. Work by Higuera et al. (Reference Higuera, Medina and Linan2008) and Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) shows that in the initial stages of capillary rise into a sharp corner, the maximum meniscus altitude is located at some finite

$x=y=0$), where the two surfaces make contact. However, this is not necessarily true at early times. Work by Higuera et al. (Reference Higuera, Medina and Linan2008) and Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) shows that in the initial stages of capillary rise into a sharp corner, the maximum meniscus altitude is located at some finite ![]() $x$. Higuera et al. (Reference Higuera, Medina and Linan2008) develop a model using lubrication theory that reveals that in a linear corner, the location of maximum altitude approaches

$x$. Higuera et al. (Reference Higuera, Medina and Linan2008) develop a model using lubrication theory that reveals that in a linear corner, the location of maximum altitude approaches ![]() $x = 0$ as

$x = 0$ as ![]() $t^{-1/3}$. Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) use an organ model and find that in corners of general geometry, the effective radius of the leading meniscus decreases as

$t^{-1/3}$. Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) use an organ model and find that in corners of general geometry, the effective radius of the leading meniscus decreases as ![]() $t^{-1/3}$. Given the scaling (2.3) between the interface radius and the width, the location of the maximum altitude is expected to approach the corner as

$t^{-1/3}$. Given the scaling (2.3) between the interface radius and the width, the location of the maximum altitude is expected to approach the corner as ![]() $t^{-1/3n}$, as we discuss further in § 6 (see (6.26) and (6.27)). Experiments and numerical simulations performed by Higuera et al. (Reference Higuera, Medina and Linan2008) find that the maximum is effectively located at

$t^{-1/3n}$, as we discuss further in § 6 (see (6.26) and (6.27)). Experiments and numerical simulations performed by Higuera et al. (Reference Higuera, Medina and Linan2008) find that the maximum is effectively located at ![]() $x=0$ for long times. Therefore, the geometric description of the liquid column given in this section is appropriate when considering the dynamics of capillary rise in a sharp corner at long times when the liquid has assumed a long and narrow geometry. Capillary rise at early times is considered separately. A model based on the work of Higuera et al. (Reference Higuera, Medina and Linan2008) is developed for corners with

$x=0$ for long times. Therefore, the geometric description of the liquid column given in this section is appropriate when considering the dynamics of capillary rise in a sharp corner at long times when the liquid has assumed a long and narrow geometry. Capillary rise at early times is considered separately. A model based on the work of Higuera et al. (Reference Higuera, Medina and Linan2008) is developed for corners with ![]() $n\geq 1$ in § 6, where we show this

$n\geq 1$ in § 6, where we show this ![]() $t^{-1/3n}$ power law.

$t^{-1/3n}$ power law.

3. Flow in a narrow open channel

In this section, we derive the equation governing the flow of a liquid into a sharp corner. We consider the case in which the liquid occupies a long and narrow space, in particular with ![]() $L_y\ll L_x \ll L_z$, where

$L_y\ll L_x \ll L_z$, where ![]() $L_x$,

$L_x$, ![]() $L_y$ and

$L_y$ and ![]() $L_z$ represent the characteristic length scales of velocity variations in their respective directions. The ratios of the characteristic length scales in the cross-sectional plane with that in the primary direction of flow are small,

$L_z$ represent the characteristic length scales of velocity variations in their respective directions. The ratios of the characteristic length scales in the cross-sectional plane with that in the primary direction of flow are small, ![]() $L_x/L_z \ll 1$ and

$L_x/L_z \ll 1$ and ![]() $L_y/L_z \ll 1$. Thus we may apply the lubrication approximation, in which we consider the flow to be approximately unidirectional,

$L_y/L_z \ll 1$. Thus we may apply the lubrication approximation, in which we consider the flow to be approximately unidirectional, ![]() $\boldsymbol {u} = u_z(x,y,z,t)\,\boldsymbol {e}_z$, and pressure gradients in the

$\boldsymbol {u} = u_z(x,y,z,t)\,\boldsymbol {e}_z$, and pressure gradients in the ![]() $xy$-plane to be negligible compared to those in the

$xy$-plane to be negligible compared to those in the ![]() $z$-direction. Thus the pressure

$z$-direction. Thus the pressure ![]() $p = p(z,t)$ responsible for flow in the channel is approximately a function of

$p = p(z,t)$ responsible for flow in the channel is approximately a function of ![]() $z$ alone (i.e. independent of

$z$ alone (i.e. independent of ![]() $x$ and

$x$ and ![]() $y$) and time

$y$) and time ![]() $t$. Such use of lubrication theory is standard in the modelling of many long and narrow flows, such as capillary flow in sharp corners (e.g. Tang & Tang Reference Tang and Tang1994; Weislogel & Lichter Reference Weislogel and Lichter1998; Higuera et al. Reference Higuera, Medina and Linan2008; Zhou & Doi Reference Zhou and Doi2020).

$t$. Such use of lubrication theory is standard in the modelling of many long and narrow flows, such as capillary flow in sharp corners (e.g. Tang & Tang Reference Tang and Tang1994; Weislogel & Lichter Reference Weislogel and Lichter1998; Higuera et al. Reference Higuera, Medina and Linan2008; Zhou & Doi Reference Zhou and Doi2020).

The corner is an open channel, meaning that the liquid flowing in it is not entirely confined by solid surfaces. As a result, the cross-sectional area of the liquid column is a function of both ![]() $z$ and

$z$ and ![]() $t$ due to the evolution with time of the liquid–air interfaces that comprise the remainder of its boundary. As such, the equation of continuity assuming incompressibility is (e.g. Lenormand & Zarcone Reference Lenormand and Zarcone1984)

$t$ due to the evolution with time of the liquid–air interfaces that comprise the remainder of its boundary. As such, the equation of continuity assuming incompressibility is (e.g. Lenormand & Zarcone Reference Lenormand and Zarcone1984)

where ![]() $A(z,t)$ is the area of the liquid cross-section, and

$A(z,t)$ is the area of the liquid cross-section, and ![]() $Q(z,t)$ is the volumetric flow rate in the axial direction.

$Q(z,t)$ is the volumetric flow rate in the axial direction.

A practical constraint for problems involving flow into a corner from a reservoir is that the volume of liquid in the column is finite for finite time (e.g. Romero & Yost Reference Romero and Yost1996; Weislogel & Lichter Reference Weislogel and Lichter1998):

This finite volume condition results in the boundary conditions (5.9) and (5.10) below, which are derived in Appendix B and presented in § 5, for the ODE obtained by applying a similarity transformation to the governing equation (4.6) derived in § 4. The area of the cross-section is found by integrating the height of the gap over the width of the liquid column ![]() $w(z,t)$:

$w(z,t)$:

in which higher-order terms due to the curvature of the interface in the ![]() $xy$-plane have been neglected since we consider the limit

$xy$-plane have been neglected since we consider the limit ![]() $s(z,t)/w(z,t) \ll 1$.

$s(z,t)/w(z,t) \ll 1$.

The flow rate is calculated by integrating the axial velocity over the area of the liquid cross-section. Due to the separation of length scales, ![]() $L_y\ll L_x\ll L_z$, the gradients of the axial velocity in the

$L_y\ll L_x\ll L_z$, the gradients of the axial velocity in the ![]() $x$- and

$x$- and ![]() $z$-directions are negligible in comparison to that in the

$z$-directions are negligible in comparison to that in the ![]() $y$-direction, and for the axial velocity we may write

$y$-direction, and for the axial velocity we may write

where ![]() $\mu$ is the dynamic viscosity, and

$\mu$ is the dynamic viscosity, and ![]() $p(z,t)$ is the pressure. Lubrication theory was applied in this way in the plane of the cross-section by Zhou & Doi (Reference Zhou and Doi2020). We impose the no-slip boundary conditions at the bounding surfaces,

$p(z,t)$ is the pressure. Lubrication theory was applied in this way in the plane of the cross-section by Zhou & Doi (Reference Zhou and Doi2020). We impose the no-slip boundary conditions at the bounding surfaces,

and find that the velocity profile is parabolic:

The corresponding expression for the velocity distribution given by Zhou & Doi (Reference Zhou and Doi2020) (see their (2.9)) for a symmetric gap is recovered when we set ![]() $c_2 = -c_1 = c/2$. The flow rate is calculated by integrating the velocity over the cross-section:

$c_2 = -c_1 = c/2$. The flow rate is calculated by integrating the velocity over the cross-section:

\begin{equation} Q(z,t) = \int_0^{w(z,t)}\int_{h_1(x)}^{h_2(x)}u_z(x,y,z,t) \,\mathrm{d} y\, \mathrm{d}\kern0.06em x=-\frac{1}{{1}2\mu}\,\frac{\partial p}{\partial z}\,\frac{c^3}{3n+1}\,w^{3n+1}(z,t). \end{equation}

\begin{equation} Q(z,t) = \int_0^{w(z,t)}\int_{h_1(x)}^{h_2(x)}u_z(x,y,z,t) \,\mathrm{d} y\, \mathrm{d}\kern0.06em x=-\frac{1}{{1}2\mu}\,\frac{\partial p}{\partial z}\,\frac{c^3}{3n+1}\,w^{3n+1}(z,t). \end{equation}

Although the velocity field depends on the parameters ![]() $c_i$ corresponding to the individual surfaces, the flow rate depends only on the combined geometric parameter

$c_i$ corresponding to the individual surfaces, the flow rate depends only on the combined geometric parameter ![]() $c$ of the gap. Thus the approximations of the area and the flow rate are unaffected by the asymmetry of the corner and depend only on the total thickness of the gap

$c$ of the gap. Thus the approximations of the area and the flow rate are unaffected by the asymmetry of the corner and depend only on the total thickness of the gap ![]() $h(x)$, a result that may be expected due to the narrow geometries required in the application of lubrication theory.

$h(x)$, a result that may be expected due to the narrow geometries required in the application of lubrication theory.

Making use of (2.3), we can write (3.3) and (3.7) in terms of the interface radius:

and

Inspecting (3.3), (3.7) and (3.8), and knowing that ![]() $s \propto cw^n$, we observe that

$s \propto cw^n$, we observe that ![]() $A \propto ws$ and

$A \propto ws$ and ![]() $Q \propto ws^3$. One may arrive at the scaling of the area by using a reasonable estimate of the area of the cross-section as a product of characteristic length scales in orthogonal directions. The scaling for the flow rate may be expected from analysis of the classical problem of unidirectional viscous flow in a channel with a high-aspect-ratio (

$Q \propto ws^3$. One may arrive at the scaling of the area by using a reasonable estimate of the area of the cross-section as a product of characteristic length scales in orthogonal directions. The scaling for the flow rate may be expected from analysis of the classical problem of unidirectional viscous flow in a channel with a high-aspect-ratio (![]() $L_y \ll L_x$) rectangular cross-section (Boussinesq Reference Boussinesq1868). When

$L_y \ll L_x$) rectangular cross-section (Boussinesq Reference Boussinesq1868). When ![]() $n=1$,

$n=1$, ![]() $s \propto w$, there is geometric similarity, and the scaling of the area and flow rate may described by a single length scale

$s \propto w$, there is geometric similarity, and the scaling of the area and flow rate may described by a single length scale ![]() $A\propto w^2 \propto s^2$ and

$A\propto w^2 \propto s^2$ and ![]() $Q\propto w^4 \propto s^4$. When

$Q\propto w^4 \propto s^4$. When ![]() $n > 1$, there is no geometric similarity, and both the area and flow rate scale with fractional powers of the linear dimensions. The proper dimensions for both quantities are achieved by the inclusion of the appropriate power of the geometric parameter

$n > 1$, there is no geometric similarity, and both the area and flow rate scale with fractional powers of the linear dimensions. The proper dimensions for both quantities are achieved by the inclusion of the appropriate power of the geometric parameter ![]() $c$ characteristic of the corner geometry.

$c$ characteristic of the corner geometry.

Rewriting the continuity equation (3.1) using the expressions (3.8), we arrive at

The finite volume condition becomes

which is used to obtain boundary conditions for (3.9) (see Appendix B for detailed derivations) that will be presented in § 5 (see (5.9) and (5.10)).

In the next section, these equations are specialized for capillary rise by substituting the appropriate expression for the pressure gradient. The relevant boundary condition is also provided.

4. Capillary rise

We examine capillary rise against gravity, or flow due to the Young–Laplace pressure, arising from the curved liquid–air interface and conservative gravitational body forces. As noted originally by Tang & Tang (Reference Tang and Tang1994), the flow is driven due to gradients in the modified pressure (Batchelor Reference Batchelor1967). Due to the long and narrow geometry of the liquid column, the axial curvature is negligible, and the mean curvature of the interface is determined primarily by the curvature in the horizontal cross-section. Since the pressure is constant in the ![]() $xy$-plane, the mean curvature must be the same at every point of the interface in the cross-section. So the interface in the cross-section is taken to be a circular arc with radius

$xy$-plane, the mean curvature must be the same at every point of the interface in the cross-section. So the interface in the cross-section is taken to be a circular arc with radius ![]() $s(z,t)$, and the modified pressure is

$s(z,t)$, and the modified pressure is

At a given time ![]() $t$, we expect the interface to converge to its equilibrium shape for which the Young–Laplace pressure balances the hydrostatic pressure as we approach the reservoir. Furthermore, at a given altitude

$t$, we expect the interface to converge to its equilibrium shape for which the Young–Laplace pressure balances the hydrostatic pressure as we approach the reservoir. Furthermore, at a given altitude ![]() $z$, we expect capillary pressure and hydrostatic pressure to balance at long times. These conditions are expressed as

$z$, we expect capillary pressure and hydrostatic pressure to balance at long times. These conditions are expressed as

or in terms of the width of the column,

\begin{equation} w(z,t) \sim \left(\frac{2c^{-1}\ell_{cg}^2\cos\theta}{z}\right)^{1/n} \quad \mathrm{as} \ z \to 0 \ \mathrm{or} \ t \to \infty, \end{equation}

\begin{equation} w(z,t) \sim \left(\frac{2c^{-1}\ell_{cg}^2\cos\theta}{z}\right)^{1/n} \quad \mathrm{as} \ z \to 0 \ \mathrm{or} \ t \to \infty, \end{equation}

where ![]() $\ell _{cg} = \sqrt {\gamma /\rho g}$ is the capillary length.

$\ell _{cg} = \sqrt {\gamma /\rho g}$ is the capillary length.

Since the radius is a hyperbolic function of the altitude ![]() $z$ in (4.2), it is implied that the capillary rise in sharp corners never reaches an equilibrium in the current model. Realistically, capillary rise changes due to other effects such as van der Waals forces, which become important for small enough length scales. We note that the profile of the meniscus is hyperbolic as reported by Hauksbee (Reference Hauksbee1712) only for the case

$z$ in (4.2), it is implied that the capillary rise in sharp corners never reaches an equilibrium in the current model. Realistically, capillary rise changes due to other effects such as van der Waals forces, which become important for small enough length scales. We note that the profile of the meniscus is hyperbolic as reported by Hauksbee (Reference Hauksbee1712) only for the case ![]() $n=1$.

$n=1$.

In the equilibrium profile (4.3), the first and second derivatives of the width become large as we approach the reservoir. In this limit, the assumptions that the inclinations of the triple lines are insignificant, and that the axial curvature of the interface is negligible, are invalid. Then the angle of the liquid–air interface with the solid boundaries would no longer be approximately equal to the equilibrium contact angle, and due to the contributions of the axial curvature to the mean curvature of the interface, (4.2) would no longer hold. Furthermore, the axial curvature would not necessarily be identical everywhere on the interface in the cross-section, which would lead to deviations of the interface from a circular arc.

We may identify conditions for the validity of these assumptions by estimating the inclinations and axial curvature given the equilibrium profile (4.2). The first derivative of the width, ![]() $\text {d}w/\text {d}z$, can be used to approximate the magnitude of the slope of the triple line, which is thus found to be

$\text {d}w/\text {d}z$, can be used to approximate the magnitude of the slope of the triple line, which is thus found to be ![]() $O(w/z)$. The axial curvature may approximated by the second derivative of the width,

$O(w/z)$. The axial curvature may approximated by the second derivative of the width,

where we have used the equilibrium relation (4.3) between ![]() $w$ and

$w$ and ![]() $z$. Therefore, the axial curvature and any perturbations to a circular interface of radius

$z$. Therefore, the axial curvature and any perturbations to a circular interface of radius ![]() $s(z,t)$ are

$s(z,t)$ are ![]() $O((w/z)^2)$. Corrections to the shape and mean curvature of the interface at equilibrium for the

$O((w/z)^2)$. Corrections to the shape and mean curvature of the interface at equilibrium for the ![]() $n = 1$ case are provided by Tang & Tang (Reference Tang and Tang1994). Corrections for general

$n = 1$ case are provided by Tang & Tang (Reference Tang and Tang1994). Corrections for general ![]() $n\geq 1$ are not included here.

$n\geq 1$ are not included here.

Going forward, we omit the functional dependence of variables for brevity. The axial gradient of the pressure (4.1) is

Using (4.5) in (3.9), we obtain the equation describing capillary rise in a power-law corner:

The time evolution equation (4.6) prior to non-dimensionalization may be compared with (3.6) of Zhou & Doi (Reference Zhou and Doi2020), which is an equivalent equation written in terms of the column width (see Appendix A) and involves both ![]() $c$ and

$c$ and ![]() $n$. We note that with the choice of the interface radius

$n$. We note that with the choice of the interface radius ![]() $s(z,t)$ as the dependent variable, (4.6) is independent of details of gap geometry aside from the power

$s(z,t)$ as the dependent variable, (4.6) is independent of details of gap geometry aside from the power ![]() $n$ in the coefficients: the fractional exponents simplify upon distribution of the derivatives, and the parameter

$n$ in the coefficients: the fractional exponents simplify upon distribution of the derivatives, and the parameter ![]() $c$ does not appear. The limited influence of the corner geometry is reminiscent of the initial proposal by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) of a universal law for capillary rise in corners and the later observation by Zhou & Doi (Reference Zhou and Doi2020) that tip dynamics are independent of

$c$ does not appear. The limited influence of the corner geometry is reminiscent of the initial proposal by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) of a universal law for capillary rise in corners and the later observation by Zhou & Doi (Reference Zhou and Doi2020) that tip dynamics are independent of ![]() $c$. The next section is dedicated to identifying the aspects of capillary rise in sharp corners that are universal and those that are not by analysing (4.6).

$c$. The next section is dedicated to identifying the aspects of capillary rise in sharp corners that are universal and those that are not by analysing (4.6).

5. Scaling and a self-similar solution

5.1. Scaling

Equation (4.6) is made dimensionless by scaling lengths and time using

Due to the absence of ![]() $c$ in (4.6), characteristic scales are used here that are independent of

$c$ in (4.6), characteristic scales are used here that are independent of ![]() $c$, or alternatively, independent of the length scale

$c$, or alternatively, independent of the length scale ![]() $c^{-1/(n-1)}$ (

$c^{-1/(n-1)}$ (![]() $n>1$) of the corner geometry. A similar choice of characteristic scales for time and altitude was made by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011), which reflects the expected universality of the phenomenon. For ease of comparison with other statements of this capillary rise problem (e.g. Higuera et al. Reference Higuera, Medina and Linan2008; Zhou & Doi Reference Zhou and Doi2020), the scaling and similarity transformation for the equivalent expression of (4.6) in terms of the width

$n>1$) of the corner geometry. A similar choice of characteristic scales for time and altitude was made by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011), which reflects the expected universality of the phenomenon. For ease of comparison with other statements of this capillary rise problem (e.g. Higuera et al. Reference Higuera, Medina and Linan2008; Zhou & Doi Reference Zhou and Doi2020), the scaling and similarity transformation for the equivalent expression of (4.6) in terms of the width ![]() $w(z,t)$ are given in Appendix A.

$w(z,t)$ are given in Appendix A.

Applying the scaling (5.1a,b,c) leads to the equation

subject to the conditions

and

5.2. Similarity solution

We observe that the problem described in (5.2), (5.3) and (5.4) is invariant under the one-parameter family of scaling transformations

thus we know that there is a similarity solution of the form (e.g. Bluman & Kumei Reference Bluman and Kumei2013; Debnath Reference Debnath2005)

Applying the transformation produces the ODE

with the conditions

and

Following an argument (see Appendix B for details) similar to that presented by Romero & Yost (Reference Romero and Yost1996) for capillary flow into a sharp horizontal groove, the inequality in (5.8b) can be used to show that the liquid column extends to a finite altitude ![]() $z^*$ (or

$z^*$ (or ![]() $\eta ^*$ in dimensionless terms) at which the cross-section reduces to a point,

$\eta ^*$ in dimensionless terms) at which the cross-section reduces to a point,

as well as to derive a boundary condition at this location,

Analogous conditions were also adopted by Weislogel & Lichter (Reference Weislogel and Lichter1998). Higuera et al. (Reference Higuera, Medina and Linan2008) and Zhou & Doi (Reference Zhou and Doi2020) derive an equivalent boundary condition expressed in terms of a function approximating the profile of the column near the tip. The ODE (5.7) was solved numerically using (5.8a), (5.9) and (5.10) (see Appendix C for details). The dimensionless tip altitudes ![]() $\eta ^*$ for a series of integer

$\eta ^*$ for a series of integer ![]() $n$ are plotted in figure 2(a). Figure 2(a) contains an inset table listing the

$n$ are plotted in figure 2(a). Figure 2(a) contains an inset table listing the ![]() $\eta ^*$ values corresponding to the first few values of

$\eta ^*$ values corresponding to the first few values of ![]() $n$, and a complete table is provided in Appendix C. In the limit as

$n$, and a complete table is provided in Appendix C. In the limit as ![]() $n\to \infty$, the boundary condition (5.10) implies that

$n\to \infty$, the boundary condition (5.10) implies that ![]() $\phi '(\eta ^*) \to -\eta ^*$. By solving the ODE numerically, we find that

$\phi '(\eta ^*) \to -\eta ^*$. By solving the ODE numerically, we find that ![]() $\lim _{n\to \infty } \eta ^* \approx 1.4326$ (see figure 2a). The corresponding solutions

$\lim _{n\to \infty } \eta ^* \approx 1.4326$ (see figure 2a). The corresponding solutions ![]() $\phi (\eta )$ are plotted in figure 2(b).

$\phi (\eta )$ are plotted in figure 2(b).

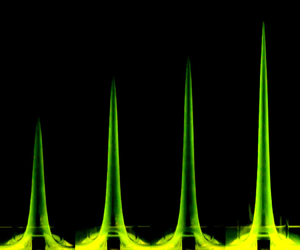

Figure 2. Solutions to the ODE (5.7). (a) The dimensionless tip altitude ![]() $\eta ^*$ as a function of

$\eta ^*$ as a function of ![]() $n$. The values of

$n$. The values of ![]() $\eta ^*$ corresponding to the first few integer

$\eta ^*$ corresponding to the first few integer ![]() $n$ are listed in the inset table. A complete table can be found in Appendix C. In the limit

$n$ are listed in the inset table. A complete table can be found in Appendix C. In the limit ![]() $n\to \infty$,

$n\to \infty$, ![]() $\phi '(\eta ^*)\to \eta ^* \approx 1.4326$. (b) The function

$\phi '(\eta ^*)\to \eta ^* \approx 1.4326$. (b) The function ![]() $\phi (\eta )$ obtained by solving the ODE numerically. The condition for hydrostatic equilibrium (5.8a),

$\phi (\eta )$ obtained by solving the ODE numerically. The condition for hydrostatic equilibrium (5.8a), ![]() $\phi (\eta ) = 1/\eta$, is shown in black.

$\phi (\eta ) = 1/\eta$, is shown in black.

5.3. Self-similarity and universality

This subsection discusses briefly the existence of self-similar and universal aspects of capillary rise in sharp corners. In the language of Barenblatt (Reference Barenblatt2003), phenomena are similar if they differ only in the values of their corresponding physical parameters while their corresponding dimensionless parameters are identical. This is the natural generalization of geometric similarity, in which dimensionless quantities like angles and length ratios are preserved while a shape is scaled. Furthermore, we say that phenomena are self-similar when there exists a time- or space-dependent scaling of dimensional quantities for which the phenomenon becomes invariant. Self-similar phenomena are characterized by power-law growth and the existence of similarity transformations through which it is possible to reduce the number independent variables and in this case obtain an ODE from a PDE. Self-similarity is often observed in the propagation of persistent singularities, such as the motion of contact lines at the edges of spreading drops (e.g. Eggers & Fontelos Reference Eggers and Fontelos2015). A common feature of self-similar phenomena is universality, since self-similarity is usually observed in the intermediate asymptotic regime in which both initial conditions and the large-scale structure of the solution are irrelevant. The term ‘universal’ is used here to refer to features of capillary rise in sharp corners that do not depend on corner geometry, or in other words that are common for all powers ![]() $n$ and geometric parameters

$n$ and geometric parameters ![]() $c$.

$c$.

As discussed in § 2.1, there is an additional length scale ![]() $c^{-1/(n-1)}$ characteristic of the corner geometry when

$c^{-1/(n-1)}$ characteristic of the corner geometry when ![]() $n > 1$, and the liquid cross-section lacks geometric similarity due to the existence of dimensionless quantities that are not constant as the size of the cross-section is varied. The system also fails to satisfy the definition of physical similarity for the same reason. However, when written in terms of the interface radius, the cross-sectional area and flow rate (3.8) scale with the same power of

$n > 1$, and the liquid cross-section lacks geometric similarity due to the existence of dimensionless quantities that are not constant as the size of the cross-section is varied. The system also fails to satisfy the definition of physical similarity for the same reason. However, when written in terms of the interface radius, the cross-sectional area and flow rate (3.8) scale with the same power of ![]() $c$, thus

$c$, thus ![]() $c$ does not appear in the evolution equation expressed in terms of the interface radius (4.6) even prior to non-dimensionalization. As noted previously, the fractional exponents in (4.6) and (5.2) simplify upon distribution of the derivatives, and information about the corner geometry remains only in the power

$c$ does not appear in the evolution equation expressed in terms of the interface radius (4.6) even prior to non-dimensionalization. As noted previously, the fractional exponents in (4.6) and (5.2) simplify upon distribution of the derivatives, and information about the corner geometry remains only in the power ![]() $n$ in the coefficients. It becomes apparent that there is a similarity transformation (5.6) that is independent of

$n$ in the coefficients. It becomes apparent that there is a similarity transformation (5.6) that is independent of ![]() $c$ and

$c$ and ![]() $n$, so we confirm the universality of

$n$, so we confirm the universality of ![]() $t^{1/3}$ proposed by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011). That is, the tip altitude advances with the same power of

$t^{1/3}$ proposed by Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011). That is, the tip altitude advances with the same power of ![]() $t$ for all corner geometries:

$t$ for all corner geometries:

\begin{equation} \frac{z^*}{\ell_{cg}(\cos\theta)^{1/2}} = \eta^*\left( \frac{\gamma (\cos\theta)^{1/2} t}{3\mu \ell_{cg}}\right)^{1/3} \end{equation}

\begin{equation} \frac{z^*}{\ell_{cg}(\cos\theta)^{1/2}} = \eta^*\left( \frac{\gamma (\cos\theta)^{1/2} t}{3\mu \ell_{cg}}\right)^{1/3} \end{equation}or

The scaling of the tip altitude with time in (5.11) is equivalent to the result in Zhou & Doi (Reference Zhou and Doi2020) (see their (3.25)) up to factors of ![]() $n$, despite differences in the choices of characteristic lengths in the intervening scaling step and in the form of the ODE obtained by similarity transformation. In (5.11) and (5.12), the constant

$n$, despite differences in the choices of characteristic lengths in the intervening scaling step and in the form of the ODE obtained by similarity transformation. In (5.11) and (5.12), the constant ![]() $c$ is absent. However, due to the dependence of the prefactor and dimensionless tip altitude

$c$ is absent. However, due to the dependence of the prefactor and dimensionless tip altitude ![]() $\eta ^*$ on

$\eta ^*$ on ![]() $n$, the rate of capillary rise is not truly universal. The prefactor

$n$, the rate of capillary rise is not truly universal. The prefactor ![]() $\eta ^*$ of the power law varies with

$\eta ^*$ of the power law varies with ![]() $n$ because

$n$ because ![]() $n$ appears in the coefficients of the nonlinear evolution equation (4.6) and in the boundary condition (5.10). The quantity

$n$ appears in the coefficients of the nonlinear evolution equation (4.6) and in the boundary condition (5.10). The quantity ![]() $\eta ^*$ decreases monotonically with the power

$\eta ^*$ decreases monotonically with the power ![]() $n$, and its value is bounded between approximately 1.6718 and 1.4350 for

$n$, and its value is bounded between approximately 1.6718 and 1.4350 for ![]() $1\leq n < \infty$ (see figure 2a). Zhou & Doi (Reference Zhou and Doi2020) also report that variations in the prefactor are small based on values obtained up to

$1\leq n < \infty$ (see figure 2a). Zhou & Doi (Reference Zhou and Doi2020) also report that variations in the prefactor are small based on values obtained up to ![]() $n = 5$, which are tabulated in their table 1.

$n = 5$, which are tabulated in their table 1.

In summary, we anticipate that capillary rise proceeds as ![]() $t^{1/3}$ for all

$t^{1/3}$ for all ![]() $c$ and

$c$ and ![]() $n$, and that the rates of capillary rise in corners characterized by the same power

$n$, and that the rates of capillary rise in corners characterized by the same power ![]() $n$ are the same regardless of the values of

$n$ are the same regardless of the values of ![]() $c$. Furthermore, we can identify another feature shared by liquid columns rising in corners. For a given

$c$. Furthermore, we can identify another feature shared by liquid columns rising in corners. For a given ![]() $n$, the profiles of the interface radius

$n$, the profiles of the interface radius ![]() $s$ as a function of the axial coordinate

$s$ as a function of the axial coordinate ![]() $z$ are identical regardless of the value of

$z$ are identical regardless of the value of ![]() $c$, and they all share the same self-similar profile. Experimental data that illustrate these results are presented in § 7.

$c$, and they all share the same self-similar profile. Experimental data that illustrate these results are presented in § 7.

In the next section, we examine the early stages of capillary rise. Power laws for the evolution of geometric features of the meniscus are identified that depend differently on the geometry of the corner than those presented for capillary rise at late times in which the liquid geometry is long and narrow. The result presented in the next section suggests that the corner geometry affects the dynamics of capillary rise in ways that are not always straightforward.

6. Capillary rise at early times

In this section, we examine the early stages of the capillary rise phenomenon using a formulation of the problem in terms of the altitude of the meniscus ![]() $Z(x,t)$. The developments in this section follow Higuera et al. (Reference Higuera, Medina and Linan2008), who reported an analogous calculation for linear corners. It is found that the maximum altitude of the meniscus does not coincide with the line of contact of the surfaces forming the corner. This problem also admits a similarity solution, which reveals the rates at which the maximum altitude of the meniscus increases and at which the location of this maximum approaches the corner.

$Z(x,t)$. The developments in this section follow Higuera et al. (Reference Higuera, Medina and Linan2008), who reported an analogous calculation for linear corners. It is found that the maximum altitude of the meniscus does not coincide with the line of contact of the surfaces forming the corner. This problem also admits a similarity solution, which reveals the rates at which the maximum altitude of the meniscus increases and at which the location of this maximum approaches the corner.

6.1. Model

First, by applying lubrication theory and making use of the separation of scales ![]() $L_y \ll L_x$ and

$L_y \ll L_x$ and ![]() $L_y \ll L_z$, we write the velocities averaged over the gap height:

$L_y \ll L_z$, we write the velocities averaged over the gap height:

where ![]() $p(x,z,t)$ is the pressure driving the flow. The pressure is approximately constant in the

$p(x,z,t)$ is the pressure driving the flow. The pressure is approximately constant in the ![]() $y$-direction as a result of the geometry, and the velocity

$y$-direction as a result of the geometry, and the velocity ![]() $u_y$ is negligible,

$u_y$ is negligible, ![]() $u_y/u_x \ll 1$ and

$u_y/u_x \ll 1$ and ![]() $u_y/u_z \ll 1$. The corresponding flux in each direction is

$u_y/u_z \ll 1$. The corresponding flux in each direction is

Using (2.2), we substitute for the gap height ![]() $h(x)$:

$h(x)$:

For an incompressible flow, mass conservation requires ![]() $\partial q_x/\partial x + \partial q_z/\partial z =0$, or

$\partial q_x/\partial x + \partial q_z/\partial z =0$, or

At the edge of the corner where the surfaces make contact, we expect the velocity and flux to vanish, or equivalently,

The reference pressure is

and a pressure boundary condition holds at the interface:

where it has been assumed that axial contributions to mean curvature are negligible, that the interface is approximately circular in horizontal cross-sections, and that the definition (2.2) and asymptotic relation (2.3) have been applied. We assume that the meniscus is a material surface that travels with the average velocity ![]() $\text {D}Z/\text {D}t = u_z$, in which case

$\text {D}Z/\text {D}t = u_z$, in which case

If we begin with the initial condition

then the characteristic scale in the vertical direction is small compared to that in the horizontal direction, ![]() $L_z \ll L_x$, and we may use lubrication theory to simplify (6.5) and (6.9) to

$L_z \ll L_x$, and we may use lubrication theory to simplify (6.5) and (6.9) to

and

6.2. Scaling and similarity solution

Scaling the lengths by

and pressure and time by

we obtain the system

and

Solving (6.15a) with (6.15b) and (6.15c) yields the solution for the pressure:

Substituting the expression for the pressure (6.16) into (6.15d), we obtain

\begin{equation} \frac{\partial \tilde{Z}}{\partial t} = 12 \tilde{x}^n\Bigg(\frac{1-\tilde{Z}(\tilde{x},\tilde{t})\,\tilde{x}^n}{\tilde{Z}(\tilde{x},\tilde{t})}\Bigg), \end{equation}

\begin{equation} \frac{\partial \tilde{Z}}{\partial t} = 12 \tilde{x}^n\Bigg(\frac{1-\tilde{Z}(\tilde{x},\tilde{t})\,\tilde{x}^n}{\tilde{Z}(\tilde{x},\tilde{t})}\Bigg), \end{equation}which can be solved with the initial condition (6.15e) to find

We observe that (6.18) is invariant under the one-parameter family of scaling transformations

Therefore, there is a similarity transformation

through which we obtain

The solution for ![]() $\zeta (\xi )$ can be written using the Lambert

$\zeta (\xi )$ can be written using the Lambert ![]() $W$-function

$W$-function

6.3. Evolution of the maximum meniscus altitude

Taking the derivative of (6.21) with respect to ![]() $\xi$, and setting

$\xi$, and setting ![]() $\zeta '(\xi )=0$, we find that there is a maximum

$\zeta '(\xi )=0$, we find that there is a maximum ![]() $\zeta ^*$ located at

$\zeta ^*$ located at ![]() $\xi ^*$ such that

$\xi ^*$ such that

The location ![]() $\xi ^*$ of the maximum is shown in figure 3(a), and the corresponding solutions to (6.21) are shown in figure 3(b). Also, it is possible to examine (6.21) to determine how the location and value of the maximum depend on the power

$\xi ^*$ of the maximum is shown in figure 3(a), and the corresponding solutions to (6.21) are shown in figure 3(b). Also, it is possible to examine (6.21) to determine how the location and value of the maximum depend on the power ![]() $n$.

$n$.

Figure 3. Similarity solution for capillary rise at early times. (a) Locations ![]() $\xi ^*$ of the maximum of the function

$\xi ^*$ of the maximum of the function ![]() $\zeta (\xi )$ as a function of

$\zeta (\xi )$ as a function of ![]() $n$. (b) Profiles of

$n$. (b) Profiles of ![]() $\zeta (\xi )$ for different

$\zeta (\xi )$ for different ![]() $n$.

$n$.

It can be shown that ![]() $\zeta ^* \approx 2.0200$ for all

$\zeta ^* \approx 2.0200$ for all ![]() $n$, and that

$n$, and that ![]() $\xi ^* \to 1$ as

$\xi ^* \to 1$ as ![]() $n\to \infty$. By defining

$n\to \infty$. By defining ![]() $\chi = \xi ^n\zeta$, we can write (6.21) and (6.23) as

$\chi = \xi ^n\zeta$, we can write (6.21) and (6.23) as

and

In writing (6.24a), we have used the fact that if (6.21) applies for all ![]() $\xi$ and

$\xi$ and ![]() $\zeta (\xi )$, then it must be true at

$\zeta (\xi )$, then it must be true at ![]() $\xi ^*$ and

$\xi ^*$ and ![]() $\zeta ^*$. Then, noting that the expressions on the right-hand sides of (6.24a) and (6.24b) are identical, we set the left-hand sides equal,

$\zeta ^*$. Then, noting that the expressions on the right-hand sides of (6.24a) and (6.24b) are identical, we set the left-hand sides equal,

and find that ![]() $\chi ^* \approx 0.6450$. Then we use (6.24a) or (6.24b) to solve for

$\chi ^* \approx 0.6450$. Then we use (6.24a) or (6.24b) to solve for ![]() $(\xi ^*)^n$, and we conclude that

$(\xi ^*)^n$, and we conclude that ![]() $(\xi ^*)^n \approx 0.3193$. Here,

$(\xi ^*)^n \approx 0.3193$. Here, ![]() $(\xi ^*)^n$ is a constant, so

$(\xi ^*)^n$ is a constant, so ![]() $\xi ^*\to 1$ as

$\xi ^*\to 1$ as ![]() $n\to \infty$. Furthermore, by using the definition of

$n\to \infty$. Furthermore, by using the definition of ![]() $\chi$, we find that

$\chi$, we find that ![]() $\zeta ^* = (\xi ^*)^{-n}\chi ^* \approx 2.0200$, which is constant for all

$\zeta ^* = (\xi ^*)^{-n}\chi ^* \approx 2.0200$, which is constant for all ![]() $n$. We observe these features in figure 3(b).

$n$. We observe these features in figure 3(b).

Due to (6.20), we find that the location of the maximum moves towards ![]() $\tilde {x}=0$ as

$\tilde {x}=0$ as

where the prefactor ![]() $\xi ^*$ is a function of

$\xi ^*$ is a function of ![]() $n$. Using physical quantities,

$n$. Using physical quantities,

\begin{equation} \frac{x^*}{[2 c^{-1}\ell_{cg}(\cos \theta)^{1/2}]^{1/n}} = \xi^*\left(\frac{\gamma (\cos\theta)^{1/2}t}{3\mu \ell_{cg}}\right)^{-1/3n}. \end{equation}

\begin{equation} \frac{x^*}{[2 c^{-1}\ell_{cg}(\cos \theta)^{1/2}]^{1/n}} = \xi^*\left(\frac{\gamma (\cos\theta)^{1/2}t}{3\mu \ell_{cg}}\right)^{-1/3n}. \end{equation}The maximum meniscus altitude increases as

or

\begin{equation} \frac{Z^*}{\ell_{cg}(\cos\theta)^{1/2}} = \zeta^*\left( \frac{\gamma (\cos\theta)^{1/2} t}{3\mu \ell_{cg}}\right)^{1/3}. \end{equation}

\begin{equation} \frac{Z^*}{\ell_{cg}(\cos\theta)^{1/2}} = \zeta^*\left( \frac{\gamma (\cos\theta)^{1/2} t}{3\mu \ell_{cg}}\right)^{1/3}. \end{equation}

Therefore, in the early stages of capillary rise, we expect the rate at which the meniscus rises (6.29) to be universal, that is, independent of ![]() $c$ and

$c$ and ![]() $n$. However, the rate at which the location of the maximum altitude approaches the corner (6.27) depends on both

$n$. However, the rate at which the location of the maximum altitude approaches the corner (6.27) depends on both ![]() $c$ and

$c$ and ![]() $n$.

$n$.

7. Experiments

7.1. Methods

Experiments were conducted in order to measure the rate of capillary rise at late times as well as the shape of the liquid column in a quadratic corner (![]() $n=2$), which was formed by the contact of a cylinder and a flat plate. A closed contour centred at

$n=2$), which was formed by the contact of a cylinder and a flat plate. A closed contour centred at ![]() $x = 0, y = \pm b_i$ with geometry described by (Stone Reference Stone2005)

$x = 0, y = \pm b_i$ with geometry described by (Stone Reference Stone2005)

where ![]() $m$ is a positive, even integer and

$m$ is a positive, even integer and ![]() $y_i = y\mp b_i$, creates a surface at

$y_i = y\mp b_i$, creates a surface at

where ![]() $n = m$ and

$n = m$ and

Corners were created by pressing a flat plate (![]() $b_1=\infty$) to a circular cylindrical tube (

$b_1=\infty$) to a circular cylindrical tube (![]() $m = 2$) of radius

$m = 2$) of radius ![]() $b_2=b$, both made of glass, so that the corner is formed by surfaces at

$b_2=b$, both made of glass, so that the corner is formed by surfaces at ![]() $h_2(x) \sim cx^2$, with

$h_2(x) \sim cx^2$, with ![]() $c=1/2b$ and

$c=1/2b$ and ![]() $h_1(x) = 0$ . Experiments were performed for two different cylinder radii,

$h_1(x) = 0$ . Experiments were performed for two different cylinder radii, ![]() $b = 4$ mm and

$b = 4$ mm and ![]() $b= 9$ mm. Figure 4(a) shows a schematic of the liquid column rising in such a configuration. Pairs of magnets placed at two axial locations were used to hold the tube and plate in contact. Prior to the experiments, the glass was cleaned using ethanol and distilled water.

$b= 9$ mm. Figure 4(a) shows a schematic of the liquid column rising in such a configuration. Pairs of magnets placed at two axial locations were used to hold the tube and plate in contact. Prior to the experiments, the glass was cleaned using ethanol and distilled water.

Figure 4. Rise of a liquid column in the corner formed by a cylinder and a plate (![]() $n=m=2$). (a) Graphical rendering of the fluid interface viewed from an angle. (b) Image of the liquid column from an experiment with a view orthogonal to the plate. Scale bar is 10 mm. (c) Geometry of a horizontal cross-section of a liquid column between a cylinder and plate.

$n=m=2$). (a) Graphical rendering of the fluid interface viewed from an angle. (b) Image of the liquid column from an experiment with a view orthogonal to the plate. Scale bar is 10 mm. (c) Geometry of a horizontal cross-section of a liquid column between a cylinder and plate.

Experiments were performed using silicone oil (Sigma Aldrich, product no. 378348) and mineral oil (Sigma Aldrich, product no. 330779), whose properties are listed in table 2. The oils were dyed using fluorescent automotive dye (The Dow Chemical Company, Fluorescent Yellow 131SC) at concentrations 5 ![]() $\mathrm {\mu }$l per 20 ml for mineral oil, and 20

$\mathrm {\mu }$l per 20 ml for mineral oil, and 20 ![]() $\mathrm {\mu }$l per 20 ml for silicone oil. For imaging, the liquid was illuminated with 365 nm UV light. An experimental image of the illuminated liquid column is shown in figure 4(b). Due to the use of fluorescent dye, the pixels corresponding to the liquid have much greater intensity values compared to those corresponding to the background. The tip altitude is identified by locating the steep gradient in pixel intensity between the background and the liquid.

$\mathrm {\mu }$l per 20 ml for silicone oil. For imaging, the liquid was illuminated with 365 nm UV light. An experimental image of the illuminated liquid column is shown in figure 4(b). Due to the use of fluorescent dye, the pixels corresponding to the liquid have much greater intensity values compared to those corresponding to the background. The tip altitude is identified by locating the steep gradient in pixel intensity between the background and the liquid.

Table 2. Relevant properties of the liquids used in experiments.

Experiments were recorded using a DSLR camera (Nikon, D5100) oriented so that the focal plane was parallel with the plate. Videos were acquired at 30 frames per second using resolution ![]() $1920 \times 1080$ pixels, and images were calibrated using an object of known size in the focal plane. Typical resolutions were around 17 pixels mm

$1920 \times 1080$ pixels, and images were calibrated using an object of known size in the focal plane. Typical resolutions were around 17 pixels mm![]() $^{-1}$.

$^{-1}$.

Trigonometric relations were used to calculate the radius of the liquid–air interface from the width. Figure 4(c) shows the cross-section of a liquid column between a cylinder of radius ![]() $b$ and a flat plate. The angle

$b$ and a flat plate. The angle ![]() $\alpha$ spanned by the wetted perimeter of the cylinder cross-section is related to the corresponding wetted length

$\alpha$ spanned by the wetted perimeter of the cylinder cross-section is related to the corresponding wetted length ![]() $a$ of the plate by the equation

$a$ of the plate by the equation

The radius of the interface is related to the separation and the wetted angle by

When ![]() $\theta = 0$, we recover the result given by Princen (Reference Princen1969) for a cylinder in contact with a plate.

$\theta = 0$, we recover the result given by Princen (Reference Princen1969) for a cylinder in contact with a plate.

7.2. Results and discussion

In this subsection, results of the experiments are reported and discussed. Videos were analysed to obtain two types of data: (1) the location ![]() $z^*(t)$ of the tip of the liquid column as a function of time, and (2) profiles of the interface radius

$z^*(t)$ of the tip of the liquid column as a function of time, and (2) profiles of the interface radius ![]() $s(z,t)$ as a function of the axial coordinate for selected times.

$s(z,t)$ as a function of the axial coordinate for selected times.

The location of the tip as a function of time is shown in figure 5 for two different oils and two different cylinder radii. The altitude of the tip is plotted as a function of the time on linear axes in figure 5(a). Figure 5(b) shows the same data scaled using (5.1a,b,c) and plotted on logarithmic axes along with the solution (5.12) using the dimensionless tip altitude ![]() $\eta ^* = 1.5761$, which corresponds to

$\eta ^* = 1.5761$, which corresponds to ![]() $n=2$. In figure 5(a), we observe that the trajectories for a single fluid (silicone oil) in corners created by cylinders of two different radii are nearly coincident prior to scaling, which supports the hypothesis that the cylinder radius does not affect the evolution of the tip altitude. Since (5.1a,b,c) does not involve the gap geometry, this overlap persists in figure 5(b) after the tip altitude and time have been non-dimensionalized. Although the oils have different viscosities, capillary lengths and contact angles, the trajectories all collapse onto the same curve after scaling.

$n=2$. In figure 5(a), we observe that the trajectories for a single fluid (silicone oil) in corners created by cylinders of two different radii are nearly coincident prior to scaling, which supports the hypothesis that the cylinder radius does not affect the evolution of the tip altitude. Since (5.1a,b,c) does not involve the gap geometry, this overlap persists in figure 5(b) after the tip altitude and time have been non-dimensionalized. Although the oils have different viscosities, capillary lengths and contact angles, the trajectories all collapse onto the same curve after scaling.

Figure 5. Location of the tip of the liquid column as a function of time. Data are shown for ![]() $b = 9$ mm in red, and

$b = 9$ mm in red, and ![]() $b = 4$ mm in blue. Solid lines indicate data for silicone oil, and dashed lines indicate data for mineral oil. (a) With dimensions and plotted on linear axes. (b) Non-dimensionalized and plotted on log-log axes. The function (5.12) with

$b = 4$ mm in blue. Solid lines indicate data for silicone oil, and dashed lines indicate data for mineral oil. (a) With dimensions and plotted on linear axes. (b) Non-dimensionalized and plotted on log-log axes. The function (5.12) with ![]() $\eta ^* = 1.5761$ (for

$\eta ^* = 1.5761$ (for ![]() $n=2$) is shown as a solid black line.

$n=2$) is shown as a solid black line.

The comparison in figure 5(b) shows that it requires a time ![]() $10^2\unicode{x2013}10^3 \mu \ell _{cg}/\gamma$ in order to approach the similarity solution, which is natural owing to the time required to evolve into a slender flow configuration and to enter the regime in which the intermediate asymptotics are relevant. Other possible contributors to the initial transients are discussed by Quéré (Reference Quéré1997) and Clanet & Quéré (Reference Clanet and Quéré2002). At long times, the tip progresses as approximately

$10^2\unicode{x2013}10^3 \mu \ell _{cg}/\gamma$ in order to approach the similarity solution, which is natural owing to the time required to evolve into a slender flow configuration and to enter the regime in which the intermediate asymptotics are relevant. Other possible contributors to the initial transients are discussed by Quéré (Reference Quéré1997) and Clanet & Quéré (Reference Clanet and Quéré2002). At long times, the tip progresses as approximately ![]() $\tilde {t}^{1/3}$, which agrees with experimental and numerical results due to Higuera et al. (Reference Higuera, Medina and Linan2008) for linear corners, and with experimental observations of Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) for power-law corners with linear, quadratic and cubic (

$\tilde {t}^{1/3}$, which agrees with experimental and numerical results due to Higuera et al. (Reference Higuera, Medina and Linan2008) for linear corners, and with experimental observations of Ponomarenko et al. (Reference Ponomarenko, Quéré and Clanet2011) for power-law corners with linear, quadratic and cubic (![]() $n=3$) corners.

$n=3$) corners.

We further investigate the validity of the model by examining the interface radius as a function of the altitude at different times. Figure 6 shows profiles of the interface radius at different times acquired for cylinder radii ![]() $b = 4$ mm and

$b = 4$ mm and ![]() $b = 9$ mm using silicone oil (figure 6a) and mineral oil (figure 6b). The data are shown rescaled according to (5.1a,b,c). For the data acquired using both oils, we observe that the tip altitudes for both radii at each of the times are nearly coincident, which is to be expected given the agreement in figure 5. In figure 6(a), the profiles acquired using silicone oil for the two radii also nearly overlap. This agreement between rescaled data for cylinder radii that differ by more than a factor of 2 suggests that the corner geometry affects neither the interface radius nor the tip altitude, and supports the use of the characteristic scales in (5.1a,b,c), which do not depend on the geometric constant

$b = 9$ mm using silicone oil (figure 6a) and mineral oil (figure 6b). The data are shown rescaled according to (5.1a,b,c). For the data acquired using both oils, we observe that the tip altitudes for both radii at each of the times are nearly coincident, which is to be expected given the agreement in figure 5. In figure 6(a), the profiles acquired using silicone oil for the two radii also nearly overlap. This agreement between rescaled data for cylinder radii that differ by more than a factor of 2 suggests that the corner geometry affects neither the interface radius nor the tip altitude, and supports the use of the characteristic scales in (5.1a,b,c), which do not depend on the geometric constant ![]() $c$.

$c$.

Figure 6. Interface radius as a function of altitude rescaled using (5.1a,b,c). Data are shown for ![]() $b = 9$ mm in red, and

$b = 9$ mm in red, and ![]() $b = 4$ mm in blue. The equilibrium profile (5.3) is shown in black. (a) Data acquired for silicone oil (

$b = 4$ mm in blue. The equilibrium profile (5.3) is shown in black. (a) Data acquired for silicone oil (![]() $\theta = 0$) at

$\theta = 0$) at ![]() $\tilde {t} = 4450$, 8900, 13 350, 22 250 for both radii. (b) Data acquired for mineral oil (

$\tilde {t} = 4450$, 8900, 13 350, 22 250 for both radii. (b) Data acquired for mineral oil (![]() $\theta = 20^\circ$) at

$\theta = 20^\circ$) at ![]() $\tilde {t} =6750$, 10 120, 13 490, 20 240.

$\tilde {t} =6750$, 10 120, 13 490, 20 240.