Published online by Cambridge University Press: 29 August 2017

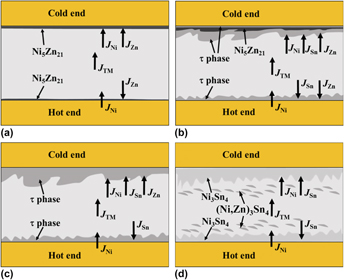

Ni/Sn–xZn/Ni (x = 1, 5, 9 wt%) joints were used to investigate the effect of Zn content on interfacial reactions during reflow under a temperature gradient. Asymmetrical growth and transformation of intermetallic compounds (IMCs) occurred between the cold and hot end interfaces. Faster IMC growth at the cold end and a more prompt IMC transformation at the hot end in a lower Zn content solder joint were identified due to the more thermomigration-induced Zn and Ni atomic fluxes toward the cold end. The main diffusion species into IMC layers changed from Zn atoms at the early stage to Sn and Ni atoms at the later stage. As a result, the IMC evolution followed (Ni,Zn)3Sn4 → Ni3Sn4 in the Ni/Sn–1Zn/Ni joint, Ni5Zn21 → τ phase → Ni3Sn4 in the Ni/Sn–5Zn/Ni joint, and Ni5Zn21 → τ phase in the Ni/Sn–9Zn/Ni joint along with the reflow time. A higher Zn content could effectively inhibit the dissolution of the hot-end Ni substrate and restrain the growth rate of the cold-end interfacial IMCs.

Contributing Editor: Jürgen Eckert

A previous error in this article has been corrected, please see doi: 10.1557/jmr.2017.379.

Please note a has been issued for this article.