Introduction

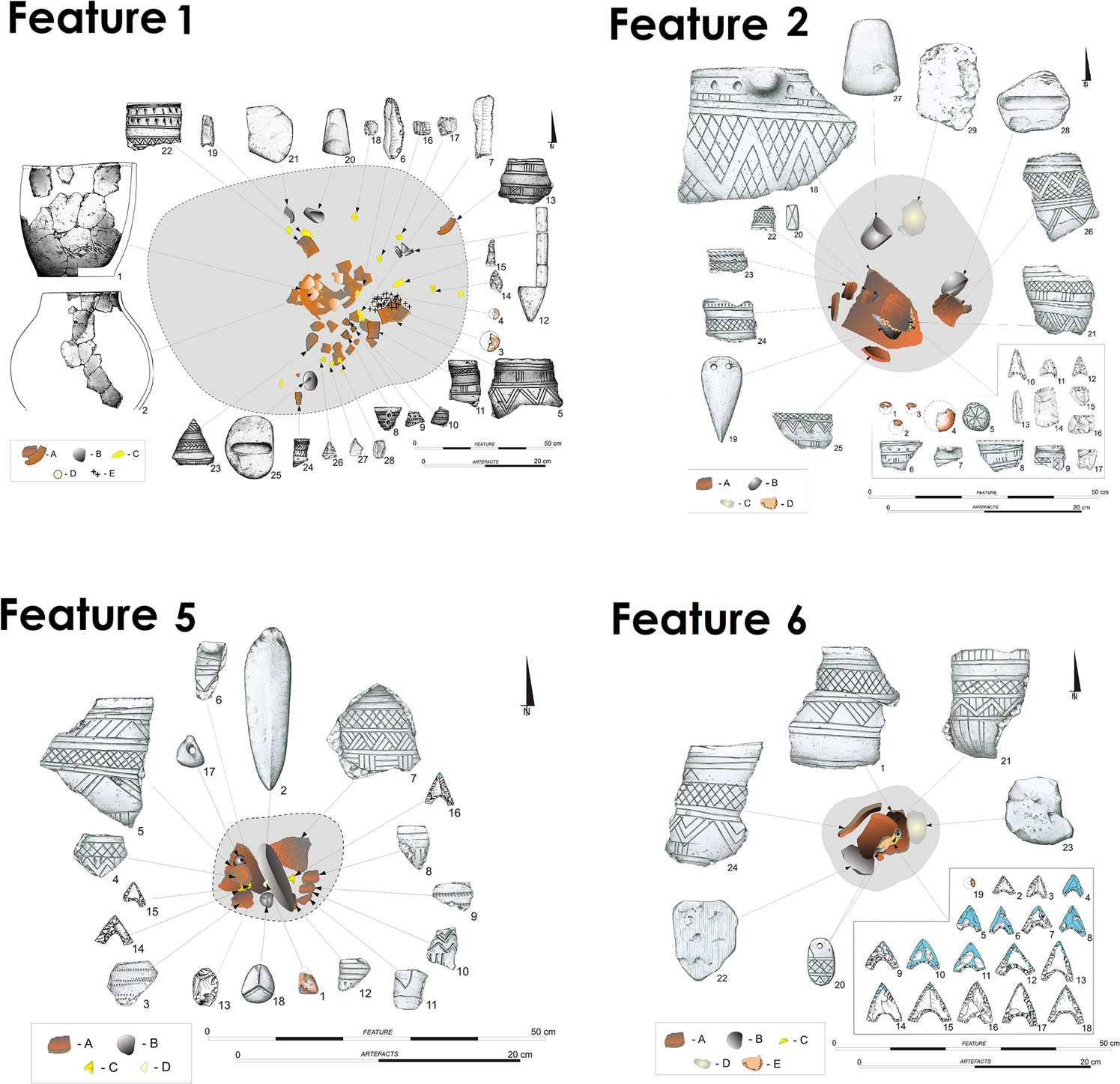

From 2014 to 2017, at the site of Supraśl 3, located in the northern Podlachian Plain in north-eastern Poland, four Bell Beakers features were discovered (Figures 1 and 2). These were shallow pits of various diameters and fillings lacking stratified deposits (Manasteski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 377–80). The observations made during excavation indicate they represent a single deposition event. The finds comprised various artefacts and fragments of artefacts, the most numerous of which were fragments of decorated pottery vessels. The three pits also contained a small amount of burnt and fragmented human and animal bones in small organic containers, probably pouches. In two cases, these were accompanied by fragments of amber ornaments and, in one, also by arrowheads. Each of these deposits was covered with a large pottery fragment. Pouches in smaller pits were also covered with larger fragments of vessels and were accompanied by artefacts of stone (tools, fragments of weapons, and items of unknown significance) and flint, including arrowheads. In one of the smaller features, the pouch contained no bone remains, but just an amber ornament and arrowheads. The latter, however, are present in all four features and are associated with the Bell Beaker package common to the eastern European periphery (see Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020). The composition and distribution of ecofacts and artefacts indicated their intentional and ritualistic nature and showed them to be related to some extent to funerary practices. This is evidenced by small amounts of burnt human bones. However, specific references are missing, so this ritual is difficult to interpret (Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 385). In all four features, a general similarity of the deposited artefacts is visible. Features 4 and 5 contained fragments of the same vessel and were consequently interpreted as being simultaneous deposits (Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 379–80). No evidence was available to sequence the deposition of the other two features. Due to the similarity of the four features, it can be assumed that they were either created at the same time or within short intervals of time. Apart from burnt bones and a fragment of one vessel with some carbon residue adhering, the features yielded no organic substances that could be used for absolute dating. Radiocarbon dating on bones was unsuccessful as they were too few and retained no collagen. The radiocarbon measurement of a bowl fragment with carbon residue gave a date of 5110 ± 35 bp or 3976–3799 bc at 95.4% probability (Poz-116826; Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020). This measurement precedes the emergence of the Bell Beaker phenomenon by a millennium. Thus, the typology of the vessel fragments was used to establish a relative date, that is that the features probably date to between 2500 and 2200 bc.

Figure 1. Map of the Bell Beaker culture: A: location of Supraśl site 3. B: plan of the site with Bell Beaker features shown in red (after Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: figs 1 and 3).

Figure 2. Plan of four Bell Beaker ritual features from Supraśl 3 (after Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: figs 4–7).

The triangular, hollow-base arrowheads deposited at Supraśl 3, along with the tanged forms, are one of two types characteristic of Bell Beaker productions (see Bailly, Reference Bailly, Arbogast and Greffier-Richard2014: 358–62; Nicolas, Reference Nicolas2017, Reference Nicolas, Kadrow and Müller2019: 116). In north-eastern Poland, however, they are extremely rare. Until the discoveries at Supraśl, only four such arrowheads were known, from a context containing Bell Beaker pottery at Szestno II in the Masurian Lake District (Januszek, Reference Januszek2020: 83–84, fig. 19.3–6). The arrowheads from Supraśl 3 are, however, unique in that they bear traces of grinding. This treatment, unusual for flint arrowheads, was already visible on some arrowheads while the features were being excavated. It was also observed that not all the specimens were ground to the same extent. The whole collection was therefore subjected to detailed macroscopic and microscopic analysis to determine the process of shaping these arrowheads and the possible reasons for grinding them. This is all the more essential as no traces of flint working, including the local production of arrowheads, were recorded at the site.

Materials and Methods

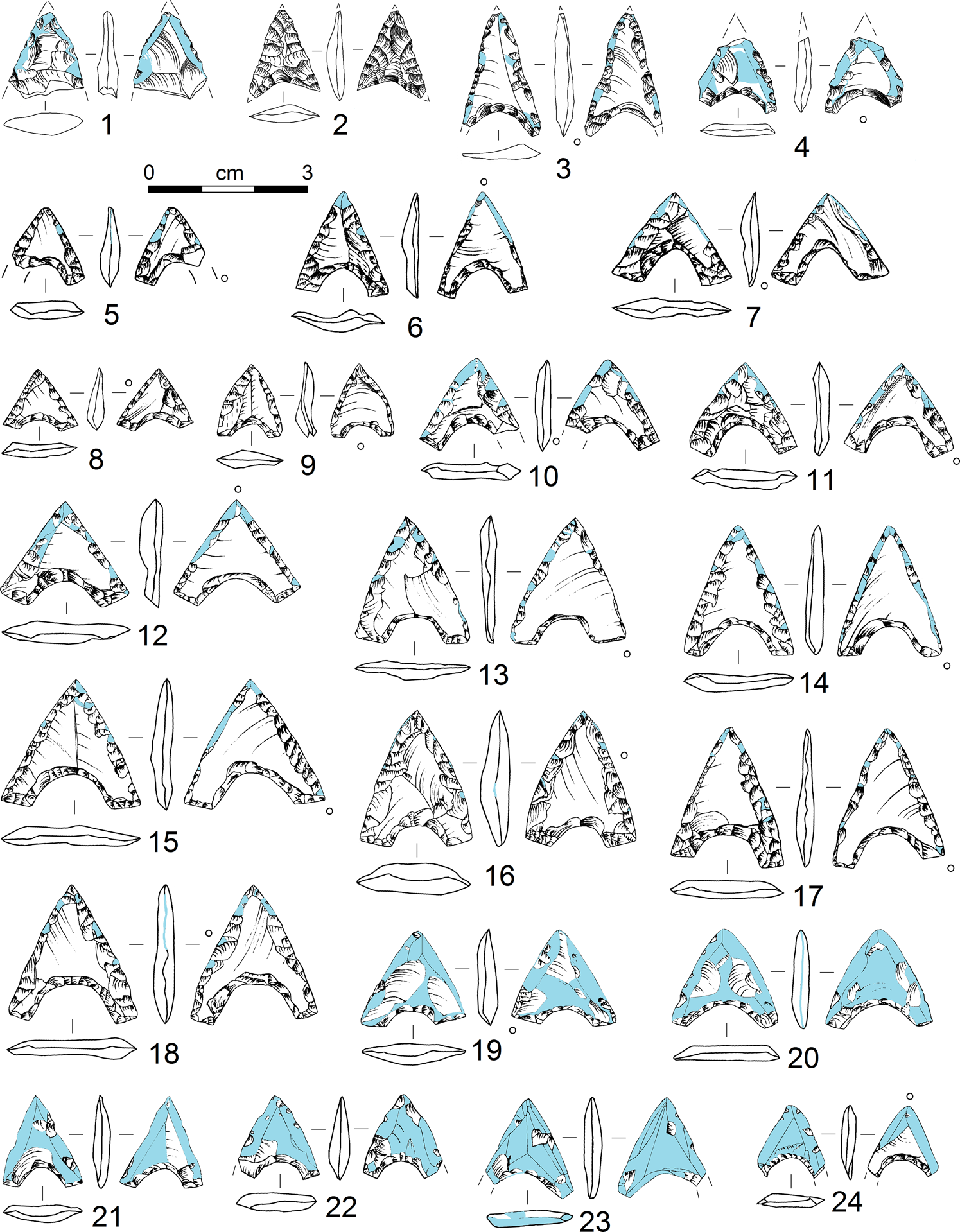

The twenty-four flint arrowheads (Figure 3) from Supraśl 3 came from four features associated with the Bell Beaker phenomenon, each containing a different number of arrowheads. In feature no. 1 there was a damaged specimen; in feature no. 2 three arrowheads were recorded; three other arrowheads were recovered from feature no. 5; and seventeen exemplars were found in feature no. 6. Macroscopic observation was used to determine the varieties of the flint raw material, processing techniques, and visible damage. The identification of the raw material was based on characteristic features such as the colour of the flint mass, its lustre, its degree of transparency, the nature of suspension in the flint mass, the presence and nature of the cortex, and compared with representative specimens from the lithic collection at the Faculty of Archaeology, University of Warsaw. The identification of the techniques used in the production process followed guidance in Madsen (Reference Madsen1984), Ginter and Kozlowski (Reference Ginter and Kozłowski1990), Whittaker (Reference Whittaker1994), Borkowski and Migal (Reference Borkowski, Migal, Brzeziński, Borkowski and Migal1996), and Inizan et al. (Reference Inizan, Reduron-Ballinger, Roche and Tixier1999). The dimensions of each arrowhead were measured with a calliper, and the weight was determined using a Steinberg SBS-LW-200A digital balance.

Figure 3. The flint arrowheads with grinding marks indicated in blue. 1: from feature no. 1; 2–4: from feature no. 2; 5–7: from feature no. 5; 8–24: from feature no. 6.

Details of the manufacturing sequence, in many cases impossible to ascertain by macroscopic inspection, including the aftermath of retouching and grinding, as well as observations of the fracture edges of damaged arrowheads and traces of micro-damage, were carried out by observation with an OPTA-TECH STX12 stereo-microscope, using low magnifications of 7× to 20×. Diagnostic areas of the arrowheads were illustrated with the use of a 20-megapixel OPTA-TECH MI20 microscope camera. No analysis of the grinding process according to the type of abrasive tool was undertaken. Only the presence of traces of intentional abrasive treatment according to the definitions of processes of grinding and polishing provided Bo Madsen (Reference Madsen1984: 49–50) was recorded.

Results

Specific arrowheads referred to in the following section are illustrated in Figure 3 and identified in the text with a bolded number in brackets that refers to that figure. Macroscopic analysis revealed that Upper Jurassic chocolate flint was used in three cases (2–4). It does not occur naturally in north-eastern Poland, its outcrops being located in southern Poland, on the north-eastern margin of the Świętokrzyskie Mountains (Budziszewski, Reference Budziszewski, Borkowski, Libera, Sałacińska and Sałaciński2008: 49–87). Other specimens are made of raw materials characteristic of different varieties of Cretaceous erratic flint (1, 5–24), but a clear identification of their provenance is currently impossible. Most arrowheads were made from flakes of various sizes, some of which showed signs of direct percussion. Flakes were generated by advanced debitage, and three partially cortical flakes were used (3, 4, 9). Two chocolate flint specimens (3, 4) with partially preserved, shiny natural surfaces resulting from weathering and abrasion of the cortex may indicate the collection of nodules of this type of flint from the surface. For six specimens, a clear identification of their preforms was impossible due to:

• the complete coverage by multidirectional removal scars on both preserved surfaces of one of the specimens (1), possibly because a splintered piece was used,

• the presence of surface bifacial retouch on another specimen (2),

• almost complete grinding of the surfaces of four arrowheads (20–23).

As for the manufacture of arrowheads, which is related to the orientation of the proximal part of the flake and consequently to the selection of the tip and base of the arrowhead, the following distinctions were made:

a) arrowheads formed from flakes whose proximal part is on the side of one of the barbs: ten specimens (3, 5, 7, 10, 11, 13–15, 17, 19),

b) arrowheads formed from flakes whose proximal part is at the tip of the arrowhead: three specimens (6, 12, 24),

c) arrowheads formed from flakes whose proximal part is in the middle of one side of the arrowhead: three specimens (8, 16, 18),

d) arrowheads formed from flakes whose proximal part is at the base of the arrowhead: two specimens (4, 9).

There were fifteen complete arrowheads (6–9, 11–21), five with broken barbs (5, 10, 22–24), one with a broken tip (4), two with a damaged tip and barb (2–3), and one with a damaged tip and broken base (1). Among the arrowheads with undamaged tips, there are examples with a penetrating, sharply pointed tip (6, 8, 9, 11–13, 15, 16, 18, 21, 23), and forms with a blunt, rounded tip (5, 7, 10, 14, 17, 19, 20, 22, 24).

Macroscopic observation also revealed the presence of retouching or grinding on the edges and surfaces of the arrowheads. There were two arrowheads with legible retouch of the sides of the edges and base, made with a retoucher (8–9); an arrowhead with surface bifacial retouch, made by pressure technique and with retouch of the edge of the recess in the base (2); fourteen arrowheads with retouch of the edges of the sides obtained by direct strikes with a hard hammer or retoucher on a hard anvil, retouching of the recess with a retoucher, and locally ground sides at the edges (3–7, 10–18); five arrowheads with ground surfaces and sides at the edges, and with a retouched base using a retoucher (19–22, 24); a specimen with ground surfaces and sides at the edges and with a one-sided ground hollow base (23). Additionally, a specimen whose base was missing had retouching of the edges of the sides on one side only, made by direct blows with a hard hammer on a hard anvil and grinding of the edges on both faces (1).

Regular retouching of the edges of the arrowhead sides is rare but is visible on single edges on each side of several exemplars (8, 9, 15). It is most often visible in hollow bases, retouched on both faces, which is the result of different edge-retouching tools having been used. Fifteen specimens exhibit more regular retouch at the base on the upper face of the flake from which the arrowhead was made (3–8, 11–19), in two cases on the lower face of the flake (9, 10), and in three specimens with a ground surface on one side (20–22). Only one arrowhead has a very regular retouch of the hollow edge, but with differently sized removal scars on each side (24).

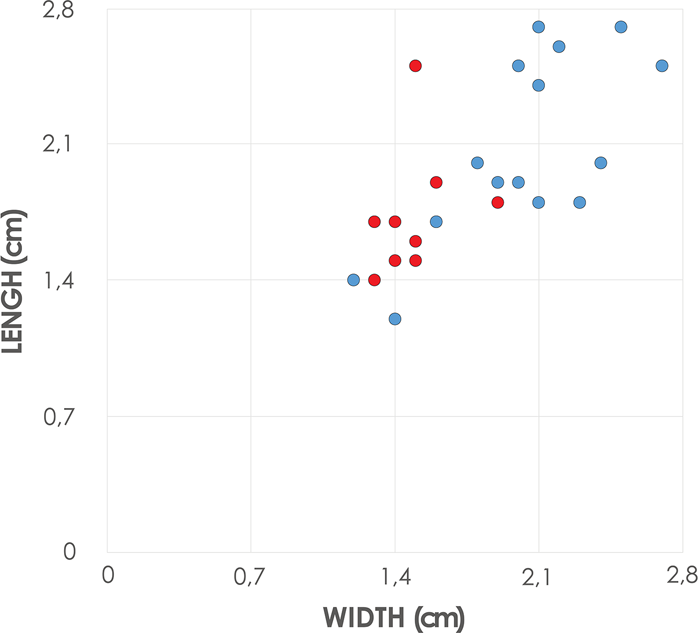

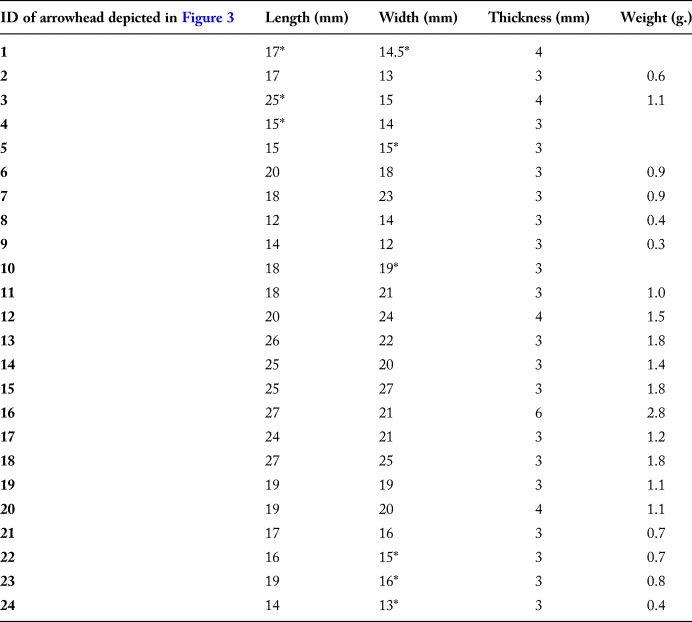

Measurements of arrowheads (Table 1) showed two length ranges: 12–20 mm (fifteen examples: 2, 5–12, 19–24; Figure 4) and 24–27 mm (seven specimens: 3, 13–18; Figure 4). The width of the shorter arrowheads less than 20 mm long is grouped in three ranges: 12–16 mm, 18–21 mm, and 23–24 mm. The width of longer arrowheads varies more widely, ranging from 15 to 27 mm. As for thickness, most arrowheads range from 3 to 4 mm. Only one specimen has a thickness of 6 mm.

Figure 4. Length-width ratio of flint arrowheads at Supraśl 3. Red dots: damaged arrowheads; blue dots: complete arrowheads.

Table 1. Measurements of flint arrowheads; * indicates measurements taken on fragmented arrowheads.

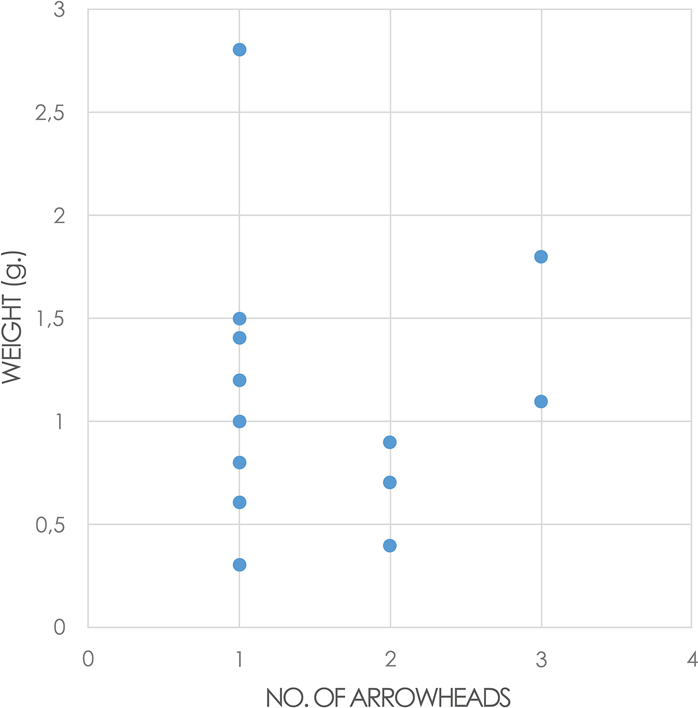

The weight of the arrowheads (Table 1; Figure 5) without significant weight loss due to damage are grouped into five weight classes: 0.3–0.4 g (three specimens: 8–9, 24), 0.6–1.2 g (eleven items: 2–3, 6–7, 11, 17, 19–23), 1.4–1.5 g (two specimens: 12, 14), 1.8 g (three examples: 13, 15, 18), and 2.8 g (one specimen: 16). The different weight classes group arrowheads of different proportions but mostly of similar length and thickness.

Figure 5. Weight of flint arrowheads at Supraśl 3.

All the arrowheads are triangular and have barbs and hollow bases, except for one with a broken base (1). The bases and barbs include a triangular hollow base and pointed barbs (one specimen: 2); an arched hollow base and rounded barbs (two arrowheads: 3, 4); an arched hollow base and squared barbs (four specimens: 5, 7, 8, 23); and semi-circular hollow bases and square barbs (sixteen arrowheads: 6, 9–22, 24).

Microscopic observation revealed that only three arrowheads had no traces of grinding . One of them, characterized by bifacial surface retouch and bifacial base edge retouch, is covered with a shiny patina (2; Figure 6: 2). The broken tip and the barb show sharp fracture edges. Two other arrowheads are characterized by retouching of the sides’ edges and base (8–9; Figure 6: 8–9). The smaller of the two has the sides formed with a reverse retouch creating a sharp, micro-serrated edge on the opposite sides of each of its faces (Figure 6: 8).

Figure 6. Examples of microscopic production traces on selected flint arrowheads. 1, 3–6: arrowheads with grinding marks; 2: arrowhead with surface bifacial retouch without grinding marks.

Among the remaining arrowheads is a specimen with partially ground, retouched edges. This caused blurring of the removal scars of the earlier retouch of the edges on one face, as well as the arises between retouch scars and the ripples of the preform removal scars on the other side of the specimen (Figure 6: 1). In this case, the grinding was carried out to shape the sides of the specimen after the tip had been broken, since the edge of the fracture is rounded by grinding. A further fourteen arrowheads have their sides shaped by edge retouching and grinding. Traces visible on the faces of most of them make clear that both sides were shaped by edge retouching, which was then partially ground to different extents. The next and last operation was to retouch the edges again, which led to the removal of the ground surface and sides to varying degrees, a shaping process that was completed by grinding the edge retouch at different lengths (Figure 6: 3–6; Figure 7: 7, 10–12; Figure 8: 13–18). One of these worth noting is the piece that is unilaterally ground on part of its dorsal face (Figure 6: 4). Grinding traces also overlie a fracture on one edge, indicating that grinding took place after the tip broke. Among some arrowheads in this group, the remnants of grinding that were not entirely removed by retouch are visible on the lateral edges (Figure 6: 5; Figure 8: 16, 18). In this case, the edge grinding has blunted them. The tips of some specimens in this group are damaged, as shown by micro-cracking and the presence of spalling from impacts (Figure 6: 3, 5; Figure 7: 7, 10, 11; Figure 8: 17, 18). The edges of these defects are sharp and indicate tip damage after the sides of the arrowheads had been shaped.

Figure 7. Examples of microscopic traces on selected flint arrowheads. 7, 10–12: arrowheads with traces of grinding; 8–9: retouched arrowheads without grinding marks.

Figure 8. Selected arrowheads with grinding marks.

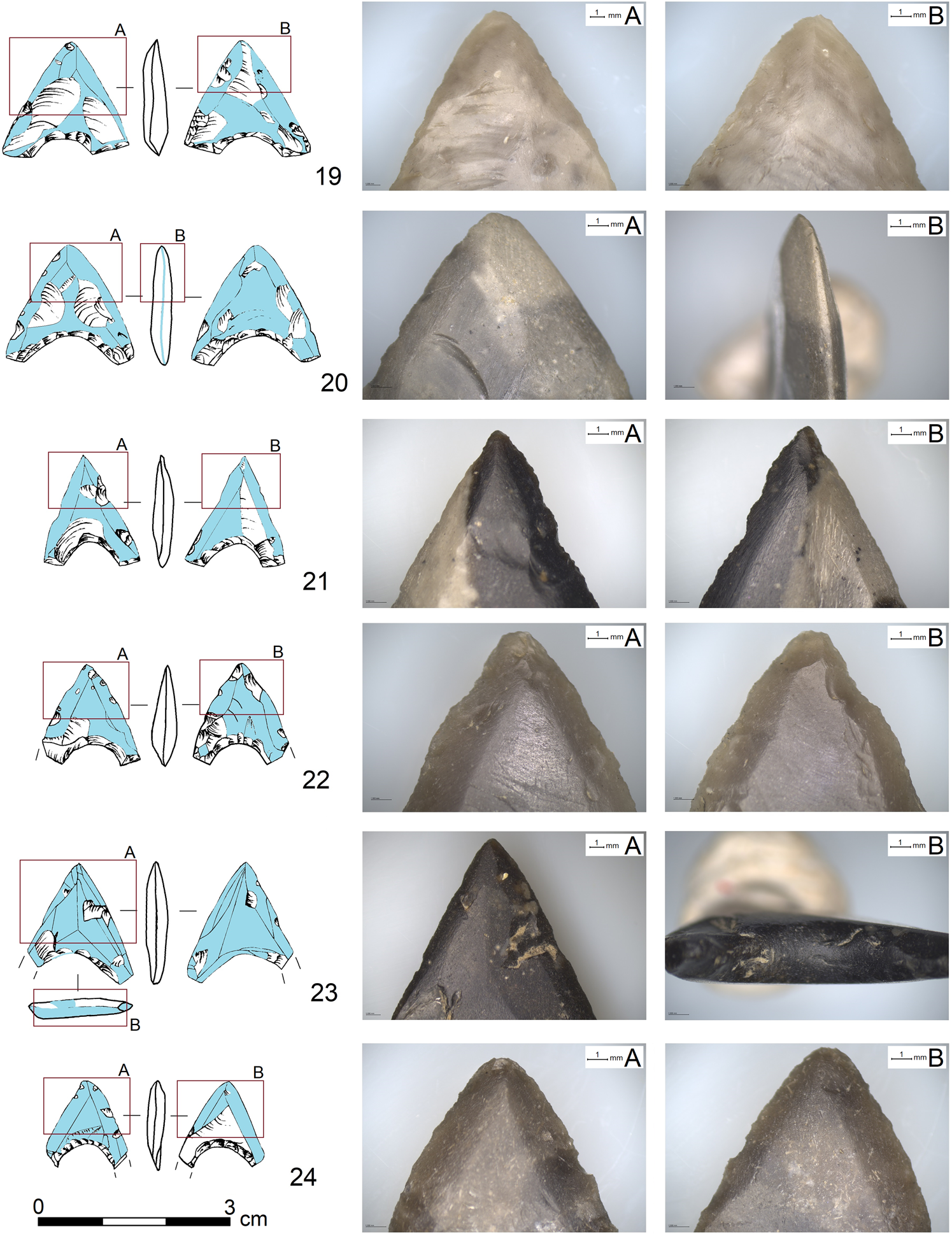

One group among the ground arrowheads consists of six whose faces and edges have been ground down. Grinding almost completely obliterated not only all the removal scars from the upper faces of the preform, but also the removal scars from the edge retouch that formed the sides (Figure 9: 19–24). In one case it led to rounding and blunting of the lateral edges (Figure 9: 20B). In another case, the grinding additionally covered one face at the base of the arrowhead and part of the other face, which abraded the removal scars of the base edge retouch on one face and partially on the other (Figure 9: 23B). Other specimens with a ground surface on both faces have a hollow base retouched on both faces before grinding. In two specimens, there are removal scars on the ground side from later percussion on the edge (Figure 9: 21, 22). This resulted in a jagged, uneven edge with visible micro-serrations along its length covered with removal scars of various sizes. Only two among the ground specimens have sharply pointed tips (Figure 9: 21, 23). The remaining arrowheads have rounded tips with micro-retouch ground down. Only in one case does a retouch removal scar on the tip overlap one side of the ground surface (Figure 9: 24A). The edges of the damaged burrs of the ground specimens are sharp, indicating that they broke off after grinding.

Figure 9. Selected arrowheads with grinding marks.

Discussion

Our arrowheads were not locally produced, as evidenced by the absence of debitage at the site and of the raw material from which they were made. The chalk flint found in the vicinity of the site is different from the material used to make the arrowheads. The only, albeit questionable, indication that the arrowheads may have been locally modified before being deposited in the features is a small fragment of an indeterminate piece, tentatively identified as a multipurpose grindstone, anvil, or sharpening stone, recorded in feature no. 6 (Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 383). It is made from Jotnian sandstone, an erratic rock commonly found in glacial formations of various regions of the northern and eastern European Plains, including north-eastern Poland. While its possible use may have been related to the grinding of the arrowheads discovered in feature no. 6 and the contemporaneous feature no. 5, it is difficult to prove whether the other two features yielding arrowheads (features nos 1 and 2) were coeval. An additional indication of the exogeneous origin of the arrowheads is the state of preservation of their surfaces, best seen among the specimens from feature no. 2: among the arrowheads found in the same context (2–4; Figure 6: 2–4), one has a surface with a shiny patina, indicating that at least one arrowhead originally came from a different pre-depositional context. By contrast, the post-depositional processes affecting the surfaces of the arrowheads were minimal and the same for each of them. These mainly involved chemical weathering, the effects of which were observed at high magnification under a scanning microscope (Klecha, Reference Klecha2017: 66–68).

Most arrowheads were made on flakes originating from an advanced stage of debitage. However, given the differential selection of where the future tip and base of the arrowhead was to be located, it can be inferred that such a selection was not determined by a strict scheme. On the contrary, best fit was common among arrowhead makers in Late Neolithic and Early Bronze Age Europe. Examples can be found in assemblages associated with Bell Beaker communities in north-eastern Poland (Januszek, Reference Januszek2020: fig. 19.3–6), with the Corded Ware group in southern Poland (Budziszewski & Tunia, Reference Budziszewski, Tunia and Kadrow2000: fig. 15), with the Nitra culture in Slovakia (Kaňakova et al., Reference Kaňakova, Batora and Nosek2019: fig. 5), or with Armorican arrowheads in Brittany (Nicolas & Guéret, Reference Nicolas and Guéret2014: 111). In the case of the arrowheads from site 3 in Supraśl, flakes of a similar thickness (3–4 mm) were selected for production, and the way they were modified only at the edges did not cause the loss of raw material volume, as is the case for surface retouch. The only exception is a slightly thicker specimen, reaching 6 mm. The thickness of similarly shaped arrowheads in a Bell Beaker assemblage from Szestno II in the Masurian Lake District is similar (2 and 4 mm; Januszek, Reference Januszek2020: 80–82). The thickness of arrowheads shaped by both edge retouch and surface retouch from the Bell Beaker culture burials of Małopolska is also similar, at 3–4.5 mm and 5 mm in a single case (Budziszewski & Włodarczak, Reference Budziszewski and Włodarczak2010: 46). Hence, it can be inferred that the arrowheads from Supraśl 3 belong to a standard size among the Bell Beaker finds in Poland. Like the arrowheads listed above, they were also more massive, and thus heavier, compared to arrowheads recorded in graves of the Corded Ware culture, which were made from thinner flakes (see Budziszewski & Tunia, Reference Budziszewski, Tunia and Kadrow2000: fig. 13C; Budziszewski et al, Reference Budziszewski, Czebreszuk, Winiarska-Kabacińska, Chachlikowski, Bednarczyk, Czebreszuk, Makarowicz and Szmyt2008: 44–45; Bargieł, Reference Bargieł, Taras and Zakościelna2009: tab. 1; Budziszewski & Włodarczak, Reference Budziszewski and Włodarczak2010: 46), including those obtained by the Levallois technique (Budziszewski & Tunia, Reference Budziszewski, Tunia and Kadrow2000: 130).

The morphology of the arrowheads from Supraśl 3 (the shape of the hollow in the base and the shape of the barbs) can be classified in four different types: 1) arrowheads with a triangular hollow base and pointed barbs; 2) arrowheads with an arched hollow base and rounded barbs; 3) arrowheads with an arched hollow base and square barbs; 4) arrowheads with a semi-circular hollow base and square barbs. Type 1 is represented by only one specimen, bifacially retouched on the surface, that corresponds to the forms of arrowheads most commonly recorded among the finds of the Kraków-Sandomierz group of the Corded Ware culture (see Włodarczak, Reference Włodarczak, Borkowski, Libera, Sałacińska and Sałaciński2008: fig. 2). In addition to its shape and manufacturing technique, it is close to the latter category of finds for the raw material used in its production—Upper Jurassic chocolate flint—which is common among arrowheads recovered in Corded Ware burials (Włodarczak, Reference Włodarczak, Borkowski, Libera, Sałacińska and Sałaciński2008: 297, fig. 3; Bargieł, Reference Bargieł, Taras and Zakościelna2009: 201). Type 2, with two specimens, is known among the burial finds of both the Corded Ware culture in different regions of its range and the Bell Beaker community (see Budziszewski & Włodarczak, Reference Budziszewski and Włodarczak2010: 72, fig. 24.B.27, C.41). Both Supraśl 3 exemplars were found in one feature only (no. 2), perhaps hinting at an integration of Bell Beaker and Corded Ware elements. Settlement traces associated with the Corded Ware culture are attested in the neighbourhood of the Bell Beaker feature no. 30 at the nearby site of Supraśl 6, also interpreted as a ritual feature (Wawrusiewicz et al., Reference Wawrusiewicz, Januszek and Manasterski2015: 161, fig. 47.4).

Types 3 and 4 are characteristic of the Bell Beaker phenomenon. As Bailly (Reference Bailly, Arbogast and Greffier-Richard2014: 359, fig. 2) has shown, the arrowheads associated with Bell Beakers, which have a hollow base as opposed to a tang, are characteristic of European sites previously associated with communities of different groups of the Corded Ware culture. On the other hand, Nicolas (Reference Nicolas, Kadrow and Müller2019: 116) suggests that their morphology reflects acculturation between the technical tradition of the Corded Ware culture (arrowheads with hollow base) and the Western Bell Beaker culture (square barbs). Only two arrowheads of types 3 and 4 are shaped through only edge retouch and no surface retouch, like some typical Bell Beaker arrowheads. Others either bear traces of grinding on the edge or on part of the faces, or they are completely ground.

Grinding was not generally used to shape flint arrowheads. The few examples that are known indicate that it was only applied to some arrowheads made of other types of rock (Thirault, Reference Thirault2007). The presence of grinding, usually of the central surfaces on one side of an arrowhead, was observed when flakes derived from ground and polished axes were used to produce flint arrowheads in various Neolithic and Early Bronze Age contexts (Libera, Reference Libera2001: 43–44). In short, grinding as a technique was not commonly associated with the initial production of arrowheads, but with the secondary shaping process and the use of waste flakes from repairs or damage to ground flint axes. This has resulted in the subconscious classification of intentional grinding marks visible in the working of arrowheads as remnants of another ground tool, from which the flakes were taken and adapted as a preform (see Pyżewicz, Reference Pyżewicz, Wawrusiewicz, Januszek and Manasterski2015: 300). In the case of the Supraśl 3 arrowheads, grinding marks are present on both faces of the specimens and cover different areas, mostly near the edges. Additionally, six arrowheads are completely or almost completely ground.

Technical analysis suggests the Supraśl 3 arrowheads were not produced from flakes acquired from ground tools but were deliberately ground. On most exemplars, grinding took place after retouching the hollow bases and lateral edges; and, in a few cases, grinding was used to shape at least part of one of the lateral edges or even the tip. Grinding usually preceded another but not very regular edge retouch, which may indicate that the lateral edges were prepared by grinding to be reshaped or sharpened by retouching. The Supraśl 3 evidence is not an isolated case of such activity, as grinding before retouching (but more specialized surface retouch) has been reported among the shaping stages of Late Neolithic Danish flint daggers (Stafford, Reference Stafford2003: 1540–44). On a few Supraśl 3 arrowheads, however, the retouching of the lateral edges was probably not completed, and the rounded edges that were left remained blunt, either because of an inability or lack of retouching skill on the maker's part. In the case of the fully ground arrowheads, their lateral edges are sharpened by grinding, and only one specimen has rounded edges, suggesting that it was unfinished.

All arrowheads are asymmetrical, even when taking damage into account. This may be due not only to the location of the proximal part of flake when making the arrowhead, but also to potential previous damage of the arrowheads and their repairs—especially at the tips. This is evidenced in specimens with broken tips, where the edge of the fracture is ground and the repair has not been completed. It would follow that the arrowheads were variously preserved, but most often repaired, before they were deposited in the features. The repairs were most probably not carried out by the original maker(s) but, based on the skill with which they were carried out, by a specialist grinder or group of such specialists. Judging by the quality of the secondary lateral edge retouch, such retouch may have been difficult or opportunistic in its application. Irregular retouch of the lateral edges, which also does not cover their entire length, is known from Bell Beaker arrowheads found at Szestno II in the Masurian Lake District (Januszek, Reference Januszek2020: fig. 19.3–6). It can therefore be assumed that it was not of aesthetic but of practical importance. Grinding, on the other hand, although more time-consuming than retouching, allows greater control during processing, and may also facilitate subsequent retouching (Madsen, Reference Madsen1984: 52, fig. 10; Stafford, Reference Stafford2003: 1541). The Supraśl 3 Bell Beaker community probably had contact with specialist grinders, as indicated by the ground stone artefacts discovered in almost every feature there, including a dagger blade made with great precision, or a composite dagger of wood, bone, or antler with lithic inserts, one of which had a point with ground lateral edges (Wawrusiewicz et al., Reference Wawrusiewicz, Januszek and Manasterski2015: 73–75, figs 39, 42) similar to those of the fully ground arrowheads from feature no. 6.

The grinding of flint arrowheads deposited in the Supraśl 3 features may be derived from the environment of the Rzucewo culture, which includes distinctive ground and polished flaked tools, but not arrowheads (Januszek, Reference Januszek2010). The purpose of grinding these artefacts, apart from axe-like tools, has so far not been fully ascertained (Osipowicz et al., Reference Osipowicz, Kuriga and Piličiauskas2016; Januszek & Pyżewicz, Reference Januszek and Pyżewicz2018; Kabaciński & Winiarska-Kabacińska, Reference Kabaciński and Winiarska-Kabacińska2020). The association of the Bell Beaker community with this culture is attested to by the artefacts present in some of the Supraśl 3 features that were made from exogeneous Pomeranian Cretaceous erratic flint typical of the production of the Rzucewo culture. Such items at Supraśl 3 include bipolar splintered pieces recorded in feature nos 1 and 2 and the polished axe-like tool from feature no. 2 (Wawrusiewicz et al., Reference Wawrusiewicz, Januszek and Manasterski2015: 67–68; Januszek, Reference Januszek2020: fig. 44.5–8; Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: figs 4.16–18, 28; 5.14–17).

Further indications of contact between the two communities are Bell Beaker vessels identified as imports and imitations, as well as forms with stylistic components of both Bell Beaker and Rzucewo affiliation discovered at sites of the Rzucewo culture, e.g. at Suchacz on the Vistula Lagoon (Manasterski, Reference Manasterski2016: 90–92, figs 29, 30; Januszek, Reference Januszek2020: tabs 5, 6). Furthermore, such contacts can be linked to amber ornaments found at Supraśl 3 (Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 384, figs 4.D, 3–4; 5.1–4; 6.D; 7.19): their provenance, if only in the form of the raw material itself, may be connected to the amber-processing activity of the people of the Rzucewo culture. That activity is documented by the discovery and excavation of amber-processing workshops in the Żuławy Wiślane area, and within the settlements on the shores of the south-eastern Baltic Sea, including the settlement of Suchacz (Mazurowski, Reference Mazurowski2014). For the Bell Beaker arrowheads from Supraśl 3, it may be tentatively suggested that grinding was associated with a technological component of the Rzucewo culture, expressing a combination of both Bell Beaker and Rzucewo techniques. However, no traces of polishing were observed under microscope on any of the Supraśl 3 arrowheads. Additionally, the edge damage after grinding and the broken barbs on some of them suggest that they were used before deposition. The damage to the barbs of three specimens did not occur post-depositionally but was caused by an impact to the central or lateral part of the barb. Grinding, on the other hand, can be considered a technique used to repair most of arrowheads after damage to the tip, as attested to by the rounded and asymmetric tips of most arrowheads.

When interpreting the grinding of arrowheads at Supraśl 3, we should consider the widespread occurrence of instances of grinding among Bell Beaker communities, from the Atlantic coast to Central Europe. This technique was indeed common, but it was mainly applied to stone tools and bone or stone adornments (e.g. Drenth et al., Reference Drenth, Freudenberg and Williams2016; Kern, Reference Kern2016; Nicolas, Reference Nicolas2020a, Reference Nicolas2020b). Perhaps grinding should be considered here as a Bell Beaker answer to a lack of skill in pressure retouching. This is not implausible when one considers the ground stone artefacts that have been recovered at Supraśl 3, among them a grindstone found with the arrowheads in feature no. 6.

Fully ground arrowheads were not imitations or replicas of metal forms, as there are no such specimens among the copper arrowheads throughout the area of Bell Beaker phenomenon. The only possible, though doubtful, purpose of grinding may have been to obtain a smooth surface that resembled the surface of Palmela-type copper arrowheads known from the Bell Beaker sphere in the Iberian Peninsula (Gutiérrez Sáez et al., Reference Gutiérrez Sáez, López del Estal, Simón Martín, Muñoz Moro, Bashore Acero and Chamón Fernández2010: 405–07), one of which has been recovered from a site c. 80 km south-east of Supraśl 3 in the Białowieża Forest (Wawrusiewicz et al., Reference Wawrusiewicz, Januszek and Manasterski2015, 182–83). The Bell Beaker components from site 3 in Supraśl are linked to this wider Bell Beaker milieu primarily by the style of the pottery and an ornamented slate plate or pendant, recovered together with fully polished arrowheads. Its only close parallels are in the Iberian Peninsula (Manasterski et al., Reference Manasterski, Januszek, Wawrusiewicz and Klecha2020: 380–82, 384). We may be dealing with skeuomorphism, involving the imitation of an object made usually in another material (Frieman, Reference Frieman and Card2013: 320–24). If we consider grinding, which is unusual in the production of flint arrowheads, and the contacts of the Supraśl 3 Bell Beaker community with the Rzucewo culture, which uses grinding to process flint tools (excluding arrowheads), a likely scenario at Supraśl 3 would consist of employing a technique (grinding) in imitation of Rzucewo procedures but not applying it to a specific item or raw material. It could produce Bell Beaker arrowheads combining a Central European morphological type with another technology in the easternmost periphery of the Bell Beaker phenomenon.

Given that grinding was not used in the production of flint arrowheads among Bell Beaker communities, we still need to resolve whether this was actually the case. It seems that the reason for the appearance of this particular treatment of arrowheads at Supraśl 3 was motivated by technological demand, but currently we cannot say with certainty whether this was the result of contacts with the Rzucewo culture or an independent invention.

The fact that fully ground arrowheads were found in only one feature at Supraśl 3 (feature no. 6) suggests an association with a ritual or symbolic function. They are distinct from the numerous other arrowheads deposited in the same feature, and perhaps illustrate the role of the grinder, who was demonstrating his craft before removing the arrowheads from use (let us recall that there was also a multifunctional tool used for grinding in the same feature). Ultimately, it is difficult to draw a line between the practical application of the technique (grinding to repair arrowheads for further use) and its symbolic dimension.

Conclusions

Flint arrowheads from features interpreted as ritual at Supraśl 3 are unique within the Bell Beaker phenomenon in Europe. While they belong to forms that are typical for the Central European Bell Beaker cultural phenomenon, the way they were processed and repaired, using a grinding technique, distinguishes them from other forms of this type. The fact that the arrowheads were found in features thought to be ritual does not contradict their practical function since they may have been perfectly functional before being removed from use. Conversely, their grinding cannot be reduced to a ritual procedure endowing them with a solely symbolic function. Indeed, the different final effects of grinding on each of the arrowheads, usually connected with repair after damage to the tip, suggests that they were used as arrowheads. Only two arrowheads (one with grinding of the edge of its fractured tip and one with a ground base) can be associated with possibly ritual grinding. It is equally difficult to ascertain where the technique of grinding flint arrowheads originated, whether it was an independent invention or a borrowing. It may have been adopted by a Bell Beaker community to repair and transform arrowheads in an area occupied by the Rzucewo culture. The innovatively transformed arrowheads would have been a visually exotic element in the North Podlachian Plain, and, alongside other objects with parallels elsewhere in Europe (e.g. an ornamented slate plate or pendant comparable to Palmela elements in the Iberian Peninsula), may have signalled the contacts of the Bell Beaker community from West to East.

Acknowledgements

We would like to thank three anonymous reviewers for constructive comments that significantly helped improve the quality of the paper and also the editors too for valuable comments on the final draft of this article.