1. Introduction

Wall-bounded liquid flows containing bubbles have received much attention because of their importance in various industrial fields such as chemical reactors (Hibiki & Ishii Reference Hibiki and Ishii2002) and nuclear plants (Krepper, Lucas & Prasser Reference Krepper, Lucas and Prasser2005). Due to the buoyancy of bubbles, the flow characteristics of bubbly flows depend on the angle between the directions of the buoyancy force and mean liquid flow. Among others, upward bubbly flow has been the subject of extensive research to gain insight into the dynamics of bubbles and their impact on various liquid flow characteristics, including turbulence, heat transfer and mixing.

The characteristics of wall-bounded upward bubbly flow in a pipe or channel are known to significantly depend on the wall-normal distribution of bubbles such as the core-peaking and wall-peaking bubble distributions. The former has a linear profile of the Reynolds shear stress around the centre, while the latter has a concave profile around the centre with a nearly uniform mean velocity except near the wall (Colin, Fabre & Kamp Reference Colin, Fabre and Kamp2012; Dabiri, Lu & Tryggvason Reference Dabiri, Lu and Tryggvason2013; Du Cluzeau, Bois & Toutant Reference Du Cluzeau, Bois and Toutant2019). Besides, the wall-peaking bubble distribution provides a higher skin friction than that of single-phase flow at the same liquid bulk velocity (Moursali, Marié & Bataille Reference Moursali, Marié and Bataille1995; Liu Reference Liu1997). One of the most important factors of determining the bubble distribution is the direction of the shear-induced lift force. Saffman (Reference Saffman1965) showed that a spherical object travelling along the mean flow direction in a shear flow experiences a lateral lift force towards the maximum relative velocity to the object velocity. However, early experiments (Sekoguchi, Sato & Honda Reference Sekoguchi, Sato and Honda1974; Liu & Bankoff Reference Liu and Bankoff1993) on upward bubbly pipe flows revealed that bubbles larger than a critical diameter were predominantly located in the middle, which is contrary to the result of Saffman (Reference Saffman1965), and thus this phenomenon is called the lift force reversal. Tomiyama et al. (Reference Tomiyama, Tamai, Zun and Hosokawa2002) examined the force acting on a single bubble in a shear flow and concluded that a modified Eötvös number, ![]() $Eo=\rho _l g l_{bub}^2/\sigma$, is the main parameter to determine the direction of the lift force, where

$Eo=\rho _l g l_{bub}^2/\sigma$, is the main parameter to determine the direction of the lift force, where ![]() $\rho _l$ is the liquid density,

$\rho _l$ is the liquid density, ![]() $g$ is the gravitational acceleration,

$g$ is the gravitational acceleration, ![]() $l_{bub}$ is the major axis of an ellipsoidal bubble and

$l_{bub}$ is the major axis of an ellipsoidal bubble and ![]() $\sigma$ is the surface tension coefficient. Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013) also suggested that the bubble deformability is a crucial factor in determining the bubble distribution in a bubbly channel flow. Adoua, Legendre & Magnaudet (Reference Adoua, Legendre and Magnaudet2009) explained the mechanism of the lift force reversal on a spheroidal bubble by observing the changes in the rotational direction of the vortices in the wake.

$\sigma$ is the surface tension coefficient. Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013) also suggested that the bubble deformability is a crucial factor in determining the bubble distribution in a bubbly channel flow. Adoua, Legendre & Magnaudet (Reference Adoua, Legendre and Magnaudet2009) explained the mechanism of the lift force reversal on a spheroidal bubble by observing the changes in the rotational direction of the vortices in the wake.

The turbulence characteristics of an upward bubbly pipe flow are affected by two different fluctuations that come from the wall shear and buoyant bubbles. They are referred to as shear-induced turbulence and bubble-induced turbulence (or pseudo-turbulence), respectively, and the characteristics of bubble-induced turbulence have been investigated through studies on rising gas bubbles in a stagnant liquid. Owing to bubble-induced turbulence, the spectral densities of the liquid velocity fluctuations follow the power of ![]() $-$3 slope, i.e.

$-$3 slope, i.e. ![]() $E(f) \sim f^{-3}$ and

$E(f) \sim f^{-3}$ and ![]() $E(k) \sim k^{-3}$ (Riboux, Risso & Legendre Reference Riboux, Risso and Legendre2010; Roghair et al. Reference Roghair, Mercado, Annaland, Kuipers, Sun and Lohse2011), and the root-mean-square (r.m.s.) velocity fluctuations are proportional to

$E(k) \sim k^{-3}$ (Riboux, Risso & Legendre Reference Riboux, Risso and Legendre2010; Roghair et al. Reference Roghair, Mercado, Annaland, Kuipers, Sun and Lohse2011), and the root-mean-square (r.m.s.) velocity fluctuations are proportional to ![]() $\langle \psi \rangle ^{0.4}$ (Risso & Ellingsen Reference Risso and Ellingsen2002; Riboux et al. Reference Riboux, Risso and Legendre2010), where

$\langle \psi \rangle ^{0.4}$ (Risso & Ellingsen Reference Risso and Ellingsen2002; Riboux et al. Reference Riboux, Risso and Legendre2010), where ![]() $f$ is the frequency,

$f$ is the frequency, ![]() $k$ is the wavenumber and

$k$ is the wavenumber and ![]() $\langle \psi \rangle$ is the total bubble volume fraction. These results were examined in the presence of background isotropic turbulence by Prakash et al. (Reference Prakash, Mercado, van Wijngaarden, Mancilla, Tagawa, Lohse and Sun2016) and Alméras et al. (Reference Alméras, Mathai, Lohse and Sun2017). When the background turbulence intensity is larger than a threshold value, the velocity fluctuations change to be proportional to

$\langle \psi \rangle$ is the total bubble volume fraction. These results were examined in the presence of background isotropic turbulence by Prakash et al. (Reference Prakash, Mercado, van Wijngaarden, Mancilla, Tagawa, Lohse and Sun2016) and Alméras et al. (Reference Alméras, Mathai, Lohse and Sun2017). When the background turbulence intensity is larger than a threshold value, the velocity fluctuations change to be proportional to ![]() $\langle \psi \rangle ^{1.3}$ (Alméras et al. Reference Alméras, Mathai, Lohse and Sun2017), while

$\langle \psi \rangle ^{1.3}$ (Alméras et al. Reference Alméras, Mathai, Lohse and Sun2017), while ![]() $E(f) \sim f^{-3}$ is still maintained (Prakash et al. Reference Prakash, Mercado, van Wijngaarden, Mancilla, Tagawa, Lohse and Sun2016). Riboux, Legendre & Risso (Reference Riboux, Legendre and Risso2013) and Amoura et al. (Reference Amoura, Besnaci, Risso and Roig2017) decomposed bubble-induced turbulence into the mean and fluctuating velocity components in a reference frame moving with each bubble, and showed that the scaling of the velocity fluctuations with

$E(f) \sim f^{-3}$ is still maintained (Prakash et al. Reference Prakash, Mercado, van Wijngaarden, Mancilla, Tagawa, Lohse and Sun2016). Riboux, Legendre & Risso (Reference Riboux, Legendre and Risso2013) and Amoura et al. (Reference Amoura, Besnaci, Risso and Roig2017) decomposed bubble-induced turbulence into the mean and fluctuating velocity components in a reference frame moving with each bubble, and showed that the scaling of the velocity fluctuations with ![]() $\langle \psi \rangle ^{0.4}$ was not observed, but

$\langle \psi \rangle ^{0.4}$ was not observed, but ![]() $E(k)$ was proportional to

$E(k)$ was proportional to ![]() $k^{-3}$. Du Cluzeau et al. (Reference Du Cluzeau, Bois, Leoni and Toutant2022) analysed the Reynolds stress transport equation of homogeneous bubbly flow with this decomposition, and showed energy conversion from the mean to fluctuating components. Pandey, Ramadugu & Perlekar (Reference Pandey, Ramadugu and Perlekar2020) explained that

$k^{-3}$. Du Cluzeau et al. (Reference Du Cluzeau, Bois, Leoni and Toutant2022) analysed the Reynolds stress transport equation of homogeneous bubbly flow with this decomposition, and showed energy conversion from the mean to fluctuating components. Pandey, Ramadugu & Perlekar (Reference Pandey, Ramadugu and Perlekar2020) explained that ![]() $k^{-3}$ scaling of the energy spectra came from the balance among the surface tension, kinetic energy and viscous dissipation.

$k^{-3}$ scaling of the energy spectra came from the balance among the surface tension, kinetic energy and viscous dissipation.

Because of the characteristics of bubble-induced turbulence being distinct from those of shear-induced turbulence, it is important to understand the interaction between them in a wall-bounded bubbly flow. Zhang, Yokomine & Kunugi (Reference Zhang, Yokomine and Kunugi2015) demonstrated that the presence of a wall can inhibit bubble-induced turbulence and the existence of bubbles can also suppress shear-induced turbulence, despite an overall enhancement in turbulence. Du Cluzeau et al. (Reference Du Cluzeau, Bois and Toutant2019) showed that shear-induced turbulence is reduced at all wall-normal locations in a bubbly channel flow. However, due to the difficulty in distinguishing and comparing these two types of turbulence, our understanding of their interaction remains limited.

For industrial applications of bubbly flow, various Reynolds-averaged Navier–Stokes (RANS) models have been developed to account for bubble-induced turbulence. Sato, Sadatomi & Sekoguchi (Reference Sato, Sadatomi and Sekoguchi1981a) suggested an algebraic RANS model for the turbulent viscosity ![]() $\nu _t$ by a linear combination of shear-induced and bubble-induced turbulence. For one-equation (Kataoka Reference Kataoka1995), two-equation (Kataoka & Serizawa Reference Kataoka and Serizawa1989; Rzehak & Krepper Reference Rzehak and Krepper2013; Ma et al. Reference Ma, Santarelli, Ziegenhein, Lucas and Fröhlich2017) and Reynolds stress (Colombo & Fairweather Reference Colombo and Fairweather2015; Du Cluzeau et al. Reference Du Cluzeau, Bois and Toutant2019) models, bubble-induced production and dissipation terms are added to existing single-phase RANS models (Speziale, Sarkar & Gatski Reference Speziale, Sarkar and Gatski1991; Spalart & Allmaras Reference Spalart and Allmaras1992; Menter Reference Menter1994). In addition to these turbulence models, force (Lucas, Krepper & Prasser Reference Lucas, Krepper and Prasser2001, Reference Lucas, Krepper and Prasser2007) and polydispersity (Liao et al. Reference Liao, Rzehak, Lucas and Krepper2015) models have been suggested to predict the bubble distribution in the wall-normal direction. Recently, an up-scaling approach using direct numerical simulation has been conducted for better prediction (Bois Reference Bois2017; Ma et al. Reference Ma, Santarelli, Ziegenhein, Lucas and Fröhlich2017; Du Cluzeau et al. Reference Du Cluzeau, Bois and Toutant2019). Du Cluzeau et al. (Reference Du Cluzeau, Bois and Toutant2019) also showed that surface tension, which was not included in most models, is the strongest force in the wall-normal momentum budget equation. Therefore, a further investigation of surface tension and its interaction with surrounding liquid is necessary.

$\nu _t$ by a linear combination of shear-induced and bubble-induced turbulence. For one-equation (Kataoka Reference Kataoka1995), two-equation (Kataoka & Serizawa Reference Kataoka and Serizawa1989; Rzehak & Krepper Reference Rzehak and Krepper2013; Ma et al. Reference Ma, Santarelli, Ziegenhein, Lucas and Fröhlich2017) and Reynolds stress (Colombo & Fairweather Reference Colombo and Fairweather2015; Du Cluzeau et al. Reference Du Cluzeau, Bois and Toutant2019) models, bubble-induced production and dissipation terms are added to existing single-phase RANS models (Speziale, Sarkar & Gatski Reference Speziale, Sarkar and Gatski1991; Spalart & Allmaras Reference Spalart and Allmaras1992; Menter Reference Menter1994). In addition to these turbulence models, force (Lucas, Krepper & Prasser Reference Lucas, Krepper and Prasser2001, Reference Lucas, Krepper and Prasser2007) and polydispersity (Liao et al. Reference Liao, Rzehak, Lucas and Krepper2015) models have been suggested to predict the bubble distribution in the wall-normal direction. Recently, an up-scaling approach using direct numerical simulation has been conducted for better prediction (Bois Reference Bois2017; Ma et al. Reference Ma, Santarelli, Ziegenhein, Lucas and Fröhlich2017; Du Cluzeau et al. Reference Du Cluzeau, Bois and Toutant2019). Du Cluzeau et al. (Reference Du Cluzeau, Bois and Toutant2019) also showed that surface tension, which was not included in most models, is the strongest force in the wall-normal momentum budget equation. Therefore, a further investigation of surface tension and its interaction with surrounding liquid is necessary.

Although there have been numerous studies on wall-bounded bubbly flows, a comprehensive understanding on the effect of bubbles on liquid flow structures is still lacking. According to different flow conditions, there exist numerous types of bubble behaviours during a bubble–wall interaction (bouncing, sliding and oscillating without collision), bubble–bubble interaction (drafting-kissing-tumbling and merging) and rising without interaction (rectilinear rise, zigzagging and spiralling). To understand the bubble–wall interaction and its effect on the near-wall coherent structures, we perform a high-resolution numerical simulation of an air–water upward bubbly pipe flow. We also examine how the turbulence statistics and skin friction are modified by the bubble size and volume fraction. Finally, we suggest an algebraic RANS model considering the interaction between bubble-induced and shear-induced turbulence from the results of the present numerical simulation. Numerical details are given in § 2. The turbulence statistics, bubble behaviour and near-wall vortical structures are discussed in §§ 3.1 and 3.2, followed by conclusions in § 4.

2. Numerical details

2.1. Governing equations and numerical method

We simulate an air–water upward bubbly pipe flow in Cartesian coordinates with an immersed boundary method (Yang & Balaras Reference Yang and Balaras2006). The governing equations for two-phase immiscible incompressible flow are the continuity and Navier–Stokes equations:

where ![]() $\boldsymbol {u}$ is the velocity,

$\boldsymbol {u}$ is the velocity, ![]() $t$ is the time,

$t$ is the time, ![]() $\varPi$ (

$\varPi$ (![]() $=\text {d}P/\text {d}\kern0.06em x+\langle \rho \rangle g$) is the sum of the mean pressure gradient and weight of air–water mixture,

$=\text {d}P/\text {d}\kern0.06em x+\langle \rho \rangle g$) is the sum of the mean pressure gradient and weight of air–water mixture, ![]() $\langle {\,\cdot\,} \rangle$ denotes an average in time and over the whole computational domain,

$\langle {\,\cdot\,} \rangle$ denotes an average in time and over the whole computational domain, ![]() $\boldsymbol {k}$ is the unit vector in the axial (upward) direction,

$\boldsymbol {k}$ is the unit vector in the axial (upward) direction, ![]() $p$ is the pressure fluctuations,

$p$ is the pressure fluctuations, ![]() $\boldsymbol {g}$ (

$\boldsymbol {g}$ (![]() $=-g\boldsymbol {k}$) is the gravitational acceleration vector,

$=-g\boldsymbol {k}$) is the gravitational acceleration vector, ![]() $\sigma$ is the surface tension coefficient,

$\sigma$ is the surface tension coefficient, ![]() $\kappa$ is the curvature,

$\kappa$ is the curvature, ![]() $\boldsymbol {n}$ is the surface-normal vector on the phase interface,

$\boldsymbol {n}$ is the surface-normal vector on the phase interface, ![]() $\delta$ is the delta function (1 at the phase interface and 0 otherwise) and

$\delta$ is the delta function (1 at the phase interface and 0 otherwise) and ![]() $\boldsymbol {f}$ is the momentum forcing to satisfy the no-slip boundary condition on the pipe wall (Yang & Balaras Reference Yang and Balaras2006). Note that (2.1) and (2.2) are solved in a periodic domain in the axial direction. Here,

$\boldsymbol {f}$ is the momentum forcing to satisfy the no-slip boundary condition on the pipe wall (Yang & Balaras Reference Yang and Balaras2006). Note that (2.1) and (2.2) are solved in a periodic domain in the axial direction. Here, ![]() $\rho$ and

$\rho$ and ![]() $\mu$ are the air–water mixture density and viscosity, respectively, defined as

$\mu$ are the air–water mixture density and viscosity, respectively, defined as

where ![]() $\psi$ is the bubble volume fraction inside a numerical cell, and the subscripts

$\psi$ is the bubble volume fraction inside a numerical cell, and the subscripts ![]() $a$ and

$a$ and ![]() $w$ denote air and water, respectively. With this formulation, the continuity of tangential stresses at an interface is implicitly satisfied (Prosperetti Reference Prosperetti2002), and a smoother velocity profile is obtained around the interface in our preliminary rising single-bubble simulation than that with a volume-weighted arithmetic formulation (

$w$ denote air and water, respectively. With this formulation, the continuity of tangential stresses at an interface is implicitly satisfied (Prosperetti Reference Prosperetti2002), and a smoother velocity profile is obtained around the interface in our preliminary rising single-bubble simulation than that with a volume-weighted arithmetic formulation (![]() $\rho = \rho _a \psi + \rho _w (1-\psi )$ and

$\rho = \rho _a \psi + \rho _w (1-\psi )$ and ![]() $\mu = \mu _a \psi + \mu _w (1-\psi )$).

$\mu = \mu _a \psi + \mu _w (1-\psi )$).

To track the phase interface, we use a level-set method (Herrmann Reference Herrmann2008; Kim Reference Kim2011):

where ![]() $\phi$ is the level-set function which is a sign-distance function from the phase interface having positive and negative values in water and air, respectively. We use a refined level-set grid method (Herrmann Reference Herrmann2008; Kim Reference Kim2011), which adopts a separate refined level-set grid in addition to the flow solver grid, to reduce numerical errors coming from the volume and surface tension estimations. The bubble volume fraction

$\phi$ is the level-set function which is a sign-distance function from the phase interface having positive and negative values in water and air, respectively. We use a refined level-set grid method (Herrmann Reference Herrmann2008; Kim Reference Kim2011), which adopts a separate refined level-set grid in addition to the flow solver grid, to reduce numerical errors coming from the volume and surface tension estimations. The bubble volume fraction ![]() $\psi$ is calculated from the analytical formula of the level-set function (van der Pijl et al. Reference van der Pijl, Segal, Vuik and Wesseling2005; Herrmann Reference Herrmann2008). In this paper,

$\psi$ is calculated from the analytical formula of the level-set function (van der Pijl et al. Reference van der Pijl, Segal, Vuik and Wesseling2005; Herrmann Reference Herrmann2008). In this paper, ![]() $r$,

$r$, ![]() $\theta$ and

$\theta$ and ![]() $z$ denote the radial, azimuthal and axial directions, respectively, and

$z$ denote the radial, azimuthal and axial directions, respectively, and ![]() $x$ and

$x$ and ![]() $y$ denote the horizontal directions in Cartesian coordinates. The numerical methods of solving (2.1), (2.2) and (2.5) are given in Appendix A.

$y$ denote the horizontal directions in Cartesian coordinates. The numerical methods of solving (2.1), (2.2) and (2.5) are given in Appendix A.

We simulate both single-phase and monodispersed bubbly pipe flows. The fluids considered are air and water at atmospheric pressure and room temperature of ![]() $20\,^\circ$C. The density and viscosity of air are

$20\,^\circ$C. The density and viscosity of air are ![]() $\rho _a=1.2$ kg m

$\rho _a=1.2$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\mu _a=1.8\times 10^{-5}$ N s m

$\mu _a=1.8\times 10^{-5}$ N s m![]() $^{-2}$, and those of water are

$^{-2}$, and those of water are ![]() $\rho _w= 998$ kg m

$\rho _w= 998$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\mu _w=1.0\times 10^{-3}$ N s m

$\mu _w=1.0\times 10^{-3}$ N s m![]() $^{-2}$, respectively (White Reference White1979). The surface tension coefficient of the air–water interface is 0.07 N m and the gravitational acceleration is

$^{-2}$, respectively (White Reference White1979). The surface tension coefficient of the air–water interface is 0.07 N m and the gravitational acceleration is ![]() $g=9.81$ m s

$g=9.81$ m s![]() $^{-2}$. The water bulk Reynolds number is fixed at

$^{-2}$. The water bulk Reynolds number is fixed at ![]() $Re_{bulk}=\rho _w u_{bulk} D/\mu _w =5300$, where

$Re_{bulk}=\rho _w u_{bulk} D/\mu _w =5300$, where ![]() $u_{bulk}$ (

$u_{bulk}$ (![]() $=\int (1-\psi ) u_{z}\,{\rm d} V/\int (1-\psi )\,{\rm d} V=0.132$ m s

$=\int (1-\psi ) u_{z}\,{\rm d} V/\int (1-\psi )\,{\rm d} V=0.132$ m s![]() $^{-1}$) is the water bulk velocity, and

$^{-1}$) is the water bulk velocity, and ![]() $D$ (

$D$ (![]() $=0.04$ m) is the pipe diameter. These pipe diameter and water bulk velocity are the same as those in the experiment by Lee et al. (Reference Lee, Kim, Lee and Park2021). The corresponding friction Reynolds number of the single-phase pipe flow is

$=0.04$ m) is the pipe diameter. These pipe diameter and water bulk velocity are the same as those in the experiment by Lee et al. (Reference Lee, Kim, Lee and Park2021). The corresponding friction Reynolds number of the single-phase pipe flow is ![]() $Re_{\tau }=\rho _w u_{\tau }R/\mu _w=180$ (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994), where

$Re_{\tau }=\rho _w u_{\tau }R/\mu _w=180$ (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994), where ![]() $u_{\tau }$ (

$u_{\tau }$ (![]() $=\sqrt {\tau _{w}/\rho _w}$) is the friction velocity,

$=\sqrt {\tau _{w}/\rho _w}$) is the friction velocity, ![]() $R$ is the pipe radius and

$R$ is the pipe radius and ![]() $\tau _{w}$ is the mean wall shear stress.

$\tau _{w}$ is the mean wall shear stress.

Figure 1 shows a schematic diagram of the present upward bubbly flow in a vertical pipe, grid indices for the momentum and level-set equations and grid distribution on a horizontal plane. As shown in figure 1(c), uniform grids are distributed on the whole domain, because small-scale flow structures are observed not only near the wall but also around the centre due to buoyant bubbles. The horizontal computational domain sizes for single-phase and bubbly flows are ![]() $1.0079D~(x) \times 1.0079D~(y)$ in Cartesian coordinates, and their axial domain sizes are

$1.0079D~(x) \times 1.0079D~(y)$ in Cartesian coordinates, and their axial domain sizes are ![]() $7.5D$ and

$7.5D$ and ![]() $3D$, respectively. The inclusion of

$3D$, respectively. The inclusion of ![]() $0.0079D$ in the horizontal domain is due to the use of an immersed boundary method. We use a smaller axial domain size of

$0.0079D$ in the horizontal domain is due to the use of an immersed boundary method. We use a smaller axial domain size of ![]() $3D$ for the present bubbly flow because the flow structures are smaller due to bubble–water interactions. We show below that this axial domain size is still large enough to capture flow structures in the bubbly flow. The number of grid points for the single-phase flow is

$3D$ for the present bubbly flow because the flow structures are smaller due to bubble–water interactions. We show below that this axial domain size is still large enough to capture flow structures in the bubbly flow. The number of grid points for the single-phase flow is ![]() $256~(x) \times 256~(y) \times 384~(z)$. From our grid resolution test (see § 2.2), we suggest that the numbers of grid points per bubble required for the momentum and level-set equations are 24 and 48, respectively. Based on this requirement, for case SM, we provide

$256~(x) \times 256~(y) \times 384~(z)$. From our grid resolution test (see § 2.2), we suggest that the numbers of grid points per bubble required for the momentum and level-set equations are 24 and 48, respectively. Based on this requirement, for case SM, we provide ![]() $384 \times 384 \times 1146$ and

$384 \times 384 \times 1146$ and ![]() $768 \times 768 \times 2292$ grid points for the momentum and level-set equations, respectively, whereas

$768 \times 768 \times 2292$ grid points for the momentum and level-set equations, respectively, whereas ![]() $256 \times 256 \times 762$ and

$256 \times 256 \times 762$ and ![]() $512 \times 512 \times 1524$ grid points are provided for other cases. The grid spacings in wall units are

$512 \times 512 \times 1524$ grid points are provided for other cases. The grid spacings in wall units are ![]() $\Delta x^+$

$\Delta x^+$ ![]() $(=\Delta x u_\tau / \nu _w) =\Delta y^+ = 1.42$ and

$(=\Delta x u_\tau / \nu _w) =\Delta y^+ = 1.42$ and ![]() $\Delta z^+ = 7.03$ for the single-phase flow, and

$\Delta z^+ = 7.03$ for the single-phase flow, and ![]() $\Delta x^+=\Delta y^+=\Delta z^+ = 1.7$–

$\Delta x^+=\Delta y^+=\Delta z^+ = 1.7$–![]() $2.5$ for the bubbly flows. The periodic boundary condition is applied to the axial and horizontal directions, and the no-slip boundary condition is satisfied on the pipe wall (immersed boundary).

$2.5$ for the bubbly flows. The periodic boundary condition is applied to the axial and horizontal directions, and the no-slip boundary condition is satisfied on the pipe wall (immersed boundary).

Figure 1. Numerical set-up: (a) schematic diagram of an upward bubbly flow in a vertical pipe; (b) grid systems for the momentum and level-set equations; (c) grids on a horizontal plane, computational boundary and immersed boundary (pipe wall). In (b), indices ![]() $i$ and

$i$ and ![]() $j$ are for the momentum equations, and indices

$j$ are for the momentum equations, and indices ![]() $2i$ and

$2i$ and ![]() $2j$ are for the level-set equation. Filled circles in blue and red are the numerical cell centres for the momentum and level-set equations, respectively.

$2j$ are for the level-set equation. Filled circles in blue and red are the numerical cell centres for the momentum and level-set equations, respectively.

Table 1 shows the cases considered in this study, where the variations of the bubble equivalent diameter ![]() $d_{eq}$ (

$d_{eq}$ (![]() $=(6V_b/{\rm \pi} )^{1/3}; V_b$ is the volume of each bubble), total bubble volume fraction

$=(6V_b/{\rm \pi} )^{1/3}; V_b$ is the volume of each bubble), total bubble volume fraction ![]() $\langle \psi \rangle$, number of bubbles

$\langle \psi \rangle$, number of bubbles ![]() $N_{bub}$, Eötvös number

$N_{bub}$, Eötvös number ![]() $Eo$ (

$Eo$ (![]() $=\rho _wgd^2_{eq}/\sigma$), friction Reynolds number

$=\rho _wgd^2_{eq}/\sigma$), friction Reynolds number ![]() $Re_\tau$, bubble Reynolds number

$Re_\tau$, bubble Reynolds number ![]() $Re_{bub}$ (

$Re_{bub}$ (![]() $=\rho _w (\langle u_{bub}\rangle - u_{bulk}) d_{eq}/\mu _w$) and averaging time for obtaining statistics

$=\rho _w (\langle u_{bub}\rangle - u_{bulk}) d_{eq}/\mu _w$) and averaging time for obtaining statistics ![]() $T_{avg}$ are listed for each case. Here,

$T_{avg}$ are listed for each case. Here, ![]() $\langle u_{bub}\rangle$ is the overall mean bubble velocity averaged over all the bubbles in the computational domain. The bubble equivalent diameters considered are

$\langle u_{bub}\rangle$ is the overall mean bubble velocity averaged over all the bubbles in the computational domain. The bubble equivalent diameters considered are ![]() $d_{eq}=2.62$, 3.30 and 4.16 mm (

$d_{eq}=2.62$, 3.30 and 4.16 mm (![]() $d_{eq}/D = 0.0655, 0.0825$ and 0.1040, respectively), and the corresponding Eötvös numbers are

$d_{eq}/D = 0.0655, 0.0825$ and 0.1040, respectively), and the corresponding Eötvös numbers are ![]() $Eo=0.96, 1.52$ and 2.42, respectively. We also performed simulations at higher

$Eo=0.96, 1.52$ and 2.42, respectively. We also performed simulations at higher ![]() $d_{eq}$ values (

$d_{eq}$ values (![]() $d_{eq} / D = 0.1310$ and 0.1650), but do not include their results here, because monodispersed bubbly flow could not be achieved due to breakup induced by turbulence.

$d_{eq} / D = 0.1310$ and 0.1650), but do not include their results here, because monodispersed bubbly flow could not be achieved due to breakup induced by turbulence.

Table 1. Cases studied: bubble equivalent diameter, total bubble volume fraction, number of bubbles, Eötvös number, friction Reynolds number, bubble Reynolds number and averaging time for obtaining statistics. Here, the names of cases denote (relative size of ![]() $d_{eq}$)–(relative magnitude of

$d_{eq}$)–(relative magnitude of ![]() $\langle \psi \rangle$), respectively. That is, (small, medium, large) correspond to the cases of

$\langle \psi \rangle$), respectively. That is, (small, medium, large) correspond to the cases of ![]() $d_{eq} =(2.62, 3.30, 4.16\,{\rm mm})$, respectively, and (low, medium, high) represent the cases of

$d_{eq} =(2.62, 3.30, 4.16\,{\rm mm})$, respectively, and (low, medium, high) represent the cases of ![]() $\langle \psi \rangle = (0.75\,\%, 1.5\,\%, 3.0\,\%)$, respectively. Note that small–medium–large and low–medium–high are used in terms of relative bubble size and volume fraction among the cases considered, and are not from absolute criteria for the bubble size and volume fraction.

$\langle \psi \rangle = (0.75\,\%, 1.5\,\%, 3.0\,\%)$, respectively. Note that small–medium–large and low–medium–high are used in terms of relative bubble size and volume fraction among the cases considered, and are not from absolute criteria for the bubble size and volume fraction.

Figure 2 shows the temporal variations of ![]() $-\varPi$ to drive a constant water mass flow rate (or a constant water bulk Reynolds number) for all cases. Since the weight of the air–water mixture is constant in time, the behaviour of

$-\varPi$ to drive a constant water mass flow rate (or a constant water bulk Reynolds number) for all cases. Since the weight of the air–water mixture is constant in time, the behaviour of ![]() $-\varPi$ essentially represents that of the mean pressure gradient. As the equivalent bubble diameter decreases at a given

$-\varPi$ essentially represents that of the mean pressure gradient. As the equivalent bubble diameter decreases at a given ![]() $\langle \psi \rangle$ and total bubble volume fraction increases at a given

$\langle \psi \rangle$ and total bubble volume fraction increases at a given ![]() $d_{eq}$, the mean pressure gradient (and

$d_{eq}$, the mean pressure gradient (and ![]() $Re_\tau$ in table 1) increases. The mean pressure gradients of bubbly flows exhibit large fluctuations as compared with that of the single-phase flow. These large fluctuations come from intermittent bubble–wall interactions, which is discussed in detail in § 3.2.

$Re_\tau$ in table 1) increases. The mean pressure gradients of bubbly flows exhibit large fluctuations as compared with that of the single-phase flow. These large fluctuations come from intermittent bubble–wall interactions, which is discussed in detail in § 3.2.

Figure 2. Temporal variations of ![]() $-\varPi$ in (2.2): red, ML; black, MM; blue, MH; green, SM; violet, LM;

$-\varPi$ in (2.2): red, ML; black, MM; blue, MH; green, SM; violet, LM; ![]() $\circ$, single phase.

$\circ$, single phase.

2.2. Validation

The use of an immersed boundary method for the present single-phase pipe flow is validated by comparing the turbulence statistics with those of Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) and Wu & Moin (Reference Wu and Moin2009) at ![]() $Re_{bulk}=5300$. The present grid spacings in Cartesian coordinates are uniform in all directions:

$Re_{bulk}=5300$. The present grid spacings in Cartesian coordinates are uniform in all directions: ![]() $\Delta x^+ = \Delta y^+ = 1.42$ and

$\Delta x^+ = \Delta y^+ = 1.42$ and ![]() $\Delta z^+ = 7.03$. These magnitudes are in between those used in Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) (

$\Delta z^+ = 7.03$. These magnitudes are in between those used in Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) (![]() $\Delta r^+=1.88, R^+ \Delta \theta ^+=8.84, \Delta z^+=7.03$) and in Wu & Moin (Reference Wu and Moin2009) (

$\Delta r^+=1.88, R^+ \Delta \theta ^+=8.84, \Delta z^+=7.03$) and in Wu & Moin (Reference Wu and Moin2009) (![]() $\Delta r^+=0.167, R^+ \Delta \theta ^+=2.22, \Delta z^+=5.31$) at the wall (

$\Delta r^+=0.167, R^+ \Delta \theta ^+=2.22, \Delta z^+=5.31$) at the wall (![]() $r=R$). The present friction velocity obtained is

$r=R$). The present friction velocity obtained is ![]() $u_\tau =0.06779 u_{bulk}$, and is very similar to

$u_\tau =0.06779 u_{bulk}$, and is very similar to ![]() $0.06789 u_{bulk}$ (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) and

$0.06789 u_{bulk}$ (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) and ![]() $0.06844 u_{bulk}$ (Wu & Moin Reference Wu and Moin2009). Figure 3 shows the Reynolds normal and shear stresses, together with those from Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) and Wu & Moin (Reference Wu and Moin2009). The present results agree very well with those of previous studies.

$0.06844 u_{bulk}$ (Wu & Moin Reference Wu and Moin2009). Figure 3 shows the Reynolds normal and shear stresses, together with those from Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) and Wu & Moin (Reference Wu and Moin2009). The present results agree very well with those of previous studies.

Figure 3. Profiles of the (a) r.m.s. velocity fluctuations and (b) Reynolds shear stress: ——, present; –![]() ${\cdot }$–

${\cdot }$–![]() ${\cdot }$–, Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994); — —, Wu & Moin (Reference Wu and Moin2009).

${\cdot }$–, Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994); — —, Wu & Moin (Reference Wu and Moin2009).

To examine if the axial domain size of ![]() $L_z = 3D$ is appropriate for the present bubbly flow, the two-point correlation coefficients of the velocity fluctuations in the axial direction are calculated and shown in figure 4 for the case of ML (lowest bubble volume fraction). As shown,

$L_z = 3D$ is appropriate for the present bubbly flow, the two-point correlation coefficients of the velocity fluctuations in the axial direction are calculated and shown in figure 4 for the case of ML (lowest bubble volume fraction). As shown, ![]() $R_{ii}$'s rapidly decrease with increasing

$R_{ii}$'s rapidly decrease with increasing ![]() $r_z$ and approach nearly zero at

$r_z$ and approach nearly zero at ![]() $r_z/D = 1.5$, indicating that the current axial domain size of

$r_z/D = 1.5$, indicating that the current axial domain size of ![]() $3D$ is reasonably large. Note that, in single-phase pipe flow, low-speed streaks near the wall extend up to 1000 viscous wall units (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994), and thus the axial domain size should be larger than about

$3D$ is reasonably large. Note that, in single-phase pipe flow, low-speed streaks near the wall extend up to 1000 viscous wall units (Eggels et al. Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994), and thus the axial domain size should be larger than about ![]() $6D$ (

$6D$ (![]() $D^+ =360$) to contain at least two streaky structures. As we discuss later, in bubbly flow, the near-wall streaky structures are rarely found in the present bubbly flow due to the agitation by bubbles. We also increase the axial domain size to

$D^+ =360$) to contain at least two streaky structures. As we discuss later, in bubbly flow, the near-wall streaky structures are rarely found in the present bubbly flow due to the agitation by bubbles. We also increase the axial domain size to ![]() $L_z = 6D$ for case ML, and provide results in figure 5 together with those for

$L_z = 6D$ for case ML, and provide results in figure 5 together with those for ![]() $L_z = 3D$. As shown, the mean bubble volume fraction

$L_z = 3D$. As shown, the mean bubble volume fraction ![]() $\bar \psi$ and the r.m.s. velocity fluctuations from two different axial domain sizes show negligible changes, indicating that

$\bar \psi$ and the r.m.s. velocity fluctuations from two different axial domain sizes show negligible changes, indicating that ![]() $L_z = 3D$ is sufficiently large. On the other hand, it was shown by Risso & Ellingsen (Reference Risso and Ellingsen2002) that for a single rising air bubble of a diameter comparable to the present one in stagnant water, the wake behind the bubble persists over dozens of bubble diameters. Thus, a small axial domain size may change the wake characteristics of the bubble. To see if this happens for the present simulation, we calculate the differences between the time-averaged and ensemble-averaged water flow variables (axial velocity and turbulent kinetic energy) for case ML. Here, the time-averaged axial velocity and turbulent kinetic energy (

$L_z = 3D$ is sufficiently large. On the other hand, it was shown by Risso & Ellingsen (Reference Risso and Ellingsen2002) that for a single rising air bubble of a diameter comparable to the present one in stagnant water, the wake behind the bubble persists over dozens of bubble diameters. Thus, a small axial domain size may change the wake characteristics of the bubble. To see if this happens for the present simulation, we calculate the differences between the time-averaged and ensemble-averaged water flow variables (axial velocity and turbulent kinetic energy) for case ML. Here, the time-averaged axial velocity and turbulent kinetic energy (![]() $\bar u_z$ and

$\bar u_z$ and ![]() $\frac {1}{2}\overline {u'_i u'_i}$, respectively) are obtained using the process in (3.1) below, and the ensemble-averaged axial velocity and turbulent kinetic energy (

$\frac {1}{2}\overline {u'_i u'_i}$, respectively) are obtained using the process in (3.1) below, and the ensemble-averaged axial velocity and turbulent kinetic energy (![]() $\tilde u_z$ and

$\tilde u_z$ and ![]() $\frac {1}{2}\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }}$ (

$\frac {1}{2}\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }}$ (![]() $u_i^{\prime \prime } = u_i - \tilde u_i$), respectively) are obtained by averaging the instantaneous water velocity fields around bubbles located at

$u_i^{\prime \prime } = u_i - \tilde u_i$), respectively) are obtained by averaging the instantaneous water velocity fields around bubbles located at ![]() $\vert r-r_o \vert \leq 0.5 \Delta r$ (

$\vert r-r_o \vert \leq 0.5 \Delta r$ (![]() $\Delta r =0.0039 D$) for two different radial positions

$\Delta r =0.0039 D$) for two different radial positions ![]() $r_o/R= 0.5$ and 0.89. The results as a function of the axial distance from the bubble centre (

$r_o/R= 0.5$ and 0.89. The results as a function of the axial distance from the bubble centre (![]() $z_o$) are shown in figure 6. As shown, both

$z_o$) are shown in figure 6. As shown, both ![]() $\tilde u_z - \bar u_z$ and

$\tilde u_z - \bar u_z$ and ![]() $\frac {1}{2} (\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }} - \overline {u'_i u'_i})$ are positive near the wake because the bubble velocity is greater than the water velocity, and are nearly zero at

$\frac {1}{2} (\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }} - \overline {u'_i u'_i})$ are positive near the wake because the bubble velocity is greater than the water velocity, and are nearly zero at ![]() $(z-z_o)/d_{eq} \approx -2.5$ (

$(z-z_o)/d_{eq} \approx -2.5$ (![]() $(z-z_o)/D \approx -0.21$), indicating that the bubble wake quickly disappears in turbulent bubbly flow unlike that from a single rising bubble. Therefore, the use of

$(z-z_o)/D \approx -0.21$), indicating that the bubble wake quickly disappears in turbulent bubbly flow unlike that from a single rising bubble. Therefore, the use of ![]() $L_z = 3D$ does not influence the bubble dynamics in turbulent bubbly flow.

$L_z = 3D$ does not influence the bubble dynamics in turbulent bubbly flow.

Figure 4. Two-point correlation coefficients of the velocity fluctuations ![]() $R_{ii}$ as a function of the axial separation distance

$R_{ii}$ as a function of the axial separation distance ![]() $r_z$ (case ML): (a)

$r_z$ (case ML): (a) ![]() $r/R=0.20$; (b)

$r/R=0.20$; (b) ![]() $r/R=0.95$.

$r/R=0.95$.

Figure 5. Profiles of the (a) mean bubble volume fraction and (b) r.m.s. velocity fluctuations for different axial domain sizes (case ML): ——, ![]() $L_z = 3D$; - - - -,

$L_z = 3D$; - - - -, ![]() $L_z = 6D$.

$L_z = 6D$.

Figure 6. Axial profiles of the differences in the time-averaged and ensemble-averaged water flow variables near a bubble (case ML): (a) ![]() $\tilde u_z - \bar u_z$ (axial velocity); (b)

$\tilde u_z - \bar u_z$ (axial velocity); (b) ![]() $(\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }} - \overline {u'_i u'_i})/2$ (turbulent kinetic energy); ——,

$(\widetilde {u_i^{\prime \prime } u_i^{\prime \prime }} - \overline {u'_i u'_i})/2$ (turbulent kinetic energy); ——, ![]() $r_o/R = 0.5$; - - - -,

$r_o/R = 0.5$; - - - -, ![]() $r_o/R = 0.89$.

$r_o/R = 0.89$.

For the validation of the present numerical method, we conduct simulations of a rising air bubble with a straight path in water–glycerol mixtures considered by Raymond & Rosant (Reference Raymond and Rosant2000), where ![]() $d_{eq} = 3$, 5 and 7 mm,

$d_{eq} = 3$, 5 and 7 mm, ![]() $\sigma _{sol}/\sigma _w=0.91$,

$\sigma _{sol}/\sigma _w=0.91$, ![]() $\rho _{sol}/\rho _w=1.20, 1.19, 1.17$ and

$\rho _{sol}/\rho _w=1.20, 1.19, 1.17$ and ![]() $1.15$ and

$1.15$ and ![]() $\mu _{sol}/\mu _w=73.3, 42.2, 24.0$ and

$\mu _{sol}/\mu _w=73.3, 42.2, 24.0$ and ![]() $13.0$ for solutions with

$13.0$ for solutions with ![]() $\psi _w$ (water volume fraction)

$\psi _w$ (water volume fraction) ![]() $=$ 18 %, 24 %, 31 % and 40 %, respectively, and the subscript ‘sol’ denotes the solution. The computational domain size is

$=$ 18 %, 24 %, 31 % and 40 %, respectively, and the subscript ‘sol’ denotes the solution. The computational domain size is ![]() $(L_x, L_y, L_z) = (4d_{eq},4d_{eq},20d_{eq})$, and the numbers of grid points per bubble equivalent diameter are

$(L_x, L_y, L_z) = (4d_{eq},4d_{eq},20d_{eq})$, and the numbers of grid points per bubble equivalent diameter are ![]() $n_{NS} = 16$ and

$n_{NS} = 16$ and ![]() $n_{LS} = 32$ for the momentum and level-set equations, respectively. Table 2 shows the variation of the terminal velocity of air bubbles with the water volume fraction, together with the experimental results by Raymond & Rosant (Reference Raymond and Rosant2000). As shown in this table, the present results are in excellent agreement with the experimental ones.

$n_{LS} = 32$ for the momentum and level-set equations, respectively. Table 2 shows the variation of the terminal velocity of air bubbles with the water volume fraction, together with the experimental results by Raymond & Rosant (Reference Raymond and Rosant2000). As shown in this table, the present results are in excellent agreement with the experimental ones.

Table 2. Variation of the terminal velocity ![]() $u_T$ with the water volume fraction

$u_T$ with the water volume fraction ![]() $\psi _w$ (single rising air bubble in water–glycerol solution). The experimental data of Raymond & Rosant (Reference Raymond and Rosant2000) are also shown for comparison.

$\psi _w$ (single rising air bubble in water–glycerol solution). The experimental data of Raymond & Rosant (Reference Raymond and Rosant2000) are also shown for comparison.

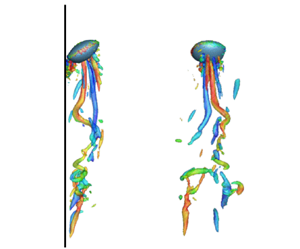

We also conduct simulations of a rising air bubble in stagnant water to examine how many grid points should be located per bubble such that bubble dynamics is correctly represented. We choose the largest bubble (![]() $d_{eq}=4.16$ mm) among those considered in the present study for these simulations. The grid resolutions tested for the Navier–Stokes and level-set equations are

$d_{eq}=4.16$ mm) among those considered in the present study for these simulations. The grid resolutions tested for the Navier–Stokes and level-set equations are ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8, 16), (16, 32), (24, 48)$ and (32, 64), respectively. This bubble requires a vertical computational domain size of

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8, 16), (16, 32), (24, 48)$ and (32, 64), respectively. This bubble requires a vertical computational domain size of ![]() $100d_{eq}$ to obtain a bubble path in equilibrium, which requires too much computational cost. Therefore, we rather use a periodic computational box in all directions with a size of

$100d_{eq}$ to obtain a bubble path in equilibrium, which requires too much computational cost. Therefore, we rather use a periodic computational box in all directions with a size of ![]() $(L_x, L_y, L_z) = (4d_{eq},4d_{eq},20d_{eq})$. With this numerical set-up, the wake behind a bubble affects its trajectory, and thus the bubble trajectory should be different from that obtained in a very large domain size. However, this numerical set-up is sufficient to examine the resolution requirement at a much lower computational cost. Figure 7 shows the trajectories of the rising bubble for different grid resolutions. The bubble trajectory from

$(L_x, L_y, L_z) = (4d_{eq},4d_{eq},20d_{eq})$. With this numerical set-up, the wake behind a bubble affects its trajectory, and thus the bubble trajectory should be different from that obtained in a very large domain size. However, this numerical set-up is sufficient to examine the resolution requirement at a much lower computational cost. Figure 7 shows the trajectories of the rising bubble for different grid resolutions. The bubble trajectory from ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$ is rectilinear, while others are oscillatory. The onsets of oscillatory trajectories occur at the same vertical position (

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$ is rectilinear, while others are oscillatory. The onsets of oscillatory trajectories occur at the same vertical position (![]() $z/d_{eq} = 5.5$) when the initial bubble location is

$z/d_{eq} = 5.5$) when the initial bubble location is ![]() $z/d_{eq}=2$, but the subsequent trajectories are different for different grid resolutions. Due to the use of Cartesian coordinates and the relative position of the bubble to the grid, the same trajectory is not expected even with a larger number of grid points. Although the trajectories are different for different grid resolutions, their characteristics from

$z/d_{eq}=2$, but the subsequent trajectories are different for different grid resolutions. Due to the use of Cartesian coordinates and the relative position of the bubble to the grid, the same trajectory is not expected even with a larger number of grid points. Although the trajectories are different for different grid resolutions, their characteristics from ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (24, 48)$ and

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (24, 48)$ and ![]() $(32,64)$ are very similar to each other. For example, their dominant frequencies of oscillation,

$(32,64)$ are very similar to each other. For example, their dominant frequencies of oscillation, ![]() $f_{path} \sqrt {d_{eq}/g}$, obtained from the power spectra of the bubble locations on the projected horizontal plane

$f_{path} \sqrt {d_{eq}/g}$, obtained from the power spectra of the bubble locations on the projected horizontal plane ![]() $(x,y)$ are 0.111 and 0.115, respectively, while that from

$(x,y)$ are 0.111 and 0.115, respectively, while that from ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (16, 32)$ is 0.056. This result suggests that the resolution of

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (16, 32)$ is 0.056. This result suggests that the resolution of ![]() $(24,48)$ should adequately predict the bubble behaviour in water. Figure 8 shows the temporal variations of vertical and horizontal velocities of the rising bubble for different grid resolutions. As shown,

$(24,48)$ should adequately predict the bubble behaviour in water. Figure 8 shows the temporal variations of vertical and horizontal velocities of the rising bubble for different grid resolutions. As shown, ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$ provides very different velocities from those from denser resolutions. The results from the grid resolutions of

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$ provides very different velocities from those from denser resolutions. The results from the grid resolutions of ![]() $(24,48)$ and

$(24,48)$ and ![]() $(32,64)$ are very similar to each other, and those of

$(32,64)$ are very similar to each other, and those of ![]() $(16,32)$ are slightly different in terms of oscillation frequency and amplitude from those of

$(16,32)$ are slightly different in terms of oscillation frequency and amplitude from those of ![]() $(24,48)$ and

$(24,48)$ and ![]() $(32,64)$. The time-averaged terminal velocities from

$(32,64)$. The time-averaged terminal velocities from ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16), (16,32), (24,48)$ and

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16), (16,32), (24,48)$ and ![]() $(32,64)$ are 1.05, 1.19, 1.21 and

$(32,64)$ are 1.05, 1.19, 1.21 and ![]() $1.20 \sqrt {g d_{eq}}$, respectively. Therefore, for the bubble of

$1.20 \sqrt {g d_{eq}}$, respectively. Therefore, for the bubble of ![]() $d_{eq} = 4.16$ mm, grid points of

$d_{eq} = 4.16$ mm, grid points of ![]() $(24,48)$ per bubble for the Navier–Stokes and level-set equations, respectively, are required for describing bubble dynamics, and grid points of

$(24,48)$ per bubble for the Navier–Stokes and level-set equations, respectively, are required for describing bubble dynamics, and grid points of ![]() $(16,32)$ are quite marginal. For a smaller size of bubble, the corresponding bubble Reynolds number becomes smaller and thus fewer grid points may be required. In our main simulations, we locate

$(16,32)$ are quite marginal. For a smaller size of bubble, the corresponding bubble Reynolds number becomes smaller and thus fewer grid points may be required. In our main simulations, we locate ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (25.2, 50.3)$,

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (25.2, 50.3)$, ![]() $(21.1, 42.2)$ and

$(21.1, 42.2)$ and ![]() $(26.6, 53.2)$ for

$(26.6, 53.2)$ for ![]() $d_{eq}= 2.62, 3.30$ and 4.16 mm, respectively, according to this resolution study. Cano-Lozano et al. (Reference Cano-Lozano, Martinez-Bazan, Magnaudet and Tchoufag2016) and Innocenti et al. (Reference Innocenti, Jaccod, Popinet and Chibbaro2021) used a volume of fluid (VoF) method to predict the dynamics of a single bubble and bubble swarm in still water at

$d_{eq}= 2.62, 3.30$ and 4.16 mm, respectively, according to this resolution study. Cano-Lozano et al. (Reference Cano-Lozano, Martinez-Bazan, Magnaudet and Tchoufag2016) and Innocenti et al. (Reference Innocenti, Jaccod, Popinet and Chibbaro2021) used a volume of fluid (VoF) method to predict the dynamics of a single bubble and bubble swarm in still water at ![]() $Re_{bub}=O(100)$, respectively, and suggested by rigorously examining the bubble path, wake dynamics and bubble shape that a resolution of

$Re_{bub}=O(100)$, respectively, and suggested by rigorously examining the bubble path, wake dynamics and bubble shape that a resolution of ![]() $d_{eq}/\Delta x_{NS} \approx 100$ should be required. Zhang, Ni & Magnaudet (Reference Zhang, Ni and Magnaudet2021, Reference Zhang, Ni and Magnaudet2022) also used the same method to predict the dynamics of a pair of bubbles rising in line at

$d_{eq}/\Delta x_{NS} \approx 100$ should be required. Zhang, Ni & Magnaudet (Reference Zhang, Ni and Magnaudet2021, Reference Zhang, Ni and Magnaudet2022) also used the same method to predict the dynamics of a pair of bubbles rising in line at ![]() $Re_{bub}=O(10)\unicode{x2013}O(100)$, and indicated that

$Re_{bub}=O(10)\unicode{x2013}O(100)$, and indicated that ![]() $d_{eq}/\Delta x_{NS} =136$ is required in the vicinity of bubbles to resolve the boundary layer and wake. Unlike those studies, we examine the turbulence characteristics of bubbly pipe flow (multiple bubbles interacting with the wall) using a marginal number of grid points, and thus the present resolution may not be sufficient to accurately capture small-scale motions behind the bubbles. Such a rigorous analysis conducted by Cano-Lozano et al. (Reference Cano-Lozano, Martinez-Bazan, Magnaudet and Tchoufag2016), Innocenti et al. (Reference Innocenti, Jaccod, Popinet and Chibbaro2021) and Zhang et al. (Reference Zhang, Ni and Magnaudet2021, Reference Zhang, Ni and Magnaudet2022) could be a formidable task for the present flow.

$d_{eq}/\Delta x_{NS} =136$ is required in the vicinity of bubbles to resolve the boundary layer and wake. Unlike those studies, we examine the turbulence characteristics of bubbly pipe flow (multiple bubbles interacting with the wall) using a marginal number of grid points, and thus the present resolution may not be sufficient to accurately capture small-scale motions behind the bubbles. Such a rigorous analysis conducted by Cano-Lozano et al. (Reference Cano-Lozano, Martinez-Bazan, Magnaudet and Tchoufag2016), Innocenti et al. (Reference Innocenti, Jaccod, Popinet and Chibbaro2021) and Zhang et al. (Reference Zhang, Ni and Magnaudet2021, Reference Zhang, Ni and Magnaudet2022) could be a formidable task for the present flow.

Figure 7. Trajectories for a rising bubble (![]() $d_{eq} = 4.16$ mm) in the periodic domain with varying grid spacing: (a) three-dimensional view; (b) top view. Blue,

$d_{eq} = 4.16$ mm) in the periodic domain with varying grid spacing: (a) three-dimensional view; (b) top view. Blue, ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$; black, (16,32); green, (24,48); red, (32,64).

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$; black, (16,32); green, (24,48); red, (32,64).

Figure 8. Temporal variations of the vertical and horizontal velocities for a rising bubble (![]() $d_{eq} = 4.16$ mm) in the periodic domain with varying grid spacing: (a) vertical velocity; (b) horizontal velocity. Blue,

$d_{eq} = 4.16$ mm) in the periodic domain with varying grid spacing: (a) vertical velocity; (b) horizontal velocity. Blue, ![]() $(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$; black, (16,32); green, (24,48); red, (32,64).

$(d_{eq}/\Delta x_{NS},d_{eq}/\Delta x_{LS}) = (8,16)$; black, (16,32); green, (24,48); red, (32,64).

3. Turbulence statistics and flow structures

3.1. Turbulence statistics

Figure 9 shows the profiles of the mean bubble volume fraction in the radial direction for five bubbly flows. Note that cases ML, MM and MH have the same ![]() $d_{eq}/D$ (

$d_{eq}/D$ (![]() $=0.0825$) but different

$=0.0825$) but different ![]() $\langle \psi \rangle$ values of 0.75 %, 1.5 % and 3.0 %, respectively, and cases SM, MM and LM have the same

$\langle \psi \rangle$ values of 0.75 %, 1.5 % and 3.0 %, respectively, and cases SM, MM and LM have the same ![]() $\langle \psi \rangle$ (

$\langle \psi \rangle$ (![]() $=1.5\,\%$) but different

$=1.5\,\%$) but different ![]() $d_{eq}/D$ values of 0.0655, 0.0825 and 0.1040, respectively. Except for case LM, the four other cases exhibit radial bubble distributions with peaks near the wall (called wall-peaking) and nearly flat profiles at the pipe centre region. Half the averaging time (

$d_{eq}/D$ values of 0.0655, 0.0825 and 0.1040, respectively. Except for case LM, the four other cases exhibit radial bubble distributions with peaks near the wall (called wall-peaking) and nearly flat profiles at the pipe centre region. Half the averaging time (![]() $T_{avg}$) in table 1 did not change the statistics near the wall but showed slight changes in the centre region (not shown here). Thus, further time averaging should provide slightly better profiles in the centre region, but requires significant amounts of additional computational time (the same argument is applied to the Reynolds normal stress profiles shown in figure 11). Case LM shows that the bubble distribution increases from the centre to

$T_{avg}$) in table 1 did not change the statistics near the wall but showed slight changes in the centre region (not shown here). Thus, further time averaging should provide slightly better profiles in the centre region, but requires significant amounts of additional computational time (the same argument is applied to the Reynolds normal stress profiles shown in figure 11). Case LM shows that the bubble distribution increases from the centre to ![]() $r/R=0.4$ and is nearly uniform at

$r/R=0.4$ and is nearly uniform at ![]() $r/R=0.4\unicode{x2013}0.8$, followed by a sharp decrease to the wall. This distribution lies between the wall-peaking and core-peaking bubble distributions. According to Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013), the direction of the lift force on a deformable bubble in wall-bounded upward bubbly flow depends on the magnitude of

$r/R=0.4\unicode{x2013}0.8$, followed by a sharp decrease to the wall. This distribution lies between the wall-peaking and core-peaking bubble distributions. According to Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013), the direction of the lift force on a deformable bubble in wall-bounded upward bubbly flow depends on the magnitude of ![]() $Eo$: i.e. bubbles move towards the centre for

$Eo$: i.e. bubbles move towards the centre for ![]() $Eo > Eo_c$ (

$Eo > Eo_c$ (![]() ${\approx }2.5$) and to the wall otherwise. As shown in table 1,

${\approx }2.5$) and to the wall otherwise. As shown in table 1, ![]() $Eo=2.42$ (slightly smaller than

$Eo=2.42$ (slightly smaller than ![]() $Eo_c$) for case LM, whereas

$Eo_c$) for case LM, whereas ![]() $Eo$'s are much smaller than

$Eo$'s are much smaller than ![]() $Eo_c$ for the four other cases. Therefore, for case LM, more bubbles move away from the wall but do not reach the centre, whereas most bubbles move towards the wall for the four other cases. For a given

$Eo_c$ for the four other cases. Therefore, for case LM, more bubbles move away from the wall but do not reach the centre, whereas most bubbles move towards the wall for the four other cases. For a given ![]() $\langle \psi \rangle$ (cases SM, MM and LM), more bubbles move to the wall with decreasing

$\langle \psi \rangle$ (cases SM, MM and LM), more bubbles move to the wall with decreasing ![]() $d_{eq}$. On the other hand, for a given bubble equivalent diameter (i.e. same

$d_{eq}$. On the other hand, for a given bubble equivalent diameter (i.e. same ![]() $Eo$; cases ML, MM and MH),

$Eo$; cases ML, MM and MH), ![]() $\bar \psi$ monotonically increases at all

$\bar \psi$ monotonically increases at all ![]() $r$'s with increasing

$r$'s with increasing ![]() $\langle \psi \rangle$.

$\langle \psi \rangle$.

Figure 9. Profiles of the mean bubble volume fraction in the radial direction. Red curve, case ML (![]() $d_{eq}/D=0.0825$ and

$d_{eq}/D=0.0825$ and ![]() $\langle \psi \rangle = 0.75\,\%$); solid black curve, case MM (

$\langle \psi \rangle = 0.75\,\%$); solid black curve, case MM (![]() $d_{eq}/D=0.0825$ and

$d_{eq}/D=0.0825$ and ![]() $\langle \psi \rangle = 1.5\,\%$); blue curve, case MH (

$\langle \psi \rangle = 1.5\,\%$); blue curve, case MH (![]() $d_{eq}/D=0.0825$ and

$d_{eq}/D=0.0825$ and ![]() $\langle \psi \rangle = 3.0\,\%$); dot-dashed curve, case SM (

$\langle \psi \rangle = 3.0\,\%$); dot-dashed curve, case SM (![]() $d_{eq}/D=0.0655$ and

$d_{eq}/D=0.0655$ and ![]() $\langle \psi \rangle = 1.5\,\%$); dashed curve, case LM (

$\langle \psi \rangle = 1.5\,\%$); dashed curve, case LM (![]() $d_{eq}/D=0.1040$ and

$d_{eq}/D=0.1040$ and ![]() $\langle \psi \rangle = 1.5\,\%$).

$\langle \psi \rangle = 1.5\,\%$).

Figure 10 shows the profiles of the mean velocities of water and bubbles and relative mean bubble velocity in the radial direction for the single-phase and bubbly flows. Here, the mean water and bubble velocities are obtained as

$$\begin{gather} \bar u_z (r) = \frac{\displaystyle\int_0^{\rm T} \int_0^{L_z} \int_0^{2{\rm \pi}} (1-\psi) u_z \,{\rm d}\theta\,{\rm d} z \,{\rm d} t}{\displaystyle\int_0^{\rm T} \int_0^{L_z} \int_0^{2{\rm \pi}} (1-\psi)\,{\rm d}\theta\,{\rm d} z\,{\rm d} t}, \end{gather}$$

$$\begin{gather} \bar u_z (r) = \frac{\displaystyle\int_0^{\rm T} \int_0^{L_z} \int_0^{2{\rm \pi}} (1-\psi) u_z \,{\rm d}\theta\,{\rm d} z \,{\rm d} t}{\displaystyle\int_0^{\rm T} \int_0^{L_z} \int_0^{2{\rm \pi}} (1-\psi)\,{\rm d}\theta\,{\rm d} z\,{\rm d} t}, \end{gather}$$ $$\begin{gather}\bar{u}_{z,{bub}} (r) =\frac{1}{T} \int^{\rm T}_0 \left\{ \frac{1}{N_{bub}(r,t)} \sum^{N_{bub}(r,t)}_{i=1} \frac{1}{V_{b_i}} \int_{V_{b_i}}{u_z \,{\rm d} V} \right\}{\rm d} t, \end{gather}$$

$$\begin{gather}\bar{u}_{z,{bub}} (r) =\frac{1}{T} \int^{\rm T}_0 \left\{ \frac{1}{N_{bub}(r,t)} \sum^{N_{bub}(r,t)}_{i=1} \frac{1}{V_{b_i}} \int_{V_{b_i}}{u_z \,{\rm d} V} \right\}{\rm d} t, \end{gather}$$

where ![]() $T$ is the integration time,

$T$ is the integration time, ![]() $L_z$ is the axial domain size,

$L_z$ is the axial domain size, ![]() $N_{bub}(r,t)$ is the number of bubbles whose centres of mass are located at

$N_{bub}(r,t)$ is the number of bubbles whose centres of mass are located at ![]() $r-0.00625D \leq r_{cm} < r+0.00625D$ at time

$r-0.00625D \leq r_{cm} < r+0.00625D$ at time ![]() $t$ and

$t$ and ![]() $V_{b_i}$ is the volume of corresponding bubble

$V_{b_i}$ is the volume of corresponding bubble ![]() $i$. The water flows with bubbles have higher mean shear rates near the wall than the single-phase flow because of the buoyant bubbles located close to the wall. As the bubble concentration near the wall increases with increasing

$i$. The water flows with bubbles have higher mean shear rates near the wall than the single-phase flow because of the buoyant bubbles located close to the wall. As the bubble concentration near the wall increases with increasing ![]() $\langle \psi \rangle$ (ML to MH) and decreasing

$\langle \psi \rangle$ (ML to MH) and decreasing ![]() $d_{eq}$ (LM to SM) (see figure 9), the mean shear rates near and at the wall increase (see also

$d_{eq}$ (LM to SM) (see figure 9), the mean shear rates near and at the wall increase (see also ![]() $Re_\tau$'s in table 1). On the other hand, the mean water velocities of bubbly flows near the centre are lower than that of the single-phase flow and decrease with increasing

$Re_\tau$'s in table 1). On the other hand, the mean water velocities of bubbly flows near the centre are lower than that of the single-phase flow and decrease with increasing ![]() $\langle \psi \rangle$ and decreasing

$\langle \psi \rangle$ and decreasing ![]() $d_{eq}$ owing to the constant mass flow rate. The magnitudes of the mean bubble velocities are greater than two times those of the mean water velocities, and those near the centre increase with decreasing

$d_{eq}$ owing to the constant mass flow rate. The magnitudes of the mean bubble velocities are greater than two times those of the mean water velocities, and those near the centre increase with decreasing ![]() $\langle \psi \rangle$ and increasing

$\langle \psi \rangle$ and increasing ![]() $d_{eq}$ (a similar observation was made in homogeneous bubbly flows by Riboux et al. (Reference Riboux, Risso and Legendre2010) and Roghair et al. (Reference Roghair, Mercado, Annaland, Kuipers, Sun and Lohse2011)). Hence, the relative mean bubble velocities are always positive for the present flows because

$d_{eq}$ (a similar observation was made in homogeneous bubbly flows by Riboux et al. (Reference Riboux, Risso and Legendre2010) and Roghair et al. (Reference Roghair, Mercado, Annaland, Kuipers, Sun and Lohse2011)). Hence, the relative mean bubble velocities are always positive for the present flows because ![]() $\bar {u}_{z,{bub}} > \bar u_z$. At

$\bar {u}_{z,{bub}} > \bar u_z$. At ![]() $r/R <0.8$, the relative mean bubble velocity is almost constant (indicating negligible wall effect in this radial region), and increases slightly with decreasing

$r/R <0.8$, the relative mean bubble velocity is almost constant (indicating negligible wall effect in this radial region), and increases slightly with decreasing ![]() $\langle \psi \rangle$. However, at

$\langle \psi \rangle$. However, at ![]() $r/R>0.8$, the relative mean bubble velocity rapidly decreases because the mean bubble velocity rapidly decreases towards the wall while the mean water velocity there increases due to rising bubbles compared with single-phase flow.

$r/R>0.8$, the relative mean bubble velocity rapidly decreases because the mean bubble velocity rapidly decreases towards the wall while the mean water velocity there increases due to rising bubbles compared with single-phase flow.

Figure 10. Profiles of the mean water and bubble velocities, and relative mean bubble velocity in the radial direction: (a) mean velocities (water and bubble); (b) relative mean bubble velocity. ![]() $\diamond$, Single phase; red, case ML; solid black, MM; blue, MH; dot-dashed, SM; dashed, LM.

$\diamond$, Single phase; red, case ML; solid black, MM; blue, MH; dot-dashed, SM; dashed, LM.

Figure 11(a–c) shows the profiles of the r.m.s. water velocity fluctuations in the radial direction for the single-phase and bubbly flows. The bubbly flows have much higher r.m.s. velocity fluctuations at all radial locations than those of the single-phase flow. The r.m.s. velocity fluctuations increase with increasing ![]() $\langle \psi \rangle$ and

$\langle \psi \rangle$ and ![]() $d_{eq}$. The behaviours of the r.m.s. velocity fluctuations near the centre are similar to those of the mean bubble volume fraction at each radial position (see figure 9): i.e. the magnitudes increase from

$d_{eq}$. The behaviours of the r.m.s. velocity fluctuations near the centre are similar to those of the mean bubble volume fraction at each radial position (see figure 9): i.e. the magnitudes increase from ![]() $r/R = 0$ to 0.4 for case LM but are nearly uniform for the other four cases. This is because the fluctuations induced by bubbles are closely related to the number of bubbles present. The axial r.m.s. velocity fluctuations near the wall also show similar behaviours to those of

$r/R = 0$ to 0.4 for case LM but are nearly uniform for the other four cases. This is because the fluctuations induced by bubbles are closely related to the number of bubbles present. The axial r.m.s. velocity fluctuations near the wall also show similar behaviours to those of ![]() $\bar \psi$, but their peak locations are at

$\bar \psi$, but their peak locations are at ![]() $r/R \approx 0.97$, while the peak of

$r/R \approx 0.97$, while the peak of ![]() $\bar \psi$ locates at

$\bar \psi$ locates at ![]() $r/R = 0.85\unicode{x2013}0.9$. This phenomenon (i.e. shift of the peak locations) is discussed in detail in § 3.2. The radial and azimuthal r.m.s. velocity fluctuations gradually increase towards the wall as compared to the axial velocity component, because these cross-flow components are affected by the wake behind rising bubbles but the axial component is directly influenced by them. Since

$r/R = 0.85\unicode{x2013}0.9$. This phenomenon (i.e. shift of the peak locations) is discussed in detail in § 3.2. The radial and azimuthal r.m.s. velocity fluctuations gradually increase towards the wall as compared to the axial velocity component, because these cross-flow components are affected by the wake behind rising bubbles but the axial component is directly influenced by them. Since ![]() $\bar \psi$ monotonically increases at all the radial locations with increasing

$\bar \psi$ monotonically increases at all the radial locations with increasing ![]() $\langle \psi \rangle$ (figure 9), the increases of the r.m.s. velocity fluctuation with

$\langle \psi \rangle$ (figure 9), the increases of the r.m.s. velocity fluctuation with ![]() $\langle \psi \rangle$ can be normalized by introducing

$\langle \psi \rangle$ can be normalized by introducing ![]() $\bar \psi$. Figure 11(d) shows the r.m.s. water velocity fluctuations normalized by

$\bar \psi$. Figure 11(d) shows the r.m.s. water velocity fluctuations normalized by ![]() $u_{bulk}$ and

$u_{bulk}$ and ![]() $\bar {\psi }^{0.4}$ for cases ML, MM and MH (

$\bar {\psi }^{0.4}$ for cases ML, MM and MH (![]() $\bar \psi = 0.75, 1.5$ and 3.0, respectively, with the same

$\bar \psi = 0.75, 1.5$ and 3.0, respectively, with the same ![]() $d_{eq}/D=0.0825$). Here,

$d_{eq}/D=0.0825$). Here, ![]() $\bar {\psi }^{0.4}$ comes from the studies of homogeneous bubbly flows (Risso & Ellingsen Reference Risso and Ellingsen2002; Martínez-Mercado, Palacios-Morales & Zenit Reference Martínez-Mercado, Palacios-Morales and Zenit2007; Roig & De Tournemine Reference Roig and De Tournemine2007; Riboux et al. Reference Riboux, Risso and Legendre2010) and laminar bubbly pipe flow (Kim, Lee & Park Reference Kim, Lee and Park2016). With this normalization, the profiles of r.m.s. velocity fluctuations for three cases collapse well among themselves at all the radial locations.

$\bar {\psi }^{0.4}$ comes from the studies of homogeneous bubbly flows (Risso & Ellingsen Reference Risso and Ellingsen2002; Martínez-Mercado, Palacios-Morales & Zenit Reference Martínez-Mercado, Palacios-Morales and Zenit2007; Roig & De Tournemine Reference Roig and De Tournemine2007; Riboux et al. Reference Riboux, Risso and Legendre2010) and laminar bubbly pipe flow (Kim, Lee & Park Reference Kim, Lee and Park2016). With this normalization, the profiles of r.m.s. velocity fluctuations for three cases collapse well among themselves at all the radial locations.

Figure 11. Profiles of the r.m.s. water velocity fluctuations in the radial direction: (a) ![]() $u_{r,rms}$; (b)

$u_{r,rms}$; (b) ![]() $u_{\theta,rms}$; (c)

$u_{\theta,rms}$; (c) ![]() $u_{z,rms}$; (d)

$u_{z,rms}$; (d) ![]() $u_{i,{rms}}/ (u_{bulk} \bar \psi ^{0.4})$.

$u_{i,{rms}}/ (u_{bulk} \bar \psi ^{0.4})$. ![]() $\diamond$, Single phase; red, case ML; solid black, MM; blue, MH; dot-dashed, SM; dashed, LM. In (d), only the cases ML, MM and MH are shown.

$\diamond$, Single phase; red, case ML; solid black, MM; blue, MH; dot-dashed, SM; dashed, LM. In (d), only the cases ML, MM and MH are shown.

As mentioned in § 1, turbulent bubbly flows contain both shear-induced and bubble-induced turbulence. If the shear-induced and bubble-induced turbulence are assumed to be independent from each other, one may decompose the Reynolds normal stresses ![]() $\overline {u_\alpha ^\prime u_\alpha ^\prime }$ as

$\overline {u_\alpha ^\prime u_\alpha ^\prime }$ as

where ![]() $R_{SIT}$ and

$R_{SIT}$ and ![]() $R_{BIT}$ denote the Reynolds normal stresses from the shear-induced and bubble-induced turbulence, respectively. Since

$R_{BIT}$ denote the Reynolds normal stresses from the shear-induced and bubble-induced turbulence, respectively. Since ![]() $R_{BIT} \sim \bar \psi ^{0.8}$ (Risso & Ellingsen Reference Risso and Ellingsen2002; Martínez-Mercado et al. Reference Martínez-Mercado, Palacios-Morales and Zenit2007; Roig & De Tournemine Reference Roig and De Tournemine2007; Riboux et al. Reference Riboux, Risso and Legendre2010; Kim et al. Reference Kim, Lee and Park2016), the results in figure 11(d) indicate that the bubble-induced turbulence is predominant even near the wall for the present flows. Note that Lu & Tryggvason (Reference Lu and Tryggvason2008), Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013) and Du Cluzeau et al. (Reference Du Cluzeau, Bois and Toutant2019) indicated the existence of an interaction between the shear-induced and bubble-induced turbulence from their wall-bounded upward bubbly flows. Since their density ratios (

$R_{BIT} \sim \bar \psi ^{0.8}$ (Risso & Ellingsen Reference Risso and Ellingsen2002; Martínez-Mercado et al. Reference Martínez-Mercado, Palacios-Morales and Zenit2007; Roig & De Tournemine Reference Roig and De Tournemine2007; Riboux et al. Reference Riboux, Risso and Legendre2010; Kim et al. Reference Kim, Lee and Park2016), the results in figure 11(d) indicate that the bubble-induced turbulence is predominant even near the wall for the present flows. Note that Lu & Tryggvason (Reference Lu and Tryggvason2008), Dabiri et al. (Reference Dabiri, Lu and Tryggvason2013) and Du Cluzeau et al. (Reference Du Cluzeau, Bois and Toutant2019) indicated the existence of an interaction between the shear-induced and bubble-induced turbulence from their wall-bounded upward bubbly flows. Since their density ratios (![]() $\rho _{bubble} / \rho _{liquid}$) considered were about 100 times larger than that of the present study, their bubble-induced turbulence was much weaker than the present one, leading to different conclusions on the effect of the bubble-induced turbulence. The instantaneous flow structures regarding bubble-induced turbulence are discussed later in this paper. In Appendix B, we suggest a modified algebraic RANS model considering the interaction between shear-induced and bubble-induced turbulence for better predictions of the mean axial velocity and wall shear stress for a wider range of liquid bulk Reynolds numbers than those of the previous algebraic RANS model (Sato et al. Reference Sato, Sadatomi and Sekoguchi1981a).

$\rho _{bubble} / \rho _{liquid}$) considered were about 100 times larger than that of the present study, their bubble-induced turbulence was much weaker than the present one, leading to different conclusions on the effect of the bubble-induced turbulence. The instantaneous flow structures regarding bubble-induced turbulence are discussed later in this paper. In Appendix B, we suggest a modified algebraic RANS model considering the interaction between shear-induced and bubble-induced turbulence for better predictions of the mean axial velocity and wall shear stress for a wider range of liquid bulk Reynolds numbers than those of the previous algebraic RANS model (Sato et al. Reference Sato, Sadatomi and Sekoguchi1981a).

Figure 12 show the probability density functions (PDFs) of the axial velocity fluctuations with normalizations with and without ![]() $\bar \psi ^{0.4}$ at

$\bar \psi ^{0.4}$ at ![]() $r/R=0.88$ for three different

$r/R=0.88$ for three different ![]() $\langle \psi \rangle$. As

$\langle \psi \rangle$. As ![]() $\langle \psi \rangle$ increases, the peak of PDF normalized by

$\langle \psi \rangle$ increases, the peak of PDF normalized by ![]() $u_{bulk}$ decreases and the PDF becomes widened. On the other hand, when normalized by

$u_{bulk}$ decreases and the PDF becomes widened. On the other hand, when normalized by ![]() $u_{bulk} \bar \psi ^{0.4}$, the three PDFs collapse quite well as observed from homogeneous bubbly flows (Risso & Ellingsen Reference Risso and Ellingsen2002; Riboux et al. Reference Riboux, Risso and Legendre2010), again indicating that the bubble-induced turbulence is dominant for the present bubbly flows. Similar results are observed for the azimuthal and radial velocities and at other radial locations.

$u_{bulk} \bar \psi ^{0.4}$, the three PDFs collapse quite well as observed from homogeneous bubbly flows (Risso & Ellingsen Reference Risso and Ellingsen2002; Riboux et al. Reference Riboux, Risso and Legendre2010), again indicating that the bubble-induced turbulence is dominant for the present bubbly flows. Similar results are observed for the azimuthal and radial velocities and at other radial locations.

Figure 12. PDFs of the axial water velocity fluctuations at ![]() $r/R=0.88$ normalized by (a)

$r/R=0.88$ normalized by (a) ![]() $u_{bulk}$ and (b)

$u_{bulk}$ and (b) ![]() $u_{bulk} \bar {\psi }^{0.4}$: red, case ML; black, MM; blue, MH.

$u_{bulk} \bar {\psi }^{0.4}$: red, case ML; black, MM; blue, MH.

Figure 13 shows the profiles of the water Reynolds shear stress in the radial direction for the single-phase and bubbly flows. The Reynolds shear stress near the wall is much larger due to bubbles than that of the single-phase flow. With increasing ![]() $d_{eq}$ (cases SM, MM and LM), the Reynolds shear stress increases over all the radial locations except very near the centre where

$d_{eq}$ (cases SM, MM and LM), the Reynolds shear stress increases over all the radial locations except very near the centre where ![]() $\overline {u_r^\prime u_z^\prime }$ is close to zero. On the other hand, with increasing

$\overline {u_r^\prime u_z^\prime }$ is close to zero. On the other hand, with increasing ![]() $\langle \psi \rangle$ (cases ML, MM and MH), it increases more near the wall but does not change at the centre region (

$\langle \psi \rangle$ (cases ML, MM and MH), it increases more near the wall but does not change at the centre region (![]() $r < 0.5R$). Hence, normalization with

$r < 0.5R$). Hence, normalization with ![]() $\bar \psi ^{0.8}$ works only for the Reynolds normal stresses, not for the Reynolds shear stress, again indicating that the effect of the shear-induced turbulence is very weak for the present flows.