1. Introduction

Rapidly growing interest in utilizing chemical energy bound in renewable carbon-free fuels such as hydrogen highlights a fundamental challenge that has not yet received proper attention. The challenge consists of understanding and modelling strong differential diffusion effects in turbulent premixed flames. More specifically, the difference between molecular diffusivities of reactants or between the Lewis number ![]() $Le=D/\kappa$ and unity is well known to substantially affect the burning rate even in intense turbulence (Lipatnikov Reference Lipatnikov2012), with such effects being especially pronounced in lean hydrogen–air flames due to a high diffusivity of H

$Le=D/\kappa$ and unity is well known to substantially affect the burning rate even in intense turbulence (Lipatnikov Reference Lipatnikov2012), with such effects being especially pronounced in lean hydrogen–air flames due to a high diffusivity of H![]() $_2$. Here,

$_2$. Here, ![]() $D$ and

$D$ and ![]() $\kappa$ are molecular diffusivity of a deficient reactant (e.g. the fuel in a lean mixture) and molecular heat diffusivity of the mixture, respectively. For instance, significant influence of the aforementioned differences on turbulent flame speed

$\kappa$ are molecular diffusivity of a deficient reactant (e.g. the fuel in a lean mixture) and molecular heat diffusivity of the mixture, respectively. For instance, significant influence of the aforementioned differences on turbulent flame speed ![]() $S_t$ was documented in experiments by Wohl & Shore (Reference Wohl and Shore1955), Karpov & Sokolik (Reference Karpov and Sokolik1961), Karpov & Severin (Reference Karpov and Severin1980), Abdel-Gayed et al. (Reference Abdel-Gayed, Bradley, Hamid and Lawes1984a), Kido et al. (Reference Kido, Kitagawa, Nakashima and Kato1989), Wu et al. (Reference Wu, Kwon, Driscoll and Faeth1990) and in many other measurements reviewed elsewhere (Kuznetsov & Sabelnikov Reference Kuznetsov and Sabelnikov1990; Lipatnikov & Chomiak Reference Lipatnikov and Chomiak2005). Recently, an extremely high magnitude of such differential diffusion effects was reported by Yang et al. (Reference Yang, Saha, Liang, Wu and Law2018).

$S_t$ was documented in experiments by Wohl & Shore (Reference Wohl and Shore1955), Karpov & Sokolik (Reference Karpov and Sokolik1961), Karpov & Severin (Reference Karpov and Severin1980), Abdel-Gayed et al. (Reference Abdel-Gayed, Bradley, Hamid and Lawes1984a), Kido et al. (Reference Kido, Kitagawa, Nakashima and Kato1989), Wu et al. (Reference Wu, Kwon, Driscoll and Faeth1990) and in many other measurements reviewed elsewhere (Kuznetsov & Sabelnikov Reference Kuznetsov and Sabelnikov1990; Lipatnikov & Chomiak Reference Lipatnikov and Chomiak2005). Recently, an extremely high magnitude of such differential diffusion effects was reported by Yang et al. (Reference Yang, Saha, Liang, Wu and Law2018).

From the qualitative perspective, the discussed effects are known to stem from variations in the local temperature and mixture composition due to an imbalance of reactant and heat fluxes to/from thin reaction zones strained and curved by turbulent eddies (Kuznetsov & Sabelnikov Reference Kuznetsov and Sabelnikov1990; Bradley, Lau & Lawes Reference Bradley, Lau and Lawes1992; Lipatnikov & Chomiak Reference Lipatnikov and Chomiak2005; Lipatnikov Reference Lipatnikov2012). Similar effects are predicted by theories of laminar premixed flames stretched by large-scale flow perturbations (Matalon & Matkowsky Reference Matalon and Matkowsky1982; Pelcé & Clavin Reference Pelcé and Clavin1982; Zel'dovich et al. Reference Zel'dovich, Barenblatt, Librovich and Makhviladze1985; Class, Matkowsky & Klimenko Reference Class, Matkowsky and Klimenko2003; Kelley, Bechtold & Law Reference Kelley, Bechtold and Law2012), but these theories are rigorous for weak perturbations of the local flame speed only. However, the problem of predicting a strong increase in the turbulent burning rate due to differential diffusion has not yet been solved. On the contrary, the vast majority of numerical models of premixed turbulent combustion, discussed in widely cited books (Peters Reference Peters2000; Poinsot & Veynante Reference Poinsot and Veynante2005) and review papers (Veynante & Vervisch Reference Veynante and Vervisch2002; Bilger et al. Reference Bilger, Pope, Bray and Driscoll2005), disregard the influence of differences in molecular transport coefficients on ![]() $S_t$.

$S_t$.

While rapid progress in direct numerical simulation (DNS) of turbulent reacting flows has been yielding new opportunities for model development, recent DNS data do not seem to clarify understanding of the differential diffusion effects in highly turbulent premixed flames. On the one hand, a significant influence of differences in molecular transport coefficients on bulk and/or local burning rates was documented in single-step-chemistry (Chakraborty & Cant Reference Chakraborty and Cant2011; Chakraborty & Lipatnikov Reference Chakraborty and Lipatnikov2013a,Reference Chakraborty and Lipatnikovb; Chakraborty, Konstantinou & Lipatnikov Reference Chakraborty, Konstantinou and Lipatnikov2016) and complex-chemistry (Lapointe, Savard & Blanquart Reference Lapointe, Savard and Blanquart2015; Savard, Bobbit & Blanquart Reference Savard, Bobbit and Blanquart2015; Lapointe & Blanquart Reference Lapointe and Blanquart2016; Aspden, Day & Bell Reference Aspden, Day and Bell2019; Rieth et al. Reference Rieth, Gruber, Williams and Chen2021; Wiseman et al. Reference Wiseman, Rieth, Gruber, Dawson and Chen2021) DNS studies. On the other hand, recent DNS studies (Aspden, Day & Bell Reference Aspden, Day and Bell2011a,Reference Aspden, Day and Bellb, Reference Aspden, Day and Bell2016; Savard & Blanquart Reference Savard and Blanquart2014; Lapointe et al. Reference Lapointe, Savard and Blanquart2015; Savard et al. Reference Savard, Bobbit and Blanquart2015; Aspden et al. Reference Aspden, Day and Bell2019) have shown that, with increasing Karlovitz number ![]() $Ka$, conditioned profiles of various local mixture characteristics, e.g. the equivalence ratio, sampled from highly turbulent flames, tend to the counterpart profiles computed for the unity Lewis number unperturbed laminar flame.

$Ka$, conditioned profiles of various local mixture characteristics, e.g. the equivalence ratio, sampled from highly turbulent flames, tend to the counterpart profiles computed for the unity Lewis number unperturbed laminar flame.

These two apparently inconsistent findings do not necessarily contradict each other, e.g. both findings were reported by analysing the same DNS data in the same papers (Lapointe et al. Reference Lapointe, Savard and Blanquart2015; Savard et al. Reference Savard, Bobbit and Blanquart2015; Aspden et al. Reference Aspden, Day and Bell2019). Nevertheless, the latter finding (conditioned profiles) is often interpreted to evidence that ‘differential diffusion disappears when the turbulent diffusivity greatly exceeds the molecular diffusivity’ (Driscoll et al. Reference Driscoll, Chen, Skiba, Carter, Hawkes and Wang2020, p. 21) or ‘local phenomena such as differential diffusion become less important in a statistical sense’ at high ![]() $Ka$ (Nilsson et al. Reference Nilsson, Carlsson, Yu and Bai2018, p. 628). Such an interpretation is further prompted by (i) a suggestion to model highly turbulent flames by using an ‘effective Lewis number’ that involves turbulent Reynolds number

$Ka$ (Nilsson et al. Reference Nilsson, Carlsson, Yu and Bai2018, p. 628). Such an interpretation is further prompted by (i) a suggestion to model highly turbulent flames by using an ‘effective Lewis number’ that involves turbulent Reynolds number ![]() ${\textit {Re}}_t$ and tends to unity as

${\textit {Re}}_t$ and tends to unity as ![]() ${\textit {Re}}_t \rightarrow \infty$ (Savard & Blanquart Reference Savard and Blanquart2014; Savard et al. Reference Savard, Bobbit and Blanquart2015) and (ii) DNS data that indicate that, with increasing

${\textit {Re}}_t \rightarrow \infty$ (Savard & Blanquart Reference Savard and Blanquart2014; Savard et al. Reference Savard, Bobbit and Blanquart2015) and (ii) DNS data that indicate that, with increasing ![]() $Ka$, conditioned profiles of fuel consumption and heat release rates, sampled from the entire flame brush, approach the counterpart profiles obtained from the unity Lewis number unperturbed laminar flame (Lapointe et al. Reference Lapointe, Savard and Blanquart2015, figures 8 and 9). However, the present authors are not aware of an experimental study that shows mitigation of the influence of differential diffusion on turbulent burning rates with increasing

$Ka$, conditioned profiles of fuel consumption and heat release rates, sampled from the entire flame brush, approach the counterpart profiles obtained from the unity Lewis number unperturbed laminar flame (Lapointe et al. Reference Lapointe, Savard and Blanquart2015, figures 8 and 9). However, the present authors are not aware of an experimental study that shows mitigation of the influence of differential diffusion on turbulent burning rates with increasing ![]() $Ka$, whereas a well pronounced influence was documented at very high Karlovitz (Karpov & Severin Reference Karpov and Severin1980; Yang et al. Reference Yang, Saha, Liang, Wu and Law2018) or Reynolds (Wu et al. Reference Wu, Kwon, Driscoll and Faeth1990; Daniele et al. Reference Daniele, Jansohn, Mantzaras and Boulouchos2011) numbers, as well as at high ratios

$Ka$, whereas a well pronounced influence was documented at very high Karlovitz (Karpov & Severin Reference Karpov and Severin1980; Yang et al. Reference Yang, Saha, Liang, Wu and Law2018) or Reynolds (Wu et al. Reference Wu, Kwon, Driscoll and Faeth1990; Daniele et al. Reference Daniele, Jansohn, Mantzaras and Boulouchos2011) numbers, as well as at high ratios ![]() $u'/S_L=O(100)$ (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013) of the root mean square (r.m.s.) turbulent velocity

$u'/S_L=O(100)$ (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013) of the root mean square (r.m.s.) turbulent velocity ![]() $u'$ to the laminar flame speed

$u'$ to the laminar flame speed ![]() $S_L$.

$S_L$.

While consistency of the two discussed findings appears to be of significant fundamental and applied interest, the present authors are not aware of any target-directed research into this issue. Even if both findings were reported in the same DNS papers (Lapointe et al. Reference Lapointe, Savard and Blanquart2015; Savard et al. Reference Savard, Bobbit and Blanquart2015; Aspden et al. Reference Aspden, Day and Bell2019), discussion of their consistency was brief (if any) and their coexistence seems to be indirectly attributed to insufficiently high Karlovitz numbers. The goal of the present communication is to bridge this knowledge gap by analysing recent DNS data that show both findings.

The DNS attributes are summarized in the next section. Numerical results are reported and discussed in § 3, followed by concluding remarks.

2. DNS attributes

Three-dimensional simulations of statistically one-dimensional and planar (effects discussed in the following could be more pronounced in statistically curved turbulent flames, which are more common in applications), lean (the equivalence ratio ![]() $\phi = 0.5$) hydrogen–air premixed flames propagating in forced turbulence under room conditions were performed employing the solver DINO (Abdelsamie et al. Reference Abdelsamie, Fru, Oster, Dietzsch, Janiga and Thévenin2016). It involves a sixth-order finite-difference central stencil and a semi-implicit third-order Runge–Kutta method for time integration in order to numerically solve the low-Mach-number formulation of the Navier–Stokes equations, as well as energy and species transport equations where chemical kinetics and mixture-averaged molecular transport are modelled using open-source library Cantera-2.3 (Goodwin et al. Reference Goodwin, Malaya, Moffat and Speth2009). A detailed chemical mechanism (nine species and 22 reversible reactions) by Kéromnès et al. (Reference Kéromnès2013) was adopted in the simulations.

$\phi = 0.5$) hydrogen–air premixed flames propagating in forced turbulence under room conditions were performed employing the solver DINO (Abdelsamie et al. Reference Abdelsamie, Fru, Oster, Dietzsch, Janiga and Thévenin2016). It involves a sixth-order finite-difference central stencil and a semi-implicit third-order Runge–Kutta method for time integration in order to numerically solve the low-Mach-number formulation of the Navier–Stokes equations, as well as energy and species transport equations where chemical kinetics and mixture-averaged molecular transport are modelled using open-source library Cantera-2.3 (Goodwin et al. Reference Goodwin, Malaya, Moffat and Speth2009). A detailed chemical mechanism (nine species and 22 reversible reactions) by Kéromnès et al. (Reference Kéromnès2013) was adopted in the simulations.

A rectangular computational domain of ![]() $\varLambda \times \beta \varLambda \times \varLambda$, where

$\varLambda \times \beta \varLambda \times \varLambda$, where ![]() $\varLambda =2.4$ mm, was discretized using a uniform Cartesian grid of

$\varLambda =2.4$ mm, was discretized using a uniform Cartesian grid of ![]() $N \times \beta N \times N$ cells. The values of

$N \times \beta N \times N$ cells. The values of ![]() $N$ are reported in table 1, with

$N$ are reported in table 1, with ![]() $\beta =18$ in cases A, B, A1 and B1 and

$\beta =18$ in cases A, B, A1 and B1 and ![]() $\beta =16$ in other four cases. Periodic boundary conditions were imposed along the

$\beta =16$ in other four cases. Periodic boundary conditions were imposed along the ![]() $x$ and

$x$ and ![]() $z$ directions, and inflow and outflow boundary conditions were set along the streamwise

$z$ directions, and inflow and outflow boundary conditions were set along the streamwise ![]() $y$ direction.

$y$ direction.

Table 1. Characteristic parameters of DNS cases.

At the inlet, the r.m.s. velocity was equal to 0.05 m s![]() $^{-1}$, with turbulence being generated using the linear velocity forcing method (Lundgren Reference Lundgren2003; Rosales & Meneveau Reference Rosales and Meneveau2005; Carroll & Blanquart Reference Carroll and Blanquart2014) between

$^{-1}$, with turbulence being generated using the linear velocity forcing method (Lundgren Reference Lundgren2003; Rosales & Meneveau Reference Rosales and Meneveau2005; Carroll & Blanquart Reference Carroll and Blanquart2014) between ![]() $y=0.5 \varLambda$ and

$y=0.5 \varLambda$ and ![]() $y=8 \varLambda$. At the beginning of each case, constant-density turbulence was simulated for at least

$y=8 \varLambda$. At the beginning of each case, constant-density turbulence was simulated for at least ![]() $50 \tau _t$. Here,

$50 \tau _t$. Here, ![]() $\tau _t=L/u'$ is the eddy turnover time, and the integral length scale

$\tau _t=L/u'$ is the eddy turnover time, and the integral length scale ![]() $L$ is approximately equal to

$L$ is approximately equal to ![]() $0.19 \varLambda$ (Lundgren Reference Lundgren2003; Rosales & Meneveau Reference Rosales and Meneveau2005; Carroll & Blanquart Reference Carroll and Blanquart2014). Turbulence generation and forcing methods used in the present study, as well as turbulence characteristics within the flame brushes, are discussed in a more detail manner elsewhere (Lee et al. Reference Lee, Dai, Wan and Lipatnikov2021a).

$0.19 \varLambda$ (Lundgren Reference Lundgren2003; Rosales & Meneveau Reference Rosales and Meneveau2005; Carroll & Blanquart Reference Carroll and Blanquart2014). Turbulence generation and forcing methods used in the present study, as well as turbulence characteristics within the flame brushes, are discussed in a more detail manner elsewhere (Lee et al. Reference Lee, Dai, Wan and Lipatnikov2021a).

Subsequently, the steady unperturbed laminar flame solution yielded by Cantera-2.3 (Goodwin et al. Reference Goodwin, Malaya, Moffat and Speth2009) was embedded into the flow field, followed by the flame propagation along the ![]() $y$-axis from right to left. When necessary, the mean inlet velocity was adjusted in order to retain the flame within the forced-flow subdomain where the transverse-averaged turbulent kinetic energy varied weakly along the

$y$-axis from right to left. When necessary, the mean inlet velocity was adjusted in order to retain the flame within the forced-flow subdomain where the transverse-averaged turbulent kinetic energy varied weakly along the ![]() $y$-axis or in time (Lee et al. Reference Lee, Dai, Wan and Lipatnikov2021a, figure 2). As a result, the flame brush never approached the inlet boundary, with the distance between the flame leading edge and the boundary being always larger than

$y$-axis or in time (Lee et al. Reference Lee, Dai, Wan and Lipatnikov2021a, figure 2). As a result, the flame brush never approached the inlet boundary, with the distance between the flame leading edge and the boundary being always larger than ![]() $0.5 \varLambda$.

$0.5 \varLambda$.

The combustion simulations were performed for at least ![]() $28 \tau _t$. Time-dependent mean quantities

$28 \tau _t$. Time-dependent mean quantities ![]() $\langle q \rangle (y,t)$ were evaluated by averaging the field

$\langle q \rangle (y,t)$ were evaluated by averaging the field ![]() $q(\boldsymbol {x},t)$ over transverse plane

$q(\boldsymbol {x},t)$ over transverse plane ![]() ${y={\rm const}}$. Statistically stationary mean quantities

${y={\rm const}}$. Statistically stationary mean quantities ![]() $\bar {q}(y)$ were computed by averaging

$\bar {q}(y)$ were computed by averaging ![]() $\langle q \rangle (y,t)$ over time at

$\langle q \rangle (y,t)$ over time at ![]() $t/\tau _t>t^*$, where

$t/\tau _t>t^*$, where ![]() $t^*=6$, 10 and 15 in cases A, B and C, respectively – see vertical dashed lines in figure 1. The combustion progress variable was defined using the fuel mass fraction, i.e.

$t^*=6$, 10 and 15 in cases A, B and C, respectively – see vertical dashed lines in figure 1. The combustion progress variable was defined using the fuel mass fraction, i.e. ![]() $c=(Y_{\textrm {H}_2,u}-Y_{\textrm {H}_2})/Y_{\textrm {H}_2,u}$. The local equivalence ratio,

$c=(Y_{\textrm {H}_2,u}-Y_{\textrm {H}_2})/Y_{\textrm {H}_2,u}$. The local equivalence ratio, ![]() $\phi$, flame curvature,

$\phi$, flame curvature, ![]() $h_m$, and strain rate,

$h_m$, and strain rate, ![]() $a_t$, were calculated as follows:

$a_t$, were calculated as follows:

Here, ![]() $\boldsymbol {n}=-\boldsymbol {\nabla } c/|\boldsymbol {\nabla } c|$ is the unit normal vector and, consequently, the curvature is positive when its centre is in combustion products,

$\boldsymbol {n}=-\boldsymbol {\nabla } c/|\boldsymbol {\nabla } c|$ is the unit normal vector and, consequently, the curvature is positive when its centre is in combustion products, ![]() $\boldsymbol {u}$ designates the flow velocity field and

$\boldsymbol {u}$ designates the flow velocity field and ![]() $X_k$ is the mole fraction of species

$X_k$ is the mole fraction of species ![]() $k$.

$k$.

Figure 1. Evolution of the normalized turbulent burning velocities ![]() $U_t^F/S_L$ (red lines) and

$U_t^F/S_L$ (red lines) and ![]() $U_t^{T}/S_L$ (black lines) in flames (a) A and A1, (b) B and B1, (c) C and C1. Results obtained from low and unity Lewis number flames are plotted in solid and dashed lines, respectively. Horizontal straight lines show mean values.

$U_t^{T}/S_L$ (black lines) in flames (a) A and A1, (b) B and B1, (c) C and C1. Results obtained from low and unity Lewis number flames are plotted in solid and dashed lines, respectively. Horizontal straight lines show mean values.

The simulation conditions are reported in table 1, where ![]() $\delta _L=(T_b-T_u)/max\{|\textrm {d} T/{\textrm {d}x}|\}$ and

$\delta _L=(T_b-T_u)/max\{|\textrm {d} T/{\textrm {d}x}|\}$ and ![]() $\tau _f=\delta _L/S_L$ are the laminar flame thickness and time scale, respectively;

$\tau _f=\delta _L/S_L$ are the laminar flame thickness and time scale, respectively; ![]() $Da=\tau _t/\tau _f$,

$Da=\tau _t/\tau _f$, ![]() $Ka=(u'/S_L)^{3/2} (\delta _L/L)^{1/2}$ and

$Ka=(u'/S_L)^{3/2} (\delta _L/L)^{1/2}$ and ![]() ${\textit {Re}}_t=u'L/\nu _u$ are the Damköhler, Karlovitz and turbulent Reynolds numbers, respectively;

${\textit {Re}}_t=u'L/\nu _u$ are the Damköhler, Karlovitz and turbulent Reynolds numbers, respectively; ![]() $T$ is the temperature;

$T$ is the temperature; ![]() $\nu _u$ is the kinematic viscosity of unburned mixture;

$\nu _u$ is the kinematic viscosity of unburned mixture; ![]() ${\rm \Delta} x$ is the grid size;

${\rm \Delta} x$ is the grid size; ![]() $\eta =L Re_t^{-3/4}$ is the Kolmogorov length scale; subscripts

$\eta =L Re_t^{-3/4}$ is the Kolmogorov length scale; subscripts ![]() $u$ and

$u$ and ![]() $b$ designate unburned and burned fluid, respectively.

$b$ designate unburned and burned fluid, respectively.

Cases A, B and C are characterized by (i) a low Lewis number ![]() $Le=0.32$ and (ii) different r.m.s. velocities

$Le=0.32$ and (ii) different r.m.s. velocities ![]() $u'$, which are increased from case A to case C. Cases A1, B1 and C1 correspond to cases A, B and C, respectively, with molecular diffusivities being set equal to

$u'$, which are increased from case A to case C. Cases A1, B1 and C1 correspond to cases A, B and C, respectively, with molecular diffusivities being set equal to ![]() $\kappa$ for each species. Thus,

$\kappa$ for each species. Thus, ![]() $Le=1$ in cases A1, B1 and C1. Since an increase in

$Le=1$ in cases A1, B1 and C1. Since an increase in ![]() $Le$ results in increasing the unperturbed laminar flame speed (Zel'dovich et al. Reference Zel'dovich, Barenblatt, Librovich and Makhviladze1985), Damköhler or Karlovitz numbers are different in each pair of the considered cases. Cases C1/H and C1/H2 are intermediate between cases C and C1, i.e. molecular diffusivities of all species with the exception of H and H

$Le$ results in increasing the unperturbed laminar flame speed (Zel'dovich et al. Reference Zel'dovich, Barenblatt, Librovich and Makhviladze1985), Damköhler or Karlovitz numbers are different in each pair of the considered cases. Cases C1/H and C1/H2 are intermediate between cases C and C1, i.e. molecular diffusivities of all species with the exception of H and H![]() $_2$, respectively, are equal to

$_2$, respectively, are equal to ![]() $\kappa$, as in case C1, whereas molecular diffusivity of H or H

$\kappa$, as in case C1, whereas molecular diffusivity of H or H![]() $_2$ is equal to its mixture-averaged value used in case C.

$_2$ is equal to its mixture-averaged value used in case C.

The adopted numerical meshes ensure 11 grid points across the thickness ![]() $\delta _L$ in cases A, A1, B and B1 and more than 20 grid points in cases C, C1, C1/H and C1/H2 characterized by the highest Karlovitz numbers. In all cases, the Kolmogorov length scale is greater than half the grid size, thus, indicating acceptable resolution of the turbulent flow (Yeung & Pope Reference Yeung and Pope1989).

$\delta _L$ in cases A, A1, B and B1 and more than 20 grid points in cases C, C1, C1/H and C1/H2 characterized by the highest Karlovitz numbers. In all cases, the Kolmogorov length scale is greater than half the grid size, thus, indicating acceptable resolution of the turbulent flow (Yeung & Pope Reference Yeung and Pope1989).

In addition to the DNS of turbulent flames, stationary laminar flames were simulated using the same chemical mechanism (Kéromnès et al. Reference Kéromnès2013) and open-access code Cantera (Goodwin et al. Reference Goodwin, Malaya, Moffat and Speth2009). Such computations were performed for unperturbed flames in cases of ![]() $Le=0.32$ and

$Le=0.32$ and ![]() $Le=1$ and for planar one-dimensional counterflow flames at different strain rates. The counterflow flames were used for comparison following common practice (Aspden et al. Reference Aspden, Day and Bell2011a,Reference Aspden, Day and Bellb, Reference Aspden, Day and Bell2019; Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013; Savard & Blanquart Reference Savard and Blanquart2014; Amato et al. Reference Amato, Day, Cheng, Bell, Dasgupta and Lieuwen2015a,Reference Amato, Day, Cheng, Bell and Lieuwenb; Lapointe et al. Reference Lapointe, Savard and Blanquart2015; Savard et al. Reference Savard, Bobbit and Blanquart2015; Lapointe & Blanquart Reference Lapointe and Blanquart2016; Zhang et al. Reference Zhang, Wang, Yu, Jin, Zhang and Huang2018; Driscoll et al. Reference Driscoll, Chen, Skiba, Carter, Hawkes and Wang2020).

$Le=1$ and for planar one-dimensional counterflow flames at different strain rates. The counterflow flames were used for comparison following common practice (Aspden et al. Reference Aspden, Day and Bell2011a,Reference Aspden, Day and Bellb, Reference Aspden, Day and Bell2019; Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013; Savard & Blanquart Reference Savard and Blanquart2014; Amato et al. Reference Amato, Day, Cheng, Bell, Dasgupta and Lieuwen2015a,Reference Amato, Day, Cheng, Bell and Lieuwenb; Lapointe et al. Reference Lapointe, Savard and Blanquart2015; Savard et al. Reference Savard, Bobbit and Blanquart2015; Lapointe & Blanquart Reference Lapointe and Blanquart2016; Zhang et al. Reference Zhang, Wang, Yu, Jin, Zhang and Huang2018; Driscoll et al. Reference Driscoll, Chen, Skiba, Carter, Hawkes and Wang2020).

3. Results and discussion

3.1. Turbulent burning velocities and conditioned profiles

Figure 1 reports evolution of turbulent burning velocities (i) ![]() $U_t^F(t)$ evaluated by integrating the fuel consumption rate

$U_t^F(t)$ evaluated by integrating the fuel consumption rate ![]() $\dot {\omega }_{\textrm {H}_2} (\boldsymbol {x},t)$ over the computational domain, i.e.

$\dot {\omega }_{\textrm {H}_2} (\boldsymbol {x},t)$ over the computational domain, i.e.

or (ii) ![]() $U_t^{T}(t)$ obtained by integrating the heat release rate

$U_t^{T}(t)$ obtained by integrating the heat release rate ![]() $\dot {\omega }_{T} (\boldsymbol {x},t)=\sum _{k=1}^{N_{sp}} h_k \dot {\omega }_k (\boldsymbol {x},t)$ over the computational domain, i.e.

$\dot {\omega }_{T} (\boldsymbol {x},t)=\sum _{k=1}^{N_{sp}} h_k \dot {\omega }_k (\boldsymbol {x},t)$ over the computational domain, i.e.

Here, ![]() $\rho$ and

$\rho$ and ![]() $Y$ designate density and mass fraction, respectively;

$Y$ designate density and mass fraction, respectively; ![]() $h_k$ and

$h_k$ and ![]() $\dot {\omega }_k$ are the enthalpy and the rate of production, respectively, of species

$\dot {\omega }_k$ are the enthalpy and the rate of production, respectively, of species ![]() $k$;

$k$; ![]() $c_p$ is the heat capacity of the mixture;

$c_p$ is the heat capacity of the mixture; ![]() $N_{sp}=9$ is the number of species. These results have been obtained from flames (a) A and A1, (b) B and B1, (c) C and C1. Results computed in cases C1/H and C1/H2 will be discussed later.

$N_{sp}=9$ is the number of species. These results have been obtained from flames (a) A and A1, (b) B and B1, (c) C and C1. Results computed in cases C1/H and C1/H2 will be discussed later.

After an initial stage, each computed curve oscillates around a mean value of ![]() $U_t^F/S_L$ or

$U_t^F/S_L$ or ![]() $U_t^{T}/S_L$ – see horizontal straight lines in figure 1. These mean values averaged at

$U_t^{T}/S_L$ – see horizontal straight lines in figure 1. These mean values averaged at ![]() $t/\tau _t>t^*$ and the dimensional mean values of

$t/\tau _t>t^*$ and the dimensional mean values of ![]() $U_t^F$ and

$U_t^F$ and ![]() $U_t^{T}$ are reported in table 1. The results obtained for

$U_t^{T}$ are reported in table 1. The results obtained for ![]() $U_t^F$ and

$U_t^F$ and ![]() $U_t^{T}$ are close to one another, thus, indicating that fuel consumption and heat release are in an equilibrium state on the global level, as expected. However, such an equilibrium state is not observed on the local level, as will be discussed later.

$U_t^{T}$ are close to one another, thus, indicating that fuel consumption and heat release are in an equilibrium state on the global level, as expected. However, such an equilibrium state is not observed on the local level, as will be discussed later.

Figure 1 and table 1 show that, in line with numerous experimental and DNS data discussed in the introduction, the present simulations do predict a significant increase in ![]() $U_t^F/S_L$ or

$U_t^F/S_L$ or ![]() $U_t^{T}/S_L$ with decreasing

$U_t^{T}/S_L$ with decreasing ![]() $Le$. It is of interest to note that the effect magnitude is increased by

$Le$. It is of interest to note that the effect magnitude is increased by ![]() $Ka$ under conditions of the present study. Indeed, a ratio of

$Ka$ under conditions of the present study. Indeed, a ratio of ![]() $(U_t^F/S_L)_{Le<1}/(U_t^F/S_L)_{Le=1}$ is equal to 1.5, 1.7 and 2.1 in the A, B and C, pairs of flames, respectively. Thus, the computed bulk turbulent burning velocities do not indicate that molecular transport is dominated by turbulent mixing in the studied flames.

$(U_t^F/S_L)_{Le<1}/(U_t^F/S_L)_{Le=1}$ is equal to 1.5, 1.7 and 2.1 in the A, B and C, pairs of flames, respectively. Thus, the computed bulk turbulent burning velocities do not indicate that molecular transport is dominated by turbulent mixing in the studied flames.

On the contrary, the conditioned profiles of the temperature, equivalence ratio, fuel consumption rate, heat release rate and species mass fractions, e.g. mass fraction of the radical H, extracted from the entire computational domain at ![]() $t/\tau _t>t^*$ and plotted in figures 2(a), 3(a), 4(a), 5(a) and 6(a), respectively, suggest the opposite conclusion, i.e. molecular transport is dominated by turbulent mixing at least in case C characterized by the highest Karlovitz number. Indeed, in this case, the conditioned profiles of

$t/\tau _t>t^*$ and plotted in figures 2(a), 3(a), 4(a), 5(a) and 6(a), respectively, suggest the opposite conclusion, i.e. molecular transport is dominated by turbulent mixing at least in case C characterized by the highest Karlovitz number. Indeed, in this case, the conditioned profiles of ![]() $\langle T \,|\, c \rangle (c)$,

$\langle T \,|\, c \rangle (c)$, ![]() $\langle \phi \,|\, c \rangle (c)$,

$\langle \phi \,|\, c \rangle (c)$, ![]() $\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$,

$\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$, ![]() $\langle \dot {\omega }_T \,|\, c \rangle (c)$ and

$\langle \dot {\omega }_T \,|\, c \rangle (c)$ and ![]() $\langle Y_{\textrm {H}} \,|\, c \rangle (c)$ (see blue dotted–dashed lines) differ significantly from the counterpart profiles obtained from the unperturbed (see squares) or highly strained (see circles) stationary planar laminar premixed flames characterized by

$\langle Y_{\textrm {H}} \,|\, c \rangle (c)$ (see blue dotted–dashed lines) differ significantly from the counterpart profiles obtained from the unperturbed (see squares) or highly strained (see circles) stationary planar laminar premixed flames characterized by ![]() $Le=0.32$. However, the conditioned profiles are sufficiently close to the counterpart profiles obtained from the unperturbed unity Lewis number flame (see pentagons). In particular, the profiles of

$Le=0.32$. However, the conditioned profiles are sufficiently close to the counterpart profiles obtained from the unperturbed unity Lewis number flame (see pentagons). In particular, the profiles of ![]() $\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$ are very close in the low Lewis number turbulent flame C and in the unity Lewis number unperturbed laminar flame, cf. blue dotted–dashed line and pentagons in figure 4(a). Even in cases B and A, the conditioned profiles are closer to the laminar-flame profiles computed for

$\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$ are very close in the low Lewis number turbulent flame C and in the unity Lewis number unperturbed laminar flame, cf. blue dotted–dashed line and pentagons in figure 4(a). Even in cases B and A, the conditioned profiles are closer to the laminar-flame profiles computed for ![]() $Le=1$ when compared with the low Lewis number flame profiles.

$Le=1$ when compared with the low Lewis number flame profiles.

Figure 2. Time-averaged conditioned profiles of temperature extracted (a) from the entire computational domain, and at (b) ![]() $\langle c_F \rangle =0.1 \pm 0.02$, (c)

$\langle c_F \rangle =0.1 \pm 0.02$, (c) ![]() $\langle c_F \rangle =0.5 \pm 0.02$, (d)

$\langle c_F \rangle =0.5 \pm 0.02$, (d) ![]() $\langle c_F \rangle =0.9 \pm 0.02$. Results computed in cases A, B and C are plotted using black solid, red dashed and blue dotted–dashed lines, respectively. Squares, pentagons and circles show profiles computed for the unperturbed laminar low Lewis number flame, the unperturbed laminar unity Lewis number flame, and critically strained (the strain rate is equal to

$\langle c_F \rangle =0.9 \pm 0.02$. Results computed in cases A, B and C are plotted using black solid, red dashed and blue dotted–dashed lines, respectively. Squares, pentagons and circles show profiles computed for the unperturbed laminar low Lewis number flame, the unperturbed laminar unity Lewis number flame, and critically strained (the strain rate is equal to ![]() $11.3/ \tau _f$), planar, stationary laminar low Lewis number flame, respectively.

$11.3/ \tau _f$), planar, stationary laminar low Lewis number flame, respectively.

Figure 3. Time-averaged conditioned profiles of equivalence ratio. Legends are explained in the caption of figure 2.

Figure 4. Time-averaged conditioned profiles of fuel consumption rate. Legends are explained in the caption of figure 2.

Figure 5. Time-averaged conditioned profiles of heat release rate. Legends are explained in the caption of figure 2.

Figure 6. Time-averaged conditioned profiles of hydrogen mass fraction ![]() $Y_{\textrm {H}}$. Legends are explained in the caption of figure 2.

$Y_{\textrm {H}}$. Legends are explained in the caption of figure 2.

It is worth remembering that if ![]() $Le$ is increased from 0.32 to 1.0,

$Le$ is increased from 0.32 to 1.0, ![]() $S_L$ is also increased – see table 1. Such an effect might be assumed to cause a higher

$S_L$ is also increased – see table 1. Such an effect might be assumed to cause a higher ![]() $U_t$ if molecular transport associated with a low Lewis number for lean hydrogen–air flames is dominated by turbulent mixing associated with

$U_t$ if molecular transport associated with a low Lewis number for lean hydrogen–air flames is dominated by turbulent mixing associated with ![]() $Le=1$. However, the last two columns in table 1 show that the dimensional

$Le=1$. However, the last two columns in table 1 show that the dimensional ![]() $\bar {U}_t^F$ or

$\bar {U}_t^F$ or ![]() $\bar {U}_t^{T}$ is significantly higher in case C when compared with case C1 characterized by a larger

$\bar {U}_t^{T}$ is significantly higher in case C when compared with case C1 characterized by a larger ![]() $S_L$. Therefore, the high

$S_L$. Therefore, the high ![]() $\bar {U}_t^F$ or

$\bar {U}_t^F$ or ![]() $\bar {U}_t^{T}$ in case C should not be attributed to an increase from

$\bar {U}_t^{T}$ in case C should not be attributed to an increase from ![]() $S_L(Le=0.32)=0.58$ to

$S_L(Le=0.32)=0.58$ to ![]() $S_L(Le=1.0)=0.78$ m s

$S_L(Le=1.0)=0.78$ m s![]() $^{-1}$.

$^{-1}$.

Thus, the DNS data involve both findings emphasized in the introduction and, consequently, are suitable for exploring their consistency, e.g. consistency of figure 1, which shows a significant influence of differential diffusion on the integrated fuel consumption or heat release rate, and figure 4(a) or 5(a), which shows that the conditioned fuel consumption rate ![]() $\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$ or heat release rate

$\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle (c)$ or heat release rate ![]() $\langle \dot {\omega }_T \,|\, c \rangle (c)$, respectively, sampled from the entire flame brush in case C approaches

$\langle \dot {\omega }_T \,|\, c \rangle (c)$, respectively, sampled from the entire flame brush in case C approaches ![]() $\dot {\omega }_{\textrm {H}_2}(c)$ or

$\dot {\omega }_{\textrm {H}_2}(c)$ or ![]() $\dot {\omega }_T(c)$, respectively, in the unperturbed unity Lewis number laminar flame.

$\dot {\omega }_T(c)$, respectively, in the unperturbed unity Lewis number laminar flame.

The apparent inconsistency between the DNS results plotted in figure 1 and figures 2(a), 3(a), 4(a), 5(a) and 6(a) is explained in figures 2–6, where conditioned profiles extracted from (b) leading, (c) median and (d) trailing layers of the mean flame brushes are reported. These three layers are characterized by the transverse-averaged combustion progress variable ![]() $\langle c \rangle (y,t)$ approximately (

$\langle c \rangle (y,t)$ approximately (![]() $\pm 0.02$) 0.1, 0.5 and 0.9, respectively. While the median conditioned profiles plotted in figures 2(c), 3(c), 4(c), 5(c) and 6(c) look similar to the conditioned profiles sampled from the entire computational domain, this is not so for the leading or trailing conditioned profiles. More specifically, the conditioned profiles (with the exception of

$\pm 0.02$) 0.1, 0.5 and 0.9, respectively. While the median conditioned profiles plotted in figures 2(c), 3(c), 4(c), 5(c) and 6(c) look similar to the conditioned profiles sampled from the entire computational domain, this is not so for the leading or trailing conditioned profiles. More specifically, the conditioned profiles (with the exception of ![]() $\langle \dot {\omega }_T \,|\, c \rangle$ in case C) sampled from the trailing layer are closer to the counterpart conditioned profiles obtained from the unperturbed low Lewis number laminar flame, cf. lines and squares in figures 2(d), 3(d), 4(d), 5(d) and 6(d). On the contrary, the conditioned profiles of

$\langle \dot {\omega }_T \,|\, c \rangle$ in case C) sampled from the trailing layer are closer to the counterpart conditioned profiles obtained from the unperturbed low Lewis number laminar flame, cf. lines and squares in figures 2(d), 3(d), 4(d), 5(d) and 6(d). On the contrary, the conditioned profiles of ![]() $\langle \phi \,|\, c \rangle (c)$,

$\langle \phi \,|\, c \rangle (c)$, ![]() $\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle$ and

$\langle \dot {\omega }_{\textrm {H}_2} \,|\, c \rangle$ and ![]() $\langle Y_{\textrm {H}} \,|\, c \rangle$ sampled from the leading layer are closer (for temperature, this trend is only pronounced at

$\langle Y_{\textrm {H}} \,|\, c \rangle$ sampled from the leading layer are closer (for temperature, this trend is only pronounced at ![]() $c>0.7$, cf. lines and circles in figure 2b, whereas the profiles of

$c>0.7$, cf. lines and circles in figure 2b, whereas the profiles of ![]() $T(c)$ obtained from the unperturbed unity Lewis number and highly strained low Lewis number laminar flames are close to one another at

$T(c)$ obtained from the unperturbed unity Lewis number and highly strained low Lewis number laminar flames are close to one another at ![]() $c<0.7$; for heat release rate, the discussed trend is weakly (if any) pronounced – see figure 5b) to the counterpart conditioned profiles obtained from the highly strained low Lewis number laminar flame, cf. lines and circles in figures 3(b), 4(b), and 6(b). It is also worth stressing that the peak fuel consumption rate evaluated at

$c<0.7$; for heat release rate, the discussed trend is weakly (if any) pronounced – see figure 5b) to the counterpart conditioned profiles obtained from the highly strained low Lewis number laminar flame, cf. lines and circles in figures 3(b), 4(b), and 6(b). It is also worth stressing that the peak fuel consumption rate evaluated at ![]() $\langle c \rangle =0.1 \pm 0.02$ is significantly higher than the peak rates in the unperturbed laminar flames (both

$\langle c \rangle =0.1 \pm 0.02$ is significantly higher than the peak rates in the unperturbed laminar flames (both ![]() $Le=0.32$ and

$Le=0.32$ and ![]() $Le=1.0$), but is close to the peak rate in the highly strained low Lewis number laminar flame. Thus, under conditions of the present simulations, apparent dominance of turbulent mixing, implied by the results shown in figures 2(a), 3(a), 4(a), 5(a) and 6(a) is an artefact of sampling statistics from the entire computational domain, whereas molecular transport plays an important role in the leading and trailing zones of the mean flame brush and significantly affects bulk turbulent burning velocity.

$Le=1.0$), but is close to the peak rate in the highly strained low Lewis number laminar flame. Thus, under conditions of the present simulations, apparent dominance of turbulent mixing, implied by the results shown in figures 2(a), 3(a), 4(a), 5(a) and 6(a) is an artefact of sampling statistics from the entire computational domain, whereas molecular transport plays an important role in the leading and trailing zones of the mean flame brush and significantly affects bulk turbulent burning velocity.

The results reported in figures 1–6 raise at least three questions.

(i) Why are differential diffusion effects more pronounced at the edges of the mean flame brush?

(ii) Why is turbulent burning velocity more sensitive to differential diffusion effects localized to the leading edge?

(iii) Why do trends observed for the conditioned profile of heat release rate, sampled from the leading edge (see figure 5b) differ from trends observed for the conditioned profiles of fuel consumption rate (see figure 4b)?

These three questions, and one more, are discussed in the next four subsections, with the focus of discussion being placed on a family of C-flames (C and C1, as well as C1/H and C1/H![]() $_2$, which will be discussed later), because they are characterized by higher Karlovitz numbers when compared with four other flames (A1, A1, B and B1).

$_2$, which will be discussed later), because they are characterized by higher Karlovitz numbers when compared with four other flames (A1, A1, B and B1).

3.2. Why are differential diffusion effects more pronounced at the leading edge?

The most evident explanation of a significant increase in the equivalence ratio, fuel consumption rate or mass fraction of H at the leading edge of a mean flame brush consists of highlighting effects that stem from the local curvature of reaction zones. Indeed, first, from purely topological reasoning, local flame curvature should be predominantly positive at low ![]() $\langle c \rangle$ and predominantly negative at large

$\langle c \rangle$ and predominantly negative at large ![]() $\langle c \rangle$. A decrease (increase) in the probability of finding positively (negatively) curved flames with

$\langle c \rangle$. A decrease (increase) in the probability of finding positively (negatively) curved flames with ![]() $\langle c \rangle$ was documented in earlier DNS studies (Sabelnikov et al. Reference Sabelnikov, Lipatnikov, Nishiki, Dave, Hernández-Pérez, Song and Im2021, figure 8a). This trend is also observed in figure 7, with the probability of finding highly curved reaction zones being large at low

$\langle c \rangle$ was documented in earlier DNS studies (Sabelnikov et al. Reference Sabelnikov, Lipatnikov, Nishiki, Dave, Hernández-Pérez, Song and Im2021, figure 8a). This trend is also observed in figure 7, with the probability of finding highly curved reaction zones being large at low ![]() $\bar {c}$.

$\bar {c}$.

Figure 7. Probabilities of finding ![]() $\delta _L h_m>1$ (black solid line) and

$\delta _L h_m>1$ (black solid line) and ![]() $\delta _L h_m<-1$ (red dashed line) versus transverse and time-averaged combustion progress variable

$\delta _L h_m<-1$ (red dashed line) versus transverse and time-averaged combustion progress variable ![]() $\bar {c}$. The probabilities have been sampled from flame zones characterized by a sufficiently high local fuel consumption rate (larger than 10 % of its peak value in the unperturbed laminar flame); case C.

$\bar {c}$. The probabilities have been sampled from flame zones characterized by a sufficiently high local fuel consumption rate (larger than 10 % of its peak value in the unperturbed laminar flame); case C.

Second, theories of laminar premixed flames stretched by large-scale flow perturbations (Matalon & Matkowsky Reference Matalon and Matkowsky1982; Pelcé & Clavin Reference Pelcé and Clavin1982; Zel'dovich et al. Reference Zel'dovich, Barenblatt, Librovich and Makhviladze1985; Class et al. Reference Class, Matkowsky and Klimenko2003; Kelley et al. Reference Kelley, Bechtold and Law2012) predict a significant influence of flame curvature on the local burning rate and, in particular, an increase in the burning rate in positively curved flames if ![]() $Le<1$. This increase stems from the local (i) enrichment (for lean hydrogen–air flames) and (ii) preheating of the reaction zone due, respectively, to imbalances of (i) molecular fluxes of fuel and oxygen towards the reaction zone and (ii) molecular fluxes of the reactants towards the zone and molecular heat transfer from it.

$Le<1$. This increase stems from the local (i) enrichment (for lean hydrogen–air flames) and (ii) preheating of the reaction zone due, respectively, to imbalances of (i) molecular fluxes of fuel and oxygen towards the reaction zone and (ii) molecular fluxes of the reactants towards the zone and molecular heat transfer from it.

For instance, the molecular diffusion term in the transport equation for a species mass fraction ![]() $Y_k$ can be decomposed as follows (Peters Reference Peters2000):

$Y_k$ can be decomposed as follows (Peters Reference Peters2000):

where ![]() $\boldsymbol {n}_k=-\boldsymbol {\nabla } Y_k/|\boldsymbol {\nabla } Y_k|$ is the unit vector normal to an isosurface of

$\boldsymbol {n}_k=-\boldsymbol {\nabla } Y_k/|\boldsymbol {\nabla } Y_k|$ is the unit vector normal to an isosurface of ![]() $Y_k(\boldsymbol {x},t)=$const. Term

$Y_k(\boldsymbol {x},t)=$const. Term ![]() $T_2$ is directly proportional to curvature of the isosurface and is known as curvature term. For major reactants (H

$T_2$ is directly proportional to curvature of the isosurface and is known as curvature term. For major reactants (H![]() $_2$ and O

$_2$ and O![]() $_2$), this term is positive in a positively curved (i.e.

$_2$), this term is positive in a positively curved (i.e. ![]() $\boldsymbol {\nabla }\boldsymbol {\cdot } \boldsymbol {n}>0$) reaction zone, because

$\boldsymbol {\nabla }\boldsymbol {\cdot } \boldsymbol {n}>0$) reaction zone, because ![]() $\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {n}_k < 0$ for these reactants. Recall that symbol

$\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {n}_k < 0$ for these reactants. Recall that symbol ![]() $\boldsymbol {n}$ designates the unit vector normal to an isosurface of

$\boldsymbol {n}$ designates the unit vector normal to an isosurface of ![]() $c(\boldsymbol {x},t)=$const, i.e.

$c(\boldsymbol {x},t)=$const, i.e. ![]() $\boldsymbol {n} = - \boldsymbol {\nabla } c/|\boldsymbol {\nabla } c|$. Moreover, the curvature term

$\boldsymbol {n} = - \boldsymbol {\nabla } c/|\boldsymbol {\nabla } c|$. Moreover, the curvature term ![]() $T_2$ is larger for the fuel, because

$T_2$ is larger for the fuel, because ![]() $D_{\textrm {H}_2}$ is significantly larger than

$D_{\textrm {H}_2}$ is significantly larger than ![]() $D_{\textrm {O}_2}$. As a result, the mass fraction of H

$D_{\textrm {O}_2}$. As a result, the mass fraction of H![]() $_2$ and, hence, the local equivalence ratio is increased in positively curved reaction zones in the case of a lean hydrogen–air mixture. Since

$_2$ and, hence, the local equivalence ratio is increased in positively curved reaction zones in the case of a lean hydrogen–air mixture. Since ![]() $D_{\textrm {H}_2}$ is also significantly larger than the molecular heat diffusivity

$D_{\textrm {H}_2}$ is also significantly larger than the molecular heat diffusivity ![]() $\kappa$ of such a mixture, similar arguments could be used to emphasize an increase in the local temperature in positively curved reaction zones. On the contrary, for atomic hydrogen,

$\kappa$ of such a mixture, similar arguments could be used to emphasize an increase in the local temperature in positively curved reaction zones. On the contrary, for atomic hydrogen, ![]() $T_2>0$ in negatively curved reaction zones, because

$T_2>0$ in negatively curved reaction zones, because ![]() $\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {n}_\textrm {H} > 0$ in the largest part of a reaction zone, with the exception of a radical recombination region (Williams Reference Williams2000) characterized by

$\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {n}_\textrm {H} > 0$ in the largest part of a reaction zone, with the exception of a radical recombination region (Williams Reference Williams2000) characterized by ![]() $c$ close to unity.

$c$ close to unity.

An important role played by term ![]() $T_2$ is shown in figures 8 and 9, which report dependencies of doubly conditioned (on the local combustion progress variable

$T_2$ is shown in figures 8 and 9, which report dependencies of doubly conditioned (on the local combustion progress variable ![]() $c$ and curvature

$c$ and curvature ![]() $h_m$) terms

$h_m$) terms ![]() $T_j$ on

$T_j$ on ![]() $h_m$ and

$h_m$ and ![]() $c$, respectively. In particular, figure 8(a) shows that, for H

$c$, respectively. In particular, figure 8(a) shows that, for H![]() $_2$, both the total diffusion term

$_2$, both the total diffusion term ![]() $\langle T_0 | c=0.75 | h_m \rangle$ (black solid line) and the curvature term

$\langle T_0 | c=0.75 | h_m \rangle$ (black solid line) and the curvature term ![]() $\langle T_2 | c=0.75 | h_m \rangle$ (blue dotted line) are significantly increased by curvature if

$\langle T_2 | c=0.75 | h_m \rangle$ (blue dotted line) are significantly increased by curvature if ![]() $|\delta _L h_m|<2$, whereas dependence of the normal diffusion term

$|\delta _L h_m|<2$, whereas dependence of the normal diffusion term ![]() $\langle T_1 | c=0.75 | h_m \rangle$ on

$\langle T_1 | c=0.75 | h_m \rangle$ on ![]() $h_m$ is less pronounced and non-monotonous, with

$h_m$ is less pronounced and non-monotonous, with ![]() $T_1$ peaking at a slightly negative curvature. Note that these results are conditioned to

$T_1$ peaking at a slightly negative curvature. Note that these results are conditioned to ![]() $c=0.75 \pm 0.02$, because the highest (over the computational domain and time) fuel consumption rate is found at a close value of the combustion progress variable in flame C. For the radical H, the curvature term

$c=0.75 \pm 0.02$, because the highest (over the computational domain and time) fuel consumption rate is found at a close value of the combustion progress variable in flame C. For the radical H, the curvature term ![]() $T_2$ also plays an important role, but results in decreasing

$T_2$ also plays an important role, but results in decreasing ![]() $T_0$ with

$T_0$ with ![]() $h_m$, as already noted when discussing (3.3).

$h_m$, as already noted when discussing (3.3).

Figure 8. Time-averaged dependencies of molecular diffusion terms ![]() $\langle T_j | c | h_m \rangle$ on the normalized local curvature

$\langle T_j | c | h_m \rangle$ on the normalized local curvature ![]() $\delta _L h_m$, sampled for (a) H

$\delta _L h_m$, sampled for (a) H![]() $_2$ and (b) H at

$_2$ and (b) H at ![]() $c = 0.75 \pm 0.02$ from the entire flame brush in case C. Black solid, red dashed and blue dotted lines show

$c = 0.75 \pm 0.02$ from the entire flame brush in case C. Black solid, red dashed and blue dotted lines show ![]() $T_0$,

$T_0$, ![]() $T_1$ and

$T_1$ and ![]() $T_2$, respectively.

$T_2$, respectively.

Figure 9. Time-averaged dependencies of molecular diffusion terms on the local combustion progress variable ![]() $c$, sampled at

$c$, sampled at ![]() $\delta _L h_m = -1 \pm 0.005$ (blue dotted lines),

$\delta _L h_m = -1 \pm 0.005$ (blue dotted lines), ![]() $0 \pm 0.005$ (red dashed lines) and

$0 \pm 0.005$ (red dashed lines) and ![]() $1 \pm 0.005$ (black solid lines) from the entire flame brush in case C. Here (a)

$1 \pm 0.005$ (black solid lines) from the entire flame brush in case C. Here (a) ![]() $\langle T_0 | c | h_m \rangle$ for H

$\langle T_0 | c | h_m \rangle$ for H![]() $_2$, (b)

$_2$, (b) ![]() $\langle T_0 | c | h_m \rangle$ for H, (c)

$\langle T_0 | c | h_m \rangle$ for H, (c) ![]() $\langle T_1 | c | h_m \rangle$ for H

$\langle T_1 | c | h_m \rangle$ for H![]() $_2$, (d)

$_2$, (d) ![]() $\langle T_1 | c | h_m \rangle$ for H, (e)

$\langle T_1 | c | h_m \rangle$ for H, (e) ![]() $\langle T_2 | c | h_m \rangle$ for H

$\langle T_2 | c | h_m \rangle$ for H![]() $_2$ and ( f)

$_2$ and ( f) ![]() $\langle T_2 | c | h_m \rangle$ for H.

$\langle T_2 | c | h_m \rangle$ for H.

The same trends are observed in figure 9, which shows dependencies of ![]() $\langle T_j | c | h_m \rangle$ on

$\langle T_j | c | h_m \rangle$ on ![]() $c$, conditioned to

$c$, conditioned to ![]() $\delta _L h_m = -1 \pm 0.005$ (blue dotted lines),

$\delta _L h_m = -1 \pm 0.005$ (blue dotted lines), ![]() $0 \pm 0.005$ (red dashed lines) and

$0 \pm 0.005$ (red dashed lines) and ![]() $1 \pm 0.005$ (black solid lines). The curvature term

$1 \pm 0.005$ (black solid lines). The curvature term ![]() $T_2$ results in increasing the molecular diffusion flux

$T_2$ results in increasing the molecular diffusion flux ![]() $\boldsymbol {\nabla }\boldsymbol {\cdot }(\rho D_k \boldsymbol {\nabla } Y_k)$ (i) for H

$\boldsymbol {\nabla }\boldsymbol {\cdot }(\rho D_k \boldsymbol {\nabla } Y_k)$ (i) for H![]() $_2$ if the local curvature is positive and (ii) for H if the local curvature is negative.

$_2$ if the local curvature is positive and (ii) for H if the local curvature is negative.

It is also of interest to note that time-averaged dependencies of ![]() $\langle T_j \,|\, c \rangle$ on

$\langle T_j \,|\, c \rangle$ on ![]() $c$, sampled from the leading and trailing zones of the mean flame brush, look similar to dependencies of

$c$, sampled from the leading and trailing zones of the mean flame brush, look similar to dependencies of ![]() $\langle T_j | c | h_m \rangle$ on

$\langle T_j | c | h_m \rangle$ on ![]() $c$, conditioned to

$c$, conditioned to ![]() $\delta _L h_m = 1 \pm 0.005$ and

$\delta _L h_m = 1 \pm 0.005$ and ![]() $-1 \pm 0.005$, respectively, cf. curves plotted in black solid and blue dotted lines, respectively, in figures 9 and 10. This similarity (i) is associated with predominance of the positive and negative curvature at

$-1 \pm 0.005$, respectively, cf. curves plotted in black solid and blue dotted lines, respectively, in figures 9 and 10. This similarity (i) is associated with predominance of the positive and negative curvature at ![]() $\langle c \rangle =0.1 \pm 0.02$ and

$\langle c \rangle =0.1 \pm 0.02$ and ![]() $0.9 \pm 0.02$, respectively (see figure 7) and (ii) supports a hypothesis that differential diffusion effects are more pronounced at the leading and trailing edges of the mean flame brush, because the local reaction zones are highly curved at small and large

$0.9 \pm 0.02$, respectively (see figure 7) and (ii) supports a hypothesis that differential diffusion effects are more pronounced at the leading and trailing edges of the mean flame brush, because the local reaction zones are highly curved at small and large ![]() $\langle c \rangle$, with the curvature signs being opposite at these two values of

$\langle c \rangle$, with the curvature signs being opposite at these two values of ![]() $\langle c \rangle$.

$\langle c \rangle$.

Figure 10. Time-averaged dependencies of conditioned molecular diffusion terms on the local combustion progress variable, sampled at ![]() $\langle c \rangle = 0.1 \pm 0.02$ (black solid lines),

$\langle c \rangle = 0.1 \pm 0.02$ (black solid lines), ![]() $0.5 \pm 0.02$ (red dashed lines) and

$0.5 \pm 0.02$ (red dashed lines) and ![]() $0.9 \pm 0.02$ (blue dotted lines) in flame C. Here (a)

$0.9 \pm 0.02$ (blue dotted lines) in flame C. Here (a) ![]() $\langle T_0 \,|\, c \rangle$ for H

$\langle T_0 \,|\, c \rangle$ for H![]() $_2$, (b)

$_2$, (b) ![]() $\langle T_0 \,|\, c \rangle$ for H, (c)

$\langle T_0 \,|\, c \rangle$ for H, (c) ![]() $\langle T_1 \,|\, c \rangle$ for H

$\langle T_1 \,|\, c \rangle$ for H![]() $_2$, (d)

$_2$, (d) ![]() $\langle T_1 \,|\, c \rangle$ for H, (e)

$\langle T_1 \,|\, c \rangle$ for H, (e) ![]() $\langle T_2 \,|\, c \rangle$ for H

$\langle T_2 \,|\, c \rangle$ for H![]() $_2$ and ( f)

$_2$ and ( f) ![]() $\langle T_2 \,|\, c \rangle$ for H.

$\langle T_2 \,|\, c \rangle$ for H.

Due to an imbalance of molecular diffusion fluxes of H![]() $_2$, O

$_2$, O![]() $_2$, and heat to and from curved reaction zones, the local temperature, equivalence ratio, fuel consumption rate and mass fraction of H are increased by curvature, as reported in figure 11. However, these quantities are substantially affected not only by the curvature. For instance, dependencies of

$_2$, and heat to and from curved reaction zones, the local temperature, equivalence ratio, fuel consumption rate and mass fraction of H are increased by curvature, as reported in figure 11. However, these quantities are substantially affected not only by the curvature. For instance, dependencies of ![]() $\langle T | c=0.75 | h_m \rangle$,

$\langle T | c=0.75 | h_m \rangle$, ![]() $\langle \phi | c=0.75 | h_m \rangle$,

$\langle \phi | c=0.75 | h_m \rangle$, ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c=0.75 | h_m \rangle$ and

$\langle \dot {\omega }_{\textrm {H}_2} | c=0.75 | h_m \rangle$ and ![]() $\langle Y_{\textrm {H}} | c=0.75 | h_m \rangle$ on

$\langle Y_{\textrm {H}} | c=0.75 | h_m \rangle$ on ![]() $\delta _L h_m$ sampled at

$\delta _L h_m$ sampled at ![]() $\langle c \rangle = 0.1 \pm 0.02$ and

$\langle c \rangle = 0.1 \pm 0.02$ and ![]() $0.9 \pm 0.02$ are substantially different, cf. black solid and blue dotted lines. Accordingly, dependencies of

$0.9 \pm 0.02$ are substantially different, cf. black solid and blue dotted lines. Accordingly, dependencies of ![]() $\langle T | c | h_m \rangle (c)$,

$\langle T | c | h_m \rangle (c)$, ![]() $\langle \phi | c | h_m \rangle (c)$,

$\langle \phi | c | h_m \rangle (c)$, ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle (c)$ and

$\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle (c)$ and ![]() $\langle Y_{\textrm {H}} | c | h_m \rangle (c)$ on

$\langle Y_{\textrm {H}} | c | h_m \rangle (c)$ on ![]() $c$, sampled from these two zones, are also substantially different (cf. left and right columns in figure 12). Effects of other flow characteristics on the conditioned quantities

$c$, sampled from these two zones, are also substantially different (cf. left and right columns in figure 12). Effects of other flow characteristics on the conditioned quantities ![]() $\langle q | c \rangle$ and behaviour of the doubly conditioned heat release rate

$\langle q | c \rangle$ and behaviour of the doubly conditioned heat release rate ![]() $\langle \dot {\omega }_{T} | c | h_m \rangle$ will further be addressed in §§ 3.4 and 3.5, respectively.

$\langle \dot {\omega }_{T} | c | h_m \rangle$ will further be addressed in §§ 3.4 and 3.5, respectively.

Figure 11. Time-averaged dependencies of doubly conditioned (a) temperature ![]() $\langle T | c=0.75 | h_m \rangle$, (b) equivalence ratio

$\langle T | c=0.75 | h_m \rangle$, (b) equivalence ratio ![]() $\langle \phi | c=0.75 | h_m \rangle$, (c) fuel consumption rate

$\langle \phi | c=0.75 | h_m \rangle$, (c) fuel consumption rate ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c=0.75 | h_m \rangle$ and (d) hydrogen mass fraction

$\langle \dot {\omega }_{\textrm {H}_2} | c=0.75 | h_m \rangle$ and (d) hydrogen mass fraction ![]() $\langle Y_{\textrm {H}} | c=0.75 | h_m \rangle$ on the normalized local curvature

$\langle Y_{\textrm {H}} | c=0.75 | h_m \rangle$ on the normalized local curvature ![]() $\delta _L h_m$, sampled from the entire flame brush (orange dotted–dashed lines), its leading zone characterized by

$\delta _L h_m$, sampled from the entire flame brush (orange dotted–dashed lines), its leading zone characterized by ![]() $\langle c \rangle (y,t)=0.1 \pm 0.02$ (black solid lines), middle zone (

$\langle c \rangle (y,t)=0.1 \pm 0.02$ (black solid lines), middle zone (![]() $\langle c \rangle =0.5 \pm 0.02$, red dashed lines) and trailing zone (

$\langle c \rangle =0.5 \pm 0.02$, red dashed lines) and trailing zone (![]() $\langle c \rangle =0.9 \pm 0.02$, blue dotted lines); case C.

$\langle c \rangle =0.9 \pm 0.02$, blue dotted lines); case C.

Figure 12. Time-averaged dependencies of doubly conditioned (a,b) temperature ![]() $\langle T | c | h_m \rangle$, (c,d) equivalence ratio

$\langle T | c | h_m \rangle$, (c,d) equivalence ratio ![]() $\langle \phi | c | h_m \rangle$, (e, f) fuel consumption rate

$\langle \phi | c | h_m \rangle$, (e, f) fuel consumption rate ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$ and (g,h) hydrogen mass fraction

$\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$ and (g,h) hydrogen mass fraction ![]() $\langle Y_{\textrm {H}} | c=| h_m \rangle$ on

$\langle Y_{\textrm {H}} | c=| h_m \rangle$ on ![]() $c$, obtained at

$c$, obtained at ![]() $\delta _L h_m=-0.1 \pm 0.005$ (blue dotted lines),

$\delta _L h_m=-0.1 \pm 0.005$ (blue dotted lines), ![]() $0 \pm 0.005$ (red dashed lines) and

$0 \pm 0.005$ (red dashed lines) and ![]() $1 \pm 0.005$ (black solid lines) in case C. Results sampled from the leading and trailing zones of the flame brush are reported in cells (a,c,e,g) and (b,d, f,h), respectively.

$1 \pm 0.005$ (black solid lines) in case C. Results sampled from the leading and trailing zones of the flame brush are reported in cells (a,c,e,g) and (b,d, f,h), respectively.

3.3. Leading point concept

The DNS results plotted in figures 1–6 indicate that both turbulent burning velocities and the conditioned profiles of ![]() $T$,

$T$, ![]() $\phi$,

$\phi$, ![]() $\dot {\omega }_{\textrm {H}_2}$,

$\dot {\omega }_{\textrm {H}_2}$, ![]() $\dot {\omega }_T$ and

$\dot {\omega }_T$ and ![]() $Y_{\textrm {H}}$, sampled at

$Y_{\textrm {H}}$, sampled at ![]() $\langle c \rangle =0.1 \pm 0.02$, are significantly affected by

$\langle c \rangle =0.1 \pm 0.02$, are significantly affected by ![]() $Le$, whereas the conditioned profiles of the same quantities, sampled from the middle of the C-flame brush, are associated with

$Le$, whereas the conditioned profiles of the same quantities, sampled from the middle of the C-flame brush, are associated with ![]() $Le=1$. This observation not only shows that differences in molecular transport coefficients of reactants and/or heat play a more important role at the leading edge of a mean turbulent flame brush, but also implies that the turbulent burning velocities are controlled by processes localized to the leading edge. This implication is in line with (i) the so-called KPP theory of convection–diffusion–reaction waves developed by Kolmogorov, Petrovsky & Piskounov (Reference Kolmogorov, Petrovsky and Piskounov1937) and extended in subsequent studies reviewed elsewhere (Ebert & van Saarlos Reference Ebert and van Saarlos2000; Sabelnikov, Petrova & Lipatnikov Reference Sabelnikov, Petrova and Lipatnikov2016) and (ii) Zel'dovich's idea about the crucial role played by leading points in propagation of premixed turbulent flames. That idea was developed in the former USSR several decades ago, as reviewed elsewhere (Kuznetsov & Sabelnikov Reference Kuznetsov and Sabelnikov1990; Lipatnikov & Chomiak Reference Lipatnikov and Chomiak2005), and was supported in recent theoretical (Sabelnikov & Lipatnikov Reference Sabelnikov and Lipatnikov2013, Reference Sabelnikov and Lipatnikov2015; Kha et al. Reference Kha, Robin, Mura and Champion2016), experimental (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2015; Zhang et al. Reference Zhang, Wang, Yu, Jin, Zhang and Huang2018) and DNS (Amato et al. Reference Amato, Day, Cheng, Bell, Dasgupta and Lieuwen2015a,Reference Amato, Day, Cheng, Bell and Lieuwenb; Kim Reference Kim2017; Dave, Mohan & Chaudhuri Reference Dave, Mohan and Chaudhuri2018; Lipatnikov, Chakraborty & Sabelnikov Reference Lipatnikov, Chakraborty and Sabelnikov2018) studies, as well as in earlier single-step chemistry (Karpov, Lipatnikov & Zimont Reference Karpov, Lipatnikov and Zimont1996) or recent complex chemistry (Verma, Monnier & Lipatnikov Reference Verma, Monnier and Lipatnikov2021) Reynolds-averaged Navier–Stokes (RANS) simulations of experiments with lean H

$Le=1$. This observation not only shows that differences in molecular transport coefficients of reactants and/or heat play a more important role at the leading edge of a mean turbulent flame brush, but also implies that the turbulent burning velocities are controlled by processes localized to the leading edge. This implication is in line with (i) the so-called KPP theory of convection–diffusion–reaction waves developed by Kolmogorov, Petrovsky & Piskounov (Reference Kolmogorov, Petrovsky and Piskounov1937) and extended in subsequent studies reviewed elsewhere (Ebert & van Saarlos Reference Ebert and van Saarlos2000; Sabelnikov, Petrova & Lipatnikov Reference Sabelnikov, Petrova and Lipatnikov2016) and (ii) Zel'dovich's idea about the crucial role played by leading points in propagation of premixed turbulent flames. That idea was developed in the former USSR several decades ago, as reviewed elsewhere (Kuznetsov & Sabelnikov Reference Kuznetsov and Sabelnikov1990; Lipatnikov & Chomiak Reference Lipatnikov and Chomiak2005), and was supported in recent theoretical (Sabelnikov & Lipatnikov Reference Sabelnikov and Lipatnikov2013, Reference Sabelnikov and Lipatnikov2015; Kha et al. Reference Kha, Robin, Mura and Champion2016), experimental (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2015; Zhang et al. Reference Zhang, Wang, Yu, Jin, Zhang and Huang2018) and DNS (Amato et al. Reference Amato, Day, Cheng, Bell, Dasgupta and Lieuwen2015a,Reference Amato, Day, Cheng, Bell and Lieuwenb; Kim Reference Kim2017; Dave, Mohan & Chaudhuri Reference Dave, Mohan and Chaudhuri2018; Lipatnikov, Chakraborty & Sabelnikov Reference Lipatnikov, Chakraborty and Sabelnikov2018) studies, as well as in earlier single-step chemistry (Karpov, Lipatnikov & Zimont Reference Karpov, Lipatnikov and Zimont1996) or recent complex chemistry (Verma, Monnier & Lipatnikov Reference Verma, Monnier and Lipatnikov2021) Reynolds-averaged Navier–Stokes (RANS) simulations of experiments with lean H![]() $_2$–air (Karpov & Severin Reference Karpov and Severin1980) or H

$_2$–air (Karpov & Severin Reference Karpov and Severin1980) or H![]() $_2$/CO–air (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013) flames, respectively.

$_2$/CO–air (Venkateswaran et al. Reference Venkateswaran, Marshall, Shin, Noble, Seitzman and Lieuwen2011, Reference Venkateswaran, Marshall, Seitzman and Lieuwen2013) flames, respectively.

The present work further supports the leading point concept by showing its consistency with recent DNS data that indicate mitigation of the influence of ![]() $Le$ on the conditioned profiles of local flame characteristics in intense turbulence. Conversely, the leading point concept supports consistency of the two investigated findings by hypothesizing that

$Le$ on the conditioned profiles of local flame characteristics in intense turbulence. Conversely, the leading point concept supports consistency of the two investigated findings by hypothesizing that ![]() $U_t$ is controlled by processes localized to the leading edge of the mean flame brush.

$U_t$ is controlled by processes localized to the leading edge of the mean flame brush.

Moreover, complex-chemistry DNS of lean hydrogen–air turbulent flames offer the following opportunity for probing the leading point concept. Among nine species included into the state-of-the-art chemical mechanisms of hydrogen combustion and in the mechanism by Kéromnès et al. (Reference Kéromnès2013) used in the present study, only atomic hydrogen H and molecular hydrogen H![]() $_2$ are characterized by molecular diffusivities much larger than the diffusivity of O

$_2$ are characterized by molecular diffusivities much larger than the diffusivity of O![]() $_2$ or heat diffusivity of the mixture. At the same time, as discussed earlier, molecular diffusion of H

$_2$ or heat diffusivity of the mixture. At the same time, as discussed earlier, molecular diffusion of H![]() $_2$ results in increasing (when compared with the unperturbed laminar flame) equivalence ratio in positively curved reaction zones, whereas molecular diffusion of H from recombination to reaction zones results in increasing

$_2$ results in increasing (when compared with the unperturbed laminar flame) equivalence ratio in positively curved reaction zones, whereas molecular diffusion of H from recombination to reaction zones results in increasing ![]() $Y_{\textrm {H}}$ in negatively curved reaction zones. Accordingly, one may assume that an increase in local burning rate should predominantly be observed (i) in negatively curved reaction zones concentrating in the trailing edge of a mean flame brush if Lewis numbers are equal to unity for all species with the exception of H, but (ii) in positively curved reaction zones concentrating in the leading edge of a mean flame brush if Lewis numbers are equal to unity for all species with the exception of H

$Y_{\textrm {H}}$ in negatively curved reaction zones. Accordingly, one may assume that an increase in local burning rate should predominantly be observed (i) in negatively curved reaction zones concentrating in the trailing edge of a mean flame brush if Lewis numbers are equal to unity for all species with the exception of H, but (ii) in positively curved reaction zones concentrating in the leading edge of a mean flame brush if Lewis numbers are equal to unity for all species with the exception of H![]() $_2$.

$_2$.

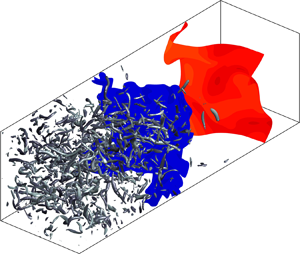

Based on the above reasoning, two extra DNS cases, C1/H and C1/H2, were run by using the mixture-averaged molecular diffusivities of H and H![]() $_2$, respectively, and setting Lewis numbers equal to unity for all other species. The computed results sampled from the entire flame brushes do show that the equivalence ratio, fuel consumption rate, heat release rate and mass fraction of H conditioned to positive curvature are larger than their values conditioned to negative curvature in case C1/H2 (cf. blue solid and dashed lines in figure 13), whereas the opposite trend is observed in case C1/H (cf. red solid and dashed lines).

$_2$, respectively, and setting Lewis numbers equal to unity for all other species. The computed results sampled from the entire flame brushes do show that the equivalence ratio, fuel consumption rate, heat release rate and mass fraction of H conditioned to positive curvature are larger than their values conditioned to negative curvature in case C1/H2 (cf. blue solid and dashed lines in figure 13), whereas the opposite trend is observed in case C1/H (cf. red solid and dashed lines).

Figure 13. Time-averaged dependencies of doubly conditioned (a) equivalence ratio ![]() $\langle \phi | c | h_m \rangle$, (b) fuel consumption rate

$\langle \phi | c | h_m \rangle$, (b) fuel consumption rate ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$, (c) heat release rate

$\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$, (c) heat release rate ![]() $\langle \dot {\omega }_T | c | h_m \rangle$, and (d) hydrogen mass fraction

$\langle \dot {\omega }_T | c | h_m \rangle$, and (d) hydrogen mass fraction ![]() $\langle Y_{\textrm {H}} | c | h_m \rangle$ on combustion progress variable. Results conditioned to

$\langle Y_{\textrm {H}} | c | h_m \rangle$ on combustion progress variable. Results conditioned to ![]() $\delta _L h_m = -1 \pm 0.005$ and

$\delta _L h_m = -1 \pm 0.005$ and ![]() $\delta _L h_m = 1 \pm 0.005$ are shown in dashed and solid lines, respectively. Results obtained from flames C1/H and C1/H2 are plotted in red and blue lines, respectively.

$\delta _L h_m = 1 \pm 0.005$ are shown in dashed and solid lines, respectively. Results obtained from flames C1/H and C1/H2 are plotted in red and blue lines, respectively.

Significant influence of molecular diffusion of atomic hydrogen on local burning structures was recently explored by Rieth et al. (Reference Rieth, Gruber, Williams and Chen2021) by analysing DNS data obtained from (i) preheated lean NH![]() $_3$/H

$_3$/H![]() $_2$/N

$_2$/N![]() $_2$–air flames propagating in a turbulent shear layer and (ii) statistically planar highly preheated lean hydrogen–air turbulent flames. In particular, by turning off the molecular diffusivity of atomic hydrogen, Rieth et al. (Reference Rieth, Gruber, Williams and Chen2021) have shown that enhanced molecular transport of H into negatively curved low-temperature heat release zones results in significantly increasing local heat release rate. A similar effect is observed in figure 13(c).

$_2$–air flames propagating in a turbulent shear layer and (ii) statistically planar highly preheated lean hydrogen–air turbulent flames. In particular, by turning off the molecular diffusivity of atomic hydrogen, Rieth et al. (Reference Rieth, Gruber, Williams and Chen2021) have shown that enhanced molecular transport of H into negatively curved low-temperature heat release zones results in significantly increasing local heat release rate. A similar effect is observed in figure 13(c).

The qualitative difference between the present cases C1/H and C1/H2 is also demonstrated in figure 14, where doubly conditioned profiles of ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle (c)$,

$\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle (c)$, ![]() $\langle \dot {\omega }_T | c | h_m \rangle (c)$ and

$\langle \dot {\omega }_T | c | h_m \rangle (c)$ and ![]() $\langle Y_{\textrm {H}} | c | h_m \rangle (c)$ sampled from the leading (red or blue lines) and trailing (black lines) zones are reported. Moreover, figures 14(b), 14(d) and 14( f) show that fuel consumption rate, heat release rate and mass fraction of H, respectively, conditioned to

$\langle Y_{\textrm {H}} | c | h_m \rangle (c)$ sampled from the leading (red or blue lines) and trailing (black lines) zones are reported. Moreover, figures 14(b), 14(d) and 14( f) show that fuel consumption rate, heat release rate and mass fraction of H, respectively, conditioned to ![]() $\langle c \rangle = 0.1 \pm 0.02$, are larger than their values conditioned to

$\langle c \rangle = 0.1 \pm 0.02$, are larger than their values conditioned to ![]() $\langle c \rangle = 0.9 \pm 0.02$ in flame C1/H2 (cf. blue and black curves), respectively. In flame C1/H, the opposite trend is documented (cf. red and black curves in figures 14a, 14c or 14e).

$\langle c \rangle = 0.9 \pm 0.02$ in flame C1/H2 (cf. blue and black curves), respectively. In flame C1/H, the opposite trend is documented (cf. red and black curves in figures 14a, 14c or 14e).

Figure 14. Time-averaged dependencies of doubly conditioned (a,b) fuel consumption rate ![]() $\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$, (c,d) heat release rate

$\langle \dot {\omega }_{\textrm {H}_2} | c | h_m \rangle$, (c,d) heat release rate ![]() $\langle \dot {\omega }_T | c | h_m \rangle$ and (e, f) hydrogen mass fraction

$\langle \dot {\omega }_T | c | h_m \rangle$ and (e, f) hydrogen mass fraction ![]() $\langle Y_{\textrm {H}} | c | h_m \rangle$ on combustion progress variable, sampled at

$\langle Y_{\textrm {H}} | c | h_m \rangle$ on combustion progress variable, sampled at ![]() $\langle c \rangle = 0.1 \pm 0.02$ (red or blue lines) and

$\langle c \rangle = 0.1 \pm 0.02$ (red or blue lines) and ![]() $0.9 \pm 0.02$ (black lines). Results conditioned to the negative

$0.9 \pm 0.02$ (black lines). Results conditioned to the negative ![]() $\delta _L h_m = -1 \pm 0.005$ or positive

$\delta _L h_m = -1 \pm 0.005$ or positive ![]() $\delta _L h_m = 1 \pm 0.005$ are shown in dashed or solid lines, respectively. Results are for (a,c,e) case C1/H and (b,d, f) case C1/H2.

$\delta _L h_m = 1 \pm 0.005$ are shown in dashed or solid lines, respectively. Results are for (a,c,e) case C1/H and (b,d, f) case C1/H2.