1. Introduction

Product design is a creative process that combines design thinking with customer needs, companies’ strategic requirements and the regulatory agencies’ constraints to develop a product (Ma & Kremer Reference Ma and Kremer2016). The demand to innovate products is so intense that the conventional product design and development approaches cannot meet the needs (Danneels Reference Danneels2002). Innovation regarding the product or process is one of the critical ideas to tackle this situation (Moon, Miller, & Kim Reference Moon, Miller and Kim2013; Lee, Lee, & Garrett Reference Lee, Lee and Garrett2019). A new approach to product design that could address the demand of sustainability, adaptability and upgradability, and also meets the exact needs of the end-user, has the potential to meet this requirement. This paper aims to serve as a tool for setting the scope and importance of such a product design approach.

1.1. Product customisation paradigms

Over time, product design has changed considerably, from individually crafted designs to product design for mass production, followed by the product design for mass customisation. These developments have been predominantly triggered either by market conditions or by the consumers’ desire for the product offering.

Up until the industrial revolution, products were designed and manufactured by craftsmen with a localised design spanning generations (Risatti Reference Risatti2013). The concepts and design processes related to mass production revolutionised the way products were designed and manufactured. Later on, technological advancement made it possible to design and manufacture products more quickly and cheaply in large quantities. This is usually attributed to the industrialist Henry Ford in the early twentieth century. The assembly-line approach to produce the Model T motor car reduced the cost of the cars to the extent that even ordinary workers could afford them (Womack, Jones, & Roos Reference Womack, Jones and Roos1990). The impact on the market was revolutionary, thus on the product design and development processes.

As society’s wishes to choose from a variety of similar products started to change, companies introduced the concept of mass customisation by providing different variants of the same product as offering to select. Mass customisation is a production strategy that focusses on the wide range of personalised products and services, through modularised product/service design, flexible processes and integration between supply chain members (Pine, Victor, & Boynton Reference Pine, Victor and Boynton1993; Fogliatto, Da Silveira, & Borenstein Reference Fogliatto, Da Silveira and Borenstein2012). Fogliatto, Da Silveira, & Borenstein (Reference Fogliatto, Da Silveira and Borenstein2012)) summarised relevant literature on mass customisation approaches with different success factors and enablers. While mass customisation provides variants of the same product, the limited availability of options often constraints the fulfilment of the end user’s needs, since variants are supplied by the product manufacturer themselves with few actual design changes (Walcher & Werger Reference Walcher, Werger, Piller and Chesbrough2011; Zhao et al. Reference Zhao, McLoughlin, Adzhiev and Pasko2019). This provided the basis for a new approach, known as Mass Individualisation (MI).

Traditionally, most products are professionally designed by people working within a firm’s design teams because those people ‘have acquired skills and capabilities that allow them to perform most design tasks with more efficiency and at a higher level of quality’ (Ulrich Reference Ulrich2011). However, this changed considerably over time, driven by technological progress. Innovation technologies (Dodgson, Gann, & Salter Reference Dodgson, Gann and Salter2005) have enabled new product design and development strategies. New technologies have provided the democratisation of the tools for both invention and production (Anderson Reference Anderson2012). Anyone with an idea can use advanced technologies for product design.

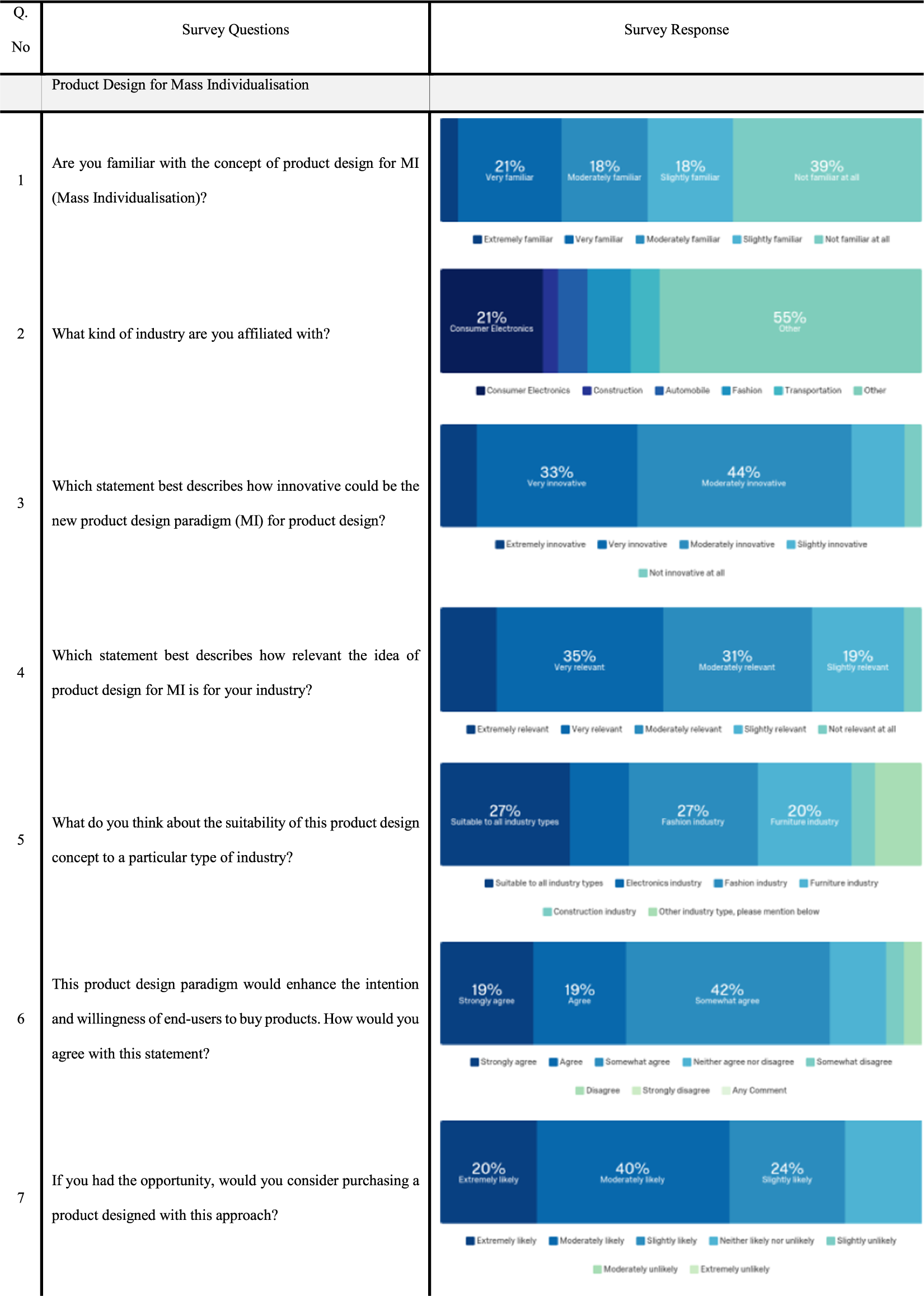

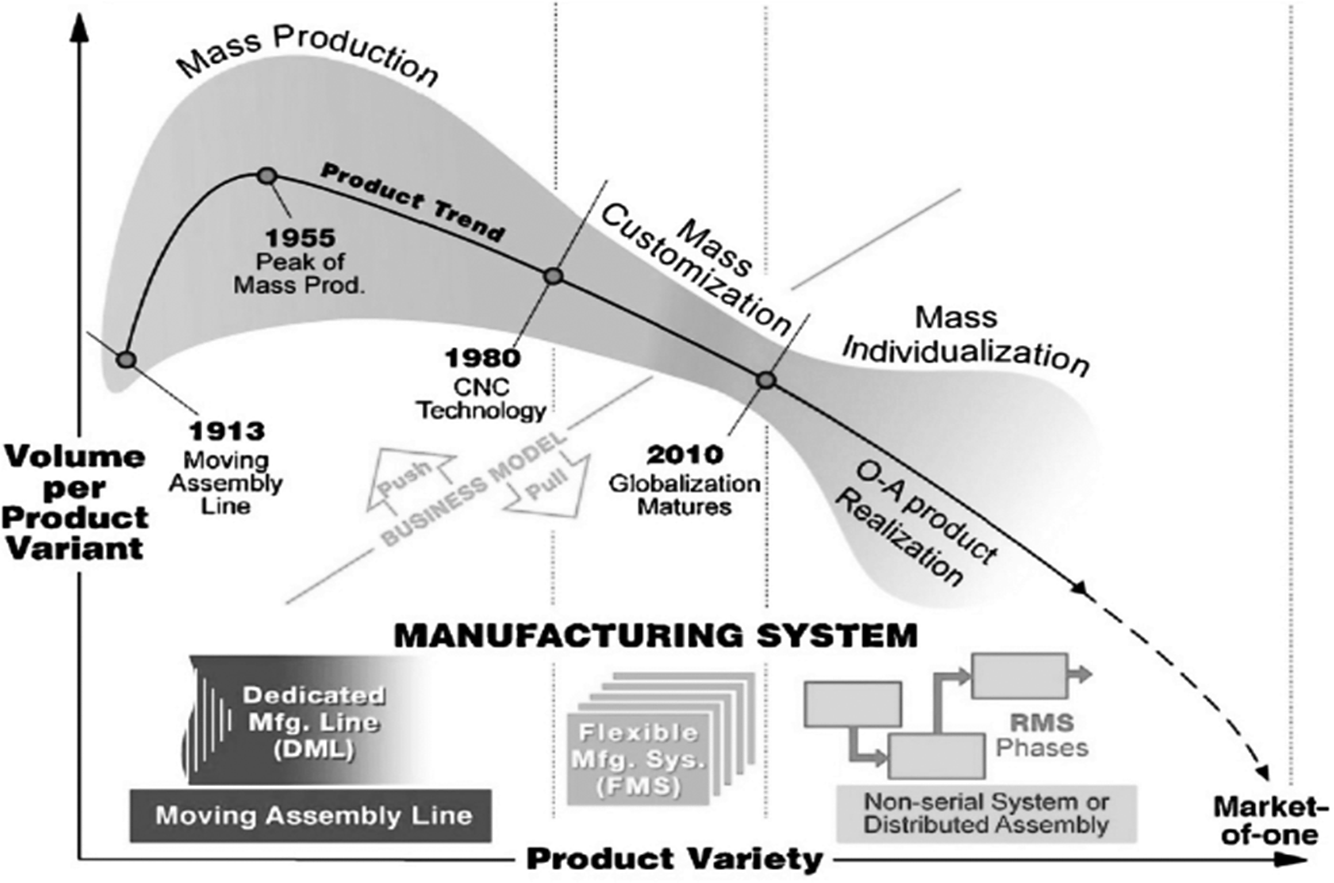

Every product design paradigm includes three essential steps: design the product, make the product and sell the product (Koren et al. Reference Koren, Hu, Gu and Shpitalni2015). Based on the sequence of these three steps, the end-user’s engagement and role in designing the product, all product design paradigms can be summarised as in Figure 1.

Figure 1. Different product design paradigms.

Figure 2 demonstrates the transformation and development of manufacturing in the last 100 years. Each product variant reduces in volume, from mass production to MI. At the same time, product variety increases, indicating an increased demand for the more individualised product offering. It approaches a situation of the market to one. This paper addresses the situation of market to one with product design for MI along with the role of networked innovation in it. Koren et al. (Reference Koren, Hu, Gu and Shpitalni2015) conducted initial research on this paradigm shift.

Figure 2. Transformation of manufacturing approaches (Koren Reference Koren2010) (image reproduced with permission of the rights holder, John Wiley & Sons).

1.2. Product individualisation

The driving force behind product individualisation is the positioning of end-users at the centre of value creation and involving them in the product development phase (Zheng et al. Reference Zheng, Lin, Chen and Xu2019). It is usually a costly matter for firms to understand the inherent and exact need of users (Jeppesen Reference Jeppesen2005; Lee & Moon Reference Lee and Moon2015). Acquiring exact needs is a very complex process, and conventional market research techniques acquire only the visible needs (Piller Reference Piller2004; Rowley Reference Rowley2005; Rungtusanatham & Salvador Reference Rungtusanatham and Salvador2008; Zhou, Ji, & Jiao Reference Zhou, Ji and Jiao2013; Payne, Peltier, & Barger Reference Payne, Peltier and Barger2021). Technological progress, increasing expectations, globalisation and demographic changes lead to more diversified individual needs and concurrently, heterogeneous markets (Bortolini, Galizia, & Mora Reference Bortolini, Galizia and Mora2018; Pessôa & Becker Reference Pessôa and Becker2020). This also leads to the idea of product individualisation along with an active and direct role of the end-users in the product design and development processes.

An emerging literature stream suggests that the inclusion of users in new product creation rather than of the internal designers can benefit organisations because it results in a product that effectively meets consumer needs. In parallel to the professional design teams, the user has begun contributing to the design process. Specific users are motivated enough and able to innovate with their ideas and are willing to share with firms is documented extensively (Frow et al. Reference Frow, Nenonen, Payne and Storbacka2015; de la Guía, Cazorla, & de-Miguel-Molina Reference De la Guía, Cazorla and de-Miguel-Molina2017; Mandolfo, Chen, & Noci Reference Mandolfo, Chen and Noci2020). User design can empower firms by improving time to market, reducing new product development costs and, above all, by producing innovative products that are better at meeting consumer needs (Ogawa & Piller Reference Ogawa and Piller2006; Hoyer et al. Reference Hoyer, Rajesh, Matilda, Manfred and Siddharth2010; Ranjan & Read Reference Ranjan and Read2016; Roberts & Darler Reference Roberts and Darler2017). This empowerment varies as per firm type and extent of user participation. The extent of participation also affects consumer preferences at the point of purchase. By taking customers as both individuals and as an integral contributor to the design process, inherent characteristics such as personal taste, innate needs and experience become critical integral parts of product design (Tseng, Jiao, & Wang Reference Tseng, Jiao and Wang2010; Gemser & Perks Reference Gemser and Perks2015; Roberts & Darler Reference Roberts and Darler2017).

However, recent changes in user aspirations and the increasing saturation of the markets have led innovators and product designers to develop more individualised products (Holle & Lindemann Reference Holle and Lindemann2015). The evolving nature of these products is disrupting supply and demand chains, forcing organisations to reconsider and reconfigure almost everything they do traditionally. These products create a new set of strategic decisions on how to create and capture value (Kim, Park, & Choi Reference Kim, Park and Choi2017; Zaggl, Hagenmaier, & Raasch Reference Zaggl, Hagenmaier and Raasch2019), how to use and manage the vast amount of new and sensitive data they generate (Balaji & Roy Reference Balaji and Roy2017; Tao et al. Reference Tao, Qi, Liu and Kusiak2018; Zhang et al. Reference Zhang, Chen, Tao and Liu2019; Aheleroff et al. Reference Aheleroff, Xu, Lu, Aristizabal, Velásquez, Joa and Valencia2020), how to redefine relationships with traditional business partners such as suppliers (Sheth Reference Sheth2019) and what role organisation should play as industry borders are expanded (Porter & Heppelmann Reference Porter and Heppelmann2014). The net impact of these products on the structure of industries varies from industry to industry, but different perspectives can be categorised (Kumar, Gattoufi, & Reisman Reference Kumar, Gattoufi and Reisman2007).

1.3. Networked innovation in product design

The final product in the product design for MI is the result of the creativity of different actors, which provides a significant incentive for the role of innovation. The future practice of Innovation 4.0, based on the ‘open innovation’ strategy initially proposed by Chesbrough (Reference Chesbrough2003), is the best suitable innovation practice for MI.

Open innovation is the application of purposeful knowledge inflows and outflows to accelerate innovation (Chesbrough Reference Chesbrough2006; Henkel, Schoberl, & Alexy Reference Henkel, Schoberl and Alexy2014). Comprehensive empirical studies of innovation processes with different kinds of literature across different disciplines identify that organisations have always sourced knowledge from outside. In the late nineteenth century, Edison’s laboratory displayed characteristics that were showing an open approach to innovation (Dahlander & Gann Reference Dahlander and Gann2010). Thus, open innovation plays a vital role in intensifying the innovation process for any organisation. It has mainly been studied in terms of different open innovation modes such as R&D outsourcing and licensing, external cooperation and open innovation performance (Abulrub & Lee Reference Abulrub and Lee2012; Pollok, Lüttgens, & Piller Reference Pollok, Lüttgens and Piller2019). This kind of involvement of internal and external actors in the innovation process requires multidirectional management and strategic integration.

Innovation 4.0 concentrates on the strategic and technological integration of different innovation aspects (Garn & Posselt Reference Garn and Posselt2014), focussing more on inclusive innovation instead of open innovation. It emphasises the networking of all the innovation areas, that is, strategies and methods, technology and products, organisation and processes, society, communication and culture (Jeschke Reference Jeschke2015). Connectivity is the core of Innovation 4.0. Everyone and everything must be interconnected. Linking all the steps in the value chain opens up many opportunities for stakeholders.

1.4. Paper structure

The paper serves as a tool for setting the scope and importance of the product design for MI, along with the industrial implication of this comparatively novel product design approach. Section 1 introduces different key research themes this paper is based on. Section 2 explains the product design for MI in detail with different associated elements. The research methodology adopted for this paper is described in Section 3. In the adopted paper structure, different literature are referred throughout the manuscript, as the literature review comprising the analysis of existing product design and customisation approaches is one of the key parts of the methodology. Section 4 summarises different results along with discussion. The paper ends with a conclusion along with the future research direction of this product design approach.

2. Product design for MI

A demand for renewed product individualisation was observed in the market to fulfil the exact needs of the customers, in the last few years (Franke & Schreier Reference Franke and Schreier2010; Tseng, Jiao, & Wang Reference Tseng, Jiao and Wang2010; Hessman Reference Hessman2014; Wang et al. Reference Wang, Ma, Yang and Wang2017; Tseng & Jiao Reference Tseng, Jiao and Salvendy2018; Montalto et al. Reference Montalto, Graziosi, Bordegoni, Di Landro and van Tooren2020). Koren et al. (Reference Koren, Hu, Gu and Shpitalni2015) proposed and named the concept ‘MI’. Product design for MI comprises an open hardware platform and multiple modules to integrate. Regarding design, MI mainly discerns from mass customisation in three areas: MI expands the design space, MI embraces intangible customer experience and MI enhances creativity and innovation through the democratisation of the product design process. The greatest extension of individualisation can be directly linked to the integration of experience not only in use, but also in purchasing, order processing, inventing and producing components/modules, delivery, upgradation, maintenance, resale and being a producer. MI combines user-centric design with networked innovation.

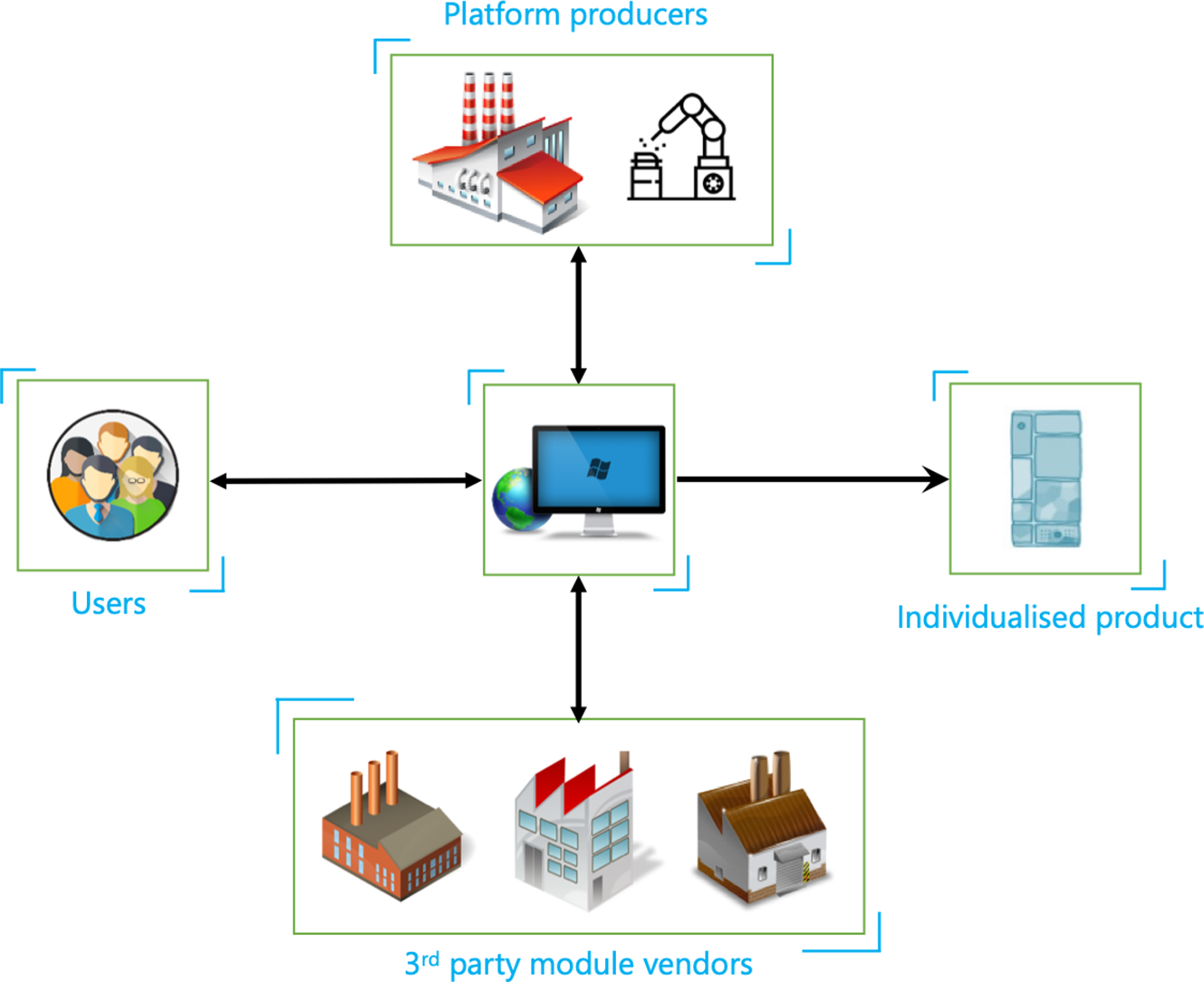

In this paper, the design for this new paradigm is approached by developing a product ecosystem comprising an open hardware platform, module options and active participation of end-users. A product ecosystem can be stated as a network of various actors engaged and active in the design process, supported by technical and business system, and the interface for end-user interaction (Zhou, Xu, & Jiao Reference Zhou, Xu and Jiao2011). Figure 3 illustrates the simplified version of the ecosystem for MI to demonstrate the interconnectivity between different actors involved in the MI. Following this research work, it will be possible to have a more detailed MI ecosystem and corresponding detailed figure. In the developed framework, it is envisaged that large manufacturers will provide the platform of the product along with interfaces for adding modules. These interfaces/modules can be satisfied by different module options. Different modules from available module options can be selected using an interactive and web-based design support system. Therefore, the end product is highly tailored to the requirements of the end-user and is most individualised. This new product design approach is named ‘Mass Individualisation’ as a large mass of products is made, but each one is tailored to the individual buyer’s needs (Koren et al. Reference Koren, Hu, Gu and Shpitalni2015). The prevalent approach of individualisation is to know the exact end-user’s needs with active involvement, from module selection to production. By linking all steps in the value chain, a world of possibilities opens for end-users and other actors. In addition, this approach targets to translate good ideas into innovative products and services quickly.

Figure 3. A simplified schematic of MI ecosystem.

In MI, the active and direct participation of the end-user results in the end product. The product offering depends on the innovation and creativity of many third-party module vendors that invent and manufacture modules. By this individualisation of end-users’ needs, inherent characteristics such as individual taste, choice and experience become an essential integral part of product design and development. End products from MI offer exponentially expanding opportunities for new and innovative applications, better product utilisation, real reflection of end-users’ need in the products (Franke, Schreier, & Kaiser Reference Franke, Schreier and Kaiser2010) and functionalities that transcend and across traditional products offer. They provide a new set of opportunities for all the actors with alteration of traditional structure and nature of competition among industries. These products redefine roles and relationships between different actors for much higher value creation. By reflecting the exact needs of users in the end products, MI dramatically improves output, efficiency and utilisation of products. This industrial product design paradigm has the potential to offer many new jobs as module options manufacturers. The purchase intention and willingness of end-users to buy products will also improve with MI. More actors in design and development would lead to more innovative and useful products. MI also offer sustainable, adaptable and upgradable end products as the end product can be upgraded by just replacing the appropriate module options with upgraded module options on the platform. These are some of the key characteristics in potential MI products which would make it beneficial.

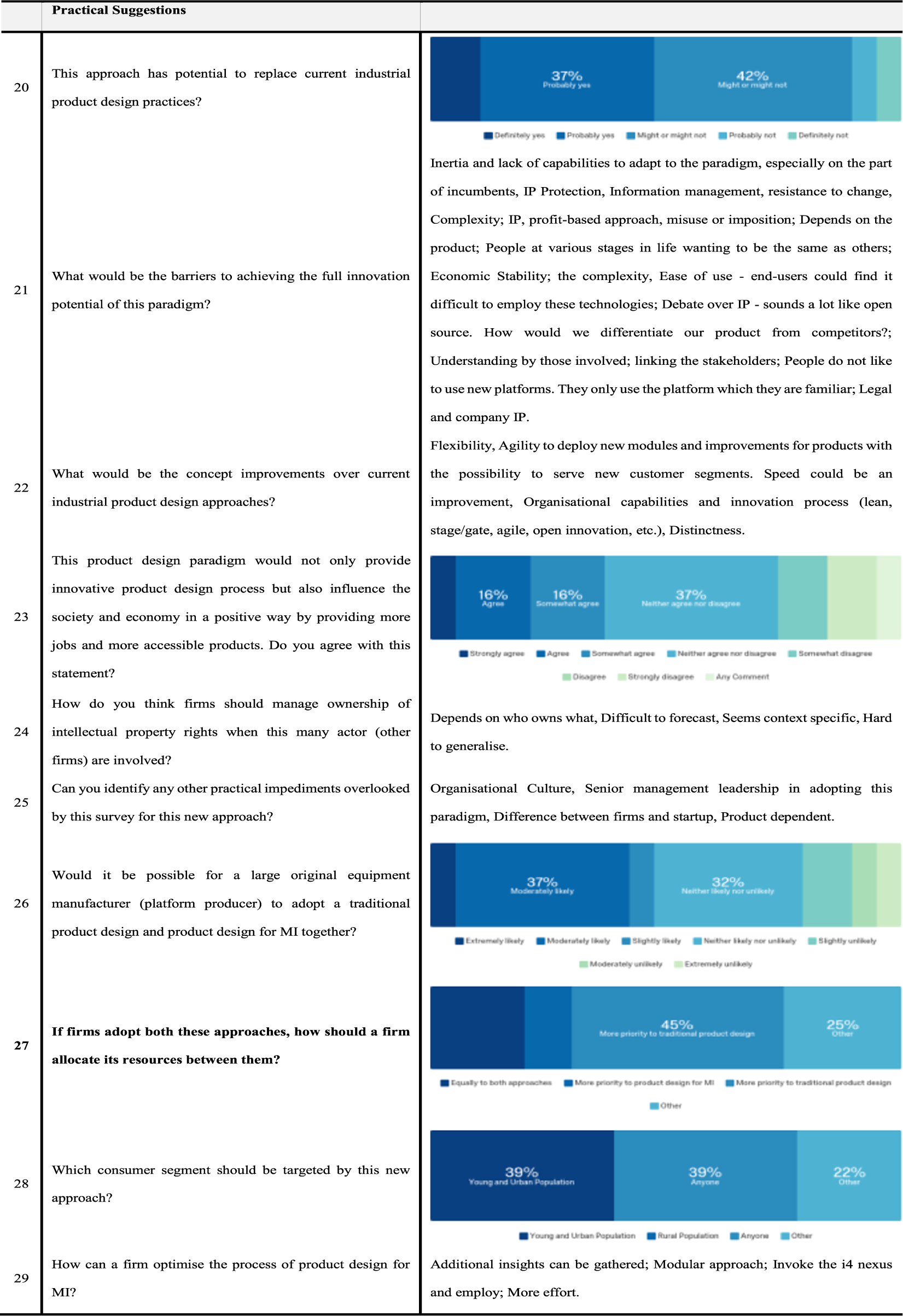

MI could be beneficial for a range of products such as smartphones, smartwatches and individualised furniture. Although MI with envisaged ecosystem has not been implemented in the market, a close design example of a MI product is a smartphone from Google, ARA. Google ARA comprises of an open platform including a structural frame or endoskeleton that connects and holds modules as per the customer’s choice, such as a display, battery, camera or speakers (Ray Reference Ray2015). Users can have many variants according to the integration of the modules in the platform. This would allow users to upgrade individual modules as advanced modules emerge or replace nonworking modules with new ones. This will provide longer lifetime cycles for the handset, and will reduce electronic waste. Figure 4 shows Google ARA with different modules.

Figure 4. Google ARA, a smartphone based on OPAP (Project ARA by Google 2016).

2.1. Roles of different actors in the ecosystem of product design for MI

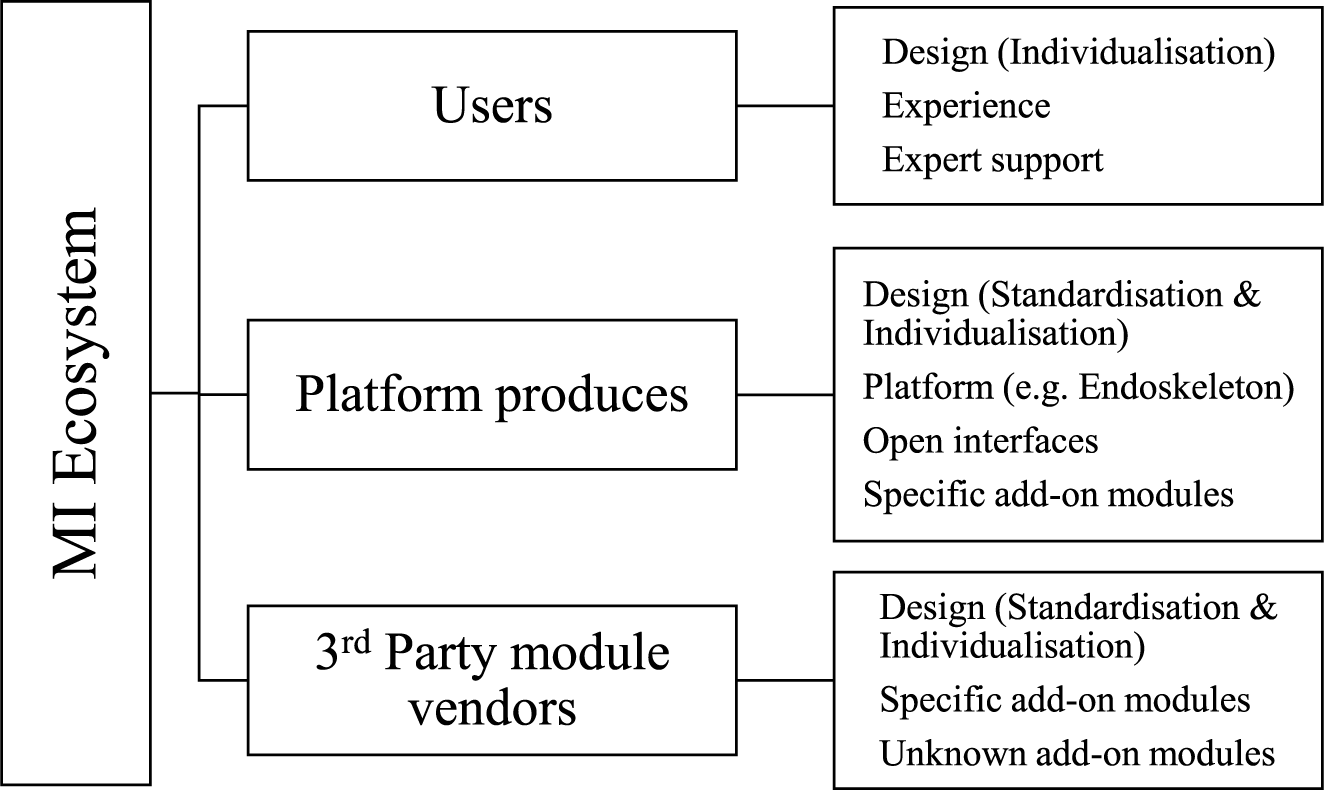

Figure 5 illustrates the roles of all the actors that are actively involved in the product design process. The end-user is an integral part of the design phase. The design phase can be divided into two parts: standardisation, where end-users have some constraints in playing with design put by other actors, and individualisation, where end-users have all the freedom to select the modules and play with design as per their exact requirements. The role and involvement of the end-user in finalising the end product are as equal as other actors, so it becomes imperative to focus on the end-user experience, which could influence the end-user’s decision of adopting that product.

Figure 5. Roles of different actors in the MI ecosystem.

The role of end-users would no longer be just passive beneficiaries, but active value-adding actor. Some end-users would be willing to design and develop their own module options but they might lack domain knowledge and associated technical challenges. To address this, the end-user would be assisted by expert support with an interactive design support system. A design support system describes a design environment which enables and empowers actors to formulate their requirements iteratively and transfer these into a producible solution by an iterative process with continuous live networked support from other actors in the MI ecosystem. This design support system would assist end-users in making better informed decisions, to anticipate customer satisfaction and adapt to customer delight.

Large manufacturers have the potential to offer a product platform with interfaces for a provision to add different modules. The large manufacturers would also provide few specific add-on modules for certain specific functionalities of the product. It is envisaged that these platform producers would also play an important role in the assembly of module options on the platform and after service of these products. The third-party module vendors will invent and manufacture module options for the end-users to opt for and to integrate into the product platform. Every actor will have the opportunity to incorporate smart and innovative capabilities in module options. Specific add-on modules with specific nature and functionality will be provided when the end-users buy the product for the first time. Unknown add-on modules would be provided to replace or upgrade the product as per the user’s requirements which were not thought of at the time of purchase. This kind of ecosystem shifts the competition basis from discrete end products to module options.

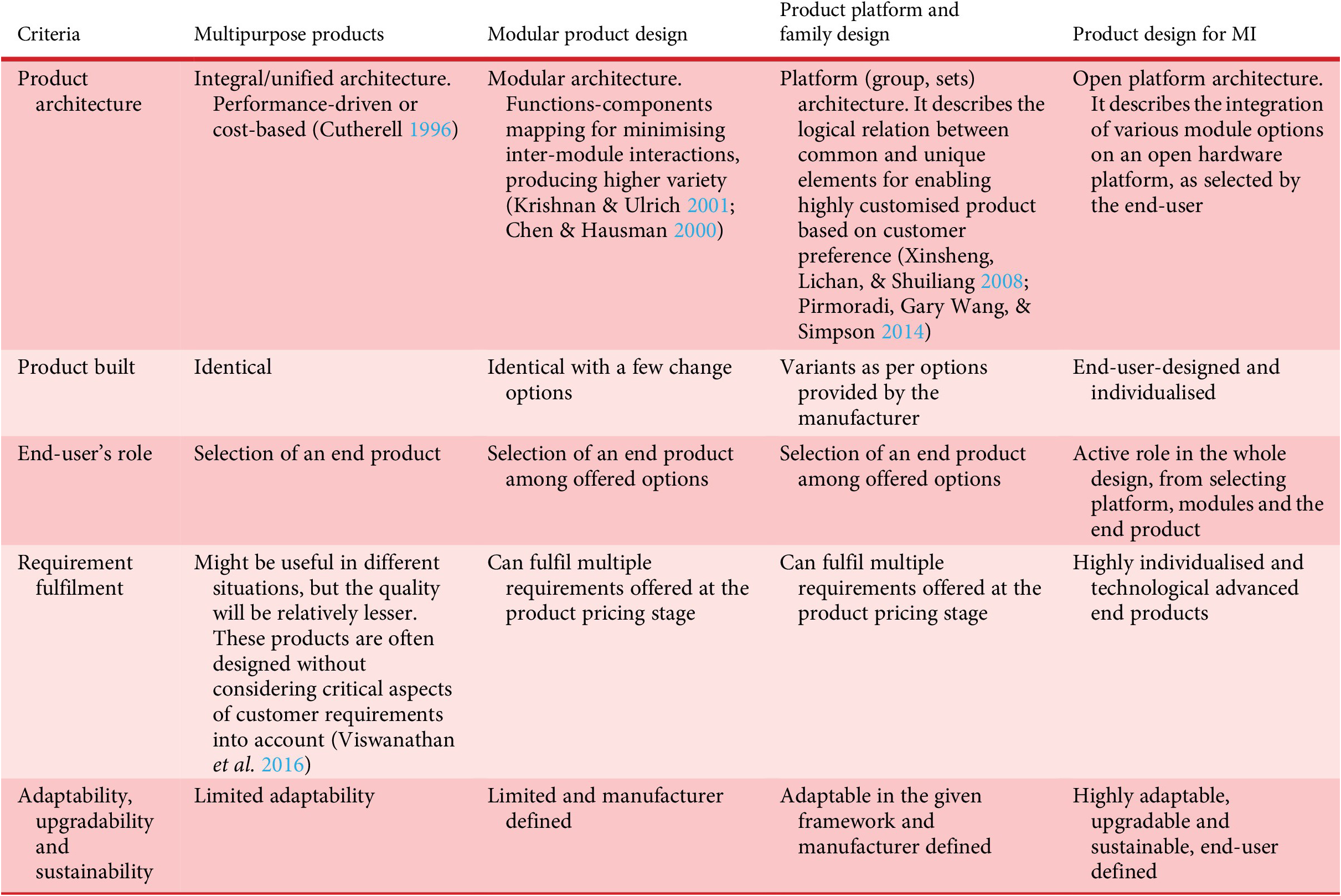

2.2. Comparison of MI with other customisation approaches

As mentioned in the earlier section, MI is a development on the existing user-centric customisation and personalisation approaches for product design including multipurpose products, product modularization and product family design. Table 1 shows how MI is different from existing product customisation and personalisation approaches.

Table 1. Comparison with existing product customisation and personalisation approaches

Abbreviation: MI, Mass Individualisation.

The variability that MI creates in traditional product design, end-user needs, regulations from different authorities and standards can be challenging. Development of the market-ready MI requires empirical research to address different issues, including monetary and resource allocation to different actors. The current framework for the ecosystem is developed considering the end-user’s perspective in the centre. This needs to be expanded by the inclusion of module options suppliers’ and platform producers’ perspectives. Given the benefits MI provides to all the actors, these challenges would be worth to address.

3. Methodology

The cross-connection among various actors in the MI design process demands new and creative solutions. To better understand this new product design paradigm and capture innovation from all the actors, different approaches to traditional product customisation and innovation are required. This section summarises the research design and methods adopted.

3.1. Overview of research methodology

As the previous section explains, MI is a relatively new concept for product design. Experimental study or case studies cannot be used without an existing implementation in the market or literature. Therefore, to investigate this uncertain context and answer the research question, only an exploratory study of current product design and customisation approaches with feedback from industry professionals and product design practitioners allows valid conclusions to be drawn. This paper serves as a tool to set the scope and importance of MI, and this is achieved by a qualitative exploration with quantitative analysis. Qualitative literature exploration is used to identify the key areas and components to be considered for the realisation and implementation of the product design of MI. Following that, this qualitative exploration is used for designing a questionnaire survey for industrial feedback and the implication of this approach.

3.2. Identification of key areas and components to be considered to realise and implement MI

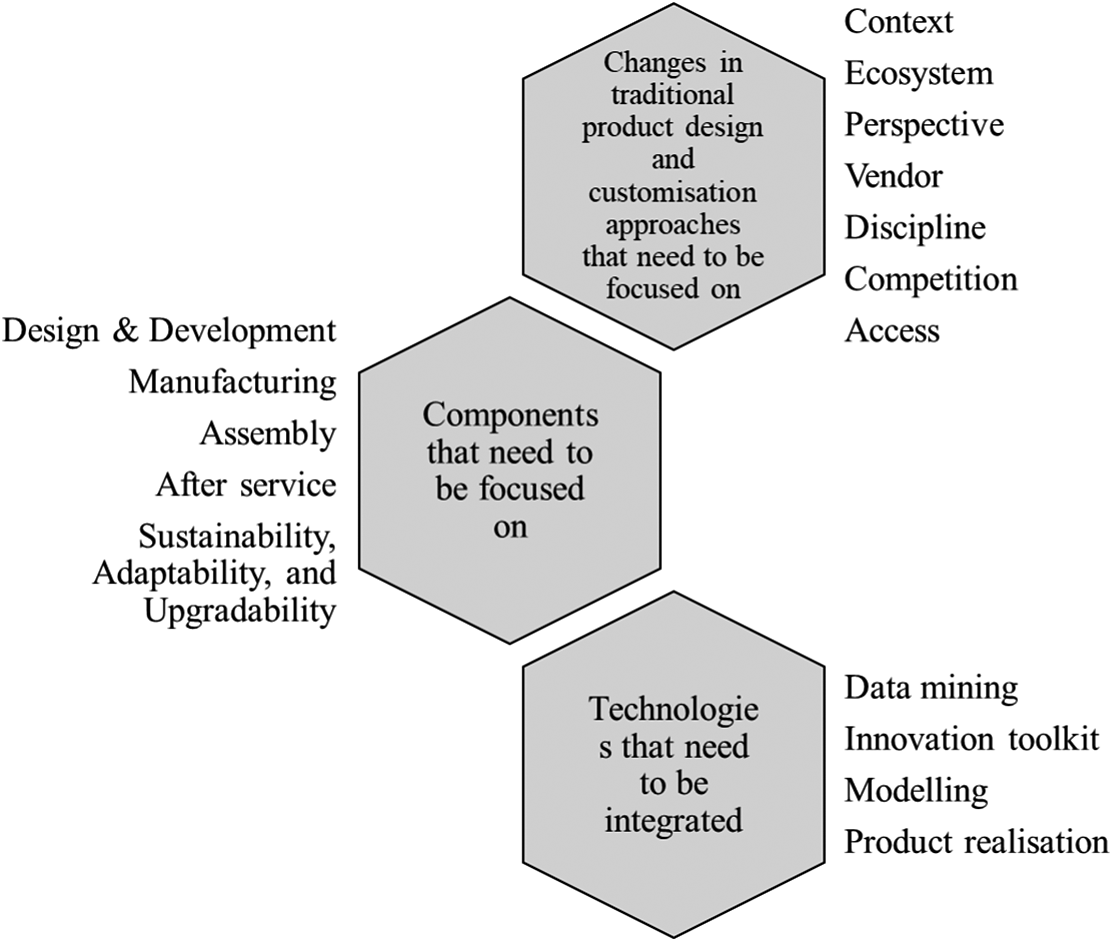

Different key areas and components, needed to be focussed on to realise and convert this innovative approach of MI into industrial practice, are identified by investigation and exploration of current product design approaches. The end product from MI will be highly individualised across different industrial sectors. With taking the theme of Innovation 4.0 as a basis, various areas of MI that need to be focussed on are categorised as follows:

(i) Changes in traditional product design and customisation approaches that need to be focussed on

(ii) Components that need to be focussed on

(iii) Technologies that need to be integrated

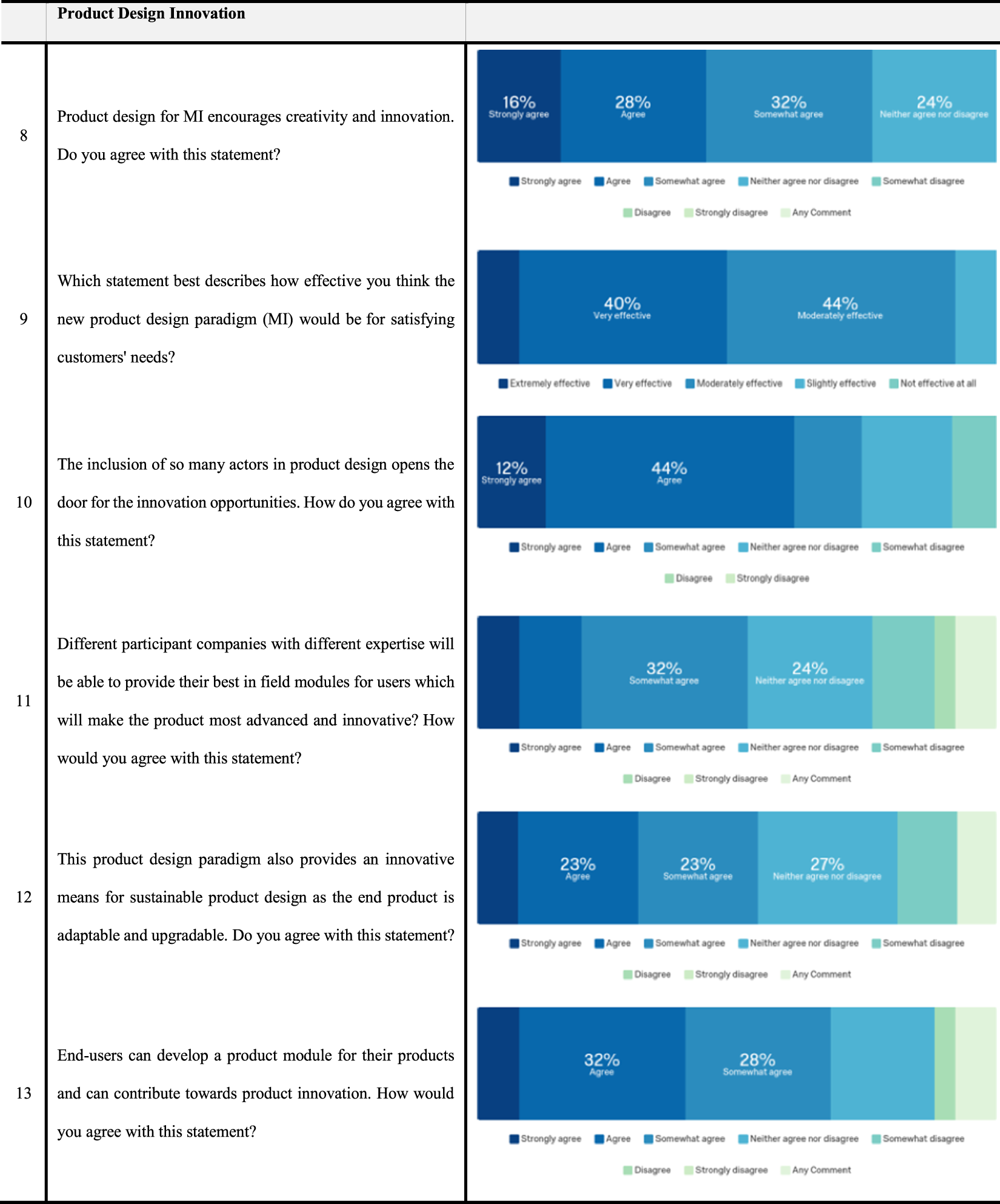

3.3. Questionnaire survey for industrial implication

The end products from product design for MI offer a vibrant, new set of opportunities for creating value and innovation. Based on the exploratory study of relevant literature, and current product design and customisation methods, a web-based industrial questionnaire survey constituting multiple-choice questions and text answer questions was designed. Text questions were included to obtain insights that might overlook by the remaining questions. As Patton (Reference Patton2002) describes, a questionnaire allows to enter into respondents perspective of the area to be investigated. Feedback on critical issues of product design for MI will provide an industrial insight on the topic. This will be helpful in developing the approach further with practical implications. Most of the critical points are based on general industrial product design. They are not industry specific. Guidelines on the formulation of good questions and construction of various open and closed questions provided by Dillman (Reference Dillman2011) were used to design the questionnaire for this survey.

Four different elements were used to select questions and to collect a wide variety of insights touching different critical points of this relatively new product design paradigm:

(i) Product design for MI

(ii) Product design innovation

(iii) Strategical and technological integration

(iv) Practical suggestions

An introductory explanation was provided in the survey about MI, and questions were designed in such a way that they would be received in a similar fashion by anyone engaged with design in general. Most of the answers to multiple-choice questions were measured on a categorical scale with an option of additional comments. The categorical scale was divided into five to seven categories, with the middle category representing a neutral standpoint. Both sides of the middle category were used to show different levels of agreement and disagreement. All the questions, covering a range of aspects and insights, are shown in Appendix A.

To obtain industrial insights, consumer product design companies (350) from different countries and different industries ranging from consumer products, design consultancy and aerospace to automobile were selected as survey participants. An invitation email was sent to respondents to take part in this survey. The survey was deployed via the Qualtrics platform. Access to this survey was given to participants by a link in the invitation email, to protect participants’ privacy. All the responses were recorded anonymously. This privacy protocol was mentioned in the invitation email. Participants’ consent to participate in the survey was implied by completing and submitting the online questionnaire. Before sending the survey to participants, the questionnaire was tested with participants working with or aware of the product design for MI. Feedback from this pilot was used to modify the questionnaire more appropriately. Responses were recorded and used further for descriptive analysis. This analysis is interpreted and presented in the following sections to reflect on industrial insights and implications.

4. Results and discussion

The explorative study of current product design and customisation methods, followed by an industrial questionnaire, provided insights and a new basis for developing the relatively new approach of MI. Different results along with discussion are presented in the following sections.

4.1. Key areas and components to be considered to realise and implement MI

The explorative literature analysis identified various key areas and components that need to be considered for the industrial implementation. Underlying factors include end-user’s willingness and preparedness to be integrated into the process of product co-design and co-creation, near-universal availability of the Internet, development of information technologies, evolving product architecture, modern manufacturing systems, such as reconfigurable flexible manufacturing. Figure 6 illustrates the findings of the explorative literature analysis of existing product design and customisation approaches.

Figure 6. Key areas to be considered for industrial implication.

Changes in traditional product design and customisation approaches

The realisation of product design for MI requires a whole set of new design principles, such as a cross-connected design support system, access to everyone. The following changes in traditional product design approaches are identified to realise the new product innovation paradigm:

(i) Context: Unlike traditional product design approaches, MI consists of horizontal networking between various actors. Every actor has an equal role in the final product and innovation process, and the end product is the end result of the creativity and innovation of various actors. The opportunity of being the active contributor than just passive beneficiary would enhance their willingness, and the live-networked support from other actors would further keep them prepared for this innovation process. Existing risk assessment and profit-sharing models (Lo Nigro & Abbate Reference Lo Nigro and Abbate2011) can be restructured for these horizontal networks.

(ii) Ecosystem: MI ecosystem consists of three main actors: end-user, platform producer and various module options providing companies (such as third-party vendors and independent module developers). All the actors can be mapped with a multilevel and cross-connected ecosystem framework to disentangle and manage the relationship among them. This framework would include the expectations and goals of participating stakeholders/actors. Strategies developed for value co-creation in a multistakeholders atmosphere for a firm (Nudurupati et al. Reference Nudurupati, Bhattacharya, Lascelles and Caton2015) can be used as a basis for the ecosystem.

(iii) Perspective: Networking between all actors becomes a central feature in this new approach. Everybody and everything are connected anytime everywhere. This approach would also encourage responsible product consumption, sharing economy and other socio-technical benefits. Social and technological innovation are closer than previously encountered, and the development of MI benefits from this.

(iv) Vendor: Smaller companies play an important role as third-party vendors. The inclusion of various module options vendors towards the end product helps to intensify the innovation in the product design and development process (Pierick & Ten Reference Pierick and Ten2000; Gulati Reference Gulati2010).

(v) Discipline: This new approach encourages excellence through the interdisciplinary network. Highly sophisticated, socio-technical systems have to be developed as a central theme with a collaboration of various academic disciplines expert and institutions. To realise and implement this approach in the market, future designers will require to look further beyond their expertise and traditional business models.

(vi) Competition: A healthy competition between all the actors need to be motivated for improved design and innovation. Approaches like competition in the multisided platform market channel (De Matta, Lowe, & Zhang Reference De Matta, Lowe and Zhang2017) can be expanded considering the different roles and settings of various actors of the MI ecosystem.

(vii) Access: The traditional close access in product design approaches has to be changed. Horizontal networking of various actors needs to be strengthened by access to all essential information to all the actors. Further models in terms of access sharing between different actors, attention to intellectual property (IP) will be required.

Components that need to be focussed on

Development of different components of the MI ecosystem requires innovative means of design, manufacturing and relevant infrastructure that have not been typically presented in existing companies. The following areas are identified to focus the approach to the new paradigm:

(i) Design and development: Design is the most critical phase of any product. The end-user has a direct role in the product design and development in MI, unlike traditional product design approaches. With an interactive design support system, they can select only those modules that can fulfil the desired requirements, thus designing a highly individualised end product. This research finds that this will be an iterative process, the end-user will select modules for the platform and then different module options will be provided by third-party vendors.

(ii) Manufacturing: In MI, the end product is made of platform, interfaces and modules/module options. These different components will be manufactured at different places. It is envisaged that the platform along with different interfaces will be manufactured by large manufacturers. Different interfaces include electrical, software and mechanical interfaces. Module options will be provided by different smaller companies with their own manufacturing facilities. This type of manufacturing needs more responsiveness in production and advanced reconfigurable manufacturing systems that can manufacture a variety of products with existing facilities (Ortega Jimenez et al. Reference Ortega Jimenez, Machuca, Garrido-Vega and Filippini2015; Wei, Song, & Wang Reference Wei, Song and Wang2017). Current manufacturing enterprises need to be equipped with the latest practices like the internet of things (IoT) to produce product timely and in an accurate manner. Internet of manufacturing things is one such example (Zhang et al. Reference Zhang, Wang, Sun, Si and Yang2015).

(iii) Assembly: A new-networked assembly line, capable of assembling different module options provided by different third-party vendors on the platforms as per end-user needs, is required. Different suppliers across the globe will offer module options as requested. It is envisaged in our investigation that the final end product can be assembled by platform manufacturers.

(iv) After services: This approach will require a new and innovative method of after service. A service point needs to be created which can be accessed by platform manufacturers to facilitate iterative communication between end-users and module options suppliers.

(v) Sustainability, adaptability and upgradability: Product design for MI contributes to the circular economy in many ways. In MI, the end product is most individualised. End-users select only those module options are which fulfil their exact requirements. This reduces overproduction of the modules or products. It is easy to use the product for a more extended time period, as the product is a precise fit to the needs. End-users can also change the modules as per the change in requirements. Thus, the end product is highly adaptable. Used modules can be put again in the marketplace for other users to use. Products can be upgraded just by replacing the existing module with an updated module instead of changing the entire product; it would significantly contribute towards sustainable product design.

Technologies that need to be integrated

Technologies are identified as one of the factors that facilitate and make the concept, the networked innovation in MI, far more practical. The improved speed, processing power, evolution of customer relationship management as a strategy, improvements in enterprise resource planning software consistent with individualised needs, data warehousing, connectivity and interfaces provide the required support to transit to new product design paradigm. New technologies allow for new ways to collaborate and coordinate across various discipline and between actors. These technologies help to create and develop new environments for actors to think about new options, to interact iteratively or to experiments with a different combination of module options into the end product. Advanced information and communications technologies have enabled an even faster exchange of distributed sources. These technologies not only provide direct means to facilitate the support system for MI, but also helps shape the strategic orientation of industrial firms towards open hardware platforms. The following technologies are identified as key contributors to this new product innovation process:

(i) Data mining, artificial intelligence (AI) and IoT: Real-time connectivity with users and vendors, cloud computing, fast processing of data, big data, data mining, data visualisation, augmented reality (AR), 3D printing, internationalisation of technologies, AI and IoT are few key technological enablers to realise and implement this new product design approach. Internet-based innovation platforms and intermediaries will assist in identifying patterns in consumption data to find opportunities and challenges. Access to these data and the demand pattern of users accelerate the process of networked innovation. Thousands of inventors and designers will be able to work together on cloud computing with different data mining resources to generate innovative solutions for this new product design paradigm. Technologies like AR and 3D printing enable fast visualisation of end products. With the help of AI, various products are able to perceive their environment and take actions to maximise their chances of successfully achieving their targets. These products will collect the information and act as per change in user preferences. One other key enabler for this innovative product design approach is the IoT. This refers to the interconnection of computing capability in everybody objects or in other terms, connecting devices over the internet. An IoT ecosystem consists of web-enabled smart devices that collect data with embedded processors and sensors send these data to an IoT gateway to analyse locally or on the cloud and then act accordingly (Whitmore, Agarwal, & Da Xu Reference Whitmore, Agarwal and Da Xu2015). IoT makes strategies like MI far more practical and cost-efficient (Yang et al. Reference Yang, Lan, Shen, Huang, Wang and Lin2017; Ikävalko, Turkama, & Smedlund Reference Ikävalko, Turkama and Smedlund2018; Deloitt’s CMO Article 2019; Shnawa Reference Shnawa2019). Information can be shared in real-time between all the actors. End-users can select the modules they want and opt to integrate the selected module option into the platform in real-time. Module option suppliers and platform providers can see what modules are being ordered, and with rapid systems retooling and reconfiguration adjust their manufacturing and assembly line appropriately (Lu & Cecil, Reference Lu and Cecil2016). Wang et al. (Reference Wang, Lin, Zhong and Xu2019) proposed a new cloud platform to integrate complex resources such as 3D printers and materials, and soft resources such as the know-how and test data to provide supports on 3D printing, design and process planning. Application of IoT for Product Lifecycle Management (Cai et al. Reference Cai, Xu, Xu, Xie, Qin and Jiang2014) and business models (Leminen et al. Reference Leminen, Westerlund, Rajahonka and Siuruainen2012) were explored in the literature. Industry 4.0 and innovation 4.0 are all two further developments of ICT with the IoT as the key enabler.

(ii) Innovation toolkit: This paper identifies the need for an innovation toolkit that would provide a design support system to funnel design potential to the end-user, and a framework to determine the optimal MI end product with optimal module options on the platform. It would guide the end-user within specific frameworks to choose modules for the platform according to their exact needs. End-users can also use this toolkit to better understand various product scenarios, that is web training can be used to learn certain specialised skills required for a custom design. This will help end-users to present their latent requirements that conventional customer requirement research tools cannot provide. The innovation toolkit can be further developed to ensure that the end product can be assembled on the planned production lines. It would also support a whole range of value-adding services, such as web services, resource planning and end-user relations management.

(iii) Modelling and simulation: Modelling and simulation have been an essential part of the product design and development process. It allows real-time, execution level events to be represented, investigated, analysed and understood. Simulation provides a rich environment for testing and analysing different approaches to operating strategies that could be effective (Dodgson, Gann, & Salter Reference Dodgson, Gann and Salter2006). The aim of having a modelling system is to provide a platform for product specifications change during the design stage. This makes it possible to represent, analyse and redesign the end product before going to prototypes. Configuration-oriented product modelling for made to order manufacturing (Jinsong et al. Reference Jinsong, Qifu, Li and Yifang2005) can be used as a basis to approach modelling in this approach. A modelling tool has to be developed that makes it easier for different actors to access the design, iterate design modifications and receive continuous feedback from other actors in the ecosystem.

(iv) Product realisation: AR, rapid prototyping and additive manufacturing are some of the critical processors that enable the realisation of the end product before the final manufacturing and assembly. However, in order to realise end product development, a new product realisation tool for end-users needs to be developed that can provide all the liberty to experience the end product and to give continuous feedback on that experience to third-party suppliers of module options and platform manufacturers. This can be built upon some available commercial platforms that provide this kind of communication between actors, that is second life (SecondLife 2017). Another such example is virtual reality shopping malls by P&G to test consumer reaction to its products compared to competitors (Dodgson, Gann, & Salter Reference Dodgson, Gann and Salter2006).

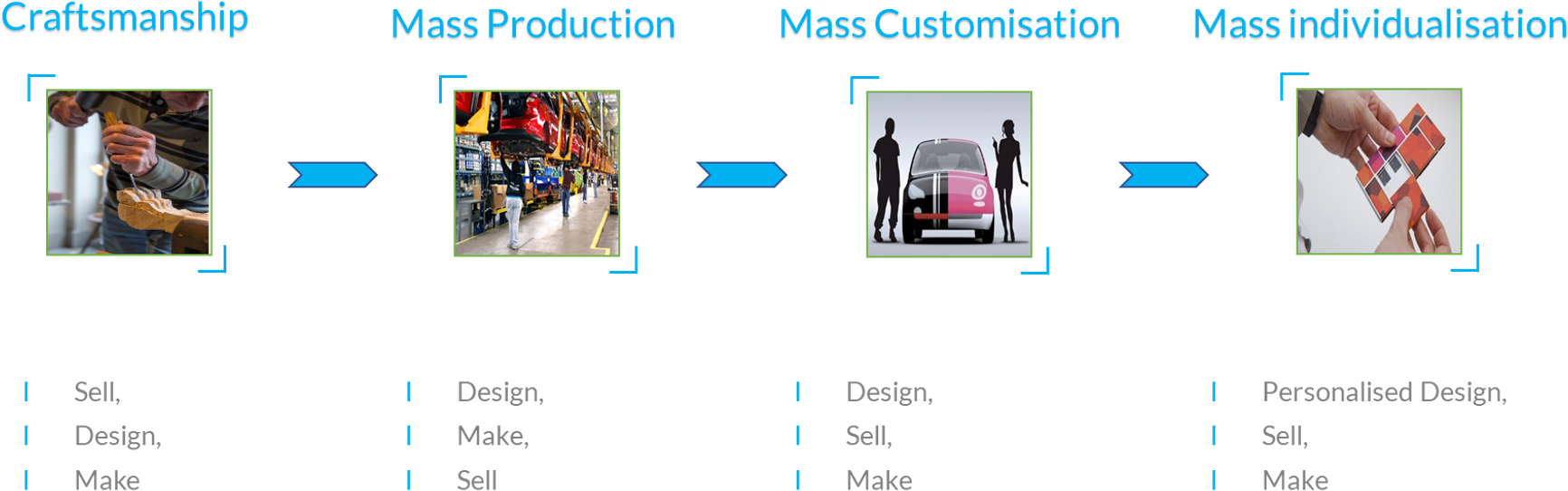

4.2. Industrial implications

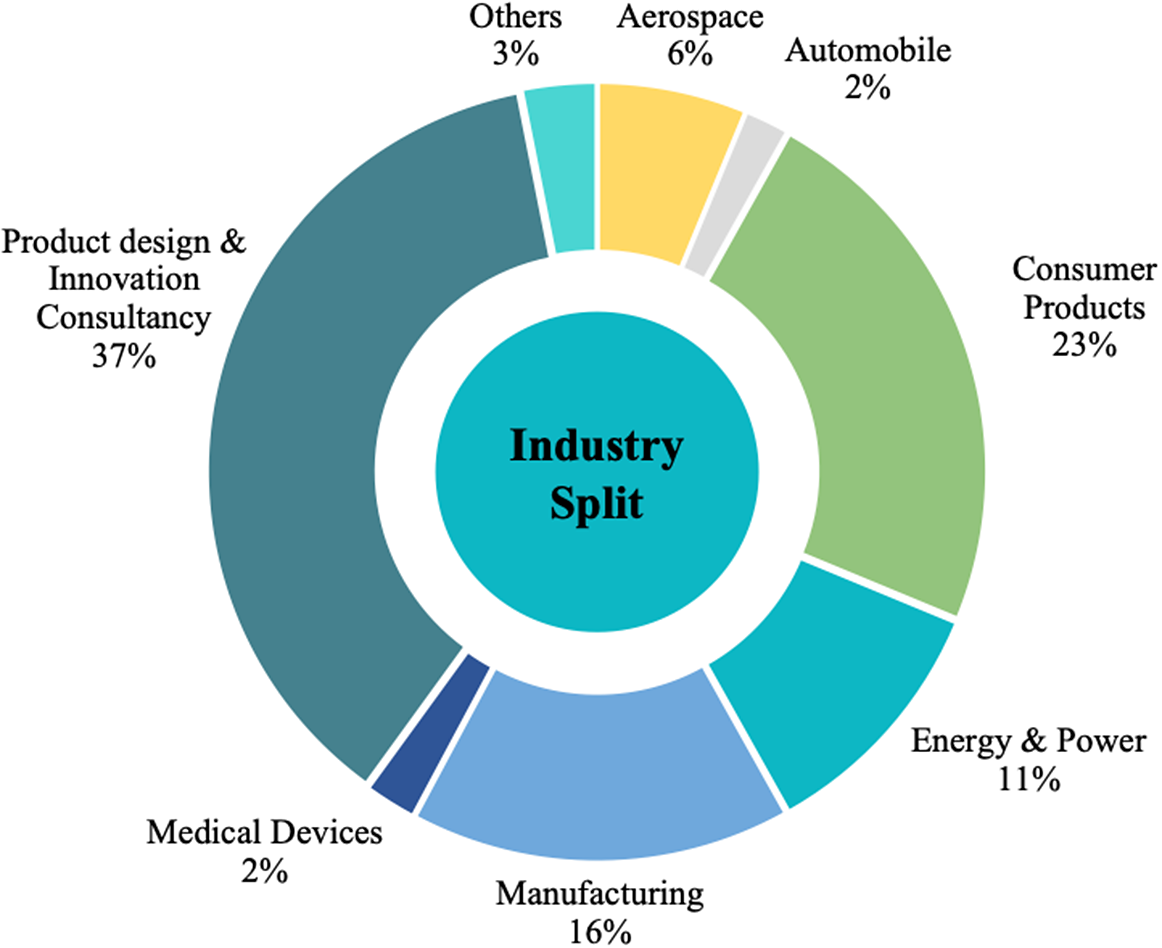

The questionnaire survey provided 50 responses, which yielded an adequate amount of important information about the innovative approach of product design for MI. These responses were analysed descriptively and statistically to understand the industrial implication. Figure 7 illustrates the industry splits of the invited survey respondents, across different sectors. Appendix A summarises the questionnaire along with the categorical and text responses. Different results in terms of responses along with analysis are explained in the following paragraphs.

Figure 7. Industry split of the questionnaire survey respondents.

The first five questions aimed at obtaining insights on the current product design approaches and the significance of the innovative product design approach of MI. It can be seen in the responses to Question 1 (Q.1) that the majority of the respondents are unfamiliar with MI. It can be explained from the fact that product design for MI is a relatively new product design approach that requires further research and development in different aspects of the approach. This work provides an initial framework in that direction. Q.2 responses provide an indication that the majority of the participants are from consumer electronics companies. This is consistent with the assertions made earlier that consumer electronics goods would be the starting point for the market implementation of the product design for MI. Responses to Q.3 are encouraging and consistent with the objective of this article that product design for MI would lead to more innovative end products tailored to the exact needs of the end-users. Q.4 was designed to understand the applicability of this approach. Responses to this question provide mixed agreement. It can be explained from the fact that some market segments, probably consumer electronics companies as demonstrated in the Q.2 responses, would regard product design for MI as a more beneficial product design approach. Q.5 was designed to understand the application of MI to types of industry. Twenty-seven percent of responses agreed with the suitability of MI with all types of industries, but interestingly equal responses showed the Consumer Electronics, the Fashion industry and the Furniture industry as leading beneficiaries. This could be inspired by the existing application of product customisation in these areas. From this survey response, this can also be understood that some users/industries might prefer standardised products rather than individualised ones.

Responses to Q.6 were significant in providing motivation for this paper, with 80% of responses indicating that MI would increase the intention and willingness of the end-users to buy end products produced by this approach. As opposed to other existing customisation approaches, MI provides end-users a platform to be a direct part of the product design and development process. It facilitates end-users to invent and work on their own idea and contribute towards the product. Q.7 was included to get an idea about the acceptability of the end product by this approach. Given the benefits of MI with open platform architecture, more than 80% of responses show that respondents would consider using a product designed with this approach.

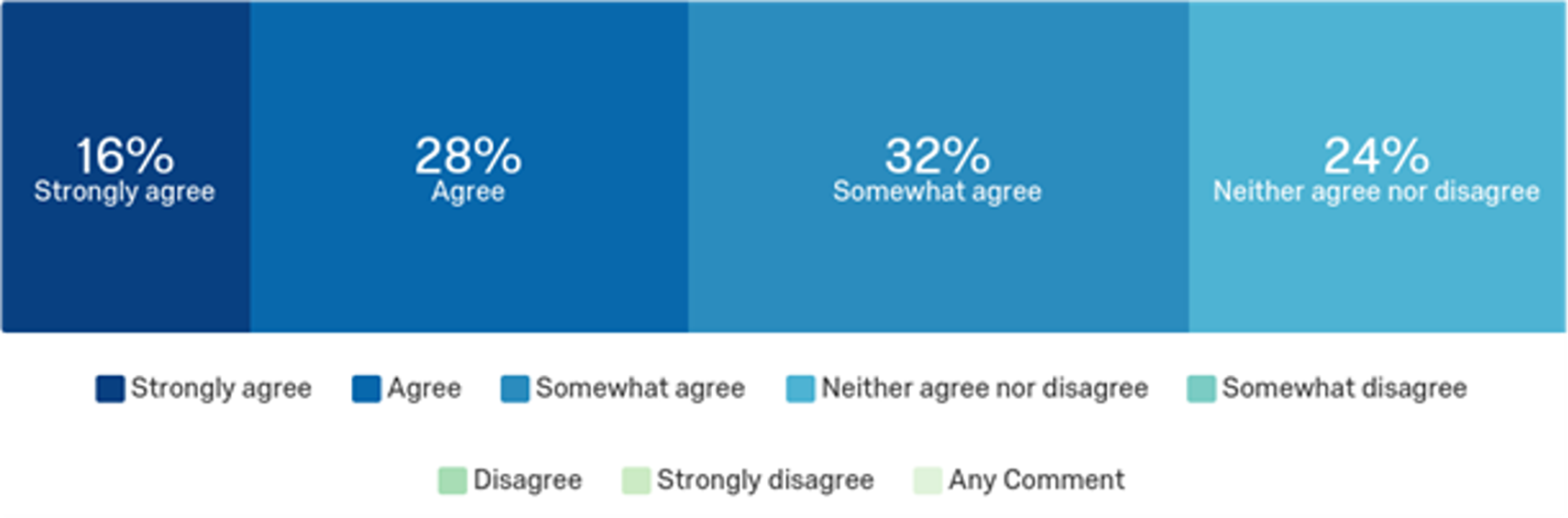

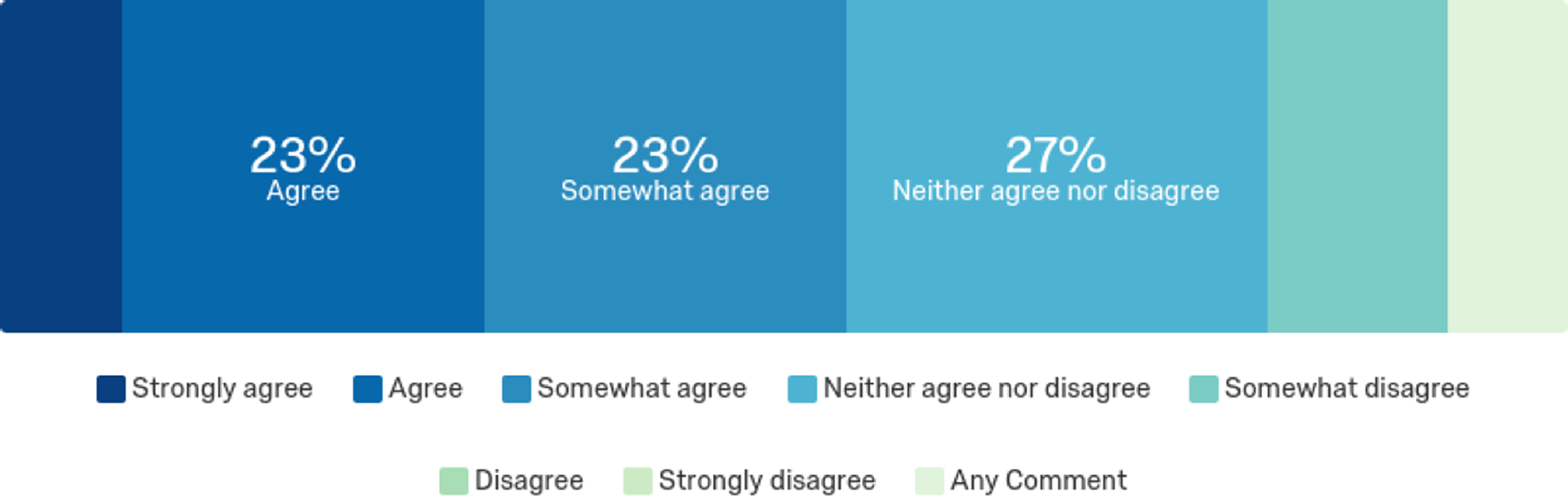

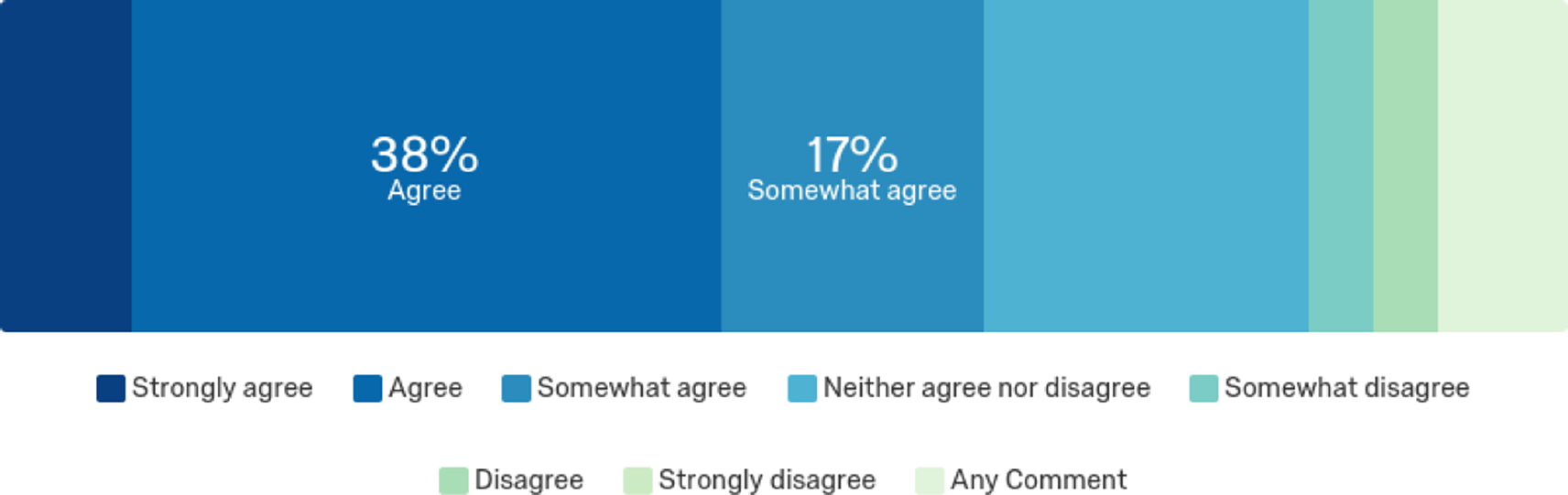

Responses to Q.8 are shown in Figure 8. These responses are very motivating as 76% of responses are in some degree of agreement with the idea that MI will encourage creativity and innovation towards producing a highly individualised end product. This creativity and innovation would play a vital role at different stages of design and development. Responses to Q.9 confirm that product design for MI will satisfy customers’ needs in the best possible way. It is evident from the fact that customers will be able to select the specific modules as per their exact requirements into the end product.

Figure 8. Responses to Question 8, ‘Product design for MI encourages creativity and innovation… statement?’

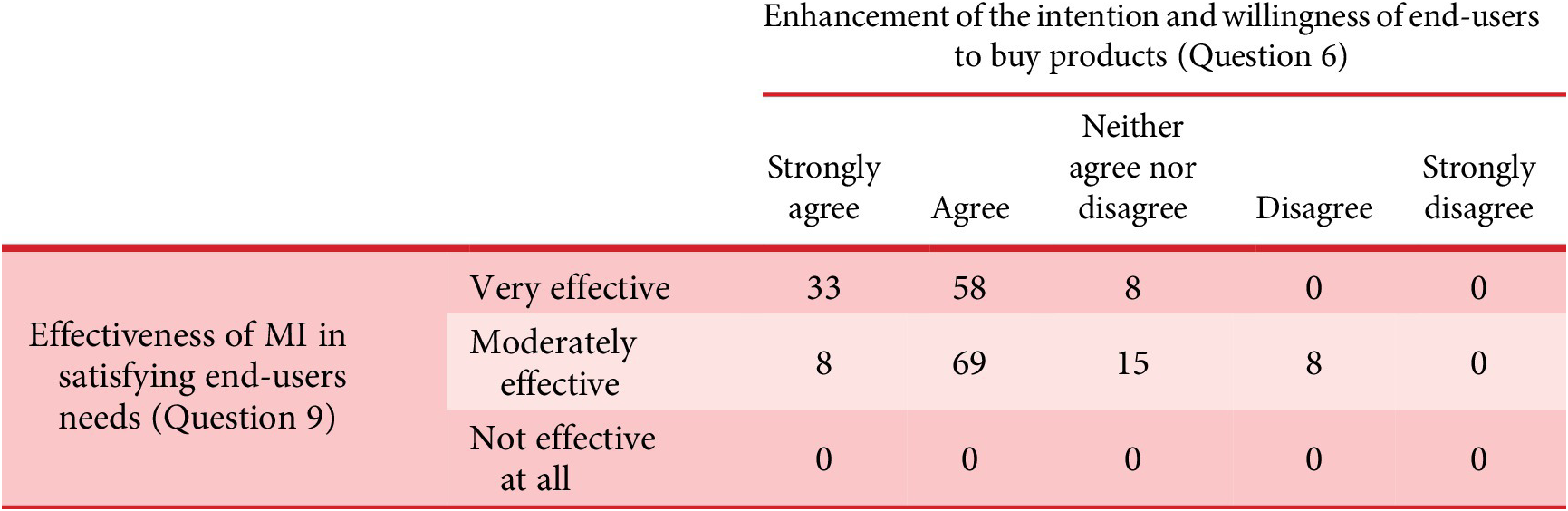

Table 2 illustrates a comparison of responses provided for Q.6 and Q.9. For ease of analysis of responses of Q.6, somewhat agree and agree responses are bundled together under agree column, so thus the somewhat disagree and disagree one under disagree column. Similarly, for the responses to Q.9, very effective and extremely effective responses are bundled together under the column of very effective response, so thus slightly effective and moderately effective under moderately effective column. It is interesting to note that the majority of responses that agree with the fact that MI would be moderately effective to very effective, also agree with the notion that it would increase the intention and willingness of the end-user to buy end products designed with this approach. This co-relation emphasises that customers would be much happier to purchase a product if it is more individualised to satisfy individual needs. This proves the potential of MI in addressing the market to one phenomenon.

Table 2. Comparison of responses of Questions 6 and 9 (responses are in percentages)

Abbreviation: MI, Mass Individualisation.

It can be seen in the responses to Q.10 that these are in line with the responses to the previous question. It indicates that the incorporation of so many actors towards getting the end product unlocks many innovation possibilities. It was envisaged in our literature analysis in earlier sections that different module options providing companies will be able to provide the most advanced and innovative products by this approach. Responses in the agreement side strengthen that analysis, but almost similar responses on the negative-side show that it might depend upon many factors, including various functional constraints put forward by the platform manufacturer and other module option providers. Q.12 responses are illustrated in Figure 9. These responses strengthen the notion that MI will be able to offer an innovative means towards sustainable and adaptable product design, as greater than 50% of responses are in agreement and 27% of responses are on a neutral standpoint.

Figure 9. Responses to Question 12, ‘This product design paradigm also… this statement?’

Thirty-two percent of the responses to Q.13 are in agreement with the notion that the end-users will be motivated enough and will contribute towards product innovation. It is evident from the fact that they will be able to select and even produce module options. However, 28% of responses are only slightly agreed with this question. It could be inspired by the fact that end users may not possess enough skills set and understanding, including acquiring appropriate requirements and generating suitable module options.

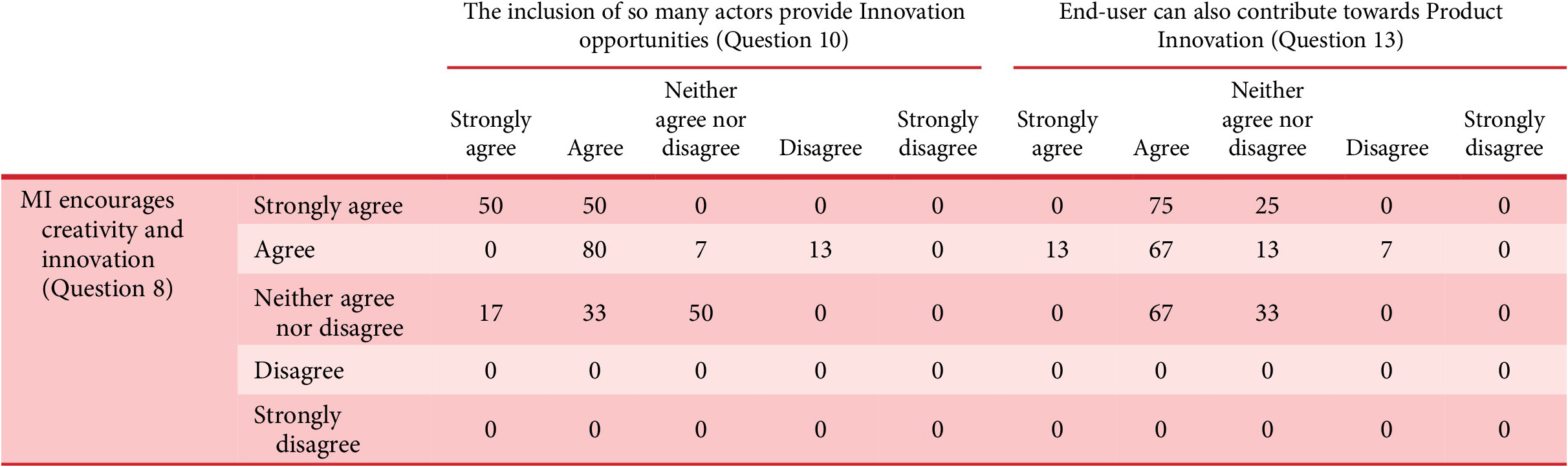

Table 3 provides a very useful comparison of Q.8 with Q.10 and Q.13. For ease of analysis of responses, somewhat agree and agree responses are bundled together under agree column, so thus the somewhat disagree and disagree one under disagree column. Q.8 explores the possible encouragement to creativity and innovation in the product design process provided by MI, and Q.10 and Q.13 explore the reason behind that encouragement. It is evident from this table that the percentage of responses that are in agreement side of the idea that MI motivates creativity and innovation, also agree with the fact that this encouragement to creativity and innovation might be because so many active actors are included in the product design process and also because of end-user’s direct contribution.

Table 3. Comparison of responses of Question 8 with Questions 10 and 13 (responses are in percentages)

Abbreviation: MI, Mass Individualisation.

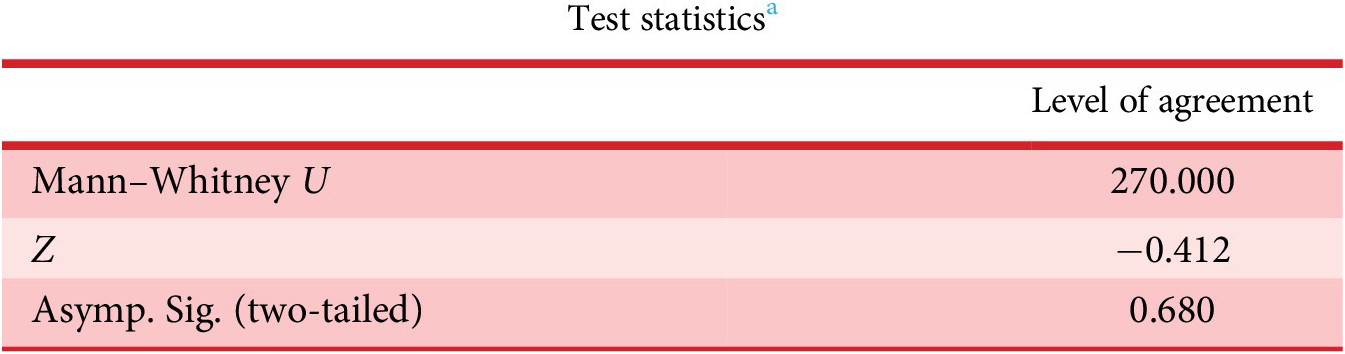

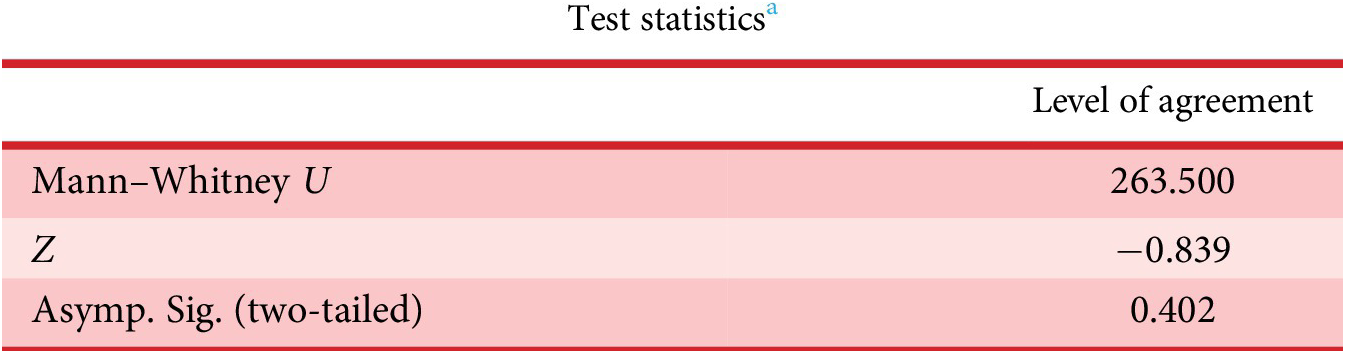

Responses to Q.8, Q.10 and Q.13 are further analysed to see any statistical difference between these responses. IBM SPSS is used to carry out this statistical analysis. A nonparametric test, known as the Mann–Whitney U test is selected for this statistical analysis. It is used to compare differences between two independent groups when the dependent variable is ordinal. ‘No difference between responses from these two groups/questions’ is used as the null hypothesis.

Tables 4 and 5 shows various outputs of the Mann–Whitney U test. Since the value of P > 0.05, the data does not show any evidence to reject the null hypothesis. From this, it can be concluded that there is no statistically significant difference between responses of Q.8 and Q.10, similarly for Q.8 and Q.13.

Table 4. Test statistics for the responses of Question 8 and Question 10.

a Grouping variable: question numbers 8 and 10.

Table 5. Test statistics for the responses of Q.8 and Q.13

a Grouping variable: question numbers 8 versus 13.

The responses to Q.14 suggest that MI provides a mean of expansion of industrial borders and bring various companies with particular competence together on a solitary platform. Above 50% of responses agree with the notion that this approach provides a basis for this. Response to Q.15–Q.18 highlighted few changes in the business strategies that will happen due to MI. Responses to Q.15 were mixed in nature. This question was designed to gain insights on the idea that MI will encourage innovation in terms of organisational structure. A possible explanation is that MI is not yet implemented in the market with an organisational structure. It can be seen in the responses to Q.16 that MI motivates positive competition in module options suppliers (i.e., third-party vendors).

The majority of the responses to Q.17 indicate that resource accessibility by cross networking in between various actors is essential for innovation in product design. Q.18 with responses is depicted in Figure 10. Above 60% of the responses are in agreement with the notion that same level networking in between module option supplier and support from the platform producers give the most effective of the innovative technology readily available. Responses to Q.19 provide an interesting insight as more than 60% of the responses agreed that MI would reduce the technological unpredictability by uniting various professional on a solitary platform.

Figure 10. Responses to Question 18, ‘Networking different actors at… this statement?’

Q.20–Q.29 were designed to obtain some practical insights and suggestions to ensure that we did not miss them in earlier questions. To gain insights on the practical benefits of product design for MI in comparison with existing product design and customisation approaches, a descriptive question, Q.22 was included. Responses to this question provided insights into many frontiers. Responses show that this new approach will give greater flexibility, speed, and distinctness, the potential of serving to a new customer segment and product innovation in terms of the product offering. These responses were quite motivational as they provided many positive improvements which product design for MI might lead in traditional product design. Q.21 provided potential barriers to achieving the full innovation capabilities of this paradigm, including complexity, dependence and differentiation. Responses to Q.23 indicate that above 65% of participants are in agreement with the notion that product design for MI will create new jobs along with more accessible products. Q.24 was designed to gain insights on intellectual property rights (IPR) in this product design approach. Responses to this question listed different perspective to handle IPR; it is challenging to forecast, it will depend upon who owns what. Responses to this question provide a basis for further investigation regarding IPR in MI.

Responses to Q.25 provided feedback on the potential practical impediments overlooked by the questionnaire survey. Q.27 was designed to obtain insights on the resources distribution strategy of a prospective firm that use both approaches, product design MI and other traditional product design approaches. Responses to this question illustrate that 45% of the resources could be allocated to the MI. This shows the potential inclination towards MI by existing product design practitioner. Once the product design for MI is implemented in the market, this distribution share has the probability to increase.

Respondents to this survey also highlighted the acceptance of this new approach by senior leadership in organisations. This could be motivated by the lack of past research and market implementation, which proves the significance of this approach. This inspires for further investigation and development in the research area of product design for MI. Q.28 was included in the survey to obtain insights on potential consumer segment where this approach can be implemented and be fruitful. Thirty-nine percent of the respondents replied that the young and urban population could be an excellent point to start. An equal number of responses were in agreement with the notion that anyone can get benefit from this new and innovative product design approach.

To summarise, the survey questions addressing different key aspects of MI helped to gain multidimensional insights on this approach. The majority of responses agreed with the co-relation that design for MI enhances creativity and innovation towards an individualised end product. However, at the same time, some responses were not in agreement with this co-relation. These responses provided the basis for further improvement in the approach. Results discussed in this section are based on the limited sample size and expert designers’ perspective. However, most of these invitations were sent to lead designers or experts associated directly with product design and development practices to obtain more realistic feedback on the approach. These findings can be further verified with a larger sample size, and with end-user data once we have a market product based on MI, in future research.

5. Conclusion and research direction

Increasing aspiration levels of customers are forcing companies to rethink their product development organisation, revise the use of technological innovation into products, and derive individualised products from them. The paper has argued that the new product individualisation approach, MI, would fulfil the exacting needs of end-users by providing highly individualised and technologically advanced products. The paper furthers the academic and industrial interest in product individualisation with MI. The product design for MI comprises an open hardware platform, mass-produced by large manufacturers and multiple independent modules invented and produced by other smaller companies. It gives freedom to end-users to integrate different modules into the platform as per their choice and thus producing highly individualised products. This type of product integration will be engaged with by all actors involved in the design and aims to help them to be more creative and innovative.

This article is positioned to connect established literature on customisation to innovative propositions for individualisation and sets the scope for MI along with providing a mean of promising opportunities to advance the field. In terms of design, MI mainly discerns from mass customisation in three areas: MI expands the design space, MI embraces intangible customer experience and MI enhances creativity and innovation through the democratisation of the product design process. The most significant extension of individualisation can be directly linked to the integration of experience not only in use, but also in purchasing, order processing, inventing and producing components/modules, delivery, upgradation, maintenance, resale and being a producer. MI combines user-centric design with networked innovation. By linking all steps in the value chain, a world of possibilities opens for end-users and other actors. In addition, this approach targets to translate good ideas into innovative products and services quickly.

MI is explored in a combined qualitative and quantitative analysis for industrial implication. To realise and implement MI in the market, different key areas are identified with an explorative analysis of the current product design and customisation approaches. An industrial survey was designed based on this analysis and was conducted to get industrial insights. The survey yielded sufficient information to provide clear insights on different aspects of this new approach. Some responses were concerned about the feasibility of the innovation management in terms of IPR, and acceptability by existing organisations. However, above 65% of the responses agreed that the end product would be more creative and innovative from MI. It was backed by the notion that the end product will be a result of the creativity and innovation of all the actors.

Research into product design for MI is at an early stage, and it requires further industry-led insights and users’ insights. It is to be noted in regard with an example mentioned in Section 2, Google ARA that was intended to provide the end-user with an individualised end product, exactly tailored to the needs of every user. But this product could not be implemented in the market in the first scheduled launch (Pensworth Reference Pensworth2019). As mentioned in Section 2, the idea of MI is relatively recent and in the absence of any existing application, this approach needs more consideration before implementing in the market. For Google ARA, platform producer and module provider are the same, Google, limiting the opportunity of networked innovation by different actors, including end-user, as opposed to envisaged for the MI where end product is the result of creativity and innovation of all the actors. Findings from the survey, in particular, responses to Q.21 and Q.25 can also provide some reflection on the failure of this case study product in market. As pointed out in the response of Q.25, organisational culture in terms of existing eco-system of smartphones could be one of the barriers in successful implementation. Project ARA would affect the whole smartphone industry at many frontiers. There would be hesitation in accepting the idea of an open platform by big established smartphone companies so lack of support from existing organisation culture could be one of the key reasons for the failure of this case study product. Response to Q.21 also pointed out that with OPAP, it would be difficult for manufacturers to differentiate their products from competitors. As noted in responses to Q.21, the inertia to adopt this new paradigm, IP protection, information management could be other reasons for the lack of due support to ARA.

Product design for MI opens a new set of opportunities in terms of product innovation. In a connected research, an innovation toolkit framework for MI is developed to obtain an optimal end product considering constraints from all the actors involved. This approach also addresses the sustainability in product design in an innovative way that can be explored and the scope this paper presents can be utilised further.

MI would need to incorporate more front-end issues such as economic evaluation of product integration, monetary models to share among different actors. Quantifying both the benefits and costs of the end products in MI is required. The challenges of multiactor participation and market uncertainties need further exploration. The influence of expanding into a new geographical and demographic market, adherence to new regulations and new technologies need to be further investigated, on economies of MI. Financial models both in terms of savings due to adaptability and upgradability, and revenues due to successful product performance in the market need to be developed. The economic justification of open platform architecture products requires the identification of appropriate measures and performance indicators that could characterise different outcomes of a MI development system.

Acknowledgement

The authors are thankful to all the survey respondents, including those participants who helped to improve the survey in the initial phase. We highly appreciate valuable responses to multiple-choice questions and constructive feedback to text questions, which helped us to obtain many practical insights on this work. We thank all the reviewers for their insightful comments and suggestions.

Competing interests

The authors declare none.

Appendix A. Questionnaire survey with responses