1. Introduction

The coating of non-planar discrete objects is a common manufacturing step for a wide variety of products (Castro et al. Reference Castro, Wu, Woolbright, Scheinpflug, Hossainy and Chen2002; Heller et al. Reference Heller, Heldman, Foehlich and Kim2003; Fujitaka & Kobayashi Reference Fujitaka and Kobayashi2006; Benjamin et al. Reference Benjamin, Bennett, Bew and Swank2008; Chen & Ho Reference Chen and Ho2009; Lee et al. Reference Lee, Brun, Marthelot, Balestra, Gallaire and Reis2016; Cade & Xinwe Reference Cade and Xinwe2017; Chappa, Bach & Macgregor Reference Chappa, Bach and Macgregor2017; Keefer & Bosch Reference Keefer and Bosch2018). Studying the evolution of coatings on non-planar objects is difficult due to the complicated shapes of some objects and the large number of competing forces that govern coating flows. Topography on the object's surface may alter the competition between viscous, surface-tension, centrifugal and gravitational forces that control coating thickness and uniformity. Undesired disturbances to the coating thickness may arise and grow over time to yield non-uniform coatings.

A commonly studied model problem involves the flow of a thin liquid film on a smooth, circular cylinder that rotates about its horizontal axis. Some of the earliest work on these coating flows, conducted by Moffatt (Reference Moffatt1977) and Pukhnachev (Reference Pukhnachev1977), studied thin liquid films on 2-D cross-sections, where axial flows and curvature variations were neglected. By considering the balance between viscous and gravitational forces in the absence of surface tension, Moffatt derived a critical rotation rate above which a steady, smooth, and asymmetric coating is supported by cylinder rotation (Moffatt Reference Moffatt1977):

Here, ![]() $\varOmega _c$ is the critical rotation rate,

$\varOmega _c$ is the critical rotation rate, ![]() $H$ is the mean coating thickness,

$H$ is the mean coating thickness, ![]() $R$ is the cylinder radius,

$R$ is the cylinder radius, ![]() $\rho$ is the liquid density,

$\rho$ is the liquid density, ![]() $g$ is the acceleration due to gravity and

$g$ is the acceleration due to gravity and ![]() $\mu$ is the liquid viscosity. Pukhnachev determined that surface tension smoothed out discontinuities that would form in the absence of surface tension (Pukhnachev Reference Pukhnachev1977). Following the early work by Moffatt (Reference Moffatt1977) and Pukhnachev (Reference Pukhnachev1977), a large body of work has examined different aspects of this problem, as summarized by Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2005) and Li & Kumar (Reference Li and Kumar2018).

$\mu$ is the liquid viscosity. Pukhnachev determined that surface tension smoothed out discontinuities that would form in the absence of surface tension (Pukhnachev Reference Pukhnachev1977). Following the early work by Moffatt (Reference Moffatt1977) and Pukhnachev (Reference Pukhnachev1977), a large body of work has examined different aspects of this problem, as summarized by Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2005) and Li & Kumar (Reference Li and Kumar2018).

Although much of the research summarized in Evans et al. (Reference Evans, Schwartz and Roy2005) and Li & Kumar (Reference Li and Kumar2018) concerns flows on 2-D cross-sections of cylinders, other studies have shed light on the stability of the coating to axial disturbances. Below the critical rotation rate (1.1), gravity leads to the formation of a liquid ridge along the cylinder axis which is unstable to axial disturbances via a Rayleigh–Taylor-like (RT) instability (Evans et al. Reference Evans, Schwartz and Roy2005). The coating may break up at various points along the cylinder circumference into droplets or fingers of liquid whose axial spacing is controlled by the balance between gravitational and surface-tension forces (Fermigier et al. Reference Fermigier, Limat, Wesfreid, Boudinet and Quilliet1992; Evans et al. Reference Evans, Schwartz and Roy2005; Balestra, Brun & Gallaire Reference Balestra, Brun and Gallaire2016; Gallaire & Brun Reference Gallaire and Brun2017; Balestra et al. Reference Balestra, Kofman, Brun, Scheid and Gallaire2018).

For flow of a thin film on the underside of a stationary planar substrate, the wavelength of the RT instability (![]() $\lambda _{RT}$) is given by the wavelength of the fastest growing sinusoidal disturbance obtained from a linear stability analysis (LSA):

$\lambda _{RT}$) is given by the wavelength of the fastest growing sinusoidal disturbance obtained from a linear stability analysis (LSA):

where ![]() $l_c = \sqrt {\rho g/\sigma }$ is the capillary length and

$l_c = \sqrt {\rho g/\sigma }$ is the capillary length and ![]() $\sigma$ is the surface tension. While the fastest growing wavelength has been shown to change over time for a stationary non-planar substrate, previous work has determined that it is initially identical to the wavelength of the RT instability on the underside of planar substrates (1.2) (Balestra et al. Reference Balestra, Brun and Gallaire2016, Reference Balestra, Kofman, Brun, Scheid and Gallaire2018). One important goal of this work is to examine the effects of topographical patterning on the growth of the RT instability on rotating cylinders, where the topography may alter the forces affecting coating behaviour at low rotation rates.

$\sigma$ is the surface tension. While the fastest growing wavelength has been shown to change over time for a stationary non-planar substrate, previous work has determined that it is initially identical to the wavelength of the RT instability on the underside of planar substrates (1.2) (Balestra et al. Reference Balestra, Brun and Gallaire2016, Reference Balestra, Kofman, Brun, Scheid and Gallaire2018). One important goal of this work is to examine the effects of topographical patterning on the growth of the RT instability on rotating cylinders, where the topography may alter the forces affecting coating behaviour at low rotation rates.

For larger rotation rates or sufficiently thin films, the coating is susceptible to the formation of axially spaced ‘rings’ or ‘bands’ of liquid through a Rayleigh–Plateau-like (RP) instability (Yih & Kingman Reference Yih and Kingman1960; Moffatt Reference Moffatt1977; Hynes Reference Hynes1978; Kovac & Balmer Reference Kovac and Balmer1980; Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In the absence of centrifugal forces, destabilizing pressure gradients imposed by axial variations in the angular curvature of the free surface compete with the stabilizing effects of the axial curvature of the free surface, causing disturbances of sufficiently long wavelength to grow. Centrifugal forces further destabilize the coating, shortening the wavelength where disturbances become unstable (Yih & Kingman Reference Yih and Kingman1960; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In a manner similar to the RT disturbance, the wavelength of the RP disturbance is taken to be the wavelength of the fastest growing sinusoidal disturbance obtained from LSA (Yih & Kingman Reference Yih and Kingman1960; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018).

By considering the balance between centrifugal and surface-tension forces in the absence of gravity, Evans et al. (Reference Evans, Schwartz and Roy2005) and Yih & Kingman (Reference Yih and Kingman1960) independently used LSA to obtain an expression that predicts the wavelength of the axially spaced rings on rotating, unpatterned cylinders:

\begin{equation} \lambda_{RP}= 2{\rm \pi} R\sqrt{2}\left(1+\frac{\rho\varOmega^2 R^{3}}{\sigma}\right)^{{-}1/2}, \end{equation}

\begin{equation} \lambda_{RP}= 2{\rm \pi} R\sqrt{2}\left(1+\frac{\rho\varOmega^2 R^{3}}{\sigma}\right)^{{-}1/2}, \end{equation}

where angular thickness variations were assumed to be negligible. Here, ![]() $\lambda _{RP}$ is the wavelength of the RP instability and

$\lambda _{RP}$ is the wavelength of the RP instability and ![]() $\varOmega$ is the cylinder rotation rate. In Hynes (Reference Hynes1978), LSA was used to derive a similar expression for

$\varOmega$ is the cylinder rotation rate. In Hynes (Reference Hynes1978), LSA was used to derive a similar expression for ![]() $\lambda _{RP}$ that accounted for gravitational effects on the coating. The effects of gravity become negligible at sufficiently high rotation rates and this expression for the RP wavelength reduces to (1.3) (Hynes Reference Hynes1978). In the present work, another important goal is to examine the effects of topographical patterning on the behaviour of the coating in the RP regime; here, the effects of surface-tension and centrifugal forces on the behaviour of the coating may be altered by the presence of topography, yielding qualitatively different behaviour than what is observed on circular cylinders.

$\lambda _{RP}$ that accounted for gravitational effects on the coating. The effects of gravity become negligible at sufficiently high rotation rates and this expression for the RP wavelength reduces to (1.3) (Hynes Reference Hynes1978). In the present work, another important goal is to examine the effects of topographical patterning on the behaviour of the coating in the RP regime; here, the effects of surface-tension and centrifugal forces on the behaviour of the coating may be altered by the presence of topography, yielding qualitatively different behaviour than what is observed on circular cylinders.

On topographically patterned objects, variations in the object's curvature may alter the shape of the coating and change how instabilities grow. Li, Carvalho & Kumar (Reference Li, Carvalho and Kumar2017) explored the growth of instabilities on 2-D cross-sections of sinusoidally patterned rotating cylinders. Finite-element method (FEM) simulations of the Stokes equations and finite-difference simulations of a lubrication-theory-based evolution equation were used to study this system. In the FEM simulations, inertial effects arising from gravitational and Coriolis forces were neglected while centrifugal forces were retained. Good agreement was found between the FEM simulations and lubrication model for sufficiently thin coatings. In the limit where gravity is negligible, two regimes of coating behaviour separated by a cutoff rotation rate ![]() $\varOmega _{cut}$ were observed in simulations. Surface-tension forces drive liquid into pattern troughs below

$\varOmega _{cut}$ were observed in simulations. Surface-tension forces drive liquid into pattern troughs below ![]() $\varOmega _{cut}$, and centrifugal forces drive liquid onto pattern crests above

$\varOmega _{cut}$, and centrifugal forces drive liquid onto pattern crests above ![]() $\varOmega _{cut}$. Li et al. (Reference Li, Carvalho and Kumar2017) reasoned that the sinusoidal topography, with wavelength

$\varOmega _{cut}$. Li et al. (Reference Li, Carvalho and Kumar2017) reasoned that the sinusoidal topography, with wavelength ![]() $\lambda _{\theta }$, would induce a small sinusoidal thickness disturbance of identical wavelength

$\lambda _{\theta }$, would induce a small sinusoidal thickness disturbance of identical wavelength ![]() $\lambda _{\theta }$ in the coating. By assuming the topography plays a negligible role in the growth of this disturbance for short times, an expression for

$\lambda _{\theta }$ in the coating. By assuming the topography plays a negligible role in the growth of this disturbance for short times, an expression for ![]() $\varOmega _{cut}$ was obtained from LSA of a coating on an unpatterned cylinder:

$\varOmega _{cut}$ was obtained from LSA of a coating on an unpatterned cylinder:

\begin{equation} \varOmega_{cut} = \sqrt{\left(\frac{\sigma}{\rho R_{m}^3}\left(\frac{4{\rm \pi}^2R_{m}^2}{\lambda_{\theta}^2}-1\right)\right)}, \end{equation}

\begin{equation} \varOmega_{cut} = \sqrt{\left(\frac{\sigma}{\rho R_{m}^3}\left(\frac{4{\rm \pi}^2R_{m}^2}{\lambda_{\theta}^2}-1\right)\right)}, \end{equation}

where ![]() $R_m$ is the mean cylinder radius. It was found that (1.4) agrees well with the coating regimes found in simulations. The capabilities of the LSA used to obtain (1.4) are limited, however. The LSA does not capture how topography affects the rate at which disturbances evolve, nor does it capture the effects of substrate and free-surface curvature in the axial direction on the liquid distribution. A third goal of this work is to address these two open questions.

$R_m$ is the mean cylinder radius. It was found that (1.4) agrees well with the coating regimes found in simulations. The capabilities of the LSA used to obtain (1.4) are limited, however. The LSA does not capture how topography affects the rate at which disturbances evolve, nor does it capture the effects of substrate and free-surface curvature in the axial direction on the liquid distribution. A third goal of this work is to address these two open questions.

In § 2, we present a lubrication-theory-based model to describe the flow of a thin coating on a rotating, 3-D topographically patterned cylinder. We start with the limiting case where gravity is neglected in § 3 and reincorporate gravity in § 4. Complementary flow visualization experiments are presented in § 5, and conclusions are provided in § 6.

2. Mathematical model

We consider the flow of a Newtonian liquid film which fully wets a topographically patterned cylinder of mean radius ![]() $R_{m}$ rotating clockwise at angular speed

$R_{m}$ rotating clockwise at angular speed ![]() $\varOmega$. The problem is defined using cylindrical coordinates

$\varOmega$. The problem is defined using cylindrical coordinates ![]() $(r,\theta ,z)$ with basis vectors

$(r,\theta ,z)$ with basis vectors ![]() $(\boldsymbol {e}_{\boldsymbol {r}},\boldsymbol {e}_{\boldsymbol {\theta }}, \boldsymbol {e}_{\boldsymbol {z}})$ in a reference frame rotating clockwise with the cylinder (

$(\boldsymbol {e}_{\boldsymbol {r}},\boldsymbol {e}_{\boldsymbol {\theta }}, \boldsymbol {e}_{\boldsymbol {z}})$ in a reference frame rotating clockwise with the cylinder (![]() $\boldsymbol {\varOmega } = -\varOmega \boldsymbol {e}_{\boldsymbol {z}},\varOmega >0$). The thickness of the liquid film

$\boldsymbol {\varOmega } = -\varOmega \boldsymbol {e}_{\boldsymbol {z}},\varOmega >0$). The thickness of the liquid film ![]() $h(\theta ,z,t)$ is defined with respect to the cylinder surface as shown in figure 1. The radial coordinate for the cylinder surface is given by

$h(\theta ,z,t)$ is defined with respect to the cylinder surface as shown in figure 1. The radial coordinate for the cylinder surface is given by ![]() $R(\theta ,z) = R_{m} + B(\theta ,z)$, where

$R(\theta ,z) = R_{m} + B(\theta ,z)$, where ![]() $B(\theta ,z)$ is a function describing the surface patterning (§ 2.3). For convenience, a new radial coordinate

$B(\theta ,z)$ is a function describing the surface patterning (§ 2.3). For convenience, a new radial coordinate ![]() $y=r-R_{m}-B(\theta ,z)$ is defined on the interval

$y=r-R_{m}-B(\theta ,z)$ is defined on the interval ![]() $0\le y\le h(\theta ,z,t)$. The position vector

$0\le y\le h(\theta ,z,t)$. The position vector ![]() $\boldsymbol {r}$ and the liquid velocity

$\boldsymbol {r}$ and the liquid velocity ![]() $\boldsymbol {u}$ are defined as

$\boldsymbol {u}$ are defined as

Note that we consider film thicknesses such that ![]() $h(\theta ,z,t)$ possesses only a single value of

$h(\theta ,z,t)$ possesses only a single value of ![]() $h$ for each

$h$ for each ![]() $\theta$ and

$\theta$ and ![]() $z$.

$z$.

Figure 1. Model geometry. (a) End view. (b) Side view.

2.1. Governing equations

In the rotating reference frame (![]() $\boldsymbol {\varOmega } = -\varOmega \boldsymbol {e}_{\boldsymbol {z}}$), the mass and momentum conservation equations for a Newtonian liquid of density

$\boldsymbol {\varOmega } = -\varOmega \boldsymbol {e}_{\boldsymbol {z}}$), the mass and momentum conservation equations for a Newtonian liquid of density ![]() $\rho$ and viscosity

$\rho$ and viscosity ![]() $\mu$ are

$\mu$ are

where ![]() $\boldsymbol {g} = -g\sin (\theta -\varOmega t)\boldsymbol {e}_{\boldsymbol {r}}-g\cos (\theta -\varOmega t)\boldsymbol {e}_{\boldsymbol {\theta }}$ is the gravitational acceleration (

$\boldsymbol {g} = -g\sin (\theta -\varOmega t)\boldsymbol {e}_{\boldsymbol {r}}-g\cos (\theta -\varOmega t)\boldsymbol {e}_{\boldsymbol {\theta }}$ is the gravitational acceleration (![]() $g= \|\boldsymbol {g}\|$) and

$g= \|\boldsymbol {g}\|$) and ![]() $p$ is the liquid pressure. On the cylinder surface, we apply no-penetration and no-slip conditions for the liquid velocities,

$p$ is the liquid pressure. On the cylinder surface, we apply no-penetration and no-slip conditions for the liquid velocities,

where ![]() $\boldsymbol {n}_{\boldsymbol {c}}$ and

$\boldsymbol {n}_{\boldsymbol {c}}$ and ![]() $\boldsymbol {t}_{\boldsymbol {c},\boldsymbol {i}}$ are the unit vectors normal and tangential to the cylinder surface,

$\boldsymbol {t}_{\boldsymbol {c},\boldsymbol {i}}$ are the unit vectors normal and tangential to the cylinder surface,

At the liquid–air interface (y = h), we apply interfacial balances for total mass, normal stress and tangential stress (Delhaye Reference Delhaye1974; Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1988; Slattery Reference Slattery2007):

where ![]() $\boldsymbol{\tau}$ denotes the viscous stress tensor and the superscripts

$\boldsymbol{\tau}$ denotes the viscous stress tensor and the superscripts ![]() $l$,

$l$, ![]() $v$ and

$v$ and ![]() $I$, respectively, denote liquid, vapour and interface quantities. Equation 2.10 is the kinematic condition. The scalar

$I$, respectively, denote liquid, vapour and interface quantities. Equation 2.10 is the kinematic condition. The scalar ![]() $\sigma$ is the surface tension of the liquid. The vectors

$\sigma$ is the surface tension of the liquid. The vectors ![]() $\boldsymbol {n}$ and

$\boldsymbol {n}$ and ![]() $\boldsymbol {t}_{\boldsymbol {i}}$ are the outward unit normal and tangent vectors of the liquid–air interface, defined as

$\boldsymbol {t}_{\boldsymbol {i}}$ are the outward unit normal and tangent vectors of the liquid–air interface, defined as

where

2.2. Scaling and evolution equations

In many applications of interest, the characteristic thickness ![]() $H$ of the liquid film is much smaller than the mean cylinder radius

$H$ of the liquid film is much smaller than the mean cylinder radius ![]() $R_m$. As a result, a small parameter

$R_m$. As a result, a small parameter ![]() $\epsilon = H/R_m \ll 1$ may be defined, and the lubrication approximation may be invoked to simplify the governing equations. Following Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2004), Evans et al. (Reference Evans, Schwartz and Roy2005), Li & Kumar (Reference Li and Kumar2015, Reference Li and Kumar2018), we introduce the following dimensionless quantities, denoted by tildes

$\epsilon = H/R_m \ll 1$ may be defined, and the lubrication approximation may be invoked to simplify the governing equations. Following Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2004), Evans et al. (Reference Evans, Schwartz and Roy2005), Li & Kumar (Reference Li and Kumar2015, Reference Li and Kumar2018), we introduce the following dimensionless quantities, denoted by tildes

\begin{equation} \left.\begin{gathered} \left(y,h,B\right) = H(\tilde{y},\tilde{h},\tilde{B}) \quad (r,z) = R_{m}(\tilde{r},\tilde{z}) \quad t = \varUpsilon\tilde{t} \\ u = \epsilon U\tilde{u} \quad v = U \tilde{v} \quad w = U \tilde{w} \\ p = P\tilde{p}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \left(y,h,B\right) = H(\tilde{y},\tilde{h},\tilde{B}) \quad (r,z) = R_{m}(\tilde{r},\tilde{z}) \quad t = \varUpsilon\tilde{t} \\ u = \epsilon U\tilde{u} \quad v = U \tilde{v} \quad w = U \tilde{w} \\ p = P\tilde{p}. \end{gathered}\right\} \end{equation} The characteristic speed ![]() $U=\rho gH^2/\mu$, characteristic pressure

$U=\rho gH^2/\mu$, characteristic pressure ![]() $P = \mu U/H$ and characteristic time

$P = \mu U/H$ and characteristic time ![]() $\varUpsilon = R_{m}/U$ are based on gravitational drainage of the coating. Order-of-magnitude estimates for select dimensional quantities in (2.17) are listed in table 1. The dimensionless amplitude of the cylinder topography

$\varUpsilon = R_{m}/U$ are based on gravitational drainage of the coating. Order-of-magnitude estimates for select dimensional quantities in (2.17) are listed in table 1. The dimensionless amplitude of the cylinder topography ![]() $\beta$, listed in table 2, is the ratio of the dimensional amplitude

$\beta$, listed in table 2, is the ratio of the dimensional amplitude ![]() $b$ of the topography to the mean cylinder radius

$b$ of the topography to the mean cylinder radius ![]() $R_m$ (

$R_m$ (![]() $\beta =b/R_{m}$). The dimensionless amplitude is assumed to be a small parameter such that

$\beta =b/R_{m}$). The dimensionless amplitude is assumed to be a small parameter such that ![]() $\beta \ll 1$. Hereafter, we drop the tilde notation from dimensionless variables for simplicity.

$\beta \ll 1$. Hereafter, we drop the tilde notation from dimensionless variables for simplicity.

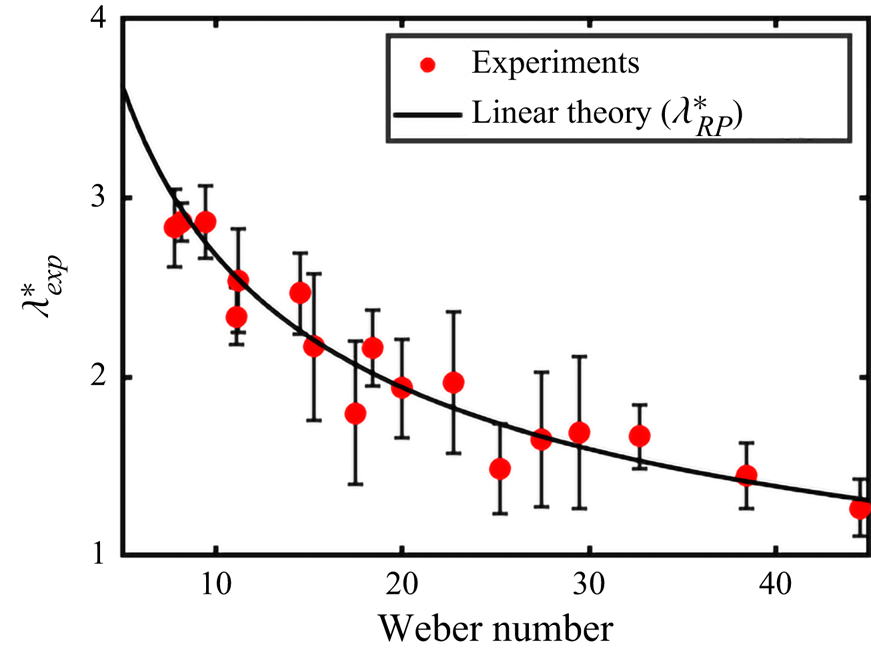

Table 1. Dimensional values for various properties.

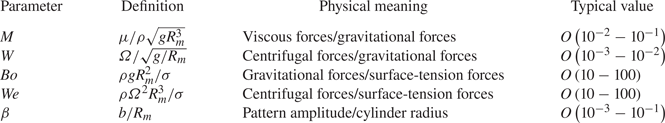

Table 2. Dimensionless parameters.

We non-dimensionalize (2.3) and (2.4) and the corresponding boundary conditions in § 2.1 using the scalings shown in (2.17) and simplify this set of equations by neglecting terms of ![]() ${O}( {\epsilon ^2})$ and smaller and the dynamics of the air. The following evolution equation for the film thickness is obtained:

${O}( {\epsilon ^2})$ and smaller and the dynamics of the air. The following evolution equation for the film thickness is obtained:

\begin{align}

\left(1+\epsilon h + \epsilon B\right)\frac{\partial

h}{\partial t} &= \frac{\partial}{\partial

\theta}\left(\cos\theta_r\left(\frac{h^3}{3}+\frac{\epsilon

h^4}{2}\right)\right) - \epsilon\boldsymbol{\tilde{\nabla}}\notag\\ &\quad

\boldsymbol{\cdot}\left(\frac{h^3}{3}\left[(W^2-\sin\theta_r)

\tilde{\boldsymbol{\nabla}}(h+B)

+\frac{1}{Bo}\tilde{\boldsymbol{\nabla}}(h+B+\tilde{\nabla}^2(h+B))\right]\right),

\end{align}

\begin{align}

\left(1+\epsilon h + \epsilon B\right)\frac{\partial

h}{\partial t} &= \frac{\partial}{\partial

\theta}\left(\cos\theta_r\left(\frac{h^3}{3}+\frac{\epsilon

h^4}{2}\right)\right) - \epsilon\boldsymbol{\tilde{\nabla}}\notag\\ &\quad

\boldsymbol{\cdot}\left(\frac{h^3}{3}\left[(W^2-\sin\theta_r)

\tilde{\boldsymbol{\nabla}}(h+B)

+\frac{1}{Bo}\tilde{\boldsymbol{\nabla}}(h+B+\tilde{\nabla}^2(h+B))\right]\right),

\end{align}

where ![]() $\theta _r = \theta -MW\epsilon ^{-2}t$ is the angular coordinate in a fixed reference frame. Equation (2.18) retains the effects of viscous, gravitational, centrifugal and surface-tension forces on the coating, while the remaining inertial and Coriolis forces are of

$\theta _r = \theta -MW\epsilon ^{-2}t$ is the angular coordinate in a fixed reference frame. Equation (2.18) retains the effects of viscous, gravitational, centrifugal and surface-tension forces on the coating, while the remaining inertial and Coriolis forces are of ![]() ${O}({\epsilon ^{2}})$ and neglected through the lubrication approximation. When the topography amplitude

${O}({\epsilon ^{2}})$ and neglected through the lubrication approximation. When the topography amplitude ![]() $\beta$ is of

$\beta$ is of ![]() ${O}(0.1)$, prior work has demonstrated that (2.18) can capture key qualitative features of the coating behaviour in two dimensions, based on comparisons with FEM simulations (Li et al. Reference Li, Carvalho and Kumar2017).

${O}(0.1)$, prior work has demonstrated that (2.18) can capture key qualitative features of the coating behaviour in two dimensions, based on comparisons with FEM simulations (Li et al. Reference Li, Carvalho and Kumar2017).

Table 2 provides definitions, physical interpretations and typical values of dimensionless parameters in (2.18). The parameters ![]() $M$ and

$M$ and ![]() $W$ are the dimensionless viscosity and rotation rate. The small parameter

$W$ are the dimensionless viscosity and rotation rate. The small parameter ![]() $\epsilon$ is the dimensionless characteristic film thickness. Lastly,

$\epsilon$ is the dimensionless characteristic film thickness. Lastly, ![]() $Bo$ and

$Bo$ and ![]() $We$ are the Bond and Weber numbers, which, respectively, give the magnitude of gravitational forces and centrifugal forces to surface-tension forces. When the cylinder is unpatterned (

$We$ are the Bond and Weber numbers, which, respectively, give the magnitude of gravitational forces and centrifugal forces to surface-tension forces. When the cylinder is unpatterned (![]() $B(\theta ,z)=0$), (2.18) reduces to the evolution equation in Evans et al. (Reference Evans, Schwartz and Roy2005). In the limit where axial variations in thickness and topography are neglected (

$B(\theta ,z)=0$), (2.18) reduces to the evolution equation in Evans et al. (Reference Evans, Schwartz and Roy2005). In the limit where axial variations in thickness and topography are neglected (![]() $\partial /\partial z=0$) and the patterning is a sinusoidal function given by

$\partial /\partial z=0$) and the patterning is a sinusoidal function given by ![]() $B(\theta ) = \beta \epsilon ^{-1}\sin (k_{\theta }\theta )$, where

$B(\theta ) = \beta \epsilon ^{-1}\sin (k_{\theta }\theta )$, where ![]() $k_{\theta}$ is the topography wavenumber, (2.18) reduces to the evolution equation in Li et al. (Reference Li, Carvalho and Kumar2017).

$k_{\theta}$ is the topography wavenumber, (2.18) reduces to the evolution equation in Li et al. (Reference Li, Carvalho and Kumar2017).

Given a set of dimensionless parameters (table 2) and initial conditions, (2.18) is solved using an alternating-direction implicit (ADI) finite-difference scheme similar to that of Mata & Bertozzi (Reference Mata and Bertozzi2011). The spatial domain is discretized using a uniform grid of ![]() $n_{\theta }\times n_z$ points, where the grid spacing is defined as

$n_{\theta }\times n_z$ points, where the grid spacing is defined as ![]() $\Delta x = 2{\rm \pi} /n_{\theta }$ and the length of the cylinder is defined as

$\Delta x = 2{\rm \pi} /n_{\theta }$ and the length of the cylinder is defined as ![]() $L = n_z\Delta x$. An initial time step of

$L = n_z\Delta x$. An initial time step of ![]() $\Delta t_0$ is set, and an adaptive time-stepping method similar to that of Mata & Bertozzi (Reference Mata and Bertozzi2011) is used to determine the time step during simulations. Spatial derivatives are approximated using second-order centred finite differences, while the time-stepping is done using a semi-implicit scheme.

$\Delta t_0$ is set, and an adaptive time-stepping method similar to that of Mata & Bertozzi (Reference Mata and Bertozzi2011) is used to determine the time step during simulations. Spatial derivatives are approximated using second-order centred finite differences, while the time-stepping is done using a semi-implicit scheme.

At each time step, an iterative procedure is applied to reduce computational time and to improve solution accuracy (Mata & Bertozzi Reference Mata and Bertozzi2011; Li & Kumar Reference Li and Kumar2018). Periodic boundary conditions are applied in both the angular direction (![]() $h(\theta =0,z) = h(\theta =2{\rm \pi} ,z)$) and the axial direction (

$h(\theta =0,z) = h(\theta =2{\rm \pi} ,z)$) and the axial direction (![]() $h(\theta ,z=0)=h(\theta ,z=L)$). To properly resolve the topography, upwards of

$h(\theta ,z=0)=h(\theta ,z=L)$). To properly resolve the topography, upwards of ![]() $n_\theta =400$ grid points are used in the angular direction. The number of grid points in the axial direction is determined from the desired length

$n_\theta =400$ grid points are used in the angular direction. The number of grid points in the axial direction is determined from the desired length ![]() $L$ and

$L$ and ![]() $n_\theta$ by

$n_\theta$ by

The value of ![]() $L$ is chosen to be at least three times larger than the wavelength of disturbances in the coating. Disturbance wavelengths were not known a priori, so

$L$ is chosen to be at least three times larger than the wavelength of disturbances in the coating. Disturbance wavelengths were not known a priori, so ![]() $L$ was increased and simulations were re-run when necessary. For topography with fine features, the number of grid points was increased until graphical accuracy was obtained, which typically required

$L$ was increased and simulations were re-run when necessary. For topography with fine features, the number of grid points was increased until graphical accuracy was obtained, which typically required ![]() $n_{\theta }\geq 400$ and

$n_{\theta }\geq 400$ and ![]() $n_{z}\geq 1200$.

$n_{z}\geq 1200$.

2.3. Topographical patterning

In the derivation of (2.18), the form of the topography has been left as an arbitrary function ![]() $B(\theta ,z)$. Here, flows are examined on sinusoidally patterned cylinders whose curvature varies in the angular direction, the axial direction or combinations thereof. Renderings of the topographies we examine are shown in figure 2, and a description of these topographies is provided below.

$B(\theta ,z)$. Here, flows are examined on sinusoidally patterned cylinders whose curvature varies in the angular direction, the axial direction or combinations thereof. Renderings of the topographies we examine are shown in figure 2, and a description of these topographies is provided below.

Figure 2. Topographically patterned cylinders with dimensionless pattern amplitude ![]() $\beta = 0.1$ of various shapes: (a) angularly patterned cylinder with

$\beta = 0.1$ of various shapes: (a) angularly patterned cylinder with ![]() $k_{\theta }=5$, (b) axially patterned cylinder with

$k_{\theta }=5$, (b) axially patterned cylinder with ![]() $k_{z}=5$ and (c) screw-shaped cylinder with

$k_{z}=5$ and (c) screw-shaped cylinder with ![]() $k_{\theta }=5$ and

$k_{\theta }=5$ and ![]() $k_{z}=5$.

$k_{z}=5$.

The simplest, limiting cases comprise topographies which are purely angular (figure 2a) or purely axial (figure 2b):

where ![]() $\beta$ is the dimensionless pattern amplitude and

$\beta$ is the dimensionless pattern amplitude and ![]() $k_{i}$ is the wavenumber of the topography in either the axial (

$k_{i}$ is the wavenumber of the topography in either the axial (![]() $i=z$) or the angular (

$i=z$) or the angular (![]() $i=\theta$) direction. One generalized form of (2.20) and (2.21) possesses both angular and axial curvature:

$i=\theta$) direction. One generalized form of (2.20) and (2.21) possesses both angular and axial curvature:

When the wavenumbers ![]() $k_{\theta }=0$ or

$k_{\theta }=0$ or ![]() $k_{z}=0$, (2.22) reduces to either (2.20) or (2.21). For non-zero

$k_{z}=0$, (2.22) reduces to either (2.20) or (2.21). For non-zero ![]() $k_{\theta }$ and

$k_{\theta }$ and ![]() $k_{z}$, an object whose topography is described by (2.22) resembles a screw-shaped cylinder (figure 2c). For any of the topographies shown above, the dimensionless wavelength of the patterning in each direction (

$k_{z}$, an object whose topography is described by (2.22) resembles a screw-shaped cylinder (figure 2c). For any of the topographies shown above, the dimensionless wavelength of the patterning in each direction (![]() $i=\theta ,z$) is given by

$i=\theta ,z$) is given by ![]() $2{\rm \pi} /k_{i}$.

$2{\rm \pi} /k_{i}$.

3. Rapidly rotating cylinder

An insightful limiting case involves the coating of cylinders which rotate so rapidly that gravitational effects are negligible. In the absence of gravity, alternate scales must be chosen to replace the gravity-based characteristic scales. After neglecting gravitational terms, we rescale (2.18) using a capillary time ![]() $T = \mu R_m/\sigma$ and capillary velocity

$T = \mu R_m/\sigma$ and capillary velocity ![]() $U = \sigma /\mu$ to obtain a new evolution equation,

$U = \sigma /\mu$ to obtain a new evolution equation,

Here, the Weber number (![]() $We = \rho \varOmega ^2 R_m^3/\sigma$) is the ratio of centrifugal forces to surface-tension forces. Note that the Weber number may also be expressed as

$We = \rho \varOmega ^2 R_m^3/\sigma$) is the ratio of centrifugal forces to surface-tension forces. Note that the Weber number may also be expressed as ![]() $We = W^2Bo$.

$We = W^2Bo$.

The behaviour of coatings on unpatterned, rapidly rotating cylinders, where ![]() $B=0$ in (3.1), has been explored extensively in prior work (Yih & Kingman Reference Yih and Kingman1960; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In simulations of coatings on rapidly rotating cylinders, axially spaced rings grow with a wavelength similar to the wavelength of the RP instability predicted by LSA (1.3) (Evans et al. Reference Evans, Schwartz and Roy2005). The dimensionless wavelength of the RP instability is given by

$B=0$ in (3.1), has been explored extensively in prior work (Yih & Kingman Reference Yih and Kingman1960; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In simulations of coatings on rapidly rotating cylinders, axially spaced rings grow with a wavelength similar to the wavelength of the RP instability predicted by LSA (1.3) (Evans et al. Reference Evans, Schwartz and Roy2005). The dimensionless wavelength of the RP instability is given by

where ![]() $\lambda ^{*}_{RP}$ depends solely on the Weber number

$\lambda ^{*}_{RP}$ depends solely on the Weber number ![]() $We$. The growth rate

$We$. The growth rate ![]() $\omega _m$ of the RP disturbance,

$\omega _m$ of the RP disturbance,

is proportional to both the characteristic film thickness ![]() $\epsilon$ and

$\epsilon$ and ![]() $We$. Over time, the spacing of the rings observed in simulations varies due to the shifting of rings and the formation of smaller satellite rings at late times (Evans et al. Reference Evans, Schwartz and Roy2005).

$We$. Over time, the spacing of the rings observed in simulations varies due to the shifting of rings and the formation of smaller satellite rings at late times (Evans et al. Reference Evans, Schwartz and Roy2005).

For a coating of initially uniform thickness, liquid has been observed to accumulate either over the pattern crests or in the pattern troughs of 2-D sinusoidally patterned cylinders (Li et al. Reference Li, Carvalho and Kumar2017). At low ![]() $We$, capillary forces level the coating and drive liquid into the troughs; at high

$We$, capillary forces level the coating and drive liquid into the troughs; at high ![]() $We$, centrifugal forces drive liquid to pattern crests, where the radius of the object is larger. An expression for the critical Weber number

$We$, centrifugal forces drive liquid to pattern crests, where the radius of the object is larger. An expression for the critical Weber number ![]() $We_c$ separating these regimes was inferred from LSA conducted on an unpatterned cylinder (

$We_c$ separating these regimes was inferred from LSA conducted on an unpatterned cylinder (![]() $B(\theta ,z) = 0$) (Li et al. Reference Li, Carvalho and Kumar2017). This expression was found to agree well with 2-D nonlinear simulations of (3.1) (Li et al. Reference Li, Carvalho and Kumar2017). Here, we more rigorously derive an expression for the critical Weber number using a long-wave analysis, where the thickness is expressed as a regular perturbation series in

$B(\theta ,z) = 0$) (Li et al. Reference Li, Carvalho and Kumar2017). This expression was found to agree well with 2-D nonlinear simulations of (3.1) (Li et al. Reference Li, Carvalho and Kumar2017). Here, we more rigorously derive an expression for the critical Weber number using a long-wave analysis, where the thickness is expressed as a regular perturbation series in ![]() $\epsilon$. In addition to providing an expression for

$\epsilon$. In addition to providing an expression for ![]() $We_c$, the long-wave analysis yields very general information about the growth rate of disturbances which the analysis in Li et al. (Reference Li, Carvalho and Kumar2017) could not.

$We_c$, the long-wave analysis yields very general information about the growth rate of disturbances which the analysis in Li et al. (Reference Li, Carvalho and Kumar2017) could not.

3.1. Long-wave analysis

A long-wave analysis, where the coating thickness is expanded as a regular perturbation series in the small parameter ![]() $\epsilon = H/R_m \ll 1$, may be used to find an analytical solution to (3.1). For this analysis, we study the flow of a coating on a screw-shaped topography (2.22), which allows us to consider curvature in the axial and angular directions simultaneously. Additionally, the pattern amplitude

$\epsilon = H/R_m \ll 1$, may be used to find an analytical solution to (3.1). For this analysis, we study the flow of a coating on a screw-shaped topography (2.22), which allows us to consider curvature in the axial and angular directions simultaneously. Additionally, the pattern amplitude ![]() $\beta$ must be

$\beta$ must be ![]() ${O}({\epsilon })$ such that

${O}({\epsilon })$ such that ![]() $\beta /\epsilon$ is

$\beta /\epsilon$ is ![]() ${O}({1})$. We expand the thickness in (3.1) as a regular perturbation series in

${O}({1})$. We expand the thickness in (3.1) as a regular perturbation series in ![]() $\epsilon$:

$\epsilon$:

with the uniform initial condition ![]() $h(\theta ,z,0) = 1$. Substituting (3.4) into (3.1) yields

$h(\theta ,z,0) = 1$. Substituting (3.4) into (3.1) yields

Equations (3.5)–(3.7) indicate that terms ![]() $h_0$,

$h_0$, ![]() $h_1$ and

$h_1$ and ![]() $h_2$ are independent of time. Application of the initial condition

$h_2$ are independent of time. Application of the initial condition ![]() $h(\theta ,z,0) = 1$ yields

$h(\theta ,z,0) = 1$ yields ![]() $h_0 = 1$ and

$h_0 = 1$ and ![]() $h_1=h_2=0$. When

$h_1=h_2=0$. When ![]() $\tilde {\boldsymbol {\nabla }}B=0$ (

$\tilde {\boldsymbol {\nabla }}B=0$ (![]() $k_{\theta }=k_{z}=0$ or

$k_{\theta }=k_{z}=0$ or ![]() $\beta =0$), we note that the solution to (3.8) is trivial, yielding

$\beta =0$), we note that the solution to (3.8) is trivial, yielding ![]() $h_3 = 0$. The following analysis is carried out for the non-trivial case.

$h_3 = 0$. The following analysis is carried out for the non-trivial case.

Equation (3.8) is solved by separation of variables, where we express ![]() $h_3$ as

$h_3$ as ![]() $h_3(\theta ,z,t) = \bar {h}_3(t)\hat {h}_3(\theta ,z)$. The resulting differential equation is

$h_3(\theta ,z,t) = \bar {h}_3(t)\hat {h}_3(\theta ,z)$. The resulting differential equation is

The terms on the left- and right-hand sides of (3.9) are equal to a constant, which we denote with the growth rate ![]() $\omega$, and solutions for

$\omega$, and solutions for ![]() $\bar {h}_3(t)$ and

$\bar {h}_3(t)$ and ![]() $\hat {h}_3(\theta ,z)$ can be obtained:

$\hat {h}_3(\theta ,z)$ can be obtained:

Here, ![]() $k = \sqrt {k_{\theta }^2+k_{z}^2}$ is a lumped wavenumber. The regular perturbation series solution with initial condition

$k = \sqrt {k_{\theta }^2+k_{z}^2}$ is a lumped wavenumber. The regular perturbation series solution with initial condition ![]() $h(\theta ,z,0) = 1$ is then

$h(\theta ,z,0) = 1$ is then

Recall that ![]() $\beta$ is

$\beta$ is ![]() ${O}({\epsilon })$, so

${O}({\epsilon })$, so ![]() $\epsilon ^2\beta$ is

$\epsilon ^2\beta$ is ![]() ${O}({\epsilon ^3})$.

${O}({\epsilon ^3})$.

According to (3.12), the topography induces a disturbance in the coating, as was observed in Li et al. (Reference Li, Carvalho and Kumar2017). For cylinders with ![]() $k\neq 0$ and

$k\neq 0$ and ![]() $\beta \neq 0$, the magnitude of

$\beta \neq 0$, the magnitude of ![]() $\beta \epsilon ^2 \omega$ controls the rate at which the disturbance develops, and the sign of

$\beta \epsilon ^2 \omega$ controls the rate at which the disturbance develops, and the sign of ![]() $\omega$ controls the location where liquid pools. The induced disturbance grows either in-phase (

$\omega$ controls the location where liquid pools. The induced disturbance grows either in-phase (![]() $\omega >0$) or out-of-phase (

$\omega >0$) or out-of-phase (![]() $\omega <0$) with the topography depending on the sign of the growth rate

$\omega <0$) with the topography depending on the sign of the growth rate ![]() $\omega$. When

$\omega$. When ![]() $\omega >0$, centrifugal forces dominate and liquid accumulates over pattern crests. When

$\omega >0$, centrifugal forces dominate and liquid accumulates over pattern crests. When ![]() $\omega <0$, capillary forces dominate and liquid accumulates in pattern troughs.

$\omega <0$, capillary forces dominate and liquid accumulates in pattern troughs.

For fixed values of ![]() $k_\theta$ and

$k_\theta$ and ![]() $k_z$ where

$k_z$ where ![]() $k\neq 0$, the critical Weber number

$k\neq 0$, the critical Weber number ![]() $We_c$ at which this transition occurs can be obtained by solving

$We_c$ at which this transition occurs can be obtained by solving ![]() $\omega (We_c) = 0$ (see (3.11))

$\omega (We_c) = 0$ (see (3.11))

A similar expression for ![]() $We_c$ on 2-D sinusoidally patterned cylinders was inferred in Li et al. (Reference Li, Carvalho and Kumar2017), where the evolution of small-amplitude disturbances on unpatterned cylinders was likened to the evolution of small-amplitude disturbances induced by a sinusoidal topography. A special case of (3.13) occurs when

$We_c$ on 2-D sinusoidally patterned cylinders was inferred in Li et al. (Reference Li, Carvalho and Kumar2017), where the evolution of small-amplitude disturbances on unpatterned cylinders was likened to the evolution of small-amplitude disturbances induced by a sinusoidal topography. A special case of (3.13) occurs when ![]() $k_{\theta }=0$ and

$k_{\theta }=0$ and ![]() $k_{z}< 1$, where

$k_{z}< 1$, where ![]() $We_c$ is less than zero. This is unphysical as all of the parameters in

$We_c$ is less than zero. This is unphysical as all of the parameters in ![]() $We$ must be greater than zero (see table 2). When

$We$ must be greater than zero (see table 2). When ![]() $We_c<0$, any realistic Weber number

$We_c<0$, any realistic Weber number ![]() $We\geq 0$ yields a positive growth rate

$We\geq 0$ yields a positive growth rate ![]() $\omega$ (3.11), and the long-wave analysis predicts that liquid will always accumulate over pattern crests, even when the cylinder does not rotate (

$\omega$ (3.11), and the long-wave analysis predicts that liquid will always accumulate over pattern crests, even when the cylinder does not rotate (![]() $We=0$).

$We=0$).

3.2. Axially patterned cylinders

To probe the limits of the long-wave approximation (3.12), simulations of (3.1) are presented for a representative case. We consider purely axially patterned cylinders ((2.21), where ![]() $k_{\theta }=0$ with

$k_{\theta }=0$ with ![]() $k_{z} = 4$) and initially undisturbed coatings of uniform thickness (

$k_{z} = 4$) and initially undisturbed coatings of uniform thickness (![]() $h(\theta ,z,t=0) = 1$). The Weber numbers used in these simulations (

$h(\theta ,z,t=0) = 1$). The Weber numbers used in these simulations (![]() $We=20$ and

$We=20$ and ![]() $10$) sit on either side of the critical Weber number (

$10$) sit on either side of the critical Weber number (![]() $We_c=15$) so the growth rates are of equal magnitude but opposite sign (

$We_c=15$) so the growth rates are of equal magnitude but opposite sign (![]() $\omega =\pm 26.67$). We extract the amplitude

$\omega =\pm 26.67$). We extract the amplitude ![]() $\bar {h}_3(t)$ of the induced disturbance from simulations by solving (3.12) for

$\bar {h}_3(t)$ of the induced disturbance from simulations by solving (3.12) for ![]() $\omega t$ at fixed points on the cylinder

$\omega t$ at fixed points on the cylinder ![]() $\theta _0$ and

$\theta _0$ and ![]() $z_0$ (e.g.

$z_0$ (e.g. ![]() $\theta _0=z_0={\rm \pi}$):

$\theta _0=z_0={\rm \pi}$):

For all of the simulations in §§ 3.2 and 3.3, ![]() $\epsilon = 0.01$ and

$\epsilon = 0.01$ and ![]() $\beta =10^{-3}$ so that the topography amplitude is 10 % of the characteristic film thickness.

$\beta =10^{-3}$ so that the topography amplitude is 10 % of the characteristic film thickness.

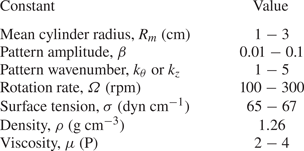

The amplitudes extracted from simulations using (3.14) are compared with those predicted by the long-wave approximation (3.10a,b) in figure 3. At early times (![]() $t<1\times 10^{4}$), good agreement is observed between the long-wave approximation and the simulations. However, deviation between the long-wave approximation and the simulations develops at later times (

$t<1\times 10^{4}$), good agreement is observed between the long-wave approximation and the simulations. However, deviation between the long-wave approximation and the simulations develops at later times (![]() $t>1\times 10^{4}$). Compared with the simulations, the long-wave approximation underpredicts the disturbance amplitude above

$t>1\times 10^{4}$). Compared with the simulations, the long-wave approximation underpredicts the disturbance amplitude above ![]() $We_c$ and overpredicts it below

$We_c$ and overpredicts it below ![]() $We_c$. These simulation results also indicate that the rate of levelling below

$We_c$. These simulation results also indicate that the rate of levelling below ![]() $We_c$ slows down over time while centrifugation above

$We_c$ slows down over time while centrifugation above ![]() $We_c$ becomes faster.

$We_c$ becomes faster.

Figure 3. Disturbance amplitude ![]() $\bar {h}_3(t)$ from simulation results (filled symbols) and the long-wave approximation (solid lines). The growth rates are

$\bar {h}_3(t)$ from simulation results (filled symbols) and the long-wave approximation (solid lines). The growth rates are ![]() $\omega = \pm 26.67$ for

$\omega = \pm 26.67$ for ![]() $We=20$ and

$We=20$ and ![]() $We=10$, respectively, with

$We=10$, respectively, with ![]() $\epsilon =0.01$ and

$\epsilon =0.01$ and ![]() $\beta = 10^{-3}$. The horizontal line marks

$\beta = 10^{-3}$. The horizontal line marks ![]() $\bar {h}_{3}(t) = 0$. The vertical line marks where the long-wave analysis deviates noticeably from the simulation results (

$\bar {h}_{3}(t) = 0$. The vertical line marks where the long-wave analysis deviates noticeably from the simulation results (![]() $t = 1.0\times 10^{4}$).

$t = 1.0\times 10^{4}$).

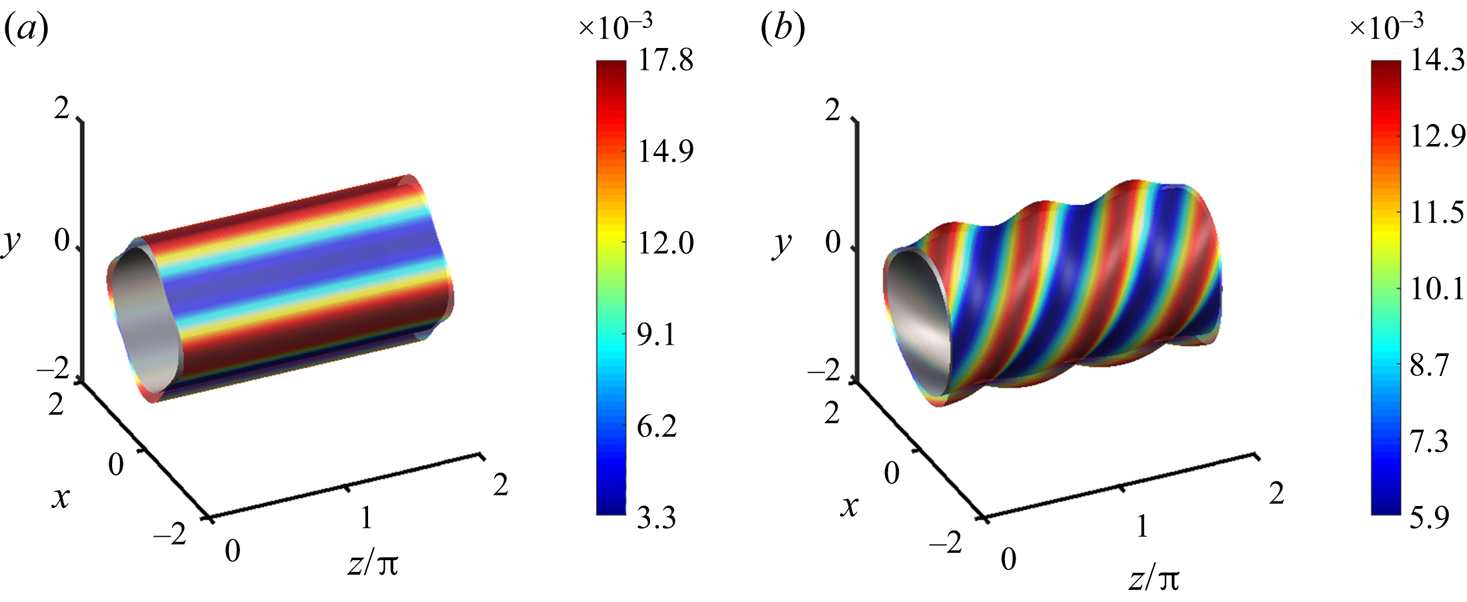

Three-dimensional renderings of the coatings for ![]() $We=10$ and

$We=10$ and ![]() $We=20$ are provided in figures 4(a) and 4(b) at the time denoted by the vertical line in figure 3 (

$We=20$ are provided in figures 4(a) and 4(b) at the time denoted by the vertical line in figure 3 (![]() $t = 1\times 10^{4}$). In these renderings, the upward-moving side of the cylinder faces the reader. Liquid accumulates in troughs for

$t = 1\times 10^{4}$). In these renderings, the upward-moving side of the cylinder faces the reader. Liquid accumulates in troughs for ![]() $We < We_c$ and over crests for

$We < We_c$ and over crests for ![]() $We>We_c$, as predicted from the long-wave analysis. We note that the spacing of the rings calculated from simulations (figure 4a,b) is identical to the wavelength of the axial topography, given by

$We>We_c$, as predicted from the long-wave analysis. We note that the spacing of the rings calculated from simulations (figure 4a,b) is identical to the wavelength of the axial topography, given by ![]() ${\lambda _z = 2{\rm \pi} /k_z \approx 1.57}$. This is different than the spacing of rings one would expect on an unpatterned cylinder, predicted from (3.2) to be

${\lambda _z = 2{\rm \pi} /k_z \approx 1.57}$. This is different than the spacing of rings one would expect on an unpatterned cylinder, predicted from (3.2) to be ![]() $\lambda _{RP}^* = 2.68$ and

$\lambda _{RP}^* = 2.68$ and ![]() $\lambda _{RP}^* = 1.94$ for

$\lambda _{RP}^* = 1.94$ for ![]() $We=10$ and

$We=10$ and ![]() $We=20$, respectively.

$We=20$, respectively.

Figure 4. The 3-D renderings of the coatings analysed in figure 3 with ![]() $\epsilon =0.01$ and

$\epsilon =0.01$ and ![]() $\beta =10^{-3}$ at

$\beta =10^{-3}$ at ![]() $t = 1\times 10^{4}$ for (a)

$t = 1\times 10^{4}$ for (a) ![]() $We = 10$ and (b)

$We = 10$ and (b) ![]() $We=20$. Rescaled film thicknesses (

$We=20$. Rescaled film thicknesses (![]() $\epsilon h$) are indicated by the colourbar. Note that the

$\epsilon h$) are indicated by the colourbar. Note that the ![]() $z$-axis is not to scale, and that the topography and film thickness have been exaggerated by 20 times for easier viewing.

$z$-axis is not to scale, and that the topography and film thickness have been exaggerated by 20 times for easier viewing.

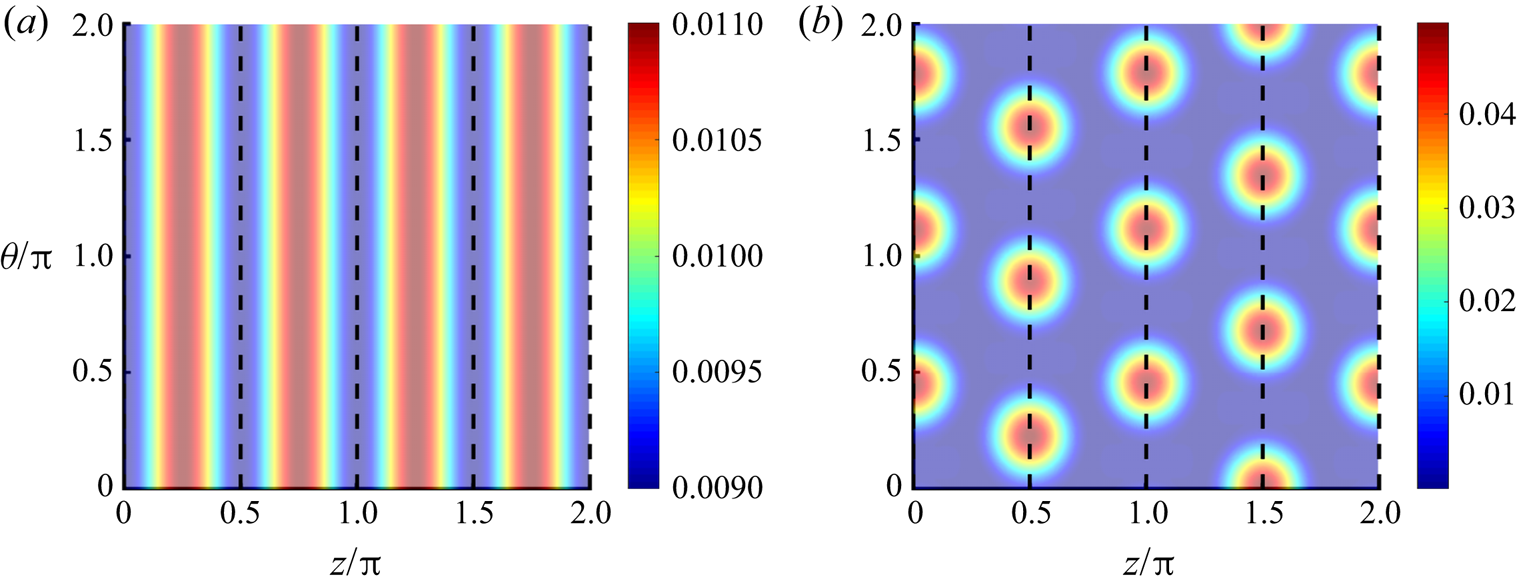

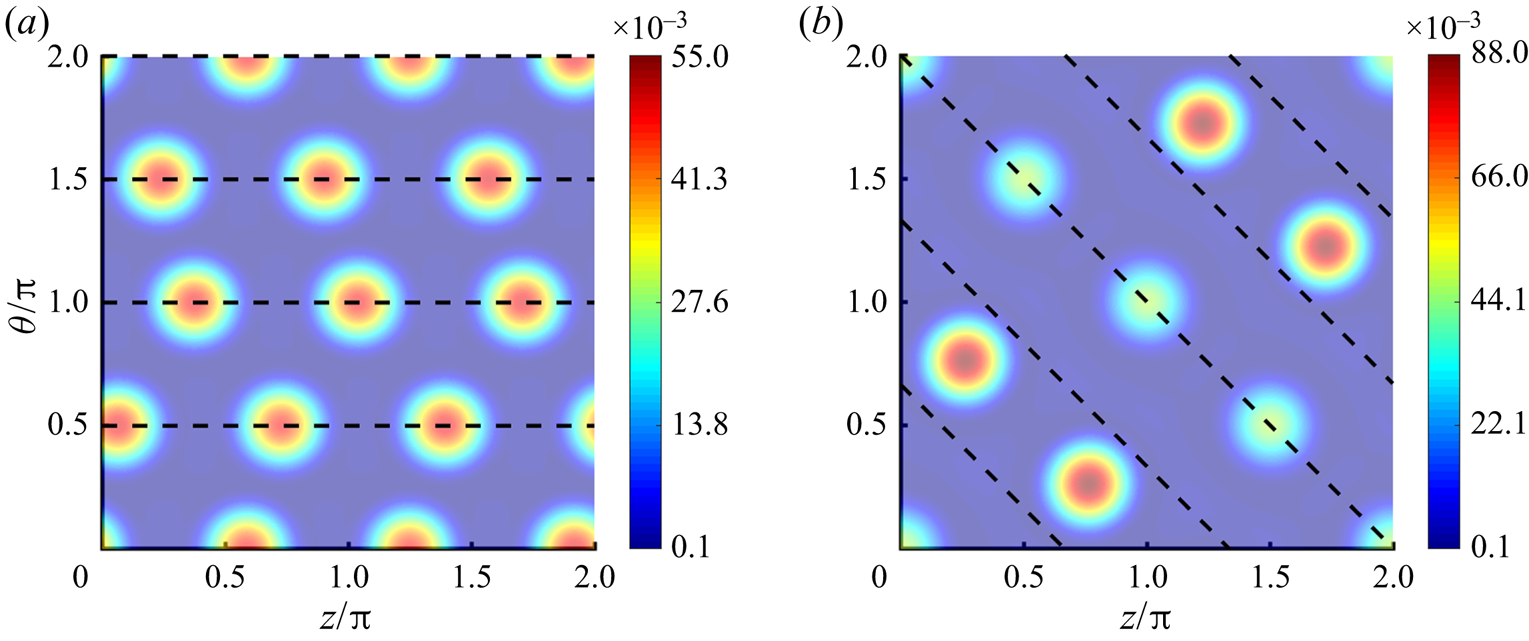

At longer times past what is shown in figures 3 and 4, non-uniformities may also develop along the angular direction, in which the cylinder is unpatterned. To examine these circumferential variations, ‘unravelled’ coating thicknesses for the simulations shown in figure 4 have been plotted against the angular and axial coordinates at ![]() $t=1.0\times 10^{6}$. Dashed black lines are used to denote the position of pattern crests. At

$t=1.0\times 10^{6}$. Dashed black lines are used to denote the position of pattern crests. At ![]() $We=10$ (figure 5a), the liquid remains confined in the pattern troughs and noticeable thickness variations do not develop around the circumference. The stability of these rings is due to the prevalence of surface-tension forces, which suppress the growth of disturbances in the angular direction.

$We=10$ (figure 5a), the liquid remains confined in the pattern troughs and noticeable thickness variations do not develop around the circumference. The stability of these rings is due to the prevalence of surface-tension forces, which suppress the growth of disturbances in the angular direction.

Figure 5. Film thicknesses for the simulations shown in figures 3 and 4 with ![]() $\epsilon =0.01$ and

$\epsilon =0.01$ and ![]() $\beta =10^{-3}$ at

$\beta =10^{-3}$ at ![]() $t=1\times 10^{6}$ for (a)

$t=1\times 10^{6}$ for (a) ![]() $We = 10$ and (b)

$We = 10$ and (b) ![]() $We=20$. Rescaled film thicknesses (

$We=20$. Rescaled film thicknesses (![]() $\epsilon h$) are indicated by the colourbars. Dashed black lines are used to denote the position of pattern crests.

$\epsilon h$) are indicated by the colourbars. Dashed black lines are used to denote the position of pattern crests.

When centrifugal forces dominate at ![]() $We=20$ (figure 5b), each band of liquid over the pattern crests segregates into angularly spaced droplets. The angular spacing of these droplets is equal to the spacing predicted by LSA on 2-D cross-sections of unpatterned cylinders (Evans et al. Reference Evans, Schwartz and Roy2004). This instability arises because centrifugal forces destabilize the axially spaced rings to angular disturbances. Over later times for the simulation shown in figure 5(b), the droplets do not migrate noticeably from their positions at

$We=20$ (figure 5b), each band of liquid over the pattern crests segregates into angularly spaced droplets. The angular spacing of these droplets is equal to the spacing predicted by LSA on 2-D cross-sections of unpatterned cylinders (Evans et al. Reference Evans, Schwartz and Roy2004). This instability arises because centrifugal forces destabilize the axially spaced rings to angular disturbances. Over later times for the simulation shown in figure 5(b), the droplets do not migrate noticeably from their positions at ![]() $t=1\times 10^6$. However, in similar simulations with larger characteristic film thicknesses

$t=1\times 10^6$. However, in similar simulations with larger characteristic film thicknesses ![]() $\epsilon$ or Weber numbers

$\epsilon$ or Weber numbers ![]() $We$, the droplets that form at later times may migrate and coalesce to form fewer, larger droplets. The results presented in figures 5(a) and 5(b) demonstrate a difference in the long-time stability of coatings below and above the critical Weber number that is not captured by the long-wave analysis.

$We$, the droplets that form at later times may migrate and coalesce to form fewer, larger droplets. The results presented in figures 5(a) and 5(b) demonstrate a difference in the long-time stability of coatings below and above the critical Weber number that is not captured by the long-wave analysis.

3.3. Angularly patterned and screw-shaped cylinders

Simulations of coatings on cylinders with angular patterning and screw-shaped patterning have been conducted under various conditions. We summarize some of the results here as the behaviour is similar to that shown in figures 3–5. At early times, agreement between the long-wave approximation and the simulations is observed. At later times, deviations between the long-wave approximation and the simulations are observed as nonlinearities become more prevalent. Below ![]() $We_c$, liquid pools in pattern troughs, and the bands of liquid that accumulate in troughs remain stable to disturbances over time. Above

$We_c$, liquid pools in pattern troughs, and the bands of liquid that accumulate in troughs remain stable to disturbances over time. Above ![]() $We_c$, liquid collects over pattern crests, but these bands of liquid are unstable to disturbances, leading to the formation of droplets with fairly regular axial and angular spacing. These droplets may merge and shift over time, causing variations in droplet sizes and spacings. We relegate these results to Appendix A.

$We_c$, liquid collects over pattern crests, but these bands of liquid are unstable to disturbances, leading to the formation of droplets with fairly regular axial and angular spacing. These droplets may merge and shift over time, causing variations in droplet sizes and spacings. We relegate these results to Appendix A.

In summary, when gravitational forces may be neglected, the behaviour of coatings on topographically patterned cylinders is controlled by the balance between centrifugal and surface-tension forces. This balance is captured by a critical Weber number above which centrifugal forces drive liquid toward pattern crests and below which surface-tension forces drive liquid into pattern troughs. An expression for this critical Weber number ![]() $We_c$ (3.13) has been rigorously derived for flows in three dimensions using a long-wave analysis. The long-wave analysis also yields a growth rate (3.11) that relates the rate of levelling (

$We_c$ (3.13) has been rigorously derived for flows in three dimensions using a long-wave analysis. The long-wave analysis also yields a growth rate (3.11) that relates the rate of levelling (![]() $We < We_c$) or centrifugation (

$We < We_c$) or centrifugation (![]() $We>We_c$) to the dimensionless characteristic film thickness, the pattern wavenumbers, the pattern amplitude and the Weber number (

$We>We_c$) to the dimensionless characteristic film thickness, the pattern wavenumbers, the pattern amplitude and the Weber number (![]() $\epsilon$,

$\epsilon$, ![]() $k_{\theta }$ and

$k_{\theta }$ and ![]() $k_{z}$,

$k_{z}$, ![]() $\beta$ and

$\beta$ and ![]() $We$, respectively). As the growth rate controls the rate at which thickness disturbances develop, it may be used to estimate the time window during which the coating may be dried before large non-uniformities develop.

$We$, respectively). As the growth rate controls the rate at which thickness disturbances develop, it may be used to estimate the time window during which the coating may be dried before large non-uniformities develop.

Although the long-wave analysis provides useful information about the growth of disturbances on topographically patterned cylinders for early times, the results shown in figures 3, 5 and 20 (see Appendix A) demonstrate that it fails to capture coating evolution at later times. Results from simulations of (3.1) show the behaviour of coatings at later times, where coatings tend to break up into individual droplets above the critical Weber number.

4. Gravitational effects

We now examine the effects of topography on coating behaviour in the presence of gravity, where the coating may sag under its own weight. Simulations of (2.18) have been carried out on unpatterned (§ 4.1) and patterned (§§ 4.2 and 4.3) cylinders in the Rayleigh–Plateau (high ![]() $W$) and Rayleigh–Taylor (low

$W$) and Rayleigh–Taylor (low ![]() $W$) regimes. The initial condition is that of a uniform-thickness coating that has been disturbed by small-amplitude random noise

$W$) regimes. The initial condition is that of a uniform-thickness coating that has been disturbed by small-amplitude random noise ![]() $G(\theta ,z)$:

$G(\theta ,z)$:

where ![]() $0\leq G(\theta ,z)\leq 1$ and

$0\leq G(\theta ,z)\leq 1$ and ![]() $\alpha /2$ is the mean amplitude. For all simulations in § 4, we set

$\alpha /2$ is the mean amplitude. For all simulations in § 4, we set ![]() $\alpha = 10^{-3}$; other problem parameters are set to values motivated by the flow visualization experiments in § 5.

$\alpha = 10^{-3}$; other problem parameters are set to values motivated by the flow visualization experiments in § 5.

4.1. Unpatterned cylinders

As discussed in § 1, axially spaced rings of liquid may form on unpatterned cylinders at large rotation rates (RP instability), and droplets may form on the underside of unpatterned cylinders at low rotation rates (RT instability). A useful estimate of the dimensionless rotation rate ![]() $W_c$ that separates the RT and RP regimes on unpatterned cylinders is the minimum rotation rate needed to support a load of liquid on a rotating cylinder in the absence of surface tension, given in dimensional form in (1.1) (Moffatt Reference Moffatt1977; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005):

$W_c$ that separates the RT and RP regimes on unpatterned cylinders is the minimum rotation rate needed to support a load of liquid on a rotating cylinder in the absence of surface tension, given in dimensional form in (1.1) (Moffatt Reference Moffatt1977; Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005):

Here, ![]() $\epsilon$ is the dimensionless characteristic film thickness and

$\epsilon$ is the dimensionless characteristic film thickness and ![]() $M$ is the dimensionless viscosity (table 2).

$M$ is the dimensionless viscosity (table 2).

A parameter sweep has been conducted to establish key features of coating behaviour in the RT (![]() $W < W_c$) and the RP (

$W < W_c$) and the RP (![]() $W>W_c$) regimes. The boundary between the RT and RP regimes predicted by (4.2) is

$W>W_c$) regimes. The boundary between the RT and RP regimes predicted by (4.2) is ![]() $W_c=0.141$ for this set of simulations.

$W_c=0.141$ for this set of simulations.

In figure 6, 3-D renderings of coatings from two representative simulations, one below ![]() $W_c$ (figure 6a,b) and one above

$W_c$ (figure 6a,b) and one above ![]() $W_c$ (figure 6c,d), are shown at two times to provide examples of coating evolution on unpatterned cylinders in the RT and RP regimes. Below

$W_c$ (figure 6c,d), are shown at two times to provide examples of coating evolution on unpatterned cylinders in the RT and RP regimes. Below ![]() $W_c$, a ridge of liquid supported by cylinder rotation and surface tension forms along the cylinder axis (figure 6a). Small undulations in the thickness and angular position of this ridge are present in figure 6(a). Over time, these undulations develop into individual fingers of liquid with regular spacing (figure 6b), a Rayleigh–Taylor-like instability. For flows on the underside of stationary, unpatterned cylinders, the dimensionless RT wavelength

$W_c$, a ridge of liquid supported by cylinder rotation and surface tension forms along the cylinder axis (figure 6a). Small undulations in the thickness and angular position of this ridge are present in figure 6(a). Over time, these undulations develop into individual fingers of liquid with regular spacing (figure 6b), a Rayleigh–Taylor-like instability. For flows on the underside of stationary, unpatterned cylinders, the dimensionless RT wavelength ![]() $\lambda ^{*}_{RT}$ is initially equal to that on stationary, planar substrates (given in dimensional quantities in (1.2)) (Fermigier et al. Reference Fermigier, Limat, Wesfreid, Boudinet and Quilliet1992):

$\lambda ^{*}_{RT}$ is initially equal to that on stationary, planar substrates (given in dimensional quantities in (1.2)) (Fermigier et al. Reference Fermigier, Limat, Wesfreid, Boudinet and Quilliet1992):

where ![]() $Bo = \rho gR^2/\sigma$ is the Bond number defined on an unpatterned cylinder. As was discussed in Evans et al., the spacing of droplets on unpatterned cylinders in the RT regime tends to be larger than that predicted by (4.3) (Evans et al. Reference Evans, Schwartz and Roy2005); this will be shown clearly in figure 7.

$Bo = \rho gR^2/\sigma$ is the Bond number defined on an unpatterned cylinder. As was discussed in Evans et al., the spacing of droplets on unpatterned cylinders in the RT regime tends to be larger than that predicted by (4.3) (Evans et al. Reference Evans, Schwartz and Roy2005); this will be shown clearly in figure 7.

Figure 6. The 3D renderings obtained from simulations on unpatterned cylinders for ![]() $M=0.0695$,

$M=0.0695$, ![]() $\epsilon = 0.07$ and

$\epsilon = 0.07$ and ![]() $Bo = 50$. The rotation rates are (a,b)

$Bo = 50$. The rotation rates are (a,b) ![]() $W=0.14$ and (c,d)

$W=0.14$ and (c,d) ![]() $W=0.8896$. The minimum rotation rate predicted by Moffatt is

$W=0.8896$. The minimum rotation rate predicted by Moffatt is ![]() $W_c=0.141$ (4.2) (Moffatt Reference Moffatt1977). Rescaled film thicknesses (

$W_c=0.141$ (4.2) (Moffatt Reference Moffatt1977). Rescaled film thicknesses (![]() $\epsilon h$) are indicated by the colourbars.

$\epsilon h$) are indicated by the colourbars.

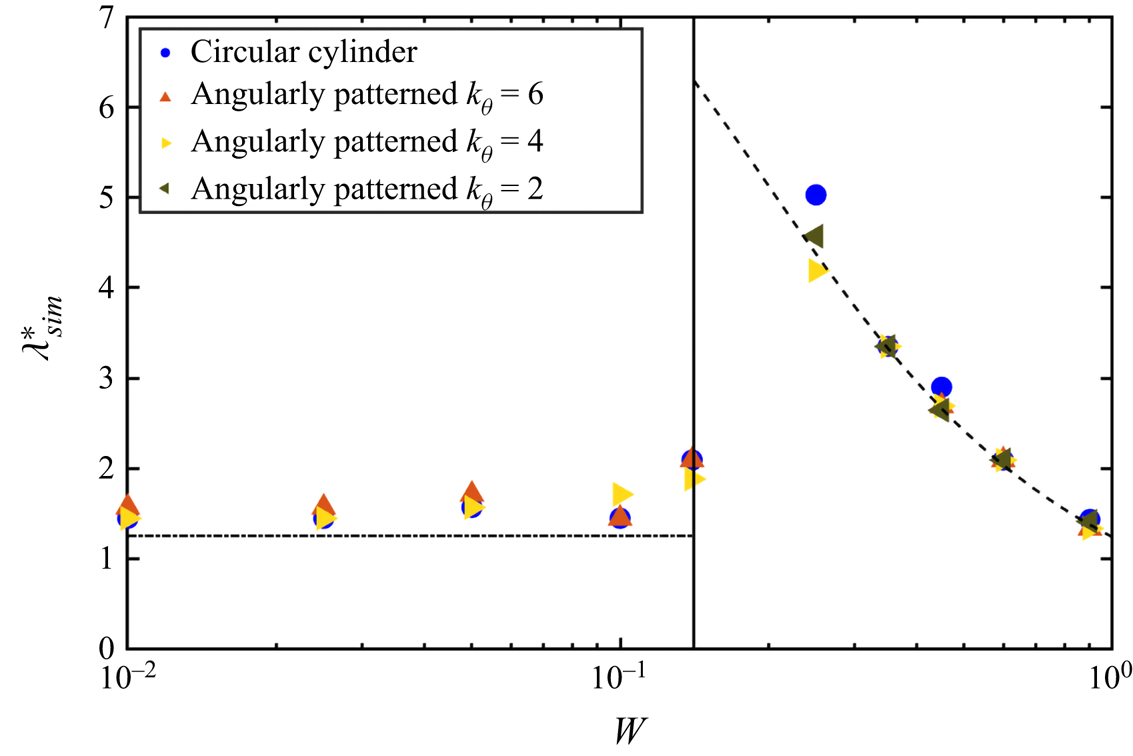

Figure 7. The spacing of disturbances calculated from simulations (![]() $\lambda ^{*}_{sim}$) of varying rotation rate on an unpatterned cylinder (blue circles). Other simulation parameters are

$\lambda ^{*}_{sim}$) of varying rotation rate on an unpatterned cylinder (blue circles). Other simulation parameters are ![]() $M=0.0695$,

$M=0.0695$, ![]() $\epsilon =0.07$ and

$\epsilon =0.07$ and ![]() $Bo=50$. The vertical line is

$Bo=50$. The vertical line is ![]() $W_c=0.141$ (4.2) while the dashed and dotted-dashed lines are the predicted wavelengths of the RP instability (3.2) and the RT instability on a flat plate with

$W_c=0.141$ (4.2) while the dashed and dotted-dashed lines are the predicted wavelengths of the RP instability (3.2) and the RT instability on a flat plate with ![]() $Bo=50$ (4.3).

$Bo=50$ (4.3).

Above ![]() $W_c$, axially spaced mounds of liquid form with fairly regular spacing (figure 6c). Over time, centrifugal forces cause these axial thickness variations to develop into axially spaced rings of liquid which are thicker on the upward-moving side of the cylinder (figure 6d). Hynes noted that above

$W_c$, axially spaced mounds of liquid form with fairly regular spacing (figure 6c). Over time, centrifugal forces cause these axial thickness variations to develop into axially spaced rings of liquid which are thicker on the upward-moving side of the cylinder (figure 6d). Hynes noted that above ![]() $W_c$, key qualitative features of coating behaviour can be captured in the limit where gravity is neglected (Hynes Reference Hynes1978). In this limit, an expression for

$W_c$, key qualitative features of coating behaviour can be captured in the limit where gravity is neglected (Hynes Reference Hynes1978). In this limit, an expression for ![]() $\lambda _{RP}^*$, the dimensionless ring spacing on unpatterned cylinders predicted by LSA, is provided by (3.2). Here, the spacing depends on the Weber number

$\lambda _{RP}^*$, the dimensionless ring spacing on unpatterned cylinders predicted by LSA, is provided by (3.2). Here, the spacing depends on the Weber number ![]() $We = W^2Bo$ (Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005).

$We = W^2Bo$ (Hynes Reference Hynes1978; Evans et al. Reference Evans, Schwartz and Roy2005).

The spacing of disturbances in the RT and the RP regimes serves as a good indicator of the boundary separating these regimes on unpatterned cylinders. In figure 7, the wavelength of disturbances calculated from simulations is shown for varying rotation rates on unpatterned cylinders. The wavelength of disturbances (![]() $\lambda ^{*}_{sim}$) is taken to be the average distance between peaks in the coating thickness. The boundary between the RT and RP regimes for an unpatterned cylinder, calculated from (4.2) (

$\lambda ^{*}_{sim}$) is taken to be the average distance between peaks in the coating thickness. The boundary between the RT and RP regimes for an unpatterned cylinder, calculated from (4.2) (![]() $W_c=0.141$), is given by the vertical line. The dashed line to the right of

$W_c=0.141$), is given by the vertical line. The dashed line to the right of ![]() $W_c$ is the predicted wavelength of the RP instability (3.2), and the dashed-dotted line to the left of

$W_c$ is the predicted wavelength of the RP instability (3.2), and the dashed-dotted line to the left of ![]() $W_c$ is the predicted spacing of the RT instability on the bottom of a flat plate (4.3). The results falling very close to

$W_c$ is the predicted spacing of the RT instability on the bottom of a flat plate (4.3). The results falling very close to ![]() $W_c$ are for

$W_c$ are for ![]() $W$ slightly less than the critical rotation rate (

$W$ slightly less than the critical rotation rate (![]() $W=0.14$).

$W=0.14$).

In the RP regime (![]() $W>W_c$), the spacing of the axially spaced rings agrees well with the wavelength predicted by LSA on an unpatterned cylinder, where the ring spacing decreases with increasing rotation rate

$W>W_c$), the spacing of the axially spaced rings agrees well with the wavelength predicted by LSA on an unpatterned cylinder, where the ring spacing decreases with increasing rotation rate ![]() $W$. In the RT regime (

$W$. In the RT regime (![]() $W < W_c$), the spacing of droplets on unpatterned cylinders is mostly unaffected by the rotation rate, varying between

$W < W_c$), the spacing of droplets on unpatterned cylinders is mostly unaffected by the rotation rate, varying between ![]() $\lambda ^{*}_{sim} = 1.45$ and

$\lambda ^{*}_{sim} = 1.45$ and ![]() $1.71$ for

$1.71$ for ![]() $0.01 \leq W\leq 0.1$. Similar to what was observed by Evans et al. (Reference Evans, Schwartz and Roy2005), the spacing in our simulations is larger than the spacing predicted for the RT instability on a flat plate (

$0.01 \leq W\leq 0.1$. Similar to what was observed by Evans et al. (Reference Evans, Schwartz and Roy2005), the spacing in our simulations is larger than the spacing predicted for the RT instability on a flat plate (![]() $\lambda ^{*}_{RT} = 1.26$) for

$\lambda ^{*}_{RT} = 1.26$) for ![]() $Bo=50$ (figure 7). Near

$Bo=50$ (figure 7). Near ![]() $W_c$, cylinder rotation better supports the coating weight and offsets some of the destabilizing effects of gravity. For

$W_c$, cylinder rotation better supports the coating weight and offsets some of the destabilizing effects of gravity. For ![]() $W=0.14$, which is slightly less than

$W=0.14$, which is slightly less than ![]() $W_c=0.141$, the spacing between droplets increases by 50 % from what is observed at lower rotation rates; however, this change in spacing with

$W_c=0.141$, the spacing between droplets increases by 50 % from what is observed at lower rotation rates; however, this change in spacing with ![]() $W$ is small compared with the changes observed in the RP regime.

$W$ is small compared with the changes observed in the RP regime.

Although computational limitations have prevented us from performing a more extensive parameter sweep, we briefly comment on how other parameters affect the regime map (figure 7) for unpatterned cylinders based on prior work and the results of limited simulations. With an increase in dimensionless viscosity ![]() $M$, the boundary between the RT and RP regimes

$M$, the boundary between the RT and RP regimes ![]() $W_c$ decreases (4.2) since a coating of fixed thickness can be supported at a lower rotation rate as viscous forces increase (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). Similarly, a decrease in the characteristic film thickness

$W_c$ decreases (4.2) since a coating of fixed thickness can be supported at a lower rotation rate as viscous forces increase (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). Similarly, a decrease in the characteristic film thickness ![]() $\epsilon$ leads to a decrease in

$\epsilon$ leads to a decrease in ![]() $W_c$. An increase in the Bond number

$W_c$. An increase in the Bond number ![]() $Bo$ decreases the spacing of both the RT and the RP instabilities, as one would expect from the expressions for their predicted wavelengths ((4.3) and (3.2)) (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018).

$Bo$ decreases the spacing of both the RT and the RP instabilities, as one would expect from the expressions for their predicted wavelengths ((4.3) and (3.2)) (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018).

4.2. Angular topography

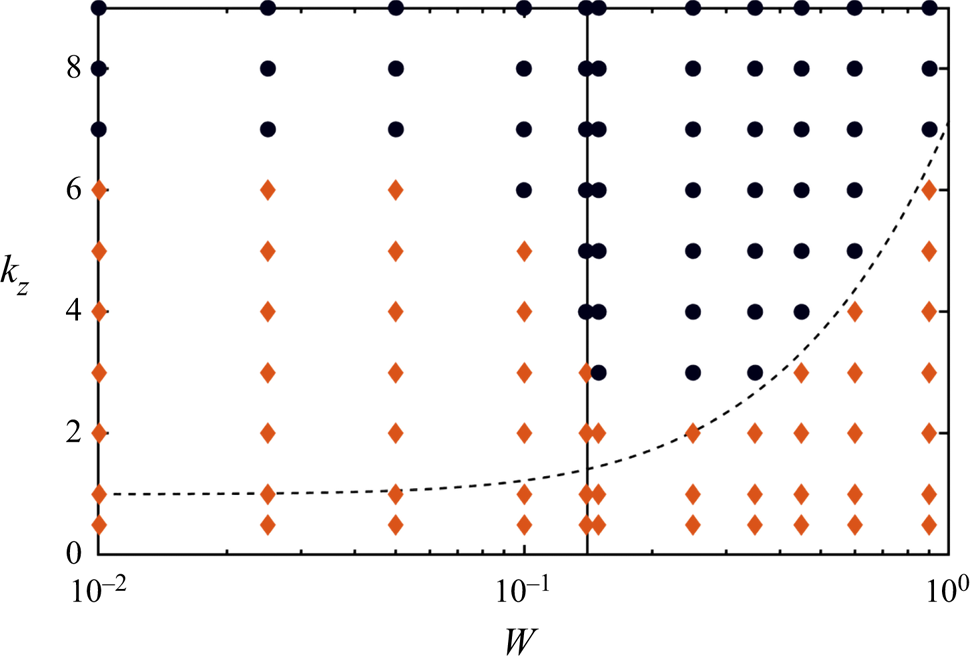

It is not obvious a priori how angular topography (2.20) alters coating behaviour, especially the formation of axial thickness variations. To explore this, a parameter sweep has been conducted for varying rotation rates ![]() $W$ and pattern wavenumbers

$W$ and pattern wavenumbers ![]() $k_{\theta }$. In figure 8, a regime map is presented to highlight the effect of angular topography on the spacing of disturbances in the RT regime (

$k_{\theta }$. In figure 8, a regime map is presented to highlight the effect of angular topography on the spacing of disturbances in the RT regime (![]() $W < W_c$) and the RP regime (

$W < W_c$) and the RP regime (![]() $W>W_c$). Here, the topography amplitude

$W>W_c$). Here, the topography amplitude ![]() $\beta =0.05$ is comparable to the film thickness

$\beta =0.05$ is comparable to the film thickness ![]() $\epsilon =0.07$. Blue circles denote results obtained for unpatterned cylinders (also shown in figure 7) while coloured triangles denote results for angularly patterned cylinders. The dashed line and dotted-dashed line are the predicted spacings of the RP and RT instabilities, respectively, ((3.2) and (4.3)), while the vertical line is

$\epsilon =0.07$. Blue circles denote results obtained for unpatterned cylinders (also shown in figure 7) while coloured triangles denote results for angularly patterned cylinders. The dashed line and dotted-dashed line are the predicted spacings of the RP and RT instabilities, respectively, ((3.2) and (4.3)), while the vertical line is ![]() $W_c=0.141$ (4.2).

$W_c=0.141$ (4.2).

Figure 8. The spacing of disturbances calculated from simulations (![]() $\lambda ^{*}_{sim}$) of varying rotation rate for angularly patterned cylinders (coloured triangles) and unpatterned cylinders (blue circles). For patterned cylinders, the topography amplitude is fixed to

$\lambda ^{*}_{sim}$) of varying rotation rate for angularly patterned cylinders (coloured triangles) and unpatterned cylinders (blue circles). For patterned cylinders, the topography amplitude is fixed to ![]() $\beta =0.05$. Other simulation parameters are identical to those listed in figure 7. The vertical line is

$\beta =0.05$. Other simulation parameters are identical to those listed in figure 7. The vertical line is ![]() $W_c=0.141$ (4.2) while the dashed and dotted-dashed lines are the predicted wavelength of the RP instability (3.2) and the RT instability on a flat plate with

$W_c=0.141$ (4.2) while the dashed and dotted-dashed lines are the predicted wavelength of the RP instability (3.2) and the RT instability on a flat plate with ![]() $Bo=50$ (4.3).

$Bo=50$ (4.3).

Over the range of rotation rates and pattern wavenumbers considered, the spacing of disturbances on angularly patterned cylinders is nearly identical to the spacing observed on unpatterned cylinders (figure 8), indicating that angular topography has a negligible effect on the axial spacing of disturbances. In the RP regime (![]() $W>W_c$), the spacing obtained for angularly patterned cylinders also agrees well with the predicted wavelength of the RP disturbances on unpatterned cylinders. To better understand this, a LSA was conducted in the limit of negligible gravity for flows on topographically patterned cylinders (see supplementary material available at https://doi.org/10.1017/jfm.2021.224). The expressions for the spacing and growth rate of axial disturbances on angularly patterned cylinders are identical to those predicted by LSA on unpatterned cylinders ((3.2) and (3.3)).

$W>W_c$), the spacing obtained for angularly patterned cylinders also agrees well with the predicted wavelength of the RP disturbances on unpatterned cylinders. To better understand this, a LSA was conducted in the limit of negligible gravity for flows on topographically patterned cylinders (see supplementary material available at https://doi.org/10.1017/jfm.2021.224). The expressions for the spacing and growth rate of axial disturbances on angularly patterned cylinders are identical to those predicted by LSA on unpatterned cylinders ((3.2) and (3.3)).

While the regime map presented in figure 8 demonstrates that the spacing of disturbances on rotating cylinders is largely unaffected by angular topography, figure 8 does not contain information regarding the effect of angular topography on the time evolution of these disturbances. To better understand this issue, we examine the results of a limited set of simulations in the RP regime (![]() $W>W_c$). Since the experiments in § 5 focus mainly on the RP regime, we relegate simulations for the RT regime to Appendix B.

$W>W_c$). Since the experiments in § 5 focus mainly on the RP regime, we relegate simulations for the RT regime to Appendix B.

The maximum axial thickness variation ![]() $(\Delta h)_{max}$, normalized by the amplitude of the initial random noise

$(\Delta h)_{max}$, normalized by the amplitude of the initial random noise ![]() $\alpha$, is calculated over time from simulations (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In figure 9,

$\alpha$, is calculated over time from simulations (Evans et al. Reference Evans, Schwartz and Roy2005; Li & Kumar Reference Li and Kumar2018). In figure 9, ![]() $\alpha ^{-1}(\Delta h)_{max}$ is shown on a logarithmic scale for simulations on an unpatterned cylinder (blue line) and an angularly patterned cylinder (red line). Dashed lines denote the initial slopes of

$\alpha ^{-1}(\Delta h)_{max}$ is shown on a logarithmic scale for simulations on an unpatterned cylinder (blue line) and an angularly patterned cylinder (red line). Dashed lines denote the initial slopes of ![]() $(\Delta h)_{max}$ in the linear regions of each simulation. Oscillations in

$(\Delta h)_{max}$ in the linear regions of each simulation. Oscillations in ![]() $(\Delta h)_{max}$ are caused by fluctuations in the maximum coating thickness and occur with a frequency of a single rotation (

$(\Delta h)_{max}$ are caused by fluctuations in the maximum coating thickness and occur with a frequency of a single rotation (![]() $\epsilon ^{2}M^{-1}W^{-1}$); while they appear to be discontinuous, each oscillation in figure 9 is smooth and contains over 10 000 time steps.

$\epsilon ^{2}M^{-1}W^{-1}$); while they appear to be discontinuous, each oscillation in figure 9 is smooth and contains over 10 000 time steps.

Figure 9. Normalized maximum axial thickness variation ![]() $\alpha ^{-1}(\Delta h)_{max}$ over time on an unpatterned cylinder (blue) and angularly patterned cylinder (red) with

$\alpha ^{-1}(\Delta h)_{max}$ over time on an unpatterned cylinder (blue) and angularly patterned cylinder (red) with ![]() $k_{\theta }=4$ and

$k_{\theta }=4$ and ![]() $\beta =0.02$. Other simulation parameters are

$\beta =0.02$. Other simulation parameters are ![]() $\alpha =10^{-3}$ (see (4.1)),

$\alpha =10^{-3}$ (see (4.1)), ![]() $M=0.0695$,

$M=0.0695$, ![]() $\epsilon = 0.07$,

$\epsilon = 0.07$, ![]() $Bo = 41.42$ and

$Bo = 41.42$ and ![]() $W = 0.8896$. Oscillations in

$W = 0.8896$. Oscillations in ![]() $(\Delta h)_{max}$ have a period of a single revolution (

$(\Delta h)_{max}$ have a period of a single revolution (![]() $\Delta t=2{\rm \pi} \epsilon ^2/MW$) and arise due to oscillations in the angular position of disturbances.