Published online by Cambridge University Press: 07 February 2023

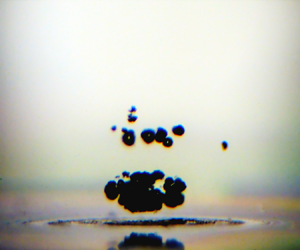

Underwater stability of an air layer trapped in a micro-structure, plastron, is critical in drag reduction applications. Here, we investigate the wetting state and plastron stability of underwater superhydrophobic surfaces (SHS) under an intense acoustic drive. Flat surfaces and SHS are subjected to short acoustic pulses of different intensities. At low amplitude, the comparison between the results of various surfaces shows that plastron behaves like a water–air interface, whose presence can be detected from the phase of the reflected acoustic waves. At moderate intensity, a wetting transition towards a completely wetting state is observed and shown to be triggered by a sufficiently large acoustic radiation pressure. This wetting transition is well captured by a simplified model by balancing radiation pressure with the critical capillary pressure for the interface sliding. Cavitation clouds appear under strong excitation; their sizes and positions greatly depend on the surface acoustic boundary condition. For SHS in a Cassie–Baxter state (with an air layer), cavitation clouds appear at specific locations (from the solid surface) corresponding to the pressure anti-node of the transient standing wave generated by the reflection. This study unprecedentedly demonstrates the capability of acoustic waves to monitor and characterize plastron stability with low and moderate amplitudes, respectively.