1. Introduction

The flow of particles in a vertical channel of infinite length bounded by parallel walls under the influence of gravity is one of the simplest examples of a granular flow. This is an approximation for the flow in the central region of a long vertical bin away from the free surface and the bottom exit. The flow is expected to be unidirectional and fully developed, and the velocity in the vertical direction is a function of only one cross-stream direction, if we assume that the system is infinite in the second cross-stream direction. This flow has been studied in experiments (Savage Reference Savage1979; Nedderman & Laohakul Reference Nedderman and Laohakul1980; Natarajan, Hunt & Taylor Reference Natarajan, Hunt and Taylor1995; Pouliquen & Gutfraind Reference Pouliquen and Gutfraind1996; Ananda, Moka & Nott Reference Ananda, Moka and Nott2008) and using theoretical models (Goodman & Cowin Reference Goodman and Cowin1971; Savage Reference Savage1979; Gutfraind & Pouliquen Reference Gutfraind and Pouliquen1996; Mohan, Nott & Rao Reference Mohan, Nott and Rao1997, Reference Mohan, Nott and Rao1999; Barker, Zhu & Sun Reference Barker, Zhu and Sun2022; Debnath, Kumaran & Rao Reference Debnath, Kumaran and Rao2022). There is consensus that the flow consists of a central plug zone, where the material flows without shearing, and relatively thin layers close to the wall where there is shearing. These flows are usually very dense, and the volume fraction is close to random close packing, though there is a decrease in the volume fraction in the shearing zones close to the wall. From the momentum balance, the normal stress in the cross-stream direction is a constant. If the decrease in the volume fraction near the walls is neglected, then the shear stress increases proportional to the distance from the centre of the channel. The precise volume fraction is difficult to measure in experiments as it is near close packing, but the flow velocities have been measured. Despite the simplicity of the configuration, there is as yet no established model for the dependence of the velocity profile, volume fraction and shear layer thickness on the system parameters such as the channel width, particle diameter and average volume fraction.

In experimental configurations, the flow rate in the fully developed unidirectional flow far from the exit depends on the width of the exit slot and the exit conditions. The discharge rate at the exit is described by the Beverloo correlation (Beverloo, Leniger & Van de Velde Reference Beverloo, Leniger and Van de Velde1961), where the velocity is proportional to the square root of the width of the exit slot. The discharge rate at the exit slot determines the average flow velocity far upstream of the exit slot, and the average volume fraction at that location is set by the flow velocity, overburden, and the particle–particle and particle–wall interactions. If the width of the channel is much smaller than the height, then the weight of the overburden at a given depth from the free surface is balanced by the frictional force exerted by the side walls (the Janssen effect; Janssen Reference Janssen1895), and the pressure is independent of depth; this is in contrast to the linear increase of pressure with depth for normal fluids. For a steady unidirectional flow, the total height of the channel does not affect the flow. Therefore, the flow profile in the central region of the channel should be amenable to a description based on the average volume fraction, the wall friction and the dimensions in that region, instead of the total height or the discharge rate fixed at the exit.

To examine a steady fully developed unidirectional flow, we consider a simpler configuration in simulations, where the channel is bounded by two flat frictional walls in the cross-stream direction, and periodic boundary conditions are imposed in the flow and spanwise directions. The average volume fraction of particles in the channel is fixed by the initial loading before the onset of flow. If the average volume fraction is small, then it is expected that the particles will accelerate continuously due to gravity, and no steady state will be reached. If the average volume fraction is near random close packing, then there will be a jammed state in which there is no flow. Here, we examine an intermediate range of the average volume fractions where there is a steady fully developed flow.

The salient feature of the flow in a channel is the presence of a plug zone at the centre where there is no shearing, and shear layers at the walls. Two possible states are predicted by frictional models, a static state and a plug flow with an indeterminate velocity. This is because frictional models do not have any rate dependence, and they do not contain any intrinsic length scale. A microscopic length scale has been included in different ways in models for dense granular flows. In the Cosserat models (Mohan et al. Reference Mohan, Nott and Rao1999; Mohan, Rao & Nott Reference Mohan, Rao and Nott2002), the particle spin is incorporated as an additional field; the length scale in this model is the distance from the walls over which there is a difference between the particle angular velocity and the material rotation rate due to the wall effect. Granular fluidity models (Aranson & Tsimring Reference Aranson and Tsimring2001; Henann & Kamrin Reference Henann and Kamrin2013) define an additional field that is a measure of the extent of ‘fluidity’ of the material at a location. The fluidity is determined from a conservation equation similar to a diffusion equation (Henann & Kamrin Reference Henann and Kamrin2013) or an order parameter equation describing the cross-over between flowing and static states (Aranson & Tsimring Reference Aranson and Tsimring2001). A different approach was followed by Dsouza & Nott (Reference Dsouza and Nott2020), where the flow rule was integrated over a representative volume with an effective mesoscopic size, to obtain constitutive relations containing the Laplacian of the rate of deformation tensor. However, these models require boundary conditions to be specified, and these boundary conditions are not prescribed. There is ambiguity in how the boundary conditions are to be imposed in different configurations. Some of these models have third and higher derivatives of the velocity, hence additional boundary conditions are required.

The incompressible ![]() $\mu (I)$ models (GDR-MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006) attempt to incorporate rate dependence in the constitutive relations through the inertia parameter

$\mu (I)$ models (GDR-MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006) attempt to incorporate rate dependence in the constitutive relations through the inertia parameter ![]() $I$. The friction coefficient

$I$. The friction coefficient ![]() $\mu$, the ratio of the shear and normal stresses, is expressed as a function of

$\mu$, the ratio of the shear and normal stresses, is expressed as a function of ![]() $I$, the shear rate non-dimensionalized by the square root of the normal stress along with suitable powers of the particle diameter and density. Universal relations, presented later in (B3) and (B4), have been proposed for the relation between the stress, volume fraction and inertia parameter. While the

$I$, the shear rate non-dimensionalized by the square root of the normal stress along with suitable powers of the particle diameter and density. Universal relations, presented later in (B3) and (B4), have been proposed for the relation between the stress, volume fraction and inertia parameter. While the ![]() $\mu (I)$ rheology has been used widely for diverse applications, it is ill-posed in the sense that it is unstable to small wavelength perturbations. Well-posed models have been proposed by incorporating compressibility and inertia parameter in the flow rule and the yield function (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

$\mu (I)$ rheology has been used widely for diverse applications, it is ill-posed in the sense that it is unstable to small wavelength perturbations. Well-posed models have been proposed by incorporating compressibility and inertia parameter in the flow rule and the yield function (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

Recently, Debnath et al. (Reference Debnath, Kumaran and Rao2022) compared the predictions of some of these models with simulation results. None of the models predict all the profiles well, and some of the models could not be solved for some values of the parameters used. For example, the model of Barker et al. (Reference Barker, Schaeffer, Shearer and Gray2017) predicts that the volume fraction is almost a constant across the channel. The occurrence of negative fluidity in the model of Henann & Kamrin (Reference Henann and Kamrin2013) in some cases is an unrealistic feature. The model of Dsouza & Nott (Reference Dsouza and Nott2020) predicts thick shear layers and higher normal stress compared to results obtained using the discrete element method (DEM).

Another issue in applying the non-local model of Kamrin & Koval (Reference Kamrin and Koval2012) is the following. The vertical flow considered by Kamrin & Koval (Reference Kamrin and Koval2012) and Kim & Kamrin (Reference Kim and Kamrin2020) is unusual, because the pressure exerted on the walls is specified, and not the loading. Therefore, the width is permitted to vary, while the pressure is maintained as constant. This is rather unrealistic, because in a practical realization, one of the walls is not fixed, but is connected to springs that maintain a constant normal stress. This configuration was used specifically because the ![]() $\mu (I)$ parameter can be calculated directly from the known normal stress, and the shear stress can be determined from the body force per unit volume. In contrast, we are examining a flow where the average volume fraction is specified, but the normal stress is not.

$\mu (I)$ parameter can be calculated directly from the known normal stress, and the shear stress can be determined from the body force per unit volume. In contrast, we are examining a flow where the average volume fraction is specified, but the normal stress is not.

The flow down an inclined plane is a configuration that has been studied widely using particle-based simulations (Silbert et al. Reference Silbert, Ertas, Grest, Halsey, Levine and Plimpton2001; Mitarai & Nakanishi Reference Mitarai and Nakanishi2005; Brewster et al. Reference Brewster, Silbert, Grest and Levine2008; Reddy & Kumaran Reference Reddy and Kumaran2007, Reference Reddy and Kumaran2010). In three-dimensional simulations of particle assemblies, there is no flow when the angle of inclination is below a minimum value of about ![]() $20^\circ$. There is steady flow over a relatively small range of angles,

$20^\circ$. There is steady flow over a relatively small range of angles, ![]() ${\sim }20^\circ \unicode{x2013} 24^\circ$, and the flow becomes unstable when the angle of inclination exceeds about

${\sim }20^\circ \unicode{x2013} 24^\circ$, and the flow becomes unstable when the angle of inclination exceeds about ![]() $25^\circ$. There are several intriguing features that are observed for a steady flow. From momentum balance, the ratio of the normal and shear stresses is equal to the tangent of the angle of inclination. The volume fraction is found to be independent of height, in contrast to the intuitive expectation of greater compaction with increasing depth due to the higher overburden. The ‘Bagnold law’ (Bagnold Reference Bagnold1954, Reference Bagnold1956) describes the relation between the stress and the velocity profile in the bulk, and the ‘granular temperature’ (defined in (2.3)) increases linearly with depth. A novel transition between an ordered and a disordered flow due to an increase in the base roughness has also been reported (Kumaran & Maheshwari Reference Kumaran and Maheshwari2012; Kumaran & Bharathraj Reference Kumaran and Bharathraj2013; Bharathraj & Kumaran Reference Bharathraj and Kumaran2017; Silbert et al. Reference Silbert, Grest, Plimpton and Levine2002). The relation between the stress and shear rate is found to obey the Bagnold law in both the ordered and disordered flows, though the Bagnold coefficients are very different.

$25^\circ$. There are several intriguing features that are observed for a steady flow. From momentum balance, the ratio of the normal and shear stresses is equal to the tangent of the angle of inclination. The volume fraction is found to be independent of height, in contrast to the intuitive expectation of greater compaction with increasing depth due to the higher overburden. The ‘Bagnold law’ (Bagnold Reference Bagnold1954, Reference Bagnold1956) describes the relation between the stress and the velocity profile in the bulk, and the ‘granular temperature’ (defined in (2.3)) increases linearly with depth. A novel transition between an ordered and a disordered flow due to an increase in the base roughness has also been reported (Kumaran & Maheshwari Reference Kumaran and Maheshwari2012; Kumaran & Bharathraj Reference Kumaran and Bharathraj2013; Bharathraj & Kumaran Reference Bharathraj and Kumaran2017; Silbert et al. Reference Silbert, Grest, Plimpton and Levine2002). The relation between the stress and shear rate is found to obey the Bagnold law in both the ordered and disordered flows, though the Bagnold coefficients are very different.

The Bagnold law, which states that the stress is proportional to the square of the shear rate, follows from dimensional analysis if the inverse of the shear rate is the only time scale in the problem. The assumption is that the particle interactions are instantaneous, and this assumption is valid if the period of the interactions is much smaller than the inverse of the shear rate. The instantaneous collision assumption is made in kinetic theory of granular flows, where the particle velocity distribution function is defined in a manner similar to the molecular distribution function in the kinetic theory of gases (Lun et al. Reference Lun, Savage, Jeffrey and Chepurniy1984; Jenkins & Richman Reference Jenkins and Richman1985; Kumaran Reference Kumaran1998). The mass, momentum and energy conservation equations are derived from the Boltzmann equation for the velocity distribution function. The energy conservation equation for the granular temperature contains an additional dissipation term due to particle interactions which is not present for a molecular fluid. In kinetic theory, it is also assumed that the system is dilute, and correlations between colliding particles are neglected due to the ‘molecular chaos’ assumption. Constitutive relations for dense granular flows have been derived using the Enskog procedure (Sela, Goldhirsch & Noskowicz Reference Sela, Goldhirsch and Noskowicz1996; Sela & Goldhirsch Reference Sela and Goldhirsch1998; Kumaran Reference Kumaran2004, Reference Kumaran2006), and attempts have been made to go beyond the molecular chaos assumption and incorporate correlations in the pre-collisional velocities of the particles (Goldhirsch & van Noije Reference Goldhirsch and van Noije2000; Kumaran Reference Kumaran2009a,Reference Kumaranb). With these refinements, it has been shown that the salient features of a dense granular flow in an inclined channel are captured adequately by models based on the hard-particle approximation (Kumaran Reference Kumaran2008, Reference Kumaran2014).

For an inclined plane flow, as the inclination angle is decreased, the maximum volume fraction in the flowing state is about 0.585–0.59, which is denoted the volume fraction for arrested dynamics, ![]() $\phi _{ad}$. The physical meaning of

$\phi _{ad}$. The physical meaning of ![]() $\phi _{ad}$ is that an assembly of perfectly hard spheres (in which the repulsive force is zero when two particles are not in contact, and infinite when they are in contact) cannot be sheared if the volume fraction

$\phi _{ad}$ is that an assembly of perfectly hard spheres (in which the repulsive force is zero when two particles are not in contact, and infinite when they are in contact) cannot be sheared if the volume fraction ![]() $\phi$ exceeds

$\phi$ exceeds ![]() $\phi _{ad}$. For

$\phi _{ad}$. For ![]() $\phi \geq \phi _{ad}$, shearing is possible only if the particles have finite stiffness. For

$\phi \geq \phi _{ad}$, shearing is possible only if the particles have finite stiffness. For ![]() $\phi < \phi _{ad}$, the Bagnold law based on the hard-particle model appears to apply even for dense granular flows. Kinetic models have been modified by incorporating a mesoscopic length scale representing particle chains to predict

$\phi < \phi _{ad}$, the Bagnold law based on the hard-particle model appears to apply even for dense granular flows. Kinetic models have been modified by incorporating a mesoscopic length scale representing particle chains to predict ![]() $\phi _{ad}$ in a sheared dense granular flow (Jenkins Reference Jenkins2006, Reference Jenkins2007; Berzi & Jenkins Reference Berzi and Jenkins2015).

$\phi _{ad}$ in a sheared dense granular flow (Jenkins Reference Jenkins2006, Reference Jenkins2007; Berzi & Jenkins Reference Berzi and Jenkins2015).

The change in the rheology at ![]() $\phi = \phi _{ad}$ is consistent with the simulation studies of Kumaran (Reference Kumaran2009c,Reference Kumarand). These showed that

$\phi = \phi _{ad}$ is consistent with the simulation studies of Kumaran (Reference Kumaran2009c,Reference Kumarand). These showed that ![]() $\phi _{ad}$ for a dense sheared inelastic hard-particle fluid is a function of the coefficients of restitution (

$\phi _{ad}$ for a dense sheared inelastic hard-particle fluid is a function of the coefficients of restitution (![]() $e_n,e_t$) in the directions perpendicular and parallel to the surfaces at contact. The value of

$e_n,e_t$) in the directions perpendicular and parallel to the surfaces at contact. The value of ![]() $\phi _{ad}$ is in the range 0.585–0.59 for smooth (

$\phi _{ad}$ is in the range 0.585–0.59 for smooth (![]() $e_t = -1$) inelastic particles with

$e_t = -1$) inelastic particles with ![]() $e_n$ less than 0.6, and 0.581–0.612 for perfectly rough (

$e_n$ less than 0.6, and 0.581–0.612 for perfectly rough (![]() $e_t = 1$) inelastic particles with

$e_t = 1$) inelastic particles with ![]() $e_n \geq 0.6$. It is significantly lower than the random close packing volume fraction

$e_n \geq 0.6$. It is significantly lower than the random close packing volume fraction ![]() $\phi _{rcp} = 0.64$ for an elastic hard-sphere fluid in the absence of shear. In contrast, the volume fraction

$\phi _{rcp} = 0.64$ for an elastic hard-sphere fluid in the absence of shear. In contrast, the volume fraction ![]() $\phi$ in the plug zone could be significantly higher than

$\phi$ in the plug zone could be significantly higher than ![]() $\phi _{ad}$ in the vertical channel. This raises the question of whether the nature of the flow in a vertical channel is qualitatively different from the flow down an inclined plane, or whether

$\phi _{ad}$ in the vertical channel. This raises the question of whether the nature of the flow in a vertical channel is qualitatively different from the flow down an inclined plane, or whether ![]() $\phi$ in the shearing zones is below

$\phi$ in the shearing zones is below ![]() $\phi _{ad}$ and the hard-particle model can be applied.

$\phi _{ad}$ and the hard-particle model can be applied.

Berzi, Jenkins & Richard (Reference Berzi, Jenkins and Richard2019, Reference Berzi, Jenkins and Richard2020) have separated the flow through an inclined chute with bumpy base and frictional side walls into two regimes: (i) a dense erodible layer near the bumpy base where ![]() $\phi \geq \phi _{c}$, a critical volume fraction; and (ii) a loose collisional layer above the erodible zone where

$\phi \geq \phi _{c}$, a critical volume fraction; and (ii) a loose collisional layer above the erodible zone where ![]() $\phi < \phi _c$. The concept of

$\phi < \phi _c$. The concept of ![]() $\phi _c$ can be linked to

$\phi _c$ can be linked to ![]() $\phi _{ad}$, which will be discussed shortly. The material in the erodible layer moves very slowly with negligible particle fluctuations compared to that in the collisional layer. The stress and dissipation rate in the collisional flow are adapted from the kinetic theory of granular flows with coefficients modified to incorporate the finite duration of contacts (Berzi & Jenkins Reference Berzi and Jenkins2015). In the erodible region, the rate-independent stresses arise because of sustained contacts, hence a rate-independent component is added to the pressure (Berzi et al. Reference Berzi, Jenkins and Richard2020). The form of the rate-independent term in pressure is motivated from the plane shear studies done by Chialvo, Sun & Sundaresan (Reference Chialvo, Sun and Sundaresan2012). The latter have shown that the rate-independent effects are dominant for

$\phi _{ad}$, which will be discussed shortly. The material in the erodible layer moves very slowly with negligible particle fluctuations compared to that in the collisional layer. The stress and dissipation rate in the collisional flow are adapted from the kinetic theory of granular flows with coefficients modified to incorporate the finite duration of contacts (Berzi & Jenkins Reference Berzi and Jenkins2015). In the erodible region, the rate-independent stresses arise because of sustained contacts, hence a rate-independent component is added to the pressure (Berzi et al. Reference Berzi, Jenkins and Richard2020). The form of the rate-independent term in pressure is motivated from the plane shear studies done by Chialvo, Sun & Sundaresan (Reference Chialvo, Sun and Sundaresan2012). The latter have shown that the rate-independent effects are dominant for ![]() $\phi \geq \phi _c$ in the limit of vanishing shear rate, and

$\phi \geq \phi _c$ in the limit of vanishing shear rate, and ![]() $\phi _c$ does not depend on

$\phi _c$ does not depend on ![]() $e_n$. It varies with the coefficient of interparticle friction

$e_n$. It varies with the coefficient of interparticle friction ![]() $\mu _p$; for example,

$\mu _p$; for example, ![]() $\phi _c = 0.587$ for

$\phi _c = 0.587$ for ![]() $\mu _p = 0.5$, which Berzi et al. (Reference Berzi, Jenkins and Richard2019, Reference Berzi, Jenkins and Richard2020) have adopted to mark the boundary between the erodible and collisional layers.

$\mu _p = 0.5$, which Berzi et al. (Reference Berzi, Jenkins and Richard2019, Reference Berzi, Jenkins and Richard2020) have adopted to mark the boundary between the erodible and collisional layers.

It is interesting to note that the range of ![]() $\phi _c$ for

$\phi _c$ for ![]() $\mu _p$ varying between

$\mu _p$ varying between ![]() $0$ and

$0$ and ![]() $1$ in the plane shear simulations of soft particles having finite stiffness (Chialvo et al. Reference Chialvo, Sun and Sundaresan2012; Berzi & Vescovi Reference Berzi and Vescovi2015) is similar approximately to

$1$ in the plane shear simulations of soft particles having finite stiffness (Chialvo et al. Reference Chialvo, Sun and Sundaresan2012; Berzi & Vescovi Reference Berzi and Vescovi2015) is similar approximately to ![]() $\phi _{ad}$ in plane shear simulations of hard inelastic rough particles having infinite stiffness (Kumaran Reference Kumaran2009c, Reference Kumarand). Chialvo et al. (Reference Chialvo, Sun and Sundaresan2012) state that

$\phi _{ad}$ in plane shear simulations of hard inelastic rough particles having infinite stiffness (Kumaran Reference Kumaran2009c, Reference Kumarand). Chialvo et al. (Reference Chialvo, Sun and Sundaresan2012) state that ![]() $\phi _c$ is similar to

$\phi _c$ is similar to ![]() $\phi _{ad}$, and this volume fraction is an important parameter to explain arrested dynamics or jamming. In the vertical channel flow, we examine whether the distinction into different zones – collisional flow and erodible bed – in an inclined plane flow is similar to that between the plug and shear layers for a vertical channel flow. The volume fraction for arrested dynamics is considered to be

$\phi _{ad}$, and this volume fraction is an important parameter to explain arrested dynamics or jamming. In the vertical channel flow, we examine whether the distinction into different zones – collisional flow and erodible bed – in an inclined plane flow is similar to that between the plug and shear layers for a vertical channel flow. The volume fraction for arrested dynamics is considered to be ![]() $\phi _{ad} = 0.587$ in the channel flow for definiteness, as we performed soft-sphere DEM simulations with

$\phi _{ad} = 0.587$ in the channel flow for definiteness, as we performed soft-sphere DEM simulations with ![]() $\mu _p = 0.5$.

$\mu _p = 0.5$.

In the vertical channel flow, the simulations are carried out to examine the flow mechanics at the particle scale, to examine which of the different approximations apply in a vertical channel flow. An important issue is whether there are multiple zones with distinct flow regimes, the nature of the rheology in these zones, and whether properties like the volume fraction and the shear rate vary continuously across these zones. Of interest is whether the relation between the friction coefficient and the shear rate varies in different zones, and the nature of the variation. Also of interest is the effect of particle stiffness on rheology in different zones. Another relevant quantity in the kinetic-theory-based models is the granular temperature, which is the mean square of the fluctuating velocity of the particles. We examine whether the variation of the granular temperature is continuous across the channel, and whether the temperature is non-zero in the plug zone. The nature of the velocity profile in the shearing zone is also examined here, to determine the universality and scaling with respect to the channel width. The relation between the slip velocity and the shear rate at the wall, and their variation with channel width, is also determined.

The simulation methodology is summarized briefly in Appendix A, and the flow configuration and preparation protocols are discussed in § 2. Appendix B summarizes the theoretical formulations that are compared with simulations in § 3. The important conclusions are summarized in § 4.

2. Flow configuration

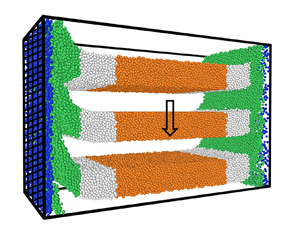

Studies are carried out on the flow through a vertical channel of rectangular cross-section with dimensions ![]() $H \times W \times B$, as shown in figure 1. The channel is bounded by two flat frictional vertical walls in the

$H \times W \times B$, as shown in figure 1. The channel is bounded by two flat frictional vertical walls in the ![]() $x$ direction at

$x$ direction at ![]() $x = 0$ and

$x = 0$ and ![]() $x = W$, and gravitational acceleration acts in the vertical

$x = W$, and gravitational acceleration acts in the vertical ![]() $y$ direction. Periodic boundary conditions are applied in the vertical

$y$ direction. Periodic boundary conditions are applied in the vertical ![]() $y$ direction and in the

$y$ direction and in the ![]() $z$ direction in the horizontal plane. Attention is confined to steady fully developed flows that are symmetric about the central plane at

$z$ direction in the horizontal plane. Attention is confined to steady fully developed flows that are symmetric about the central plane at ![]() $x = W/2$, therefore results are shown only for

$x = W/2$, therefore results are shown only for ![]() $0 \leq x \leq W/2$. The width of the channel is varied in the range

$0 \leq x \leq W/2$. The width of the channel is varied in the range ![]() $60 \, d_p \leq W \leq 150 \, d_p$, and the other two dimensions are

$60 \, d_p \leq W \leq 150 \, d_p$, and the other two dimensions are ![]() $B = 40 \, d_p$ and

$B = 40 \, d_p$ and ![]() $H = 60 \, d_p + \Delta H$, where

$H = 60 \, d_p + \Delta H$, where ![]() $d_p$ is the nominal particle diameter, and the choice of

$d_p$ is the nominal particle diameter, and the choice of ![]() $\Delta H$ is discussed shortly. The total number of particles is

$\Delta H$ is discussed shortly. The total number of particles is ![]() $1.7 \times 10^5$ for a system of width

$1.7 \times 10^5$ for a system of width ![]() $60 \, d_p$, and

$60 \, d_p$, and ![]() $4.1 \times 10^5$ for a system of width

$4.1 \times 10^5$ for a system of width ![]() $150 \, d_p$. A polydisperse mixture of particles is used, where 30 % of the particles have diameter

$150 \, d_p$. A polydisperse mixture of particles is used, where 30 % of the particles have diameter ![]() $0.9 \, d_p$, 40 % have diameter

$0.9 \, d_p$, 40 % have diameter ![]() $d_p$, and 30 % have diameter

$d_p$, and 30 % have diameter ![]() $1.1 \, d_p$.

$1.1 \, d_p$.

Figure 1. The configuration and coordinate system for analysing the flow in a vertical channel bounded by two flat frictional walls. The hatched surfaces are the flat frictional walls in the ![]() $x$ direction, and periodic boundary conditions are applied in the other two directions.

$x$ direction, and periodic boundary conditions are applied in the other two directions.

The preparation protocol is shown in figure 2. Initially, a flat surface is placed at the bottom of the channel. The channel is filled by raining the particles uniformly under the effect of gravity up to a height ![]() $H - \Delta H$. After the particles settle, the bottom is removed and the periodic boundary conditions are imposed in the vertical

$H - \Delta H$. After the particles settle, the bottom is removed and the periodic boundary conditions are imposed in the vertical ![]() $y$ and spanwise

$y$ and spanwise ![]() $z$ directions. Here, the value of

$z$ directions. Here, the value of ![]() $\Delta H$ is chosen such that a desired value of the average volume fraction

$\Delta H$ is chosen such that a desired value of the average volume fraction ![]() $\bar {\phi }$, the ratio of the total volume of the particles to the volume of the channel, can be obtained. For

$\bar {\phi }$, the ratio of the total volume of the particles to the volume of the channel, can be obtained. For ![]() $W = 60\unicode{x2013}150 \,d_p$, a final steady state is achieved for

$W = 60\unicode{x2013}150 \,d_p$, a final steady state is achieved for ![]() $\bar {\phi }$ in the range

$\bar {\phi }$ in the range ![]() $\bar {\phi }_{cr}$ to

$\bar {\phi }_{cr}$ to ![]() $\bar {\phi }_{max}$. When

$\bar {\phi }_{max}$. When ![]() $\bar {\phi }$ is greater than

$\bar {\phi }$ is greater than ![]() $\bar {\phi }_{max} = 0.62$, the channel jams and there is no flow. When

$\bar {\phi }_{max} = 0.62$, the channel jams and there is no flow. When ![]() $\bar {\phi }$ is decreased below

$\bar {\phi }$ is decreased below ![]() $\bar {\phi }_{cr}$, there is an oscillatory and then an accelerating flow (Debnath, Kumaran & Rao Reference Debnath, Kumaran and Rao2019). The value of

$\bar {\phi }_{cr}$, there is an oscillatory and then an accelerating flow (Debnath, Kumaran & Rao Reference Debnath, Kumaran and Rao2019). The value of ![]() $\bar {\phi }_{cr}$ is found to be 0.59 for

$\bar {\phi }_{cr}$ is found to be 0.59 for ![]() $W = 100\unicode{x2013}150 \,d_p$. The present study is restricted to the steady fully developed flows.

$W = 100\unicode{x2013}150 \,d_p$. The present study is restricted to the steady fully developed flows.

Figure 2. Preparation protocol for the channel flow. An impenetrable surface is placed at the bottom (a), and particles are filled in up to a height ![]() $(H - \Delta H)$. The bottom is removed (b), periodic boundary conditions are applied in the

$(H - \Delta H)$. The bottom is removed (b), periodic boundary conditions are applied in the ![]() $y$ and

$y$ and ![]() $z$ directions, and the flow is evolved to reach steady state.

$z$ directions, and the flow is evolved to reach steady state.

Raafat, Hulin & Herrmann (Reference Raafat, Hulin and Herrmann1996) studied the flow of sand grains in a capillary tube, where the ratio of the particle size to the tube diameter was relatively small, in the range 6–30. The average volume fraction ![]() $\bar {\phi }$ was in between the dilute regime where there is a free fall of grains, and the dense slow flow regime. At these intermediate average volume fractions, density waves are observed in the channel, in the form of bubbles and clogs. For the relative small size of the tube used, finite-size effects are likely to be important. This is different from the present analysis, where the size ratio is in the range 60–150, and

$\bar {\phi }$ was in between the dilute regime where there is a free fall of grains, and the dense slow flow regime. At these intermediate average volume fractions, density waves are observed in the channel, in the form of bubbles and clogs. For the relative small size of the tube used, finite-size effects are likely to be important. This is different from the present analysis, where the size ratio is in the range 60–150, and ![]() $\bar {\phi }$ is in the dense flow regime. Due to this, density waves are not observed here.

$\bar {\phi }$ is in the dense flow regime. Due to this, density waves are not observed here.

The time required for the flow to attain a steady fully developed state is ![]() $2 \times 10^3 \sqrt {d_p/g}$, and the averaging time for calculating the properties is

$2 \times 10^3 \sqrt {d_p/g}$, and the averaging time for calculating the properties is ![]() $6 \times 10^2 \sqrt {d_p/g}$. To calculate the variation of the properties in the cross-stream

$6 \times 10^2 \sqrt {d_p/g}$. To calculate the variation of the properties in the cross-stream ![]() $x$ direction, the channel is divided into bins of width

$x$ direction, the channel is divided into bins of width ![]() $d_p$, except for the bin near the wall, which is set to

$d_p$, except for the bin near the wall, which is set to ![]() $1.5 \, d_p$. The velocity, angular velocity and granular temperature fields are calculated as

$1.5 \, d_p$. The velocity, angular velocity and granular temperature fields are calculated as

$$\begin{gather} \boldsymbol{v} =

\frac{\sum_{i=1}^N m_i

\boldsymbol{v}_i}{\sum_{i=1}^N m_i},

\end{gather}$$

$$\begin{gather} \boldsymbol{v} =

\frac{\sum_{i=1}^N m_i

\boldsymbol{v}_i}{\sum_{i=1}^N m_i},

\end{gather}$$

$$\begin{gather}\boldsymbol{\varOmega} =

\frac{\sum_{i=1}^N I_i

\boldsymbol{\varOmega}_i}{\sum_{i=1}^N

I_i}, \end{gather}$$

$$\begin{gather}\boldsymbol{\varOmega} =

\frac{\sum_{i=1}^N I_i

\boldsymbol{\varOmega}_i}{\sum_{i=1}^N

I_i}, \end{gather}$$

$$\begin{gather}T = \frac{1}{6N} \sum_{i=1}^N \left(m_i (\boldsymbol{v}_i-\boldsymbol{v})^2 + I_i (\boldsymbol{\varOmega}_i - \boldsymbol{\varOmega})^2\right), \end{gather}$$

$$\begin{gather}T = \frac{1}{6N} \sum_{i=1}^N \left(m_i (\boldsymbol{v}_i-\boldsymbol{v})^2 + I_i (\boldsymbol{\varOmega}_i - \boldsymbol{\varOmega})^2\right), \end{gather}$$

where N is the number of particles whose centres lie in the bin, ![]() $m_i$ and

$m_i$ and ![]() $I_i = \frac {1}{10} m_i d_i^2$ are the mass and moment of inertia of particle

$I_i = \frac {1}{10} m_i d_i^2$ are the mass and moment of inertia of particle ![]() $i$, and

$i$, and ![]() $\boldsymbol {v}_i$ and

$\boldsymbol {v}_i$ and ![]() $\boldsymbol {\varOmega }_i$ are the linear and angular velocities of that particle. The stress tensor

$\boldsymbol {\varOmega }_i$ are the linear and angular velocities of that particle. The stress tensor ![]() $\boldsymbol {\sigma }$ is

$\boldsymbol {\sigma }$ is

\begin{equation} \boldsymbol{\sigma} = \frac{1}{V} \sum_{i=1}^N \left[ \left( \sum_{j \neq i}^{n_{contacts}} \frac{\boldsymbol{F}_{ij} \,\boldsymbol{x}_{ij}}{2} \right) + m_i (\boldsymbol{v}_i - \boldsymbol{v}) (\boldsymbol{v}_i - \boldsymbol{v}) \right]. \end{equation}

\begin{equation} \boldsymbol{\sigma} = \frac{1}{V} \sum_{i=1}^N \left[ \left( \sum_{j \neq i}^{n_{contacts}} \frac{\boldsymbol{F}_{ij} \,\boldsymbol{x}_{ij}}{2} \right) + m_i (\boldsymbol{v}_i - \boldsymbol{v}) (\boldsymbol{v}_i - \boldsymbol{v}) \right]. \end{equation}

Here, ![]() $V$ is the volume of the bin, and the summation

$V$ is the volume of the bin, and the summation ![]() $j$ is carried out over all contacts of particle

$j$ is carried out over all contacts of particle ![]() $i$. The first term in (2.4) is the contribution to the stress due to interparticle interactions, and the second term is the kinetic contribution due to the particle fluctuating velocities. The rate of dissipation of energy per unit volume

$i$. The first term in (2.4) is the contribution to the stress due to interparticle interactions, and the second term is the kinetic contribution due to the particle fluctuating velocities. The rate of dissipation of energy per unit volume ![]() $D$ is calculated as

$D$ is calculated as

\begin{equation} D = \frac{1}{V \tau} \sum_{i=1}^N \sum_{j \neq i}^{n_{contacts}} \int_0^\tau(\boldsymbol{F}_{ij} \boldsymbol{\cdot} \boldsymbol{v}_{ij}) \,{\rm d}t, \end{equation}

\begin{equation} D = \frac{1}{V \tau} \sum_{i=1}^N \sum_{j \neq i}^{n_{contacts}} \int_0^\tau(\boldsymbol{F}_{ij} \boldsymbol{\cdot} \boldsymbol{v}_{ij}) \,{\rm d}t, \end{equation}

where ![]() $\tau$ is the period of the simulation. The rate of dissipation of energy is also a local quantity, evaluated for all the particles with centres within a bin.

$\tau$ is the period of the simulation. The rate of dissipation of energy is also a local quantity, evaluated for all the particles with centres within a bin.

The DEM and the simulation parameters are described in Appendix A. In the results, the particle density is considered to be ![]() $1$, so that the mass dimensions in all quantities are scaled appropriately.

$1$, so that the mass dimensions in all quantities are scaled appropriately.

3. Results

3.1. Velocity and stress profiles

There is a steady flow for a small range of the average volume fraction ![]() $\bar {\phi } = 0.59\unicode{x2013} 0.61$. The average velocity fluctuates in time for

$\bar {\phi } = 0.59\unicode{x2013} 0.61$. The average velocity fluctuates in time for ![]() $\bar {\phi } = 0.62$, and there is no flow when

$\bar {\phi } = 0.62$, and there is no flow when ![]() $\bar {\phi }$ exceeds

$\bar {\phi }$ exceeds ![]() $0.62$. The typical time series for the velocity of the centre of mass

$0.62$. The typical time series for the velocity of the centre of mass ![]() $u_{cm}$, scaled by its time-averaged value

$u_{cm}$, scaled by its time-averaged value ![]() $\bar {u}_{cm}$, is shown in figure 3. It is observed that there are fluctuations of 1–2 % for

$\bar {u}_{cm}$, is shown in figure 3. It is observed that there are fluctuations of 1–2 % for ![]() $\bar {\phi } = 0.62$. In contrast, for

$\bar {\phi } = 0.62$. In contrast, for ![]() $0.59 \leq \bar {\phi } \leq 0.61$, the variation in the velocity of the centre of mass is less than 1 %, indicating that there is uniform steady flow.

$0.59 \leq \bar {\phi } \leq 0.61$, the variation in the velocity of the centre of mass is less than 1 %, indicating that there is uniform steady flow.

Figure 3. A typical time series of the centre of mass velocity ![]() $u_{cm}$ divided by its time-averaged value

$u_{cm}$ divided by its time-averaged value ![]() $\bar {u}_{cm}$ for a channel of width 100 particle diameters and for average volume fraction

$\bar {u}_{cm}$ for a channel of width 100 particle diameters and for average volume fraction ![]() $\bar {\phi } = 0.62$ (

$\bar {\phi } = 0.62$ (![]() $\circ$),

$\circ$), ![]() $\bar {\phi } = 0.61$ (

$\bar {\phi } = 0.61$ (![]() $\triangle$),

$\triangle$), ![]() $\bar {\phi } = 0.6$ (

$\bar {\phi } = 0.6$ (![]() $\nabla$) and

$\nabla$) and ![]() $\bar {\phi } = 0.59$ (

$\bar {\phi } = 0.59$ (![]() $\diamond$).

$\diamond$).

The velocity profiles, shown as functions of cross-stream distance in figure 4(a), exhibit a plug-like behaviour in the central region, a shear zone close to the wall and significant slip at the wall. Both the slip velocity ![]() $u_{slip}$ and the maximum velocity

$u_{slip}$ and the maximum velocity ![]() $u_{max}$ increase as

$u_{max}$ increase as ![]() $\bar {\phi }$ decreases, and as the channel width

$\bar {\phi }$ decreases, and as the channel width ![]() $W$ increases. Both

$W$ increases. Both ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ increase by a factor of

$u_{max}$ increase by a factor of ![]() $5$ or more when

$5$ or more when ![]() $\bar {\phi }$ is decreased from

$\bar {\phi }$ is decreased from ![]() $0.62$ to

$0.62$ to ![]() $0.59$. There is also a significant increase in

$0.59$. There is also a significant increase in ![]() $u_{max}$ and

$u_{max}$ and ![]() $u_{slip}$, by a factor of

$u_{slip}$, by a factor of ![]() $3$ when

$3$ when ![]() $W$ is increased from

$W$ is increased from ![]() $60 \, d_p$ to

$60 \, d_p$ to ![]() $150 \, d_p$. From figure 4, it is also evident that the length scale for the shearing region at the wall is also a function of

$150 \, d_p$. From figure 4, it is also evident that the length scale for the shearing region at the wall is also a function of ![]() $\bar {\phi }$ and

$\bar {\phi }$ and ![]() $W$.

$W$.

Figure 4. The velocity ![]() $u_y$ as a function of

$u_y$ as a function of ![]() $x/d_p$ (a) and the scaled velocity

$x/d_p$ (a) and the scaled velocity ![]() $(u_y - u_{slip})/(u_{max}-u_{slip})$ as a function of

$(u_y - u_{slip})/(u_{max}-u_{slip})$ as a function of ![]() $x/\delta _{0.95}$. Here,

$x/\delta _{0.95}$. Here, ![]() $u_{slip}$ is the slip velocity at the wall,

$u_{slip}$ is the slip velocity at the wall, ![]() $u_{max}$ is the maximum velocity at the centre and

$u_{max}$ is the maximum velocity at the centre and ![]() $\delta _{0.95}$ is the distance at which

$\delta _{0.95}$ is the distance at which ![]() $(u_y - u_{slip})/(u_{max}-u_{slip}) = 0.95$. The average volume fractions are

$(u_y - u_{slip})/(u_{max}-u_{slip}) = 0.95$. The average volume fractions are ![]() $\bar {\phi } = 0.62$ (

$\bar {\phi } = 0.62$ (![]() $\circ$),

$\circ$), ![]() $\bar {\phi } = 0.61$ (

$\bar {\phi } = 0.61$ (![]() $\triangle$),

$\triangle$), ![]() $\bar {\phi } = 0.6$ (

$\bar {\phi } = 0.6$ (![]() $\nabla$) and

$\nabla$) and ![]() $\bar {\phi } = 0.59$ (

$\bar {\phi } = 0.59$ (![]() $\diamond$). The profiles are shown in black for

$\diamond$). The profiles are shown in black for ![]() $W = 60 \, d_p$, blue for

$W = 60 \, d_p$, blue for ![]() $W = 100 \, d_p$, green for

$W = 100 \, d_p$, green for ![]() $W = 120 \, d_p$ and brown for

$W = 120 \, d_p$ and brown for ![]() $W = 150 \, d_p$. The red dashed line in (b) is the exponential fit equation (3.1).

$W = 150 \, d_p$. The red dashed line in (b) is the exponential fit equation (3.1).

In figure 4(b), the scaled velocity is defined as ![]() $(u_y - u_{slip})/(u_{max} - u_{slip})$. This is plotted as a function of the scaled distance from the wall,

$(u_y - u_{slip})/(u_{max} - u_{slip})$. This is plotted as a function of the scaled distance from the wall, ![]() $x/\delta _{0.95}$, where

$x/\delta _{0.95}$, where ![]() $\delta _{0.95}$ is the distance at which

$\delta _{0.95}$ is the distance at which ![]() $(u_y - u_{slip})/(u_{max}-u_{slip}) = 0.95$. Plotted in these scaled coordinates, the scaled velocity follows a universal profile that is independent of

$(u_y - u_{slip})/(u_{max}-u_{slip}) = 0.95$. Plotted in these scaled coordinates, the scaled velocity follows a universal profile that is independent of ![]() $\bar {\phi }$ and

$\bar {\phi }$ and ![]() $W$. Thus the scaled velocity profile has a universal form, though

$W$. Thus the scaled velocity profile has a universal form, though ![]() $u_{slip}$,

$u_{slip}$, ![]() $u_{max}$ and

$u_{max}$ and ![]() $\delta _{0.95}$ vary significantly with

$\delta _{0.95}$ vary significantly with ![]() $\bar {\phi }$ and

$\bar {\phi }$ and ![]() $W$. The red dashed line in figure 4(b) is the fit

$W$. The red dashed line in figure 4(b) is the fit

This exponential function provides an excellent fit for the scaled velocity profile for the entire range of ![]() $\bar {\phi }$ and

$\bar {\phi }$ and ![]() $W$ examined here. The average velocity

$W$ examined here. The average velocity ![]() $\bar {u}$ is then expressed in terms of

$\bar {u}$ is then expressed in terms of ![]() $u_{max}$,

$u_{max}$, ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $\delta _{0.95}$ as

$\delta _{0.95}$ as

There are some granular flows for which the scaled velocity profiles are self-similar, such as the Bagnold profile for the flow down an inclined plane, or the error function profiles in shearing zones in split-bottom geometries (Fenistein & van Hecke Reference Fenistein and van Hecke2003). A self-similar velocity profile has not been established in previous studies for the granular flow in a vertical channel, though Pouliquen & Gutfraind (Reference Pouliquen and Gutfraind1996) fitted an exponential profile for the velocity in the shearing zone. The exponential scaling in the latter resulted from the assumption that the momentum transport is an activated process, where the probability of yielding depends on the difference between the stress and a yield stress. The shear stress and the velocity are then given by an exponential function.

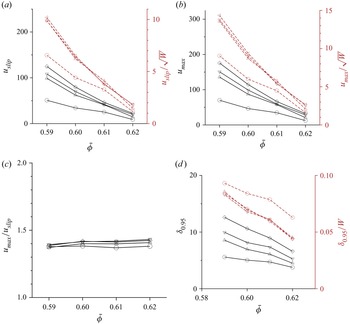

In figures 5(a) and 5(b), ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ are shown as functions of

$u_{max}$ are shown as functions of ![]() $\bar {\phi }$ for different values of

$\bar {\phi }$ for different values of ![]() $W$. Both

$W$. Both ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ decrease by about one order of magnitude when

$u_{max}$ decrease by about one order of magnitude when ![]() $\bar {\phi }$ is increased from

$\bar {\phi }$ is increased from ![]() $0.59$ to

$0.59$ to ![]() $0.62$. In these figures,

$0.62$. In these figures, ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ scaled by

$u_{max}$ scaled by ![]() $\sqrt {W}$ are shown by the brown lines referenced to the right ordinate. It is observed that there is an excellent collapse of the data for

$\sqrt {W}$ are shown by the brown lines referenced to the right ordinate. It is observed that there is an excellent collapse of the data for ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ when scaled by

$u_{max}$ when scaled by ![]() $\sqrt {W}$ for

$\sqrt {W}$ for ![]() $W \geq 100 \, d_p$, though the collapse is not as good for

$W \geq 100 \, d_p$, though the collapse is not as good for ![]() $W = 60 \, d_p$. This is expected if the Froude number for

$W = 60 \, d_p$. This is expected if the Froude number for ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}$ based on

$u_{max}$ based on ![]() $W$ is a constant. The ratio

$W$ is a constant. The ratio ![]() $u_{max}/u_{slip}$ is shown in figure 5(c). It is remarkable that this ratio is nearly a constant, varying by about 2 % in a very small range 1.37–1.40 for all values of

$u_{max}/u_{slip}$ is shown in figure 5(c). It is remarkable that this ratio is nearly a constant, varying by about 2 % in a very small range 1.37–1.40 for all values of ![]() $W$ and

$W$ and ![]() $\bar {\phi }$.

$\bar {\phi }$.

Figure 5. Plotted as a function of ![]() $\bar {\phi }$: (a)

$\bar {\phi }$: (a) ![]() $u_{slip}$ (black lines referenced to left ordinate) and

$u_{slip}$ (black lines referenced to left ordinate) and ![]() $(u_{slip}/\sqrt {W})$ (brown lines referenced to right ordinate); (b)

$(u_{slip}/\sqrt {W})$ (brown lines referenced to right ordinate); (b) ![]() $u_{max}$ (black lines referenced to left ordinate) and

$u_{max}$ (black lines referenced to left ordinate) and ![]() $(u_{max}/\sqrt {W})$ (brown lines referenced to right ordinate); (c) the ratio of

$(u_{max}/\sqrt {W})$ (brown lines referenced to right ordinate); (c) the ratio of ![]() $u_{max}$ and

$u_{max}$ and ![]() $u_{slip}$; and (d) the shear layer thickness

$u_{slip}$; and (d) the shear layer thickness ![]() $\delta _{0.95}$ (black lines referenced to left ordinate ) and

$\delta _{0.95}$ (black lines referenced to left ordinate ) and ![]() $\delta _{0.95}/W$ (brown lines referenced to right ordinate). The channel widths are

$\delta _{0.95}/W$ (brown lines referenced to right ordinate). The channel widths are ![]() $60 \,d_p$ (

$60 \,d_p$ (![]() $\circ$),

$\circ$), ![]() $100 \,d_p$ (

$100 \,d_p$ (![]() $\triangle$),

$\triangle$), ![]() $120 \,d_p$ (

$120 \,d_p$ (![]() $\nabla$) and

$\nabla$) and ![]() $150\, d_p$ (

$150\, d_p$ (![]() $\diamond$).

$\diamond$).

The thickness of the shear zone ![]() $\delta _{0.95}$ is shown as a function of

$\delta _{0.95}$ is shown as a function of ![]() $\bar {\phi }$ in figure 5(d). This thickness decreases as

$\bar {\phi }$ in figure 5(d). This thickness decreases as ![]() $\bar {\phi }$ increases and as

$\bar {\phi }$ increases and as ![]() $W$ decreases, indicating that

$W$ decreases, indicating that ![]() $\delta _{0.95}$ is dependent on

$\delta _{0.95}$ is dependent on ![]() $\bar {\phi }$ and

$\bar {\phi }$ and ![]() $W$. Shown in brown lines in figure 5(d), referenced to the right ordinate, is the ratio

$W$. Shown in brown lines in figure 5(d), referenced to the right ordinate, is the ratio ![]() $\delta _{0.95}/W$. This ratio is independent of the channel width for

$\delta _{0.95}/W$. This ratio is independent of the channel width for ![]() $W \geq 100\,d_p$, but not for

$W \geq 100\,d_p$, but not for ![]() $W = 60\,d_p$. This indicates that

$W = 60\,d_p$. This indicates that ![]() $\delta _{0.95}$ increases approximately proportional to

$\delta _{0.95}$ increases approximately proportional to ![]() $W$ for the flow in the vertical channel. A consequence of these scaling relations is that the average flow velocity in (3.2) is proportional to

$W$ for the flow in the vertical channel. A consequence of these scaling relations is that the average flow velocity in (3.2) is proportional to ![]() $\sqrt {W}$, provided that

$\sqrt {W}$, provided that ![]() $W$ is greater than about

$W$ is greater than about ![]() $100 \, d_p$. Thus the Froude numbers based on the average velocity, maximum velocity and slip velocity are independent of the channel width, and they depend only on the average volume fraction. This scaling law for the velocity is similar to the Beverloo correlation (Beverloo et al. Reference Beverloo, Leniger and Van de Velde1961), which postulates that the average velocity through an orifice of width

$100 \, d_p$. Thus the Froude numbers based on the average velocity, maximum velocity and slip velocity are independent of the channel width, and they depend only on the average volume fraction. This scaling law for the velocity is similar to the Beverloo correlation (Beverloo et al. Reference Beverloo, Leniger and Van de Velde1961), which postulates that the average velocity through an orifice of width ![]() $D$ is independent of

$D$ is independent of ![]() $d_p$ for

$d_p$ for ![]() $d_p \ll D$. From dimensional analysis, the flow velocity has to be scaled by

$d_p \ll D$. From dimensional analysis, the flow velocity has to be scaled by ![]() $\sqrt {gD}$.

$\sqrt {gD}$.

Cawthorn (Reference Cawthorn2011) has obtained an analytical solution of an incompressible ![]() $\mu (I)$ model for the vertical channel flow. The assumptions used are linear variation of

$\mu (I)$ model for the vertical channel flow. The assumptions used are linear variation of ![]() $\mu$ with

$\mu$ with ![]() $I$, no variation in

$I$, no variation in ![]() $\phi$, and a no-slip boundary condition at the rough walls. This solution predicts that the velocity in the plug is proportional to

$\phi$, and a no-slip boundary condition at the rough walls. This solution predicts that the velocity in the plug is proportional to ![]() $W^{3/2}$, and the scaled thickness of the shear layer

$W^{3/2}$, and the scaled thickness of the shear layer ![]() $\delta _{0.95}/W$ is a constant for high flow rate. In contrast, Mohan et al. (Reference Mohan, Nott and Rao1999) have used an asymptotic analysis for purely rough walls, and their Cosserat model predicts that the shearing zone thickness is proportional to

$\delta _{0.95}/W$ is a constant for high flow rate. In contrast, Mohan et al. (Reference Mohan, Nott and Rao1999) have used an asymptotic analysis for purely rough walls, and their Cosserat model predicts that the shearing zone thickness is proportional to ![]() $W^{1/3}$ in the limit

$W^{1/3}$ in the limit ![]() $d_p \ll W$. Recently, Barker et al. (Reference Barker, Zhu and Sun2022) have obtained an analytical solution using a compressible

$d_p \ll W$. Recently, Barker et al. (Reference Barker, Zhu and Sun2022) have obtained an analytical solution using a compressible ![]() $\mu (I)$ based model, and compared it with their DEM results. They have performed simulations in a periodic cell, where the gravitational acceleration is in opposite directions in the two halves of the cell separated by the vertical mid-plane. This results in a zero-velocity condition at the mid-plane and at the periodic boundaries, which is equivalent to a no-slip boundary condition at the wall. Linear approximations for the dependence of

$\mu (I)$ based model, and compared it with their DEM results. They have performed simulations in a periodic cell, where the gravitational acceleration is in opposite directions in the two halves of the cell separated by the vertical mid-plane. This results in a zero-velocity condition at the mid-plane and at the periodic boundaries, which is equivalent to a no-slip boundary condition at the wall. Linear approximations for the dependence of ![]() $\mu$ and

$\mu$ and ![]() $\phi$ on

$\phi$ on ![]() $I$ are used in the model of Barker et al. (Reference Barker, Zhu and Sun2022); this results in an exponential variation of

$I$ are used in the model of Barker et al. (Reference Barker, Zhu and Sun2022); this results in an exponential variation of ![]() $\phi$ with distance from the wall. There is a difference between the exponential profiles predicted by the model and simulation results. However, the model prediction for the velocity profile, which is the sum of linear and exponential functions of the distance from the wall, is in reasonable agreement with simulation results. The average velocity and shear layer thickness are proportional to

$\phi$ with distance from the wall. There is a difference between the exponential profiles predicted by the model and simulation results. However, the model prediction for the velocity profile, which is the sum of linear and exponential functions of the distance from the wall, is in reasonable agreement with simulation results. The average velocity and shear layer thickness are proportional to ![]() $W^{3/2}$ and

$W^{3/2}$ and ![]() $W$, respectively, which are similar to the values in Cawthorn (Reference Cawthorn2011).

$W$, respectively, which are similar to the values in Cawthorn (Reference Cawthorn2011).

The average velocity is proportional to ![]() $W^{3/2}$ for the following reason. The maximum shear stress at the wall

$W^{3/2}$ for the following reason. The maximum shear stress at the wall ![]() $\sigma _{xy}$ is proportional to

$\sigma _{xy}$ is proportional to ![]() $W$ from the momentum balance equation, if the volume fraction variation in the shearing zones is neglected. If the wall friction coefficient is a constant, then the normal stress

$W$ from the momentum balance equation, if the volume fraction variation in the shearing zones is neglected. If the wall friction coefficient is a constant, then the normal stress ![]() $\sigma _{xx}$ is also proportional to

$\sigma _{xx}$ is also proportional to ![]() $W$. If a constant friction constant is substituted in the linear

$W$. If a constant friction constant is substituted in the linear ![]() $\mu (I)$ model, then the shear rate at the wall scales as

$\mu (I)$ model, then the shear rate at the wall scales as ![]() $\sqrt {\sigma _{xx}/\rho d_p^2} \sim g^{1/2}W^{1/2}/d_p$ for large

$\sqrt {\sigma _{xx}/\rho d_p^2} \sim g^{1/2}W^{1/2}/d_p$ for large ![]() $I$, where

$I$, where ![]() $d_p$ is the particle diameter. The shear layer thickness increases proportional to

$d_p$ is the particle diameter. The shear layer thickness increases proportional to ![]() $W$ in the models of Cawthorn (Reference Cawthorn2011) and Barker et al. (Reference Barker, Zhu and Sun2022). Consequently, the maximum and average velocities are proportional to

$W$ in the models of Cawthorn (Reference Cawthorn2011) and Barker et al. (Reference Barker, Zhu and Sun2022). Consequently, the maximum and average velocities are proportional to ![]() $g^{1/2} W^{3/2}/d_p$, where

$g^{1/2} W^{3/2}/d_p$, where ![]() $g$ is the acceleration due to gravity. It should be noted that this

$g$ is the acceleration due to gravity. It should be noted that this ![]() $W^{3/2}$ scaling can be derived in the limit

$W^{3/2}$ scaling can be derived in the limit ![]() $I \gg 1$ only if a linear relation is postulated between

$I \gg 1$ only if a linear relation is postulated between ![]() $\mu$ and

$\mu$ and ![]() $I$. If the nonlinear relationship is used where the friction coefficient asymptotes to constants for large

$I$. If the nonlinear relationship is used where the friction coefficient asymptotes to constants for large ![]() $I$, then the scaling is more complicated.

$I$, then the scaling is more complicated.

For fixed channel width, the velocity scaling ![]() $g^{1/2} W^{3/2}/d_p$ implies that the maximum velocity increases as the particle diameter decreases, and it diverges as the inverse of the particle diameter for

$g^{1/2} W^{3/2}/d_p$ implies that the maximum velocity increases as the particle diameter decreases, and it diverges as the inverse of the particle diameter for ![]() $W/d_p \gg 1$. In contrast, the Beverloo correlation (Beverloo et al. Reference Beverloo, Leniger and Van de Velde1961) is based on the assumption that the particle diameter

$W/d_p \gg 1$. In contrast, the Beverloo correlation (Beverloo et al. Reference Beverloo, Leniger and Van de Velde1961) is based on the assumption that the particle diameter ![]() $d_p$ is not a relevant length scale when it is small compared to the orifice diameter. If the channel width is substituted for the orifice diameter in the Beverloo correlation, then the velocity scaling

$d_p$ is not a relevant length scale when it is small compared to the orifice diameter. If the channel width is substituted for the orifice diameter in the Beverloo correlation, then the velocity scaling ![]() $(g W)^{1/2}$ is obtained in the limit

$(g W)^{1/2}$ is obtained in the limit ![]() $W \gg d_p$. The Beverloo scaling is observed in the present study, where smooth frictional walls are used and there is significant slip at the wall. If our results are found to be robust, then they imply that the nature of the wall may not change the scaling for

$W \gg d_p$. The Beverloo scaling is observed in the present study, where smooth frictional walls are used and there is significant slip at the wall. If our results are found to be robust, then they imply that the nature of the wall may not change the scaling for ![]() $\delta _{0.95}$, but can change qualitatively the scaling of the velocity and the flow rate.

$\delta _{0.95}$, but can change qualitatively the scaling of the velocity and the flow rate.

Another issue that needs to be examined is the ratio of the wall roughness scale and the particle diameter. A standard procedure for generating rough walls is to use frozen spherical particles at the wall, and the wall particle diameter is usually considered equal to that for the flowing particles. In Barker et al. (Reference Barker, Zhu and Sun2022), periodic boundary conditions and a reverse flow were used for generating rough walls. One future avenue of research is to transition from rough to smooth walls by decreasing successively the wall particle diameter relative to the flowing particle diameter, and examining the scaling of the average velocity separately with the flowing and wall particle diameters (Kumaran & Bharathraj Reference Kumaran and Bharathraj2013; Bharathraj & Kumaran Reference Bharathraj and Kumaran2017). This would provide some insight into whether the wall roughness or the flowing particle diameter is the relevant length scale for the shear rate at the wall.

The slip velocity ![]() $u_{slip}$ and

$u_{slip}$ and ![]() $u_{max}-u_{slip}$ are proportional to

$u_{max}-u_{slip}$ are proportional to ![]() $\sqrt {W}$, and

$\sqrt {W}$, and ![]() $\delta _{0.95}$ is proportional to

$\delta _{0.95}$ is proportional to ![]() $W$, and the ratio

$W$, and the ratio ![]() $u_{slip}/({\rm d} u_y/{{\rm d}\kern0.7pt x})$ at the wall is proportional to

$u_{slip}/({\rm d} u_y/{{\rm d}\kern0.7pt x})$ at the wall is proportional to ![]() $W$. Therefore, if the slip boundary condition

$W$. Therefore, if the slip boundary condition ![]() ${\rm d} u_y/{{\rm d}\kern0.7pt x} = u_{slip}/l_s$ is used at the wall, and the velocity gradient is calculated from (3.1), then the slip length

${\rm d} u_y/{{\rm d}\kern0.7pt x} = u_{slip}/l_s$ is used at the wall, and the velocity gradient is calculated from (3.1), then the slip length ![]() $l_s$ increases proportional to

$l_s$ increases proportional to ![]() $W$. This is different from earlier studies of Mohan et al. (Reference Mohan, Rao and Nott2002), where the slip length was considered a constant.

$W$. This is different from earlier studies of Mohan et al. (Reference Mohan, Rao and Nott2002), where the slip length was considered a constant.

The slip velocity defined in Shojaaee et al. (Reference Shojaaee, Brendel, Török and Wolf2012) is the relative velocity at the point of contact between a particle and the wall. The contact velocity of the particle surface includes the translational velocity of the particle centre and the cross-product of the rotation velocity and the vector distance between the point of contact and particle centre. However, in the current study, the slip velocity is assumed to be the velocity of the interval closest to the wall, not the surface velocity of the particle at contact. The particle angular velocity is also reported separately, and it is found that the angular velocity deviates from one half of the vorticity close to the wall.

The normal and shear stress profiles are shown in figure 6. As required by the momentum balance, the normal stress in the cross-stream direction, ![]() $\sigma _{xx}$, is a constant across the channel. This constant value increases significantly as

$\sigma _{xx}$, is a constant across the channel. This constant value increases significantly as ![]() $\bar {\phi }$ increases. The shear stress

$\bar {\phi }$ increases. The shear stress ![]() $\sigma _{xy}$ is close to a linear function of distance from the centre; there is departure from linearity in the shear zone due to the variation in

$\sigma _{xy}$ is close to a linear function of distance from the centre; there is departure from linearity in the shear zone due to the variation in ![]() $\phi$. There is very little change in the slope of

$\phi$. There is very little change in the slope of ![]() $\sigma _{xy}$ as

$\sigma _{xy}$ as ![]() $\bar {\phi }$ is changed, because the variation in

$\bar {\phi }$ is changed, because the variation in ![]() $\bar {\phi }$ is less than 5 %.

$\bar {\phi }$ is less than 5 %.

Figure 6. The normal stress ![]() $\sigma _{xx}$ (black, left vertical axis) and shear stress

$\sigma _{xx}$ (black, left vertical axis) and shear stress ![]() $\sigma _{xy}$ (brown, right vertical axis) in the flow of a granular material in a vertical chute of width

$\sigma _{xy}$ (brown, right vertical axis) in the flow of a granular material in a vertical chute of width ![]() $100 \, d_p$. The average volume fractions are

$100 \, d_p$. The average volume fractions are ![]() $\bar {\phi } = 0.62$ (

$\bar {\phi } = 0.62$ (![]() $\circ$),

$\circ$), ![]() $\bar {\phi } = 0.61$ (

$\bar {\phi } = 0.61$ (![]() $\triangle$),

$\triangle$), ![]() $\bar {\phi } = 0.6$ (

$\bar {\phi } = 0.6$ (![]() $\nabla$) and

$\nabla$) and ![]() $\bar {\phi } = 0.59$ (

$\bar {\phi } = 0.59$ (![]() $\diamond$). The black vertical lines are boundaries between the plug and the dense shearing zones, the blue vertical lines are the boundaries between dense and loose shearing zones, and the red vertical line is the boundary between the loose shearing zone and the wall shearing zone.

$\diamond$). The black vertical lines are boundaries between the plug and the dense shearing zones, the blue vertical lines are the boundaries between dense and loose shearing zones, and the red vertical line is the boundary between the loose shearing zone and the wall shearing zone.

The cross-stream normal stress ![]() $\sigma _{xx}$ is shown as a function of

$\sigma _{xx}$ is shown as a function of ![]() $\bar {\phi }$ for different channel widths

$\bar {\phi }$ for different channel widths ![]() $W$ in figure 7(a). There is a significant increase in

$W$ in figure 7(a). There is a significant increase in ![]() $\sigma _{xx}$ as

$\sigma _{xx}$ as ![]() $W$ is increased, and as

$W$ is increased, and as ![]() $\bar {\phi }$ is increased. However, the ratio of the normal stress to the channel width,

$\bar {\phi }$ is increased. However, the ratio of the normal stress to the channel width, ![]() $(\sigma _{xx}/W)$, shown by the brown lines referenced to the right ordinate in figure 7(a), varies very little as

$(\sigma _{xx}/W)$, shown by the brown lines referenced to the right ordinate in figure 7(a), varies very little as ![]() $W$ is varied for

$W$ is varied for ![]() $W > 60 \, d_p$. This implies that

$W > 60 \, d_p$. This implies that ![]() $\sigma _{xx}$ increases approximately proportional to

$\sigma _{xx}$ increases approximately proportional to ![]() $W$. To put this in perspective, recall that

$W$. To put this in perspective, recall that ![]() $\sigma _{xy}$ at the wall increases proportional to

$\sigma _{xy}$ at the wall increases proportional to ![]() $W$ if the decrease in

$W$ if the decrease in ![]() $\phi$ close to the wall is neglected from the momentum balance. This is in agreement with the finding of Barker et al. (Reference Barker, Zhu and Sun2022). When both

$\phi$ close to the wall is neglected from the momentum balance. This is in agreement with the finding of Barker et al. (Reference Barker, Zhu and Sun2022). When both ![]() $\sigma _{xx}$ and

$\sigma _{xx}$ and ![]() $\sigma _{xy}$ at the wall are proportional to

$\sigma _{xy}$ at the wall are proportional to ![]() $W$, the friction coefficient

$W$, the friction coefficient ![]() $\mu _{wall}$ at the wall should be independent of

$\mu _{wall}$ at the wall should be independent of ![]() $W$. Figure 7(b) shows that this is indeed the case. The wall friction coefficient is independent of

$W$. Figure 7(b) shows that this is indeed the case. The wall friction coefficient is independent of ![]() $W$, but it decreases as

$W$, but it decreases as ![]() $\bar {\phi }$ increases. The latter trend may be understood by noting that small changes in

$\bar {\phi }$ increases. The latter trend may be understood by noting that small changes in ![]() $\bar {\phi }$ affect

$\bar {\phi }$ affect ![]() $\sigma _{xy}$ less strongly than

$\sigma _{xy}$ less strongly than ![]() $\sigma _{xx}$. Thus the value of

$\sigma _{xx}$. Thus the value of ![]() $\sigma _{xx}$ across the channel is determined from the wall shear stress required to balance the weight of the material per unit area of the wall and the wall friction coefficient that is a function of

$\sigma _{xx}$ across the channel is determined from the wall shear stress required to balance the weight of the material per unit area of the wall and the wall friction coefficient that is a function of ![]() $\bar {\phi }$ for specific wall and particle properties.

$\bar {\phi }$ for specific wall and particle properties.

Figure 7. (a) The cross-stream normal stress ![]() $\sigma _{xx}$ as a function of

$\sigma _{xx}$ as a function of ![]() $\bar {\phi }$ is shown by the black lines referenced to the left ordinate, and the ratio

$\bar {\phi }$ is shown by the black lines referenced to the left ordinate, and the ratio ![]() $\sigma _{xx}/W$ is shown by the brown lines referenced to the right ordinate. (b) The wall friction coefficient

$\sigma _{xx}/W$ is shown by the brown lines referenced to the right ordinate. (b) The wall friction coefficient ![]() $\mu _{wall}$ as a function of

$\mu _{wall}$ as a function of ![]() $\bar {\phi }$. The channel widths are

$\bar {\phi }$. The channel widths are ![]() $60 \, d_p$ (

$60 \, d_p$ (![]() $\circ$),

$\circ$), ![]() $100 \, d_p$ (

$100 \, d_p$ (![]() $\triangle$),

$\triangle$), ![]() $120 \, d_p$ (

$120 \, d_p$ (![]() $\nabla$) and

$\nabla$) and ![]() $150 \, d_p$ (

$150 \, d_p$ (![]() $\diamond$).

$\diamond$).

3.2. Comparison with kinetic models

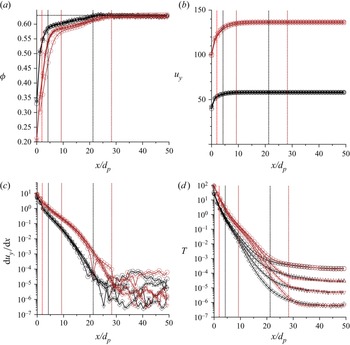

The volume fraction ![]() $\phi$ as a function of cross-stream distance

$\phi$ as a function of cross-stream distance ![]() $x/d_p$ is shown in figure 8(a) for channel width

$x/d_p$ is shown in figure 8(a) for channel width ![]() $W = 100 \, d_p$. The region at the centre of the channel is the ‘plug’ zone where

$W = 100 \, d_p$. The region at the centre of the channel is the ‘plug’ zone where ![]() $\phi$ is a constant. The boundary of the plug zone is indicated by the black vertical lines for the four different values of

$\phi$ is a constant. The boundary of the plug zone is indicated by the black vertical lines for the four different values of ![]() $\bar {\phi }$. It is interesting to note that

$\bar {\phi }$. It is interesting to note that ![]() $\phi$ in the plug is

$\phi$ in the plug is ![]() ${\sim }0.63$, which is discernibly lower than the random close packing volume fraction

${\sim }0.63$, which is discernibly lower than the random close packing volume fraction ![]() $\phi _{rcp} = 0.64$ for a monodisperse system. This indicates that the plug zone is not a jammed assembly of particles, but there is particle agitation even in this plug zone, and the granular temperature

$\phi _{rcp} = 0.64$ for a monodisperse system. This indicates that the plug zone is not a jammed assembly of particles, but there is particle agitation even in this plug zone, and the granular temperature ![]() $T$ in this region is measurable, as shown in figure 8(c). When

$T$ in this region is measurable, as shown in figure 8(c). When ![]() $\bar {\phi }$ is decreased, the volume fraction in the plug zone is nearly a constant, but the thickness of the plug zone decreases. At the lowest average volume fraction

$\bar {\phi }$ is decreased, the volume fraction in the plug zone is nearly a constant, but the thickness of the plug zone decreases. At the lowest average volume fraction ![]() $\bar {\phi } = 0.59$, the plug zone occupies less than half of the channel width

$\bar {\phi } = 0.59$, the plug zone occupies less than half of the channel width ![]() $W$. It should be noted that there is no layering in this region even at

$W$. It should be noted that there is no layering in this region even at ![]() $\bar {\phi } = 0.62$. It is also verified that there is no crystallization; the

$\bar {\phi } = 0.62$. It is also verified that there is no crystallization; the ![]() $Q_6$ order parameter (Kumaran Reference Kumaran2009c,Reference Kumarand) in this region is below 0.4.

$Q_6$ order parameter (Kumaran Reference Kumaran2009c,Reference Kumarand) in this region is below 0.4.

Figure 8. (a) The volume fraction ![]() $\phi$, (b) the shear rate

$\phi$, (b) the shear rate ![]() ${\rm d}u_y/{\rm d}\kern0.7pt x$, (c) the granular temperature

${\rm d}u_y/{\rm d}\kern0.7pt x$, (c) the granular temperature ![]() $T$, and (d) the rates of shear production of energy (black) and dissipation (red) due to particle interactions for

$T$, and (d) the rates of shear production of energy (black) and dissipation (red) due to particle interactions for ![]() $W = 100 \, d_p$. The average volume fractions are

$W = 100 \, d_p$. The average volume fractions are ![]() $\bar {\phi } = 0.62$ (

$\bar {\phi } = 0.62$ (![]() $\circ$),

$\circ$), ![]() $\bar {\phi } = 0.61$ (

$\bar {\phi } = 0.61$ (![]() $\triangle$),

$\triangle$), ![]() $\bar {\phi } = 0.6$ (

$\bar {\phi } = 0.6$ (![]() $\nabla$) and

$\nabla$) and ![]() $\bar {\phi } = 0.59$ (

$\bar {\phi } = 0.59$ (![]() $\diamond$). The black vertical lines are boundaries between the plug and dense shearing zones; the blue vertical lines are boundaries between the dense and loose shearing zones; and the red line is a boundary between the loose and wall shearing zones.

$\diamond$). The black vertical lines are boundaries between the plug and dense shearing zones; the blue vertical lines are boundaries between the dense and loose shearing zones; and the red line is a boundary between the loose and wall shearing zones.

There is a transition from the plug zone to a ‘dense shearing’ zone when ![]() $\phi$ decreases below 0.63 at the black vertical lines in figure 8(a). A change in the slope of

$\phi$ decreases below 0.63 at the black vertical lines in figure 8(a). A change in the slope of ![]() $\phi$ is evident at the boundary of the plug and dense shearing zones, and

$\phi$ is evident at the boundary of the plug and dense shearing zones, and ![]() $\phi$ decreases continuously in the dense shearing zone. The blue vertical lines are drawn in figure 8(a) where

$\phi$ decreases continuously in the dense shearing zone. The blue vertical lines are drawn in figure 8(a) where ![]() $\phi = \phi _{ad} = 0.587$, where

$\phi = \phi _{ad} = 0.587$, where ![]() $\phi _{ad}$ is the volume fraction for arrested dynamics. This is the boundary between the dense and ‘loose shearing’ zones. Very close to the wall, within a distance of about two particle diameters, there is a wall shearing layer with a steep decrease in

$\phi _{ad}$ is the volume fraction for arrested dynamics. This is the boundary between the dense and ‘loose shearing’ zones. Very close to the wall, within a distance of about two particle diameters, there is a wall shearing layer with a steep decrease in ![]() $\phi$, marked by a red vertical line. The distinctions between the plug and dense shearing zones (marked by black vertical lines) and the loose and wall shearing zones (marked by a red vertical line) are clearer in figure 9, where clear breaks are seen in the profiles of the ratios of the angular velocity to shear rate, and the shear rate to square root of the granular temperature

$\phi$, marked by a red vertical line. The distinctions between the plug and dense shearing zones (marked by black vertical lines) and the loose and wall shearing zones (marked by a red vertical line) are clearer in figure 9, where clear breaks are seen in the profiles of the ratios of the angular velocity to shear rate, and the shear rate to square root of the granular temperature ![]() $\sqrt {T}$. For the highest average volume fraction

$\sqrt {T}$. For the highest average volume fraction ![]() $\bar {\phi } = 0.62$, there appears to be no loose shearing zone as

$\bar {\phi } = 0.62$, there appears to be no loose shearing zone as ![]() $\phi$ decreases to

$\phi$ decreases to ![]() $\phi _{ad} = 0.587$ in the wall shearing zone. For lower values of

$\phi _{ad} = 0.587$ in the wall shearing zone. For lower values of ![]() $\bar {\phi }$, there is a clear distinction between the dense and loose shearing zones at

$\bar {\phi }$, there is a clear distinction between the dense and loose shearing zones at ![]() $\phi = \phi _{ad}$, and the loose and wall shearing zones.

$\phi = \phi _{ad}$, and the loose and wall shearing zones.

Figure 9. The ratios of (a) ![]() $\varOmega _z$ to

$\varOmega _z$ to ![]() $\omega _z$, and (b)

$\omega _z$, and (b) ![]() $({\rm d} u_y/{{\rm d}\kern0.7pt x})/\sqrt {T}$ versus

$({\rm d} u_y/{{\rm d}\kern0.7pt x})/\sqrt {T}$ versus ![]() $x/d_p$, for

$x/d_p$, for ![]() $W = 100\,d_p$ and

$W = 100\,d_p$ and ![]() $\bar {\phi } = 0.62$ (

$\bar {\phi } = 0.62$ (![]() $\circ$),

$\circ$), ![]() $\bar {\phi } = 0.61$ (

$\bar {\phi } = 0.61$ (![]() $\triangle$),

$\triangle$), ![]() $\bar {\phi } = 0.6$ (

$\bar {\phi } = 0.6$ (![]() $\nabla$) and

$\nabla$) and ![]() $\bar {\phi } = 0.59$ (

$\bar {\phi } = 0.59$ (![]() $\diamond$).

$\diamond$).