Introduction

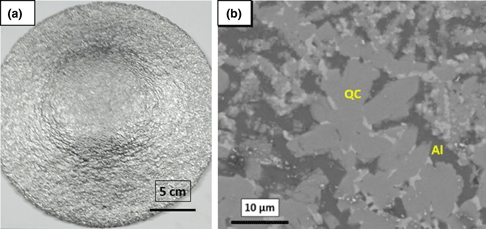

Quasicrystals were first reported in 1984 by Shechtman et al. [Reference Shechtman, Blech, Gratias and Cahn1]. They were observed in a rapidly solidified Al–Mn alloy, displaying a distinct point group symmetry from all previously known metallic structures, m![]() $\bar{3}\bar{5}$. This point group contains a 5-fold rotational symmetry, which makes this atomic structure incompatible with translational symmetry. Quasicrystals are known to be formed by nonconventional structural units, such as icosahedral and decagonal, yielding 5-fold and 10-fold rotational symmetries, respectively, which are found in the vast majority of these phases [Reference Huttunen-Saarivirta2] and can be identified, for example, by electron diffraction analysis, Fig. 1, taken from Bindi et al. [Reference Bindi, Yao, Lin, Hollister, Andronicos, Distler, Eddy, Kostin, Kryachko, MacPherson, Steinhardt, Yudovskaya and Steinhardt3]. Octagonal and dodecagonal structural units may also be found in specific alloy systems [Reference Huttunen-Saarivirta2]. These units cannot be properly referred to as unit cells since they lack translational symmetry. For instance, icosahedral quasicrystals have an icosahedron as a structural unit, which cannot alone fill a volume without leaving gaps. Thus, in certain atomic sites of this atomic structure, a second “unit cell” would be necessary to completely fill the space. One of the models used to understand how this atomic structure can fill the space is the Penrose Model. Following this model, quasicrystals would be formed by two different tiles (unit cells), which must be placed edge to edge with specific matching rules that would allow perfect space filling. These rules lead to a mosaic picture displaying 5-fold symmetry, which is nonperiodic and ordered at the same time as the quasicrystals [Reference Steinhardt4].

$\bar{3}\bar{5}$. This point group contains a 5-fold rotational symmetry, which makes this atomic structure incompatible with translational symmetry. Quasicrystals are known to be formed by nonconventional structural units, such as icosahedral and decagonal, yielding 5-fold and 10-fold rotational symmetries, respectively, which are found in the vast majority of these phases [Reference Huttunen-Saarivirta2] and can be identified, for example, by electron diffraction analysis, Fig. 1, taken from Bindi et al. [Reference Bindi, Yao, Lin, Hollister, Andronicos, Distler, Eddy, Kostin, Kryachko, MacPherson, Steinhardt, Yudovskaya and Steinhardt3]. Octagonal and dodecagonal structural units may also be found in specific alloy systems [Reference Huttunen-Saarivirta2]. These units cannot be properly referred to as unit cells since they lack translational symmetry. For instance, icosahedral quasicrystals have an icosahedron as a structural unit, which cannot alone fill a volume without leaving gaps. Thus, in certain atomic sites of this atomic structure, a second “unit cell” would be necessary to completely fill the space. One of the models used to understand how this atomic structure can fill the space is the Penrose Model. Following this model, quasicrystals would be formed by two different tiles (unit cells), which must be placed edge to edge with specific matching rules that would allow perfect space filling. These rules lead to a mosaic picture displaying 5-fold symmetry, which is nonperiodic and ordered at the same time as the quasicrystals [Reference Steinhardt4].

Figure 1: Electron diffraction patterns of a natural decagonal quasicrystal, using (a) selected area and (b) convergent beam electron diffraction pattern. This quasicrystal was found in the Khatyrka meteorite. Adapted from Bindi et al. [Reference Bindi, Yao, Lin, Hollister, Andronicos, Distler, Eddy, Kostin, Kryachko, MacPherson, Steinhardt, Yudovskaya and Steinhardt3]. The image is licenced under CC BY-ND 4.0 (http://creativecommons.org/licenses/by/4.0/).

These phases have been extensively studied due to their unique atomic structures and their functional properties, including tribological and thermal behaviors, as well as to their mechanical properties [Reference Dubois5]. However, technological applications involving load-bearing components have not yet reached a mature level. This can be attributed to several reasons, two of the most important being (i) their usually complicated processing that either requires rapid solidification or powder metallurgy methods and (ii) their inherent brittleness. This latter issue led to substantial efforts by the academic community to fabricate composites reinforced with these phases to balance the brittleness of the quasicrystals with the presence of a ductile matrix. The present review aims to discuss the studies focused on developing these composite materials over the past decade. This review also brings to the discussion the first published studies that were, mostly, responsible for the advances on quasicrystal-related research reported recently. We will begin with a short review on the general aspects of quasicrystal-forming metallic systems, their properties, and applications, and then, the focus will be on developments of quasicrystal-reinforcing composites for use as wear-resistant and high-strength materials.

General Aspects of Quasicrystals and the Motivation for Using Them as Reinforcing Phases in Composites

Quasicrystal-forming systems

Most of the metallic quasicrystal-forming systems are Al-based, with hundreds of alloy compositions found to date. Among the most important quasicrystal-forming Al-based systems are Al–Mn [Reference Shechtman, Blech, Gratias and Cahn1], Al–Cr [Reference Inoue, Kimura and Masumoto6], Al–Fe–Cr [Reference Galano, Audebert, Cantor and Stone7], Al–Cu–Fe [Reference Tsai, Inoue and Masumoto8], Al–Ni–Co [Reference Tsai, Inoue and Masumoto9, Reference Winkelmann, Cios, Tokarski, Nolze, Hielscher and Kozieł10], Al–Cu–Co [Reference Tsai, Inoue and Masumoto9], Al–Cu–Fe–Cr [Reference Dong and Dubois11], Al–Pd–Mn [Reference Tsai, Inoue, Yokoyama and Masumoto12], and their modifications through alloy addition [Reference Galano, Audebert, Stone and Cantor13, Reference Wolf, Coury, Kaufman, Bolfarini, Kiminami and Botta14, Reference Wolf, Sitta, Martini, Jorge, Bolfarini, Kiminami and Botta15, Reference Ma, You and He16]. Most of these quasicrystals were discovered in the early 1990s by Inoue, Tsai and collaborators. In addition to Al-based systems, other important metallic systems forming quasicrystals are worth mentioning, such as Mg-based [Reference Nie, Kang, Deng, Guo, Han and Zhu17, Reference Xu, Teng and Geng18, Reference Geng, Teng, Zhou, Zhao and Leng19, Reference Liu, Yang and Ye20], Ti-based [Reference Kelton, Kim and Stroud21, Reference Han, Zhong, Zhang, Liu and Wang22], and Cd-based [Reference Tsai, Guo, Abe, Takakura and Sato23, Reference Labib, Fujita, Ohhashi and Tsai24].

Quasicrystals can be divided in relation to their “forming ability” from the metallic melt. While most systems can form quasicrystals only through rapid solidification, there are systems that can form them using conventional metallurgical processes (usually slow solidification processes). Sometimes this division is discussed in the literature regarding the stability of the quasicrystalline phases, considering as stable phases the ones that can be formed in slow solidification conditions, and as metastable phases the ones that require rapid solidification. This classification is, however, not strictly precise since establishing unequivocally the stability of quasicrystals is difficult. These phases usually form from peritectic reactions, grow in a sluggish fashion, and are surrounded by complex phases. This makes the identification of phase boundaries and phase stability very challenging. Additionally, most of the so-called stable quasicrystals are actually not stable in low temperatures such as the icosahedral phase that forms in the Al–Cu–Fe system, which decomposes into a crystalline approximant below a certain temperature [Reference Huttunen-Saarivirta2]. Thus, the term “stable” when referred to quasicrystals should be used with caution. However, we will sometimes make use of it when discussing quasicrystals that were experimentally observed in microstructures even after long annealing thermal treatments. It should be mentioned though, that this fact alone does not suffice to prove the thermodynamic stability of a phase.

Several examples can be found in the literature about Al-based quasicrystals fabricated under low solidification conditions. The most studied one belongs to the Al–Cu–Fe system [Reference Huttunen-Saarivirta2, Reference Holland-Moritz, Herlach and Urban25, Reference Murty, Koteswara Rao and Mukhopadhyay26, Reference Holland-Moritz, Schroers, Herlach, Grushko and Urban27], although a significant amount of papers have been published on Al–Ni–Co [Reference Wolf, Sitta, Martini, Jorge, Bolfarini, Kiminami and Botta15, Reference Grushko, Holland-Moritz and Bickmann28, Reference Grushko and Holland-Moritz29, Reference Grushko and Velikanova30, Reference Grushko and Holland-Moritz31, Reference Grushko and Velikanova32] and Al–Cu–Fe–Cr [Reference Dubois5, Reference Dong and Dubois11, Reference Wolf, Coury, Kaufman, Bolfarini, Kiminami and Botta14, Reference Wolf, Kube, Sohn, Xie, Cha, Scanley, Kiminami, Bolfarini, Botta and Schroers33] systems. Usually, it is observed that only alloys containing three or more elements can form quasicrystals under these processing conditions. However, Tsai et al. [Reference Tsai, Guo, Abe, Takakura and Sato23] have shown the formation of a stable quasicrystal in a Cd–Yb alloy. These “stable” quasicrystals are of great interest because they can be fabricated on a large scale, by different processing methods. Most quasicrystals, however, can only be fabricated by rapid solidification of metallic melts. These “metastable” quasicrystals are found in several Al-based systems, such as Al–Mn [Reference Coury, Botta, Bolfarini, Kiminami and Kaufman34], Al–Cr [Reference Inoue, Kimura and Masumoto6], Al–V [Reference Inoue, Kimura and Masumoto6], Al–Fe–Cr [Reference Galano, Audebert, Cantor and Stone7], and in their chemical modifications [Reference Galano, Audebert, Stone and Cantor13, Reference Audebert, Galano, Rios, Kasama, Peres, Kiminami, Botta and Bolfarini35, Reference Stan-Głowińska, Lityńska-Dobrzyńska, Kania, Dutkiewicz, Rogal, Skuza, Wojewoda-Budka, Gordillo and Wiezorek36, Reference Stan-Głowińska, Lityńska-Dobrzyńska, Morgiel, Góral, Gordillo and Wiezorek37].

Functional properties and technological applications

Al-based quasicrystals show interesting tribological properties such as high hardness, low friction coefficient, and nonstick properties [Reference Dubois5, Reference Dubois and Belin-Ferré38, Reference Rabson39]. Thus, many efforts have been made toward the fabrication of quasicrystalline coatings with improved tribological properties, especially for applications involving sliding wear [Reference Dubois5, Reference Guo, Chen, Yu, Liao and Coddet40, Reference Sales, Merstallinger, Ustinov, Polishchuk and Melnichenko41, Reference Matthews, Lang and Shechtman42, Reference Lee, Hsu, Naugle and Liang43, Reference Silva Guedes de Lima, Medeiros Gomes, Guedes de Lima, Dragoe, Barthes-Labrousse, Kouitat-Njiwa and Dubois44]. However, these materials are not currently applied on a large scale and their production is basically restricted to scientific research up to now. The closest application achievement of quasicrystalline coatings, which even reached mass production, was as nonstick coating on frying pans, aiming to replace Teflon® in kitchen utensils [Reference Dubois45]. However, this application was not successful, and the product was discontinued. According to Dubois [Reference Dubois45], this was due to the pan manufacturer that did not apply the necessary thermal treatment after the plasma spray process, which was required to enhance the material's corrosion resistance.

Al-based quasicrystals are also heat and electrical insulators and potential applications of these materials as thermal barrier coatings have been proposed and studied. An Al–Co–Fe–Cr alloy that forms an approximant phase of the quasicrystal has been studied as a potential candidate to be applied as thermal barrier coatings in engines [Reference Dubois5, Reference Wolf, Schulz, Savoie, Bolfarini, Kiminami and Botta46]. Quasicrystalline approximants are phases with complex crystalline structures, usually containing several atoms. These structures present many atomic configurations that resemble a quasicrystal structure; however, they are periodic phases. They usually form in neighboring quasicrystalline compositions and the chemical and structural similarities lead to physical properties that resemble the quasicrystals [Reference Dubois5, Reference Ferreira, de Oliveira, Zepon and Bolfarini47]. The interest behind using quasicrystals for heat insulation is due to their thermal expansion coefficient, which is similar to the usual metallic materials used as substrates in these applications, such as steels and superalloys. This similarity in the thermal expansion coefficient can potentially reduce interfacial thermal stresses generated between the traditional thermal barrier coatings (ceramic materials) and metallic substrates.

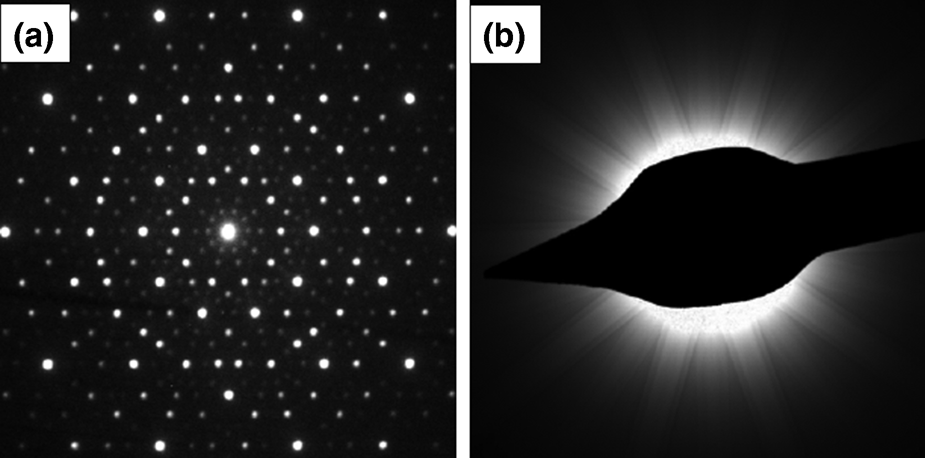

Despite interesting physical properties presented by quasicrystals, using them in environments where mechanical loads are relatively high becomes restricted due to their inherent brittleness. Quasicrystals are particularly brittle at room temperature due to difficulties of dislocation movement without diffusion and in fact, they only experience plastic deformation in temperatures above ~70% of its melting temperature [Reference Caillard, Mompiou, Bresson and Gratias48]. Zou et al. [Reference Zou, Kuczera, Sologubenko, Sumigawa, Kitamura, Steurer and Spolenak49] have performed an interesting study on determining a limiting sample size where the mechanical behavior of a single icosahedral Al–Pd–Mn quasicrystal changes from brittle to ductile at room temperature, see Fig. 2. They produced single quasicrystalline pillars using an FIB (focused ion beam) system with cylindrical shapes [Figs. 2(b) and 2(c)] and diameters ranging from 140 nm to 2 μm and then performed compressive tests using a nanoindenter. They showed that the single quasicrystal can display significant compressive strain [up to 50%, Fig. 2(d)], at room temperature, when the sample size is below 350–510 nm. This is an important result because it shows that only nano-sized quasicrystalline samples can display plastic deformation at room temperature. Thus, using quasicrystals in “large” (above nanometer) components will always be restricted due to their brittleness and they have to be analyzed such as the ceramic materials, where fracture strength can be estimated using Griffith's criterion [Reference Griffith50].

Figure 2: (a) Strength and fracture/deformation mechanisms for icosahedral Al–Pd–Mn pillars. According to Zou et al. [Reference Zou, Kuczera, Sologubenko, Sumigawa, Kitamura, Steurer and Spolenak49], the sample size of a single quasicrystal pillar of the system Al–Pd–Mn that would lead a transition from brittle fracture mode (crack control) to a plastic deformation mode (displacive plasticity) is close to 400 nm. Above this size, the sample fracture is dominated by Griffith's criterion. Below that size, the yielding stress (Hardness/3) of the quasicrystal would be lower than its fracture resistance, and thus, the material would experience plastic deformation even at room temperature. If the sample size is further reduced, there will be a substantial increase in the plasticity observed until a certain point from which, it will begin to decrease due to diffusion control of the plastic flow, reducing the strength as the surface-to-volume ratio increases. (b) 140 nm diameter Al–Pd–Mn quasicrystal pillar after mechanical testing, displaying plastic strain close to 60%. (c) 1800 nm diameter Al–Pd–Mn quasicrystal pillar after mechanical testing, displaying brittle fracture with limited plastic strain, ~3%. (d) Plastic strains observed in the different sized samples analyzed in that study. Adapted from Zou et al. [Reference Zou, Kuczera, Sologubenko, Sumigawa, Kitamura, Steurer and Spolenak49]. The images are licenced under CC BY-ND 4.0 (http://creativecommons.org/licenses/by/4.0/).

The brittle behavior restricts single-phased quasicrystals to be used as protective coatings (in applications involving mechanical stresses) and prohibits them from being used in bulk form. Even wear protection coating applications can be challenging because the quasicrystalline layer usually presents cracking, which is developed upon cooling during coating fabrication. Since cracking introduces large defects inside these materials, according to Griffith's criterion, the final product will have relatively low fracture resistance. This is particularly important for the final wear resistance of the material and restricts the feasibility of obtaining wear-resistant coatings even with deposition processes that can yield high-quality coatings or films. Thus, even if the quasicrystal layer shows a high-quality microstructure, their application is restricted to low load levels during operation or testing. For instance, the wear behavior on pin-on-disk testing of single-phased quasicrystalline coatings is extremely sensitive to the loads applied during the tests, as it also happens for ceramic materials [Reference Hutchings and Shipway51]. Single-phased quasicrystalline coatings behave well under low loads during wear testing. However, if sufficiently high loads are applied, the coatings will fail catastrophically and the coating's integrity will be impaired.

As a consequence, for applications involving mechanical stresses, it is of great interest to use the unique quasicrystalline properties as reinforcing phases on metal matrix composites (MMCs). This can be achieved by different methods depending on the quasicrystal system and on the application targeted. For instance, fabricating high-strength Al alloys reinforced with quasicrystals depends on obtaining nanometric quasicrystalline particles that will provide superior mechanical strength, particularly at high temperatures [Reference Galano, Audebert, Escorial, Stone and Cantor52, Reference Inoue53]. Wear-resistant Al alloys, on the other hand, usually present coarse hard phases embedded in the Al-matrix, as the Al–Si alloys. Therefore, obtaining coarse quasicrystalline particles showing good metallurgical bond with the Al-matrix is important. Since MMCs are the main scope of the present review, the recent developments on this topic reported in the literature will be discussed in detail in the next sections.

Several applications, other than protective coatings and high-strength alloys, have also been studied for quasicrystals, including their use as: solar light absorbers [Reference Dubois45], abrasive polishing agent [Reference Chen, Qiang and Dong54], reinforcing agents in polymers [Reference Chukov, Stepashkin, Tcherdyntsev, Olifirov and Kaloshkin55, Reference Tcherdyntsev, Stepashkin, Chukov, Olifirov and Senatov56], catalysts [Reference Tanabe, Kameoka and Tsai57, Reference Zhang, Guo, Wang, Ma, Li, Zhang and He58, Reference Pandey, Bhatnagar, Mishra, Yadav, Shaz and Srivastava59], hydrogen storage [Reference Liu, Zhai, Li, Tao, Liu, Zhao, Jiang and Gao60, Reference Liu, Liu, Sun, Chen, Zhao, Guo and Su61, Reference Kelton and Gibbons62, Reference Shekhtman, Hakobyan, Aleksanyan, Dolukhanyan, Ter-Galstyan and Sakharov63], among others. We will not discuss them in this review any further. More information regarding these properties and applications can be found in the detailed and high-quality reviews by Dubois [Reference Dubois5, Reference Dubois45, Reference Dubois64].

Manufacturing quasicrystals and their composites

Fabrication of single-phased quasicrystalline alloys can be achieved by several means, ranging from nonconventional to conventional metallurgical methods. They include mechanical alloying [Reference Barua, Murty, Mathur and Srinivas65, Reference Sviridova, Shevchukov, Shelekhov, Diakonov, Tcherdyntsev and Kaloshkin66], rapid solidification processes, such as melt-spinning [Reference Huttunen-Saarivirta and Vuorinen67], gas-atomization [Reference Huttunen-Saarivirta2], and Cu-mold quenching [Reference Wolf, Bolfarini, Kiminami and Botta68], thermal spraying and film deposition [Reference Shaitura and Enaleeva69] and also by conventional casting [Reference Huttunen-Saarivirta2]. Usually, single-phased quasicrystals are obtained from metallic systems that can form these phases under more stable (low cooling rates) processing conditions. This is because normally, these phases form from peritectic reactions, and thus, subsequent thermal treatments are necessary to obtain a single-phased quasicrystalline alloy. For further details on fabrication of single-phased quasicrystals, the reader is urged to refer to a review by Huttunen-Saarivirta [Reference Huttunen-Saarivirta2].

On the other hand, fabricating MMCs reinforced with quasicrystalline phases may be done using virtually any quasicrystal system. The “stable” quasicrystals reinforcing a metallic matrix are mostly fabricated by powder metallurgy. In this case, the quasicrystal is produced either by gas-atomization or mechanical alloying, and then, the composite can be fabricated by different methods that can include: a mechanical mixture of powders to be subsequently consolidated [Reference Wolf, Aliaga, Travessa, Afonso, Bolfarini, Kiminami and Botta70], deposited onto a substrate by thermal spraying [Reference Guo, Chen, Yu, Liao and Coddet40], spray formed [Reference Wolf, e Silva, Zepon, Kiminami, Bolfarini and Botta71], conventionally casted [Reference Wolf, Bolfarini, Kiminami and Botta72], and more recently by additive manufacturing [Reference Fu, Kang, Liao, Gao and Coddet73]. In turn, MMCs reinforced with “metastable” quasicrystals need to be processed using rapid solidification techniques since they only form under these conditions. The most commonly used methods are melt-spinning [Reference Galano, Audebert, Stone and Cantor13], Cu-mold quenching [Reference Koga, e Silva, Wolf, Kiminami, Bolfarini and Botta74], gas-atomization [Reference Leonard, Rommel, Watson, Policandriotes and Aindow75], thermal spraying [Reference Watson, Nardi, Ernst, Cernatescu, Bedard and Aindow76], and additive manufacturing [Reference Kang, Fu, Coddet, Guelorget, Liao and Coddet77].

The next sections will discuss, in detail, developments and advances reported in the literature over the past decade (and some older, but groundbreaking studies as well) that include fabrication and characterization of MMCs reinforced with different quasicrystalline systems. We aim to bring a critical evaluation of what has been done to date and the next challenges to be faced to advance in future applications of these materials. We will begin with metastable processing involving rapid solidification methods and then we will move to the “stable” quasicrystalline-based composites.

Al-Matrix MMCs Reinforced with Nano-Sized Quasicrystals

MMCs produced by melt-spinning and Cu-mold quenching

Most of the initial studies about quasicrystal-reinforcing composites were performed by melt-spinning or Cu-mold quenching (usually die-casting) a liquid metal [Reference Inoue53, Reference Inoue, Watanabe, Kimura, Takahashi, Nagata and Masumoto78, Reference Inoue and Kimura79, Reference Schurack, Eckert and Schultz80, Reference Schurack, Eckert and Schultz81, Reference Schurack, Eckert and Schultz82]. The reason for using melt-spinning and die-casting is related to the high cooling rates that can be achieved using these fabrication techniques and the fact that most quasicrystals can only form upon rapid solidification. Melt-spinning can achieve one of the highest cooling rates during an alloy solidification due to the low thickness (usually around 30 μm) of the ribbons produced and the fact that they solidify on a high-speed rotating Cu-wheel, thus being a key technique to study quasicrystal forming ability. Cu-mold quenching (die-casting) can also achieve enough cooling rates to form metastable quasicrystals. However, the cooling rates are substantially lowered by the usual sample's thickness produced by this technique, in the range of mm. Despite this limitation, fabricating the composites via die-casting can be very interesting since the samples are more adequate for mechanical testing and also, it is possible to vary the applied cooling rates (e.g., by using a wedge-shaped Cu-mold), and thus monitor the limiting thickness from which a desired composite microstructure can be obtained.

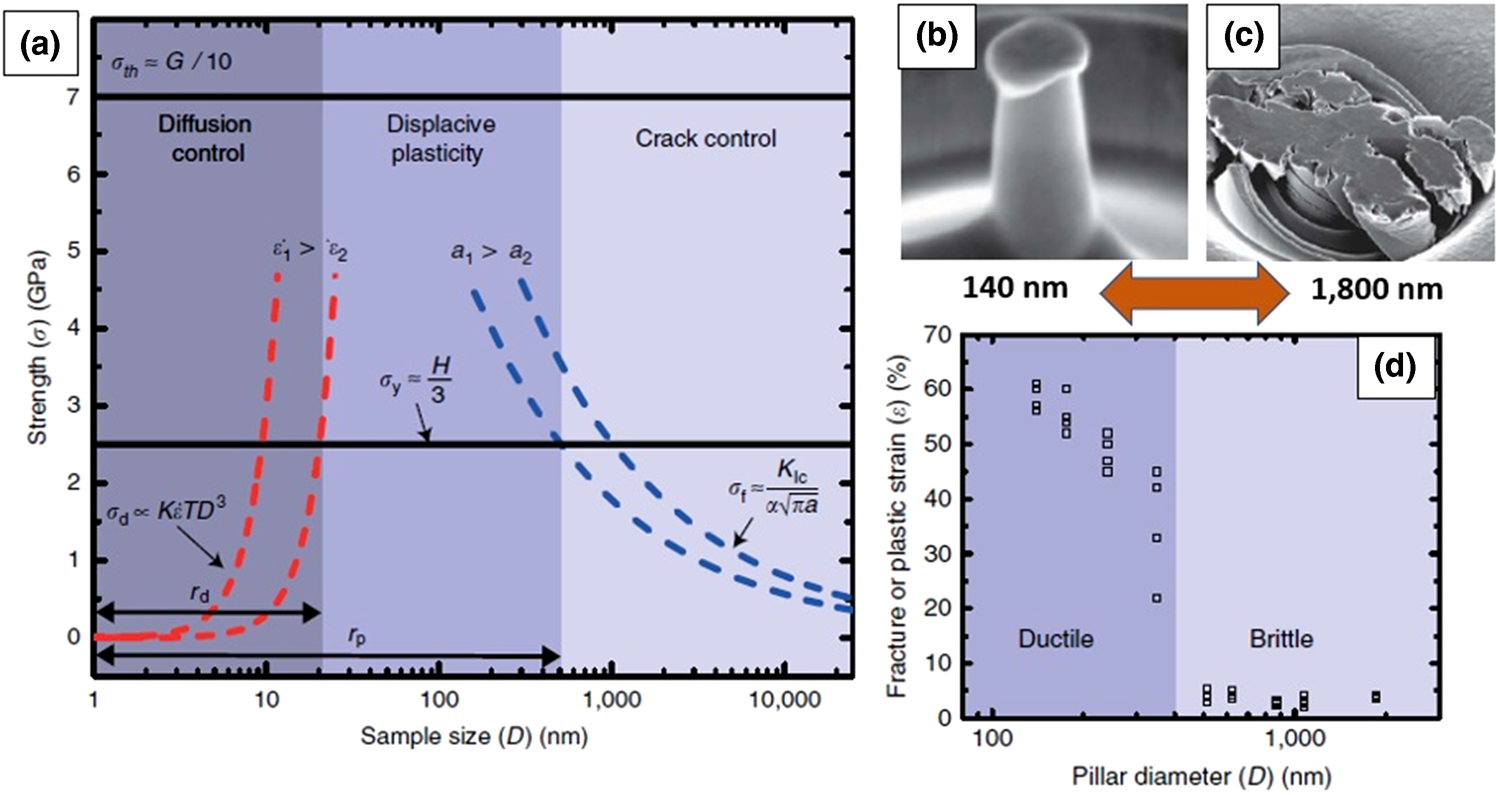

As already mentioned, the first reported quasicrystal-forming system, from Shechtman et al. [Reference Shechtman, Blech, Gratias and Cahn1], was observed in a melt-spun Al–Mn alloy and naturally, the following quasicrystal-related studies were made in the same system. The first reported microstructures containing Al-FCC (face-centered cubic) and quasicrystals belong to the Al–Mn, Al–Mn–Ce, and Al–Mn–Fe systems and were reported by Inoue et al. [Reference Inoue, Watanabe, Kimura, Takahashi, Nagata and Masumoto78] and Schurack et al. [Reference Schurack, Eckert and Schultz80]. In one of the mentioned studies [Reference Inoue, Watanabe, Kimura, Takahashi, Nagata and Masumoto78], the alloys were fabricated by melt-spinning and showed tensile strengths above 1000 MPa. This outstanding mechanical strength led to many subsequent studies that aimed at improving processability and mechanical properties of these materials. In particular, one of the most interesting features presented by these composites was their ability to retain high percentages (around 60%) of their room temperature yield strength when tested around 250 °C, where the conventional high-strength Al alloys (7XXX and 2XXX series) would only retain about 10–30% [Reference Audebert, Galano, Rios, Kasama, Peres, Kiminami, Botta and Bolfarini35]. The high-temperature mechanical strength depends on the thermal stability of the quasicrystal, on how long this phase can maintain its atomic structure and, equally importantly, on the nanometric particle size when it is submitted to these temperatures. Figure 3, adapted from Ref. [Reference Galano, Audebert, Escorial, Stone and Cantor83], shows a hot-stage TEM (transmission electron microscopy) analysis of a melt-spun Al93Fe4.2Cr2.8 (%at.) alloy, which forms nanoquasicrystalline particles [Fig. 3(a)] embedded in an Al-FCC matrix. In this analysis, the decomposition of the icosahedral phase, after heating the sample to 474 °C was noticed. It can be observed that a faceted squared-shaped particle nucleates from the rounded quasicrystal and after 35 min completely “consumes” the icosahedral phase.

Figure 3: The decomposition of an icosahedral quasicrystalline phase from the Al–Fe–Cr system, by hot-stage TEM. The sample was heated to 474 °C (a) and held until the end of the decomposition reaction (b) and (c). It can be observed that the quasicrystalline phase was completely consumed by another intermetallic phase after 35 min of exposure in this temperature. Reprinted from Galano et al. [Reference Galano, Audebert, Escorial, Stone and Cantor83]. Copyright (2009), with permission from Elsevier.

In the recent literature, several authors have reported studies that aimed at finding alloying elements that would increase thermal stability of quasicrystals. Audebert, Galano and collaborators have performed extensive work on developing Al–Fe–Cr-based alloys with nanoquasicrystalline phases embedded in an Al-FCC matrix with improved mechanical and thermal properties [Reference Galano, Audebert, Cantor and Stone7, Reference Galano, Audebert, Stone and Cantor13, Reference Audebert, Galano, Rios, Kasama, Peres, Kiminami, Botta and Bolfarini35, Reference Galano, Audebert, Escorial, Stone and Cantor83, Reference Audebert, Galano and Saporiti84, Reference Galano, Marsh, Audebert, Xu and Ramundo85]. The Al–Fe–Cr system forms nanometric icosahedral precipitates embedded in an Al-FCC matrix when rapidly solidified in specific chemical compositions, such as Al93Fe4.2Cr2.8 [Reference Galano, Audebert, Stone and Cantor13] (%at.). The authors studied the effects of Ti, V, Nb, and Ta additions on the formation of the icosahedral quasicrystal, its thermal stability, and mechanical properties among other features. It was found that partial substitution of Fe and Cr for one of the listed elements increased the quasicrystal thermal stability [Reference Galano, Audebert, Escorial, Stone and Cantor83]. The stabilizing effect of these alloying elements on the quasicrystal structure can be understood in terms of a space frustration model of the icosahedral structure and from the thermal diffusivity of those elements in Al [Reference Galano, Audebert, Stone and Cantor13, Reference Audebert, Galano and Saporiti84].

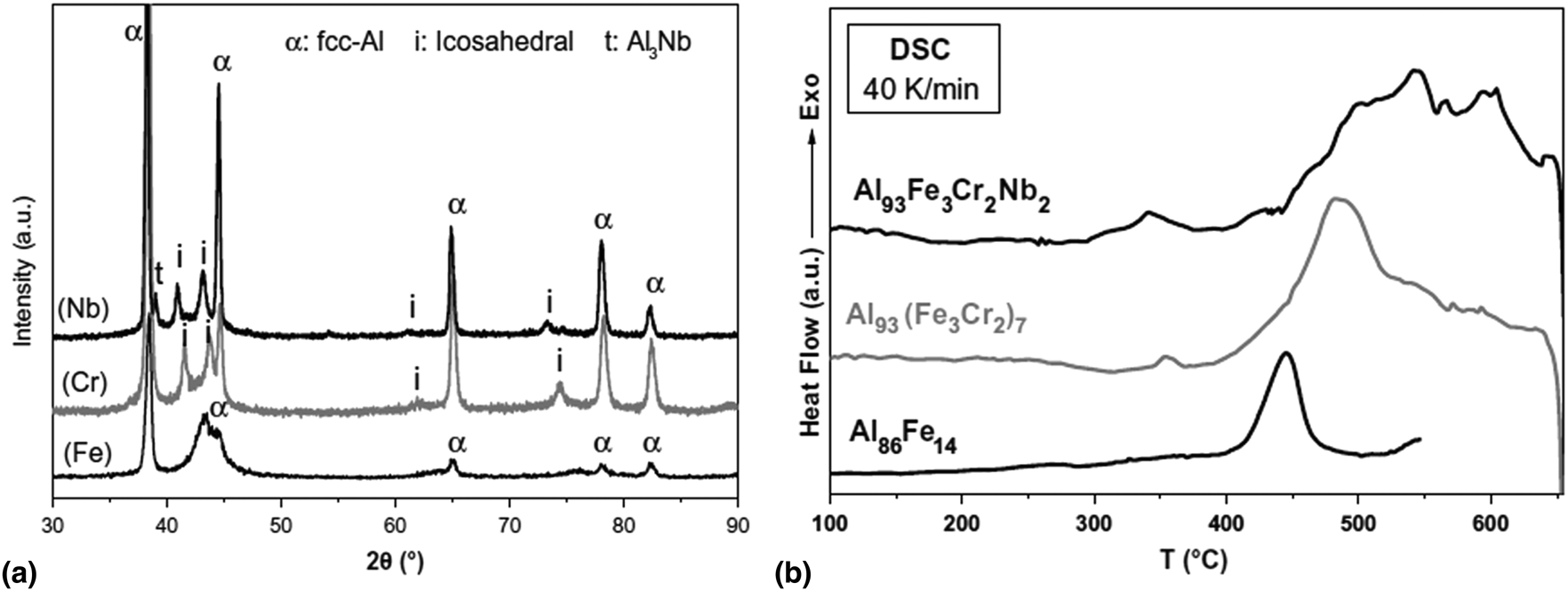

These stabilizing effects were experimentally confirmed by Audebert et al. [Reference Audebert, Galano and Saporiti84] in melt-spun alloys with chemical compositions, indicated in Fig. 4. The X-ray diffraction (XRD) patterns show that as Cr and Nb alloying elements are added, the i-phase (icosahedral phase) reflections become more defined and intense, indicating larger particle sizes and fractions. The differential scanning calorimetry (DSC) results show that the alloying elements increase the decomposition starting temperature of the quasicrystal.

Figure 4: (a) XRD patterns of Al–Fe, Al–Fe–Cr, and Al–Fe–Cr–Nb melt-spun alloys, showing that the icosahedral reflections are enhanced and better defined with alloying additions of Cr and Nb in the binary alloy. (b) DSC analysis from the same alloys, indicating that Cr and Nb additions increase the decomposition temperature of the quasicrystalline phase and extend it almost close to the alloy's melting temperature. Reprinted from Audebert et al. [Reference Audebert, Galano and Saporiti84]. Copyright (2013), with permission from Elsevier.

In the studies conducted by this group, the melt-spun Al–Fe–Cr–(M = Ti, V, Nb, T) alloys showed, at room temperature, similar ultimate tensile strength (UTS) values, ranging from 650 to 700 MPa [Reference Galano, Audebert, Escorial, Stone and Cantor52] and displayed virtually no plastic deformation. At elevated temperatures, the Ti-containing alloy performed better, maintaining UTS values above 400 MPa even at 350 °C. However, all samples showed UTS values above ~250 MPa when tested at 350 °C, which is substantially higher than what would be found for commercial high-strength Al alloys [Reference Audebert, Galano, Rios, Kasama, Peres, Kiminami, Botta and Bolfarini35].

These findings indicate that Ti is probably the most interesting alloying element to be added to the Al–Fe–Cr quasicrystal-forming system. Not only does it show interesting thermal stability, but it also shows superior mechanical properties. In addition, if we look at melting temperatures of Ti, V, Nb, and Ta, we will find, respectively, 1660, 1890, 2468, and 3017 °C. Thus, in terms of processability, Ti addition seems to be very appealing due to its lower melting temperature, which would then facilitate fabrication of ingots and atomized powders of this material. We will discuss the development of gas-atomized powders and extruded alloys from the Al–Fe–Cr-based system in the next subsection.

The Al–Mn system was also recently re-evaluated by different authors regarding alloying addition. Adding rare-earth elements, such as Ce, was one of the first attempts to increase stability of the quasicrystalline phase [Reference Inoue, Watanabe, Kimura, Takahashi, Nagata and Masumoto78]. However, a recent study by Coury et al. [Reference Coury, Botta, Bolfarini, Kiminami and Kaufman34] showed, using electron microscopy, that Ce is virtually absent within the Al–Mn quasicrystalline structure and its presence leads to the formation of a crystalline Al–Mn–Ce-based intermetallic. Stan-Głowińska et al. assessed the influence of Fe addition to the Al–Mn quasicrystal [Reference Stan-Głowińska, Lityńska-Dobrzyńska, Kania, Dutkiewicz, Rogal, Skuza, Wojewoda-Budka, Gordillo and Wiezorek36, Reference Stan-Głowińska, Lityńska-Dobrzyńska and Rogal86, Reference Stan-Głowińska, Rogal, Góral, Wierzbicka-Miernik, Wojewoda-Budka, Schell and Lityńska-Dobrzyńska87]. The authors used wedge die-casting [Reference Stan-Głowińska, Lityńska-Dobrzyńska and Rogal86, Reference Stan-Głowińska, Rogal, Góral, Wierzbicka-Miernik, Wojewoda-Budka, Schell and Lityńska-Dobrzyńska87] to evaluate the limiting thickness and cooling rates necessary to obtain refined quasicrystalline particles embedded in an Al-matrix. They showed that the Fe-containing alloys could form this microstructure if cooling rates in the order of 103 K/s were applied, resulting in a limiting thickness for this composite microstructure between 600 μm and 1 mm. The binary alloy (Al–Mn), on the other hand, did not show the formation of the icosahedral phase in the cast samples, which is a strong indicative that Fe enhances the stability and facilitates the formation of the quasicrystalline phase. The authors also studied the influence of Mo and V addition to the Al–Mn–Fe alloy using melt-spinning to fabricate the samples [Reference Stan-Głowińska, Lityńska-Dobrzyńska, Kania, Dutkiewicz, Rogal, Skuza, Wojewoda-Budka, Gordillo and Wiezorek36]. Both Mo and V additions resulted in quasicrystal-containing alloys (as for the ternary sample) and it was demonstrated that these elements can further enhance the stability of the quasicrystalline phase. This was shown by subsequent hot-compaction of the melt-spun alloys at 390 °C. Only the quaternary alloys retained the quasicrystalline phase after the sintering process, indicating that further alloying addition to the Al–Mn-based quasicrystal is potentially interesting for designing new alloy compositions. Naglič and collaborators [Reference Naglič, Samardžija, Delijić, Kobe, Dubois, Leskovar and Markoli88, Reference Naglič, Samardžija, Delijić, Kobe, Leskovar and Markoli89] showed that adding Cu, Mg, and Si to the binary Al–Mn quasicrystal-forming alloy led to the formation of quasicrystals on Cu-mold quenched samples with a thickness of about 5 mm. This represents a substantial increase in the processability of these alloys, allowing fabrication of relatively thick-walled materials with composite microstructure.

MMCs produced by gas-atomization and powder metallurgy

Although melt-spinning and Cu-mold quenching liquid metals are two of the most important laboratory techniques used to study phase formation and mechanical properties of quasicrystalline composites, using them for mass production and technological applications is limited. Gas-atomization, on the other hand, is a well-established manufacturing process, which can supply the cooling rates required to obtain nanoquasicrystals embedded in the Al-FCC matrix.

Audebert et al. [Reference Audebert, Galano, Rios, Kasama, Peres, Kiminami, Botta and Bolfarini35] fabricated Al–Fe–Cr–Nb alloys by gas-atomization and discussed the difficulties that arise when alloying elements with different melting temperatures, especially Al and Nb. The authors used an Fe–Nb pre-alloy to facilitate the melting process and three different thermal conditions (temperature that the alloy was melted and the holding time in that temperature). One of the main issues that the authors found was related to chemical composition control, especially in reaching the targeted Al and Nb contents. Nonetheless, the authors showed that for specific atomization conditions, this alloy's powder can be fabricated with the desired microstructure. Another important result was related to the particle size above which no icosahedral phase forms. They showed that for powder particles above 175 μm, no quasicrystalline particles were identified. In addition, particles below 75 μm were the ones with higher quasicrystalline phase content. In the same study, the atomized powders were subsequently extruded at 375 °C. This condition was chosen based on previous studies of this alloy that showed no decomposition of the icosahedral phase at this temperature [Reference Galano, Audebert, Stone and Cantor13]. The authors showed that the powder microstructure was preserved in the extruded material.

Prior to the above-mentioned work, Todd et al. [Reference Todd, Chlup, O'Dwyer, Lieblich and García-Escorial90] showed that it is possible to fabricate Al93Fe3Cr2Ti2 products by gas-atomization and hot-extrusion. Only powders with particle size <100 μm were analyzed in that study and the authors showed that with reducing powder size, the icosahedral phase reflections on XRD patterns presented higher intensity and were better defined. The powder sizes below 50 μm yielded larger fractions of the quasicrystalline phase. The authors studied the influence of several extrusion parameters and the initial powder size in the final mechanical properties. Tensile tests showed that using initial powder sizes ranging between 25 and 50 μm led to yield stress values around 500 MPa, UTS values close to 600 MPa and elongation close to 6% at room temperature.

Although Al–Fe–Cr-based extruded alloys were proven to show high strength at room and elevated temperatures, one of the main drawbacks is the lower ductility that they present under tension, when compared to commercial high-strength Al alloys [Reference Pedrazzini, Galano, Audebert, Collins, Hofmann, Abbey, Korsunsky, Lieblich, Garcia Escorial and Smith91]. Aiming to improve the extruded Al–Fe–Cr–Ti alloy's ductility, Pedrazzini et al. [Reference Pedrazzini, Galano, Audebert, Collins, Hofmann, Abbey, Korsunsky, Lieblich, Garcia Escorial and Smith91] fabricated composites of the quasicrystalline alloy with fractions of pure Al fibers that were mixed with the atomized alloy prior to the extrusion process. The authors showed that with no Al fiber addition, the extruded alloy showed, under tensile tests at room temperature, a yield stress of 544 MPa and elongation of 6.4% while 10–20% volumetric additions of pure Al fibers, enhanced the elongation to 7.4% at a cost of yield stress reduction to 481 MPa.

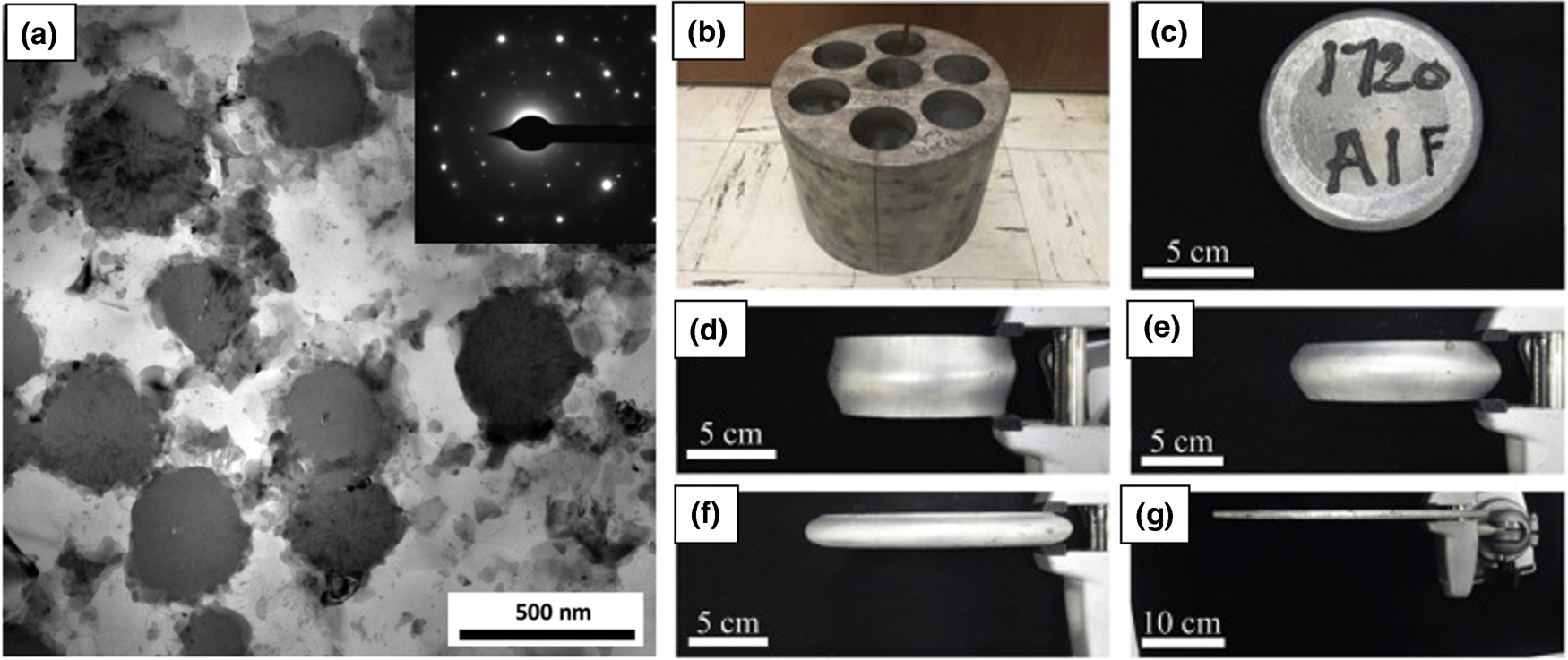

Interesting recent developments have been published on rapidly solidified Al–Cr–Mn–Co–Zr alloys, firstly reported by Watson et al. [Reference Watson, Gordillo, Cernatescu and Aindow92]. In this first publication, the authors studied nanoquasicrystalline phase formation on gas-atomized powders of an alloy with the following composition: Al93.8Cr2.6Co1.6Mn1.5Zr0.5 (%at.). The powders, with particle size inferior to 34 μm, showed a microstructure composed mainly by an icosahedral phase and the Al-FCC matrix. The powder samples were blind die compacted at 310 °C and then forged at temperatures ranging from 260 to 315 °C, resulting in cylindrical parts with a height reduction of 90%. The mechanical properties of the forged composite were assessed by tensile tests in different temperatures. At room temperature, the samples showed tensile yield strength of 690 MPa and elongation of 6%. At 315 °C, samples showed yield strength of 400 MPa and 10% of elongation. Achieving a significant reduction through forging processes is an important improvement toward future applications of these composite materials. The mechanical properties displayed by this composite appear to be enhanced in relation to the previously discussed works. This is a consequence of the forging process, which can effectively improve the reinforcing phase distribution though the Al-matrix [Fig. 5(a)], yielding an optimized material for mechanical strength and ductility.

Figure 5: (a) TEM micrograph and electron diffraction pattern of the Al93.8Cr2.6Co1.6Mn1.5Zr0.5 forged alloy. The electron diffraction pattern confirms the icosahedral symmetry of the quasicrystalline particles. (b) Blind die compacted samples (of Al–Cr–Co–Mn–Zr alloys) and the cylindrical cuts for producing the initial forging samples. (c) Axial view of a forged sample (30% height reduction). (d–g) Slide views of the forged samples after (d) 30%, (e) 50%, (f) 70%, and (g) 90% of height reduction. (a) Reprinted from Watson et al. [Reference Watson, Gordillo, Cernatescu and Aindow92]. Copyright (2016), with permission from Elsevier. (b–g) Reprinted from Leonard et al. [Reference Leonard, Rommel, Li, Watson, Policandriotes and Aindow93]. Copyright (2020), with permission from Elsevier.

Following the advances brought by Watson and collaborators, Leonard et al. [Reference Leonard, Rommel, Watson, Policandriotes and Aindow75, Reference Leonard, Rommel, Li, Watson, Policandriotes and Aindow93] have further improved the ductility and processability of the Al–Cr–Co–Mn–Zr quasicrystalline composites, studying the influence of Cr–Co–Mn–Zr content and forging parameters on the microstructure and mechanical properties of these alloys. In their recent work [Reference Leonard, Rommel, Li, Watson, Policandriotes and Aindow93], three different compositions of the Al–Cr–Co–Mn–Zr system were fabricated by gas-atomization, subsequently blind die compacted at 310 °C and then forged at different temperatures and reductions. The particle size used in this work was below 40 μm. The forging parameters evaluated were temperature (300, 315, 330, 345, and 370 °C) and height reduction from cylindrical samples (30%, 50%, 70%, and 90%). Figure 5(b) shows the blind die compacted samples and the cylindrical cuts from which the forging samples were removed. Figures 5(c)–5(g) show the samples after different forging steps. Figures 5(c) and 5(d) show the samples after 30% reduction (axial and slide views, respectively). Figures 5(e)–5(g) show slide views of the samples after 50%, 70%, and 90% reductions, respectively. The authors showed that there was no decomposition of the quasicrystalline phase during the thermomechanical processes applied and for the samples with large height reduction a more refined microstructure was obtained where the large quasicrystalline particles were fractured and better dispersed in the Al-matrix. This effectively enhanced the elongation displayed by the composites, under tensile tests, to values up to ~15% at room temperature. The samples yielding these large elongation values, displayed tensile yield strength around 450 MPa. These results suggest a feasible processing route to obtain quasicrystalline composites with improved ductility, which is one of the most important issues holding back their applications and thus are very promising. The latest publication of the same research group, by Rommel et al. [Reference Rommel, Leonard, Watson, Policandriotes and Aindow94], evaluated the corrosion resistance of this powder-processed Al-based composite in NaCl solution. The authors studied the effects of the initial powder particle size and phase constitution on the corrosion severity and concluded that the composite shows good corrosion resistance in the conditions studied.

Recent advances on additive manufacturing processes of metallic materials have also opened up new possibilities for fabricating MMCs reinforced with quasicrystals. This is because most of the manufacturing processes are based on laser sintering of metallic powders, such as selective laser melting (SLM), which can yield high cooling rates (necessary to form most quasicrystals) and produce geometrical complex products. Kang et al. [Reference Kang, Fu, Coddet, Guelorget, Liao and Coddet77, Reference Kang, El Mansori, Lu, Lin and Huang95] have made interesting studies on fabrication of in situ icosahedral Al–Fe–Cr quasicrystals by mixing pure Al powders with Al–Cu–Fe–Cr decagonal quasicrystals and then using the SLM process. The formation of the icosahedral Al–Fe–Cr quasicrystal took place after the mixed powders were melted and then rapidly solidified. Kairy et al. [Reference Kairy, Gharbi, Nicklaus, Jiang, Hutchinson and Birbilis96] observed the formation of Mg–Cu–Zn-based nanometric quasicrystals during the SLM process of an AA7075 aluminum alloy, which had never been observed previously. This is extremely interesting because it allows, from a commercially available material, fabrication of these composites using additive manufacturing processes. There is a relatively limited number of studies using additive manufacturing for processing MMCs reinforced with quasicrystals. Thus, this could be an exciting area to be explored and that could yield future technological applications of these materials.

Al-Matrix MMCs Reinforced with Micron-Sized Quasicrystals

MMCs produced by powder metallurgy

Quasicrystals that can be fabricated with or without rapid solidification are, as already mentioned at the beginning of this review, sometimes referred to as the “stable” ones. They are particularly interesting because their processing can be less expensive and, in principle, more flexible. However, these quasicrystalline phases usually form in narrow composition ranges and are surrounded by several intermetallic phases, take the Al–Cu–Fe phase diagram [Reference Quiquandon, Quivy, Devaud, Faudot, Lefebvre, Bessière and Calvayrac97] as an example. These two issues complicate the process because when a quasicrystal-forming alloy composition is cast, the microstructures obtained are usually multi-phased, which leads to a brittle material. In addition, most of the known quasicrystal-forming alloys do not form from casting a two-phase microstructure with the quasicrystal in equilibrium with a solid solution, such as Al-FCC.

The Al–Cu–Fe system is a good example to explain this condition. Between the compositions of the icosahedral phase and the Al-FCC, a third phase, ω-Al7Cu2Fe, does not allow the formation of the microstructure containing Al-FCC and quasicrystal. The same issue is found in most of the known quasicrystal-forming systems [Reference Grushko and Velikanova32]. This is the reason why almost all the studies on Al-matrix composites reinforced with “stable” quasicrystals are based on obtaining a powder of the quasicrystalline alloy, then fabricating the composite by mixing this material with a ductile second phase (e.g., Al powder) and consolidating it, usually by sintering processes.

Tsai et al. [Reference Tsai, Aoki, Inoue and Masumoto98] were the first to report the fabrication of an Al-matrix composite reinforced with Al–Cu–Fe quasicrystals by ball-milling this phase with Al powder. The mixtures were then hot pressed to consolidate the composite. In this work, different volumetric proportions of the reinforcing phase and two different sintering temperatures were used (400 and 600 °C). The authors observed a transformation of the icosahedral phase to the ω-Al7Cu2Fe during sintering at 600 °C. This phase transformation occurs because the ω-phase is in between Al-FCC and the quasicrystal in the phase diagram and the high temperatures applied in the sintering process led to Al diffusion into the quasicrystal resulting in its decomposition.

Following this first publication, other studies have been published focusing on the possible fabrication methods to obtain these composites and on their mechanical properties [Reference Tang, Anderson, Gnaupel-Herold and Prask99, Reference Kaloshkin, Tcherdyntsev, Laptev and Physics100, Reference Ali, Scudino, Anwar, Shahid, Srivastava, Uhlenwinkel, Stoica, Vaughan and Eckert101, Reference Bonneville, Laplanche, Joulain, Gauthier-Brunet and Dubois102, Reference Lityńska-Dobrzyńska, Dutkiewicz, Stan-Głowińska, Wajda, Dembinski, Langlade and Coddet103, Reference Shadangi, Sharma, Shivam, Basu, Chattopadhyay, Majumdar and Mukhopadhyay104]. Bonneville and collaborators have performed extensive studies on Al-matrix composites reinforced with Al–Cu–Fe particles [Reference Bonneville, Laplanche, Joulain, Gauthier-Brunet and Dubois102, Reference Laplanche, Joulain, Bonneville, Gauthier-Brunet, Dubois and El Kabir105, Reference Joseph, Gauthier-Brunet, Monchoux, Joulain, Brisset, Tromas, Douin, Pettinari, Bonneville and Dubois106, Reference El Kabir, Joulain, Gauthier, Dubois, Bonneville and Bertheau107]. The authors have used several different processing routes such as a hot isostatic pressing (HIP) process [Reference Bonneville, Laplanche, Joulain, Gauthier-Brunet and Dubois102], spark plasma sintering (SPS) [Reference Joseph, Gauthier-Brunet, Monchoux, Joulain, Brisset, Tromas, Douin, Pettinari, Bonneville and Dubois106], and gas-pressure infiltration [Reference Laplanche, Joulain, Bonneville, Schaller and El Kabir108] to study microstructural evolution and mechanical properties of the composites. Ali, Scudino and collaborators have also contributed with important studies on the mechanical properties of hot-extruded Al-matrix composites reinforced with Al–Cu–Fe particles [Reference Ali, Scudino, Anwar, Shahid, Srivastava, Uhlenwinkel, Stoica, Vaughan and Eckert101, Reference Ali, Scudino, Liu, Srivastava, Mukhopadhyay, Samadi Khoshkhoo, Prashanth, Uhlenwinkel, Calin and Eckert109].

One common aspect of all the above studies is that, depending on the consolidation temperature, the quasicrystalline reinforcing phase can partially or completely transform to the ω-Al7Cu2Fe phase. According to Tsai et al. [Reference Tsai, Aoki, Inoue and Masumoto98], sintering above 600 °C leads to complete transformation of the icosahedral phase. Subsequent studies have monitored this reaction in detail in the consolidated samples [Reference Ali, Scudino, Anwar, Shahid, Srivastava, Uhlenwinkel, Stoica, Vaughan and Eckert101, Reference Joseph, Gauthier-Brunet, Monchoux, Joulain, Brisset, Tromas, Douin, Pettinari, Bonneville and Dubois106]. This phase transformation was shown to be beneficial for the mechanical properties. This is because the ω-phase has a lower density than the quasicrystal, which results in a volumetric expansion of the reinforcing particles within the Al-matrix, improving interfacial bonding between the particles and the matrix and introducing compressive stresses in the ductile matrix [Reference Ali, Scudino, Anwar, Shahid, Srivastava, Uhlenwinkel, Stoica, Vaughan and Eckert101].

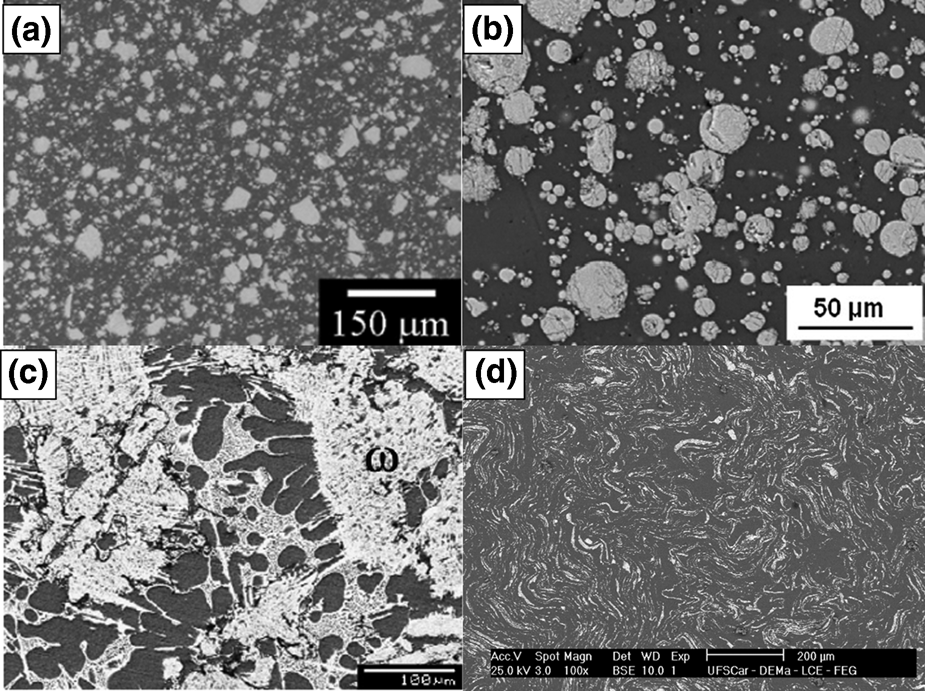

Figure 6 shows examples of the typical microstructures obtained in Al + Al–Cu–Fe composites. In Fig. 6(a), the composite was fabricated by uniaxial hot pressing followed by hot extrusion [Reference Ali, Scudino, Liu, Srivastava, Mukhopadhyay, Samadi Khoshkhoo, Prashanth, Uhlenwinkel, Calin and Eckert109]. Figure 6(b) shows a composite that was fabricated by uniaxial hot pressing [Reference Lityńska-Dobrzyńska, Dutkiewicz, Stan-Głowińska, Wajda, Dembinski, Langlade and Coddet103]. Figure 6(c), on the other hand, shows the fabrication of the composite by gas-pressure infiltration of the quasicrystalline powder in molten Al [Reference Laplanche, Joulain, Bonneville, Schaller and El Kabir108]. This is a different process where the quasicrystal phase is added to the liquid matrix which is then solidified. Other authors have also tried this approach [Reference Fleury, Lee, Choi, Kim and Kim110, Reference Yuan, Hou, Zhao and Yan111]; however, they report a complex microstructure formed after matrix solidification due to partial dissolution of the quasicrystalline particles. Figure 6(d) shows a composite microstructure fabricated by hot-extrusion [Reference Wolf, Aliaga, Travessa, Afonso, Bolfarini, Kiminami and Botta70]. This latter microstructure shows wave-like patterns of the reinforcing phase. This microstructure resulted from the high energy ball mixing of the Al and quasicrystalline powders, which led to a flattening of the Al powder increasing its surface area, where fine quasicrystalline particles could adhere, prior to the extrusion process.

Figure 6: Al + Al–Cu–Fe composites fabricated by (a) uniaxial hot-pressing and subsequently hot-extrusion, (b) uniaxial hot-pressing, (c) gas-pressure infiltration of Al–Cu–Fe particles in a molten Al-alloy, and (d) hot-extrusion of high-energy ball-milled powder composites. (a) Reprinted from Ali et al. [Reference Ali, Scudino, Liu, Srivastava, Mukhopadhyay, Samadi Khoshkhoo, Prashanth, Uhlenwinkel, Calin and Eckert109]. Copyright (2011), with permission from Elsevier. (b) Reprinted from Dobrzyńska et al. [Reference Lityńska-Dobrzyńska, Dutkiewicz, Stan-Głowińska, Wajda, Dembinski, Langlade and Coddet103], Copyright (2015), with permission from Elsevier. (c) Reprinted from Laplanche et al. [Reference Laplanche, Joulain, Bonneville, Schaller and El Kabir108]. Copyright (2009), with permission from Elsevier. (d) Reprinted from Wolf et al. [Reference Wolf, Aliaga, Travessa, Afonso, Bolfarini, Kiminami and Botta70], licenced under CC BY-ND 4.0 (http://creativecommons.org/licenses/by/4.0/).

The strengthening mechanisms of the reinforcing quasicrystalline particles in the above-referred cases are significantly different than the ones from the rapid-solidified quasicrystals (previous section). The reinforcing particle sizes are much coarser in the stable-quasicrystal composites because the microstructure is fabricated ex situ, that is, quasicrystals and ductile matrix are fabricated separately, mixed, and then consolidated. The reinforcing particles in these composites are in the micron-size range. This means that most of the strengthening effects of these quasicrystalline particles are based on load transfer from the matrix to the particle and secondary strengthening due to dislocation interactions and multiplication as a consequence of introduced interfacial stresses between matrix and particles [Reference Tang, Anderson, Gnaupel-Herold and Prask99, Reference Ali, Scudino, Liu, Srivastava, Mukhopadhyay, Samadi Khoshkhoo, Prashanth, Uhlenwinkel, Calin and Eckert109]. Orowan strengthening can also occur if submicrometric particles are involved, which is a minor effect in the case of composites such as the ones from Fig. 6 [Reference Tang, Anderson, Gnaupel-Herold and Prask99].

The consequence of this coarser microstructure is that the mechanical strength of these composites is inferior to the ones reinforced with rapid-solidified quasicrystals. This can be seen by the substantially lower tensile yield stresses of these materials (usually lower than 200 MPa [Reference Tang, Anderson, Gnaupel-Herold and Prask99] at room temperature) and further supported by the fact that most mechanical tests reported in these studies were performed using compression. This is because the large and brittle quasicrystalline particles act as stress concentration that will lead to the low tensile strength observed. Compressive yield strength in the range of 300–400 MPa were reported for Al + Al–Cu–Fe composites with a volume of particle reinforcement in the range of 40–60% [Reference Bonneville, Laplanche, Joulain, Gauthier-Brunet and Dubois102, Reference Ali, Scudino, Liu, Srivastava, Mukhopadhyay, Samadi Khoshkhoo, Prashanth, Uhlenwinkel, Calin and Eckert109], at room temperature.

Although most of the studies about MMCs reinforced with stable quasicrystals are based on the Al–Cu–Fe system, a few have also fabricated Al-matrix composites reinforced with Al–Pd–Mn-based quasicrystals using hot extrusion [Reference Wolf, Aliaga, Travessa, Afonso, Bolfarini, Kiminami and Botta70] and Al–Cu–Cr–Fe-based quasicrystals using SPS or uniaxial compression [Reference Li, Tian, Li, Wang and Liu112, Reference Li, Wang, Sun, Hu, Khor, Wang and Dong113, Reference Lu, Celis, Kenzari, Fournée and Zhou114]. In these studies, the same type of coarse particle reinforcement was observed.

Thus, applications of these composites as high-strength materials do not seem feasible and this is mostly due to the difficulties in obtaining a refined dispersion of the reinforcing phase. However, applying these materials for tribological protection is one possible way of using a few of the unique properties of quasicrystals.

MMCs produced by slow solidification/conventional processing

As already stated, some quasicrystal systems can be produced using conventional metallurgical processes because they can be obtained using slow solidification. Composite processing, on the other hand, is more complicated because it would require finding a quasicrystal-forming system that shows a phase field with stability between Al-FCC and the quasicrystal. If that did not exist, then the methods for obtaining such composites would be only the ones described in the previous subsection.

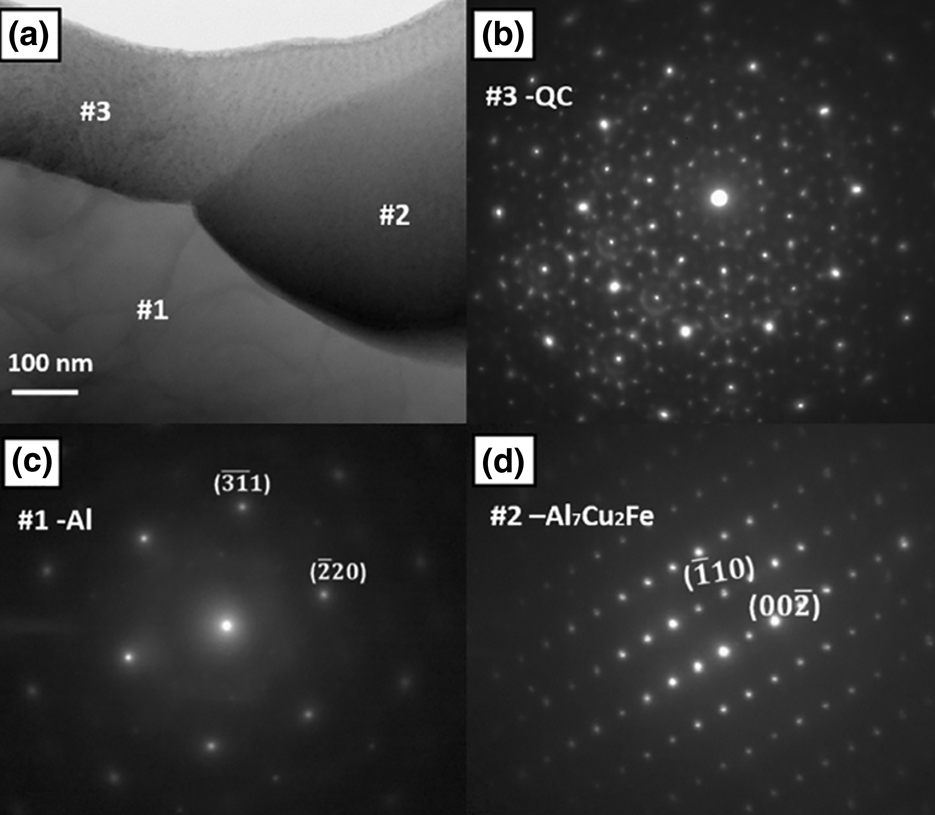

In a recent publication, Wolf et al. [Reference Wolf, Bolfarini, Kiminami and Botta72] have shown, experimentally, that the Al–Cu–Fe–Cr system can form this two-phase co-existence between a decagonal quasicrystal and Al-FCC in a cast alloy. In that study, an Al85Cu6.75Fe3.375Cr4.875 (%at.) alloy ingot was cast and then annealed at 600 °C for 10 h. The resulting microstructure contained, in volumetric percentages, 48.7% of decagonal quasicrystals, 43.5% of Al-FCC, and 7.8% of ω-Al7Cu2Fe. The decagonal phase formed during the annealing step from a peritectic reaction between a liquid phase (formed from the eutectic Al–Al2Cu of the as-cast ingot) and a quaternary Al–Cr-rich intermetallic phase that forms as a primary phase in this alloy when solidified under slow cooling rates [Reference Wolf, e Silva, Zepon, Kiminami, Bolfarini and Botta71]. Figure 7 shows TEM images that identified and confirmed this microstructure. This was the first time such a composite microstructure was obtained using only conventional metallurgical processes.

Figure 7: TEM micrographs of the cast and annealed Al85Cu6.75Fe3.375Cr4.875 alloy with the phase identification by electron diffraction of the phases that composes the composite microstructure. (a) Bright field micrograph displaying the alloy´s microstructure. Electron diffraction patterns taken from the quasicrystalline (b), Al-FCC (c), and Al7Cu2Fe (d) phases. Reprinted from Wolf et al. [Reference Wolf, Bolfarini, Kiminami and Botta72]. Copyright (2019), with permission from Elsevier.

This work brought important outcomes to the development of Al-matrix composites reinforced with quasicrystals because they can now be fabricated virtually by any metallurgical method. For instance, large-scale fabrication of these MMCs can be obtained by conventional casting ingots if a proper annealing step is also performed. Thus, tons of this composite material may be fabricated using the alloy developed in that work, which was virtually impossible in any of the previously known quasicrystal-reinforcing composites. In addition to the processing improvements, the reinforcing particle/matrix interface is probably stronger in this case because the metallurgical bonds between the phases were formed during solidification as opposed to the sintered products by powder metallurgy. The microstructure obtained using conventional casting will consist of large quasicrystalline particles, which can be used against wear and friction, but are not quite optimal for mechanical strength. In the latter case, the quasicrystal particles will need to be refined.

Metastable processing can also be used to fabricate the Al–Cu–Fe–Cr-based composites because the decagonal phase formation is facilitated under rapid solidification conditions. The same phases found after annealing of the cast ingot, were formed when a similar alloy was gas-atomized [Reference Wolf, e Silva, Zepon, Kiminami, Bolfarini and Botta71], without further need for thermal treatments. In addition, the microstructure was more refined in the atomized powders. This also opens up possibilities for additive manufacturing of this alloy, in the sense that the final microstructure is probably going to be very refined and possibly present high-mechanical strength. However, this hypothesis has not been tested yet.

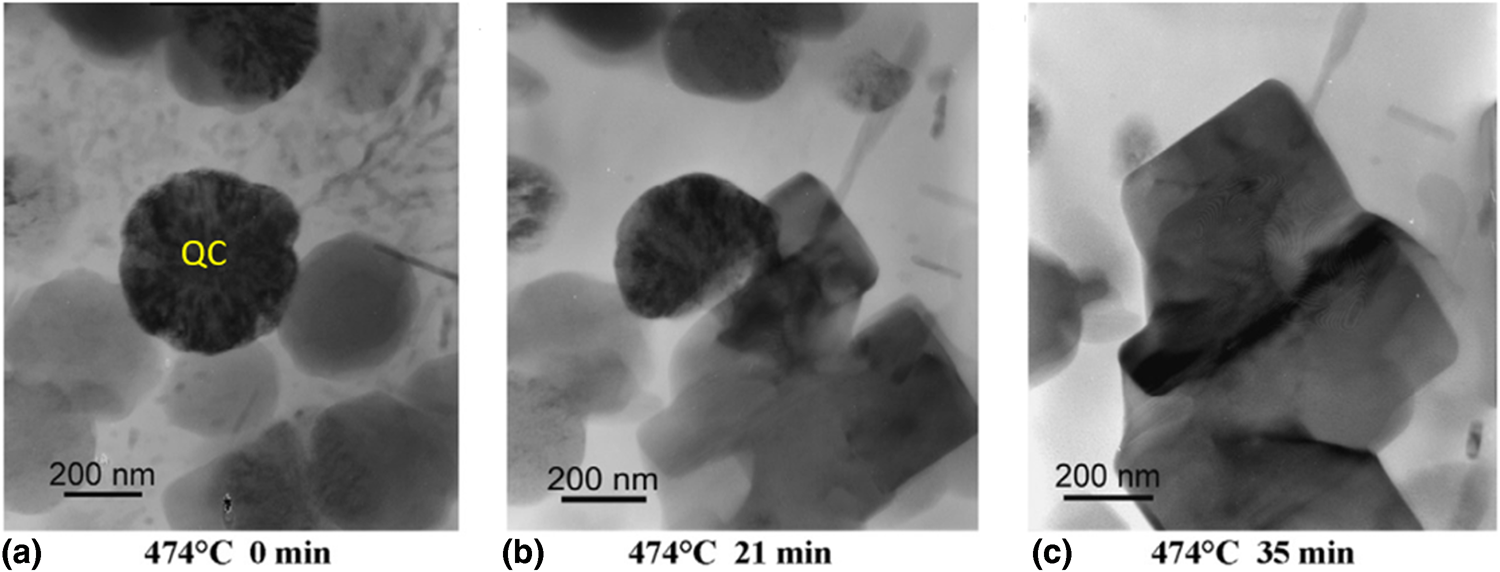

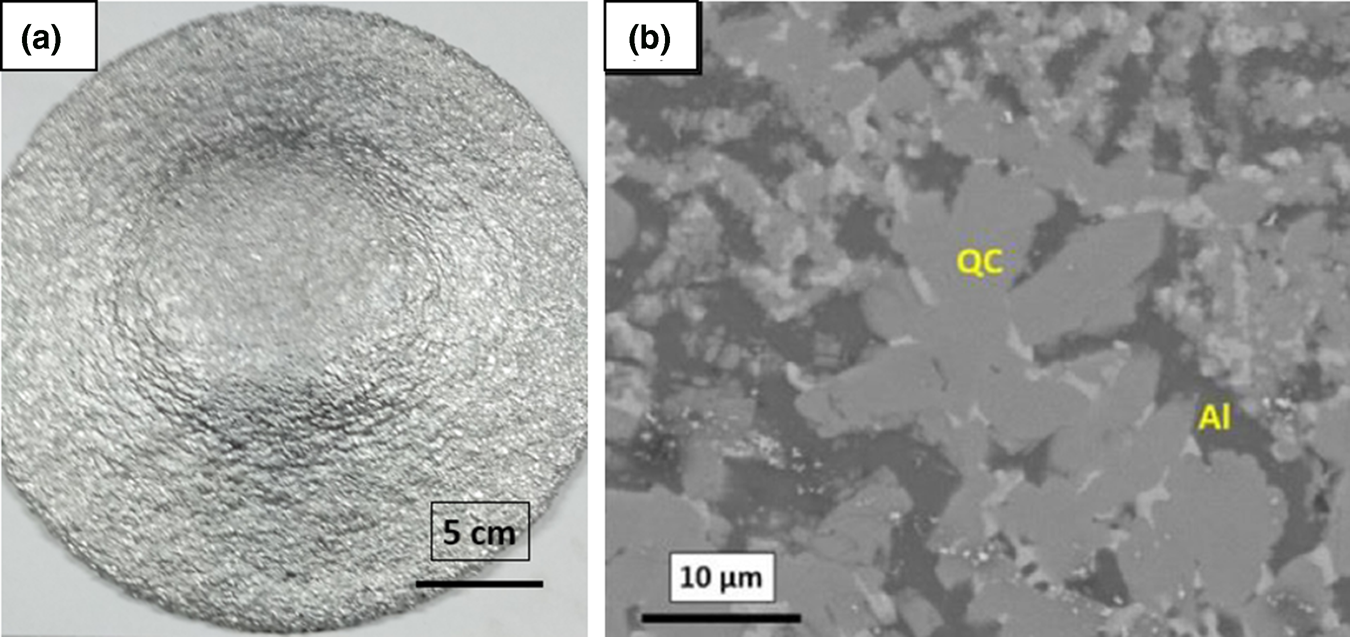

The spray-forming technique was also used to fabricate this composite and the quasicrystal phase was formed directly during solidification with no need of further thermal treatments to obtain the Al-FCC + quasicrystal microstructure in the bulk material. Figure 8(a) shows a ~2 kg composite sample, fabricated in a single processing step, by spray forming an Al85Cu6Fe3Cr6 (%at.) alloy. This sample was obtained directly from the melt during the solidification process and contained mainly the decagonal quasicrystal and Al-FCC phases [Fig. 8(b)]. This was a result from the solidification mechanisms of the spray-forming process. The atomized droplets that were completely or partially solidified during spraying of the metallic stream contained the decagonal phase, which forms as a primary phase upon rapid solidification [Reference Wolf, e Silva, Zepon, Kiminami, Bolfarini and Botta71]. When these droplets impinge the deposit being formed, they can be totally or partially re-melted. Considering the particles that were only partially re-melted, they will contain the decagonal phase that will then act as an inoculant for the further growth of this phase. Because of the spray-forming process characteristics, the material displays a coating-like microstructure (layered microstructure with porosity) and the low solidification rates the bulk material experienced during deposition led to formation of large quasicrystalline particles, which are appropriate for applications of this material on protection against wear and friction.

Figure 8: (a) ~2 kg spray formed composite with (b) microstructure consisting mainly of Al-FCC and quasicrystals. Reprinted from Wolf et al. [Reference Wolf, e Silva, Zepon, Kiminami, Bolfarini and Botta71]. Copyright (2020), with permission from Elsevier.

The sliding wear behavior of the sprayed composite was assessed by pin-on-disk tests which showed a superior performance of this material in comparison to an Al–Si A380 alloy when tested in two different conditions, showing half of the wear rate experienced by the Al–Si alloy. The coefficient of friction shown by the composite was also lower than the Al–Si alloy. In addition, the authors have shown in a recent publication [Reference Wolf, Koga, Schulz, Savoie, Kiminami, Bolfarini and Botta115] that this composite has a significantly improved (two times higher) wear resistance when compared to a single-phased Al–Cu–Fe–Cr decagonal quasicrystal fabricated by high velocity oxygen fuel spraying (HVOF). Most of the previously published wear-related studies on quasicrystalline materials are based on single-phased (or nearly single-phased) quasicrystals [Reference Dubois5, Reference Shaitura and Enaleeva69, Reference Lang, Sordelet, Besser, Schechtman, Biancaniello and Gonzalez116] and, although interesting results have been reported, the brittleness of the quasicrystalline phase leads to a transition on the behavior of these materials under sliding wear, depending on the load applied. However, adding a ductile second phase to its microstructure can reduce their load sensitivity, yielding materials and coatings with improved wear resistance.

Opportunities for Future Research

Based on the literature review performed in this work, potentially interesting opportunities for new research on the development of Al-matrix quasicrystalline composites can be associated with:

(i) The development of the next generation of high-strength aluminum alloys with appropriate ductility for application at room temperature, and especially at high temperatures, related to the Al–Cr–Mn–Co–Zr alloy. As discussed, this alloy can be processed by many thermomechanical methods and can yield materials with improved ductility at room temperature yet maintaining high values of tensile strength. There is room for research on the development and optimization of the manufacturing processes, especially regarding gas-atomization and thermomechanical processing, which are not trivial and decisive for the success of applying this material.

(ii) The Al–Cu–Fe–Cr system also appears among the most promising ones. Since it can be fabricated using virtually any metallurgical process, developing a viable casting procedure for obtaining high-quality MMCs can lead to improved tribological properties. In addition, there is room for assessing new compositions with different fractions of quasicrystal content depending on the alloy's composition. Another key point for further developing this MMC is to refine the quasicrystal particles, which can lead to improved mechanical strength.

Figure 9: Al-matrix composite reinforced with Al–Fe–Cr quasicrystals, fabricated in situ by SLM a powder mixture of Al–Cu–Fe–Cr quasicrystals and Al (a,b). (c) Simple and (d) complex shapes can be fabricated by SLM. Reprinted from Kang et al. [Reference Kang, El Mansori, Lu, Lin and Huang95]. Copyright (2018), with permission from Elsevier.

(iii) Technological applications of quasicrystalline-based coatings and surfaces with improved wear resistance are probably restricted to adding a ductile second phase to balance the quasicrystal's brittleness. There are many possible ways for obtaining this microstructure. The Al–Cu–Fe–Cr system is a very appealing one because the composite microstructure can be obtained as a coating or a bulk material, opening up several possibilities for processing strategies. Cold spraying metastable quasicrystals embedded in Al-matrix, such as the Al–Cr–Mn–Co–Zr alloy, is also a promising way to obtain these wear-resistant materials.

(iv) Additive manufacturing: the new manufacturing processes introduced for 3D printing metals, such as SLM, can be effectively used to fabricate MMCs reinforced with quasicrystals. The high cooling rates that can be achieved, make it possible to fabricate refined microstructures, which would, in turn, result in high-strength materials. In addition, the possibilities of fabricating complex shapes from gas-atomized powders (Fig. 9) and the significant industrial interest make this manufacturing process even more attractive.

Concluding Remarks

Quasicrystals certainly have unique properties that are of interest in many areas and, although technological applications of these materials have encountered several drawbacks, the latest achievements reported in the literature points out, in the author's opinion, an optimistic scenario for the next studies on the developments of new Al-matrix composites with improved properties and processability.

Recent developments in improving high-strength Al alloy compositions and processing routes can catalyze their application, especially at high temperatures, where commercial Al alloys cannot be used and Ti alloys are used instead. These high-strength quasicrystalline composites could certainly be applied in these cases if their mechanical properties and processing methods are adequate (and financially advantageous). This has been the focus of recent studies on these high-strength Al alloys. The recent discovery of the viability for producing, on a large scale, ingots of Al-matrix composites reinforced with Al–Cu–Fe–Cr quasicrystals can, on the other hand, catalyze their use in applications such as tribological and thermal protection.

Acknowledgments

The authors thank the institutional and financial support received over several years to research quasicrystalline alloys and composites, in particular, Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Universidade Federal de São Carlos (UFSCar), and Universidade Federal de Minas Gerais (UFMG). We also thank the colleagues in Brazil and abroad that have contributed to our quasicrystal-related studies.