Introduction

For decades, the link between manufacturing, economic development, and colonialism during the globalizing nineteenth and twentieth centuries has been subject to considerable debate. Dependency-school theorists have long argued that imperial ‘core’ countries stifled domestic handicraft industries in the ‘periphery’ by flooding colonial markets with manufactures from the metropole and coercing colonized people to produce raw materials.Footnote 1 Meanwhile, many neoclassical economists have contended that industrial development was inherently handicapped in much of the ‘Global South’ by endogenous factors, including purported ‘backwardness’ in non-Western societies, a lack of dynamism of indigenous elites, and/or geographic conditions that predisposed the south to focus on primary production, in lieu of manufacturing, to meet rising demand for raw materials in the ‘Global North’.Footnote 2 Although belonging to different ideological camps, both schools share certain key perspectives: first, that the ‘Western’ model of modernization was the road to development; second, that handicraft industries in the Global South were unable to withstand competition from machine-made imports; and third, that the ability of colonized regions to achieve economic growth was determined by demand and/or policies from the Global North, thus discounting indigenous economic agency. Crucially, however, the responses of local actors to both colonial policies and broader global economic forces could produce more complex outcomes than these outlooks allow.

An expanding empirical-historical literature has emerged that refutes the longstanding idea in the historiography of a rapid and straightforward ‘deindustrialization’ in the Global South during the second half of the nineteenth century. This revised perspective rests in part on a reframing of the concept of deindustrialization. Dependency and neoclassical scholars have narrowly cast deindustrialization as a relative decline in the output of industry compared to other economic sectors. However, recent studies have highlighted industrial resilience and even expansion – in terms of nominal output, labour force participation and innovation – in what have formally been identified as ‘de-industrialized’ regions. In particular, household-based handicraft artisans often survived and even prospered by utilizing labour- and skill-intensive methods instead of, or sometimes alongside, mechanized capital-intensive industries. In some cases, particularly in the Global South, such labour-intensive manufacturing provided a viable pathway to eventual structural change.Footnote 3 And even in places where labour-intensive handicraft industries did not ultimately generate a turn to mechanized industrialization, the resilience of handicraft sectors played a crucial role in enabling artisanal households across the Global South to make ends meet.

The most prominent example that has cast doubt on the consequences of globalization and colonialism for outright deindustrialization has been British India, where dynamic handicraft industries persevered by serving diverse internal markets, while mechanized mills developed alongside machine-made imports well into the twentieth century. Footnote 4 Recently, studies on other parts of the Global South have strengthened the case for a more nuanced take on deindustrialization. For example, regarding colonial Indonesia, where according to Jeffrey Williamson industry was damaged more ‘than almost anywhere else in the non-European periphery’, Footnote 5 several scholars have argued that various forms of textile production survived, and even thrived, despite Dutch colonial policies that targeted the growing Javanese population as a market for cloth produced in the Netherlands.Footnote 6 Likewise, historians have increasingly challenged preconceived assumptions about the de-industrializing effects of globalization in sub-Saharan Africa.Footnote 7 These works have all shown the importance of incorporating local factors and actors into explanations of industrial decline and resilience. Indeed, colonialism and global economic forces affected domestic industries across the Global South quite differently. In some cases global trade stimulated growth and evolution of local industries, while others experienced decline during the globalizing nineteenth century. Several studies have illustrated that where industrial decline did occur, it was often precipitated by shifting local dynamics rather than solely by competition with imported goods. In East Africa, for example, demographic disruptions in the nineteenth and early twentieth centuries played a central role in the eventual decline of industries in both southern Malawi and southwestern Tanzania, while Madagascar’s weaving industry suffered from exploitative forced labour policies that diverted labour away from manufacturing; meanwhile, textile industries in West Africa proved more resilient despite comparatively higher per-capita imports of machine-made cloth.Footnote 8

Most of the studies referred to above have been written by regional experts, and as of yet, ‘South-South’ comparisons on the resilience of local textile industries have been lacking. This paper aims to make such comparisons, and to identify inter-regional connections, with the aim of uncovering how local industries coped with the effects of colonization and broader global forces, building primarily on our previous work on the history of domestic cloth production in Java and sub-Saharan Africa. These particular regions at first sight may seem unrelated, located on separate continents and colonized by different European powers. Nevertheless, our cases display interesting cross-imperial interactions, which in recent years have been put on the research agenda as vital areas of study for furthering global history.Footnote 9 While we derive inspiration largely from Java and Africa, our conclusions may be more broadly applicable to relationships between global trade and local markets in the Global South during the nineteenth and early-twentieth centuries. We make particular reference to debates surrounding colonial India, which shared trade connections with both Java and sub-Saharan Africa and offers insights into certain characteristics of handicraft manufacturing that helped domestic producers in the Global South thrive amid globalization and colonization during these centuries. We place particular emphasis on one crucial, yet understudied element in the explanation for the resilience or relocation of local production: consumer preference.

Central to our argumentation are four hypotheses. First, we suggest that the ability of many handicraft textile industries to persevere and even flourish in the context of globalization was strongly linked to the capacity of local producers to more effectively and efficiently cater to certain segments of the consumer market than most suppliers of mass-produced imports. This provided domestic producers with a competitive edge in supplying particular products, thus allowing artisans to continue operating parallel to rising machine-produced imports. Consequently, even where local industries experienced a decline in the domestic market share, which indeed occurred across the Global South, this did not necessarily imply broad deindustrialization. Second, we contend that these local industries often benefited from global integration, which could simultaneously boost consumer demand, stimulate the development of new methods, and broaden access to industrial inputs. In fact, the often-assumed zero-sum relationship between handicraft and machine-based manufacturing obscures what in some cases could be complementary dynamics. Third, the capacity of producers to adapt to changing market conditions was indicative of the considerable degree of agency exercised by both domestic producers and consumers amid increasing colonial interventions that often aimed at diverting raw materials to metropolitan industrialists and funnelling metropolitan manufactures into colonial markets. Our fourth hypothesis is a caveat, which helps account for diverse industrial outcomes among handicraft industries in different locales: local conditions, such as geographical distance to markets, or increasing monetization, influenced the degree to which handicraft producers enjoyed – or effectively wielded – various advantages.

We begin by introducing our theoretical framework and outlining unique organizational and strategic characteristics of handicraft production in the Global South that enabled producers to remain competitive within key segments of the domestic market even in the seeming absence of a comparative advantage in industrial production. We focus specifically on how consumer demand particularities, producer access to industrial input supplies, and (seasonally) low production costs in the Global South could help domestic textile industries thrive in the midst of globalization. Thereafter, we detail how various local industries fared when confronted with colonial interventions in local production processes and markets, highlighting the agency of local producers and consumers in response to policies that often directly aimed at undermining manufacturing and securing domestic raw materials for metropolitan industrialists.

Complicating the market: Comparative advantage, competitive advantage

Market-oriented deindustrialization arguments derive their theoretical foundations from basic Ricardian trade theory: from the nineteenth century, world regions with a comparative advantage in manufacturing (primarily in the Global North) prevailed as providers of industrial goods to the global marketplace, while regions with a comparative advantage in raw materials production (the Global South) abandoned manufacturing for domestic markets in favour of tropical commodity production oriented toward global markets.

India has long been a crucial case in the deindustrialization thesis given that Indian artisans, who had once supplied much of the world’s clothing, rapidly lost important export markets in Asia, western Africa, and Europe as cheaper mass-produced cloth increasingly flowed out of the industrializing Global North by the late eighteenth century. At nearly the same time, India began exporting substantial quantities of raw cotton and importing machine-made British cloth.Footnote 10 But despite this dramatic shift in the composition of India’s global trade and the loss of the sub-continent’s large export markets, deindustrialization did not progress in a clear, linear fashion. Through the nineteenth and early twentieth centuries, significant portions of the Indian artisanal sector adapted to altered global economic conditions and thrived alongside factory-produced imports by incorporating new technologies and materials and, above all, focusing on extensive variegated consumer markets within India. As of the 1920s, artisanal weavers reportedly still supplied 20% of the cloth on the Indian market and by the late 1930s, accounted for 25% of the market share by value, which Roy suggests may have even been as high as 54% when non-cotton fibres are included.Footnote 11 Meanwhile, a domestic mechanized textile sector emerged in some Indian towns, Bombay in particular, by the last quarter of the nineteenth century. These domestic factories supplied both coarse cloth to Indian consumers and low-cost yarn to artisanal weavers, while they exported yarn to East Asia and cloth to external markets, including East and West Africa, where Indian-made factory products competed fiercely with British versions.Footnote 12 Although the share of textiles in India’s total export value had declined considerably since the early nineteenth century, absolute exports were on the rise by the late nineteenth century, growing steadily from 14.9 to 390.1 million yards between 1878 and 1940.Footnote 13

Domestic manufacturers in the historically much more internally-oriented handicraft textile industries of Java and sub-Saharan Africa were not confronted with similar nineteenth-century crises of diminished export markets, but they did face largescale imports of factory-produced cloth from the nineteenth century onward. Nevertheless, as in India, many artisanal manufacturers continued to thrive amid increasing supplies of machine-made cloth from industrializing countries, which seem to have competed more directly with each other than with artisanal products. In West Africa, British factory-produced cloth ousted Indian handloom products during the nineteenth century, only to be confronted with cheaper factory-made imports from Japan and India in the 1930s, which Johnson points out were ‘cheap enough to drive half the English cottons off the West Africa market – but not, apparently, to drive out local production.’Footnote 14 The Tiv of Nigeria, for example, consumed large amounts of imported cloth by the 1950s, but reportedly still wove more than half of the cloth consumed in the region along with large quantities for nearby markets.Footnote 15

The adaptation and survival of handicraft manufacturers in places like India, Java, and sub-Saharan Africa well into the twentieth century is a clear indication that simple comparative advantage – based solely on price dynamics – is an insufficient explanation of industrial vitality. We suggest that artisans could wield distinct competitive advantages in relation to consumer demand that allowed them to thrive in the marketplace alongside often cheaper machine-made products. Footnote 16 The concept of competitive advantage extends beyond the comparative cost of factors of production by also taking into account additional factors that may allow producers to offer qualitatively superior goods (or services) relative to their rivals. These factors can, for instance, include the skill, quality, or organization of the labour involved in production; the ability of the producer to match output with consumer expectations, dictated partly by intimate market knowledge; and/or targeted branding and marketing strategies that allow producers to compete with their market rivals. The concept arose from studies of strategic competitive practices among largescale modern firms, but it provides a surprisingly useful framework for historically investigating market dynamics and producer strategies that enabled small-scale handicraft manufacturers to remain viable. Footnote 17

In the nineteenth century, artisanal textile manufacturers and factory-based producers shared a unifying industrial thread – both utilized raw materials to turn out cloth geared toward consumers. Here, however, the similarities fade. We argue that much of the oversimplification inherent in market-centred deindustrialization conceptualizations arises from the conflation of what were, in fact, fundamentally different – and in some ways complementary – industrial entities. At the heart of competitive advantage theory are two ‘alternative, viable approaches’ to coping with competition: ‘cost leadership’, which centres on delivering the lowest-cost product to compete on the basis of price, and ‘differentiation’, which entails delivering unique products and/or services to compete on the basis of quality. Footnote 18 In addition, while some producers focus on specific niche markets, others cater to a much broader range of consumers.

We argue that as factory production in the the ‘core’ began to rapidly increase during the nineteenth and early twentieth centuries, domestic handicraft producers in many parts of the ‘periphery’ innately pursued clear differentiation strategies. These were influenced in part by path-dependent structural features of local handicraft industries and provided numerous niches for domestic manufacturers to serve highly specified local markets. In sharp contrast to handicraft manufacturers, many largescale machine-based textile mills pursued cost-leadership strategies that hinged upon uniform production of comparatively cheap and plain cloth, geared toward mass consumption.Footnote 19

Handicraft and machine-made products generally diverged sharply in qualitative terms, particularly during the early developmental stages of factory-based manufacturing. As we will illustrate, not only were nineteenth- and early twentieth-century hand-woven products often higher in quality due to a greater focus on craftsmanship, they were also precisely geared toward differentiated consumer preferences. This constituted a competitive advantage afforded by both the closeness – in physical and cultural terms – of domestic producers to their consumer base and the greater flexibility of small-scale producers to quickly alter their design methods to accommodate specific – and changeable – consumer demands.

Even where factory production arose within the Global South, as in India, artisans and mass manufacturers could co-exist, provided they pursued different competitive strategies. Critics of the classic deindustrialization thesis have argued that differentiated strategies and adaptation were key to Indian artisans’ ability to adapt to changing conditions amid both rising machine-made imports from British factories and the growth of Bombay’s mills, which churned out large amounts of cheap mass-produced cloth but moved ‘parallelly’ with artisanal manufacturers, ‘rather than encroaching on one another’s market’.Footnote 20 While mills focused on producing cloth for less intricate garments, like men’s shirts and pants, artisans dominated the market for more complex materials used for women’s blouses and saris, reflecting a ‘polymorphic’ structure in the Indian textile industry.Footnote 21

In contrast to mass manufactures, artisanal items were often – though not exclusively – geared toward higher segments of the market, implying a smaller overall market share. However, handicraft products could reach a wider consumer base as production costs for elaborate artisanal products declined with the introduction of imported inputs and new technologies. For example, the adoption of cost-reducing methods to produce imitation silver thread enabled Surat’s jari manufacturers to enlarge the industry by marketing their products to non-elite consumers, leading to a twelve-fold expansion in employment between 1916 and 1930.Footnote 22 We see a similar ‘democratization’ of expensive, hand-painted batiks with the emergence of block wax-printing techniques in colonial Indonesia (next section). Even where machine-made cloth, imported or otherwise, ultimately came to account for a larger overall share of local markets, this did not necessarily mean that the output of handicraft industries was in sharp decline, particularly given that cloth consumption was broadly rising in much of the Global South during the nineteenth and twentieth centuries. In fact, as Johnson points out with respect to West Africa, some handicraft sectors may have even been expanding their absolute output well into the second half of the twentieth century as per-capita consumption soared.Footnote 23 Similarly, Morris notes that even when India’s handloom industry experienced a 5% decrease in its total domestic market share between 1900 and 1914, its nominal output was continuing to expand.Footnote 24

The ability of handicraft manufacturers to effectively adapt to shifting global economic conditions depended upon local characteristics, which helps account for varying degrees of industrial resilience among handicraft textile industries in the Global South. Chief among these conditions were: ingrained regional textile traditions, which afforded artisanal know-how and intimacy with consumer markets; an ample industrial labour supply, required for labour-intensive production; proximity (or trade-network connections) to local markets, which provided consumer outlets for both domestic and imported cloth; and, finally, ready access to global markets, which supplied new sources of industrial inputs, stimulus for local manufacturing innovations, and income-generating export opportunities that could boost domestic demand for consumer goods. Footnote 25 These local conditions could, in turn, influence the relative capacity of producers to respond flexibly to new international trading challenges (and opportunities) that emerged under colonialism and globalization. A full analysis of the implications of globalization and colonization for domestic handicraft industries must thus move beyond a simple market-oriented accounting of factor prices or dependency-oriented narrative of colonial manipulation. We must instead closely examine the characteristics of these industries and the markets they served, which helped determine the relative competitive advantage, and thus viability, of local handicraft manufacturers.

Local consumers and the power of preference

While global textile exporters effectively dominated large segments of local textile markets, particularly for plain grey and bleached cloth, they were ill-equipped to compete in others. As Richardson has pointed out with respect to sub-Saharan Africa, cloth consumers were highly selective and would regularly reject products that did not suit their tastes or needs.Footnote 26 Prestholdt has shown that the specificity of consumer demand in East Africa was so strong that it directly influenced the output of foreign textile producers seeking to capture the region’s market.Footnote 27 While producers sought to accommodate local demands, the ability of factory-based manufacturers to efficiently and successfully adapt to specific, and often shifting, local fashions was constrained by the very nature of globally oriented mechanized manufacturing. The cost-reducing production tactics pursued by many factory-based manufacturers necessarily relied on a strategy of minimizing their range of products to keep costs low.Footnote 28 Even among advanced industrial producers, Porter notes, where there is ‘complex segmentation within geographic markets … the local firm will be well suited to perceive and adapt to the various segments of the local market’.Footnote 29 Moreover, the flexibility of early factory-based production was encumbered by the very machines that helped speed up production. Alterations to products were often slow and expensive, leading most mass producers to focus on low-cost output of large quantities of standardized products.Footnote 30 Haynes argues that in the context of nineteenth-century India, where demand for elaborate designs was in ‘continual flux’, artisanal producers quickly altered their manufactures, exhibiting ‘flexible specialization’ that enabled them to remain current, while ‘mass-producing mills with elaborate divisions of labour, heavy investments in capital, and inflexible technologies were at a serious disadvantage in meeting these needs of consumers’.Footnote 31

Likewise, skilled local weavers in sub-Saharan Africa were well positioned to accommodate high consumer specificity, even down to the demands of particular clients. A missionary in early-twentieth-century Ufipa (southwestern Tanzania), for example, noted the diverse preferences of consumers, which arose from considerations of ‘taste, vanity or rank’. These were only ‘minor complications’ for skilled weavers, who could deftly accommodate various requests and alter prices according to the complexity of design.Footnote 32 Importantly, artisans were attuned to fluctuations in local consumer demand and often responded by developing new designs and fashions to suit shifting tastes. In mid-nineteenth-century Ufipa, rising local incomes – stimulated by the region’s engagement with nineteenth-century ivory traders – led to demand for a wider array of high-quality products among regional elites. Weavers responded by developing methods for spinning finer thread and began incorporating a wider array of colours to produce elaborate patterns. Although elite consumption had initially stimulated these craft developments, average consumers too began to desire more elaborate domestic garments offered by local artisans.Footnote 33 In southern Nigeria, female weavers in the Igbo town of Akwete likewise developed elaborate patterned and brocaded cloths in response to growing demand stimulated by rising cash crop export profits during the mid-nineteenth century.Footnote 34 Aronson notes that Akwete weavers, who were producing on a nearly full-time basis well into the late-twentieth century, could skilfully produce ‘an almost infinite array of designs’, enabling them to accommodate specific consumer commissions and even reproduce high-quality artisanal versions of particularly popular import patterns.Footnote 35

Similarly, textile manufacturers in Java were keenly aware of shifts in domestic consumer needs. As the next section illustrates, Javanese textile manufacturers developed new products during the nineteenth century to accommodate increasing demand among local consumers. In doing so, they would effectively oust machine-made imports that unsuccessfully attempted to replicate and replace traditional Javanese materials.

Dutch prints in Java and Africa

The case of European factory-produced textile exports to Java illustrates how efforts to compete with local varieties in Global South markets often resulted in disappointment. For example, during a brief period of British colonial rule in Java (1811–16), British merchants attempted to introduce English-made calicoes that they believed would suit local consumer tastes. However, in 1815 Lieutenant-Governor Sir Thomas Stamford Raffles noted that the quality of these imports left much to be desired. The British had sent a first trial of factory-dyed wax-print imitations based on specific Javanese and Malayan patterns to Java, but they soon found that local consumers were not interested in the fabrics because ‘the natives had discovered that the colours would not stand, and the remainder were no longer in demand’.Footnote 36

Alongside durability, design was also a crucial consideration for the discerning consumer. Many foreign travellers were amazed by the traditional Javanese handicrafts, like hand-painted batik tulis textiles, ‘which, concerning their designs, could educate European masters’.Footnote 37 Producing the traditional Javanese hand-painted batik tulis was a labour-intensive and expensive process that was moreover geared to satisfy local tastes of particularly elite consumers. In Central Java, for instance, fashions were highly influenced by the sultans in the kratons (palaces), who traditionally favoured specific colours and patterns. In the northeast coast of Java, with its longstanding batik production and trade traditions, producers had much more flexibility to adapt quickly to the different tastes of domestic as well as foreign consumers, such as Europeans, Chinese, and Japanese, which were often much more playful and colourful.Footnote 38 Still, batik tulis catered to relatively upper-end segments of the local market for cloth. For lower-income Javanese consumers, the emerging low-priced factory-printed cloth had initially been an attractive alternative, even if the quality was not as high as the locally produced – but largely unaffordable – batik cloth. However, in the 1860s local producers developed new techniques to compete with printed imports in the middle- and lower-market segments on the basis of quality and price. Enterprising Javanese artisans developed wax-print stamping techniques (cap batik) that could more closely approximate traditional hand-painted batik designs than could Dutch producers, enabling local artisans to quickly reclaim the lower end of the market, as the production costs, and thus prices, of cap batik were much lower.

Although symmetrical cap batik prints did not perfectly replicate the more beautiful (and pricier) hand-painted batik tulis, the locally hand-stamped prints still suited local tastes far better than mass-produced imports. Consequently, if Javanese peasants could not afford the more expensive batik tulis, they would overwhelmingly choose the locally stamped cap batik over cheaper imported materials.Footnote 39 Contemporaries noted that this local product innovation successfully started to outcompete much of the factory-made wax-print imitations from Europe.Footnote 40 One observer around 1900 even called the new technique ‘the answer of the Javanese batik industry to European factory competition’.Footnote 41 Ultimately, Dutch merchants were forced to seek out alternative markets for their export-oriented prints, particularly in East and West Africa, where they could be more effectively marketed.Footnote 42

For example, the Dutch textile printing company P.F. Vlissingen & Co. (Vlisco) shifted attention to the Swahili Coast of central East Africa, where global trade was concentrated on the small mainland-adjacent island of Zanzibar. Here, Dutch-made prints proved far more successful than on Java, partly due to specific local circumstances and partly due to particular production and marketing strategies employed by Dutch manufacturers, which ideally suited the region’s demand conditions.Footnote 43 From the mid-nineteenth century, resident Indian merchants and local Swahili women had begun stamping imported cloth to enrich plain textiles.Footnote 44 A domestic weaving industry was also beginning to emerge on Zanzibar, spurred by the island’s rise as a global entrepot and the recent settlement of artisans from India and the Arabian peninsula.Footnote 45 However, these industrial activities were still in an early developmental phase when Dutch prints (transported by German merchants) entered the market during the final decades of the nineteenth century. Thus, unlike in Java, the prospect of stiff competition from locally manufactured prints was consequently minimal, one crucial factor for the success of Dutch prints in the region. At the same time, highly developed information networks on the island of Zanzibar and the adjacent coastline provided foreign merchants with detailed information on local demand that could be quickly transmitted to Dutch printers, thus helping to mitigate the endemic problem of ‘delays in responding to markets that can be unacceptable’ in the business of fashion and undermine the capacity of foreign producers to serve distant consumers.Footnote 46 Indeed, designs, which included ‘birds, leaves, flowers, words, sentences or even proverbs’ were ‘frequently suggested locally, particularly from Zanzibar’.Footnote 47

Perhaps most critical, however, was the unique production strategy employed by Dutch printers, who actively favoured product differentiation over mass production in order to serve the specific needs of Swahili consumers. As Ryan points out, Dutch textile printers utilized the cheap labour of children and old women to cost-effectively hand-stamp very small quantities of frequently changing patterns – commissioned on the basis of specific demand information obtained from Zanzibar – on cloth imported from Manchester to serve the ‘insatiable demands’ of Swahili women for ever-changing designs of what became known as kanga cloths. They had found that ‘return on investment was guaranteed if the market was carefully considered’, while British firms, in contrast, which mass-produced prints using copper rollers, struggled to capture the Swahili market during the nineteenth century.Footnote 48 Dutch wax-prints had also been introduced with success in the Gold Coast (modern-day Ghana) and other West African markets in the late-nineteenth century, where they continue to remain popular today, with Vlisco maintaining its targeted approach of catering to precise local demand patterns.

Imports: Complements or substitutes?

The marked success of Dutch prints in Africa helps underscore the importance of product differentiation in Global South markets and illustrates that the differentiation strategy that benefited local artisans could also be effectively employed by foreign producers – provided that they were willing to favour quality over quantity. Still, however, this did not imply that successful imports were positioned to displace domestic textiles. As Porter notes, ‘product differentiation … creates layers of insulation against competitive warfare because buyers have preferences and loyalties to particular sellers’ if they offer highly valued, unique products.Footnote 49 Consequently, in many cases, cloth imports did not function as direct substitutes for domestic textiles; instead, they took on a more benign position as complementary products that were consumed alongside locally made products. Indeed, this principle helps explain why Dutch wax-prints struggled in Javanese markets – where similar local cloths outcompeted imports – but performed better among consumers in East and West Africa, where designs inspired by Javanese batik were novel complementary products alongside domestic cloth, such as kente cloth produced on the Gold Coast (see Figure 1).

Figure 1. Detail of Javanese batik & Gold Coast kente cloth, late-nineteenth to early twentieth century.

Sources: Javanese batik from Vlisco archives, 19th century (left): https://stories.textilehive.com/vlisco-dd07e10c70b4; Ewe Kente Cloth, late 19th-early 20th century (right): Brooklyn Museum, Robert B. Woodward Memorial Fund, 71.211.

In West Africa, Thornton points out, regions that were significant importers of factory-made cloth also tended to be substantial producers of cloth.Footnote 50 West Africa’s early engagement with Atlantic trading had exposed the region to imported materials for several centuries – comprised of handmade cloth from India and Europe from the seventeenth century and then of machine-made textiles from the nineteenth century.Footnote 51 Yet local industries remained resilient, even as imports per capita progressively increased and then surged in the nineteenth century, tripling between the 1850s and 1900.Footnote 52 Fage notes that rising imports were illustrative of a growing consumer base that was simply purchasing more cloth and in wider varieties, including both domestic styles and products from abroad.Footnote 53 Consequently, even where imported cloth was met with success in West African markets, the presence of these materials did not result in the demise of popular domestic varieties. Even today, Ghana’s signature loom-patterned kente cloth, for example, continues to flourish alongside patterned Vlisco prints. In the river delta area of southern Nigeria, where imported cloth has been integrated into the local economy for several centuries, Aronson found in the early 1980s that imported cloth and regionally made textiles (including Akwete cloth) served different functions in local ceremonies, illustrating the depth and persistence of complementarity even as imports have become increasingly plentiful.Footnote 54

In parts of East Africa, imported cloth likewise served complementary functions alongside domestic cloth in areas with deeply entrenched local textile traditions. Take, for example, the largescale imports of plain machine-made cloth exported to East Africa during the nineteenth century. Nearly all cloth imported from the United States from the 1830s onward was unbleached merekani – America’s ‘greatest trade staple’ in East Africa.Footnote 55 So too was most of the cloth shipped from Bombay, which entered the region in rapidly growing quantities from the late 1870s (see Figure 2). Both plain unbleached and basic dyed cloths took on unique use-values on the coast, as a form of collateral,Footnote 56 and in much of the interior, where they circulated as the principal commodity-currency along caravan trade routes crisscrossing inland Tanzania up to the end of the nineteenth century. As such, imported cloth rose immensely in value in the interior, leaving ample space for locally made cloth to serve clothing functions, particularly in places like Ufipa, where domestic weavers produced elaborate patterned designs often based on particular consumer requests.Footnote 57

Figure 2. Exports of cloth from Bombay to East Africa, 1871–1909.

Source: Bombay Presidency, Annual Statement of the Trade and Navigation of the Presidency of Bombay (Bombay: Government Central Press, various issues 1871–1910).

In contrast, weavers along the Benadir Coast of what is today Somalia, had long specialized in the production of plain white cloth. Consequently, plain imports would ultimately pose a greater competitive threat here, especially unbleached American cloth, renowned for its exceptional durability, which set it apart from products exported by other industrializing countries.Footnote 58 However, competition from abroad incentivized innovation among Benadir weavers rather than destroying the local industry. Weavers deftly adapted by developing a new product – striped futa benaadir – which accorded with rising regional demand for patterned cloth. By differentiating their products, Benadir weavers secured a new competitive advantage.Footnote 59 The striped patterns were so popular that German manufacturers attempted to replicate colourful Benadir products in the early decade of the twentieth century, but the lower-quality imitations – which failed to hold their dye and contained large amounts of gruel (a substance used to bulk up fabric) – were reportedly ‘much less esteemed by the natives’, who could detect the imported versions by both feel and smell.Footnote 60

In nearby Ethiopia, plain imported cloth similarly became increasingly available during the nineteenth century but was generally used for the production of utilitarian trousers, whereas overlaying shamma robes, the focal piece of traditional Abyssinian dress, continued to be largely produced by domestic weavers. Foreign mass-manufacturers introduced machine-made shammas, but as in the case of Dutch prints in Java and German imitations of futa benaadir in Somalia, foreign-made replicas failed to compete with local versions on the basis of quality. A British consular official noted that ‘native woven shammas are of finer quality and more lasting than the imported’ and reported that imported versions struggled to compete, particularly as increasing amounts of imported yarn helped to reduce the cost of domestic shamma production.Footnote 61 During the same period, local artisans in Zanzibar often transformed plain imports into more palatable cloth by hand-stamping designs and attaching colourful locally woven border pieces.Footnote 62

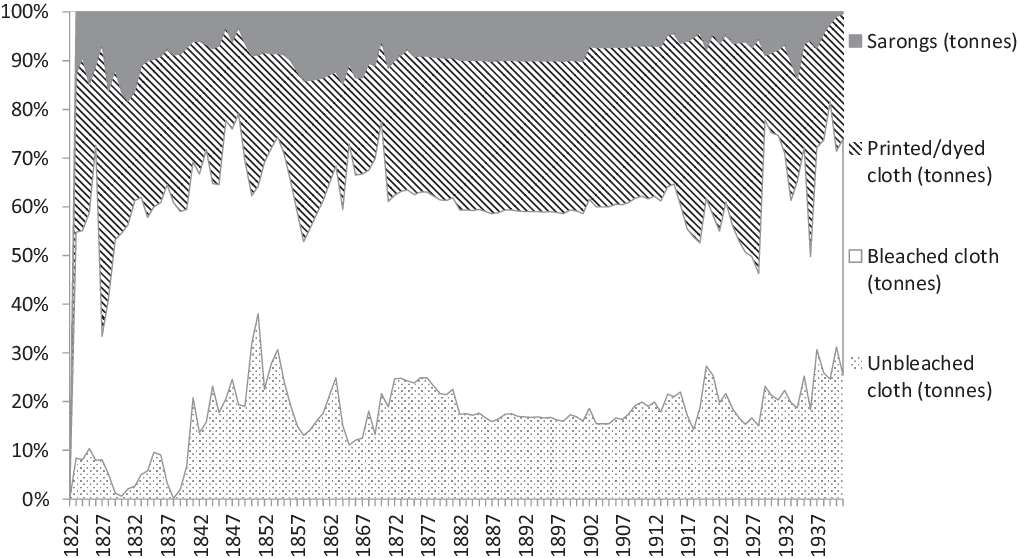

In Java, too, plain imported cloth filled a largely complementary niche alongside elaborate domestic patterned cloth and even helped supplement local industrial developments by providing cheap unbleached ‘canvases’ on which local printers could create fashionable designs for the local market. Thus, while Dutch imitation wax-prints struggled to maintain footing in Java, unbleached and bleached cloth fared better, making up over half of the volume of cloth imports entering the colony between the 1820s and 1930s (see Figure 3). When the Dutch retook colonial control from the British in 1816, they copied Britain’s earlier initiatives to corner Javanese markets with Dutch-made cloth in an effort to stimulate the lagging Dutch textile industry.Footnote 63 Although imports of cotton cloth from the Netherlands rose dramatically, with a seven-fold increase between 1830 and 1900, import quantities supplied no more than one-third of local demand towards the end of the nineteenth century.Footnote 64 This should also be seen in the context of spectacular population growth: whereas the Javanese population numbered just under 11 million people in 1831, this figure had nearly quadrupled to 41 million a century later.Footnote 65 Despite rising imports of factory-made cloth over the course of the nineteenth century, the majority of this rapidly expanding Javanese consumer base was still being served by indigenous handicraft production around the turn of the twentieth century.

Figure 3. Composition of cloth imports to Java (in volume), 1822–1940.

Based on: Database Indonesian Textiles (Creator: Pierre van der Eng), version 2015.

The weaver’s toolkit: Industrial inputs in the Global South

The particularities of consumer demand addressed in the preceding section have been given scant attention by most theorists of deindustrialization, who emphasize the purported ability of machine-produced imports to effectively outcompete locally made cloth on the basis of cost. Williamson, for example, highlights declining nineteenth-century transportation costs and technological innovations that enhanced global market integration and stimulated already existing patterns of specialization: Global South producers increasingly focused on exporting raw materials – which were rising in price due to growing global demand – while the industrializing Global North supplied the world with comparatively low-cost industrial products. The result was widespread deindustrialization in the ‘periphery’. Footnote 66 Scholars have assumed that, within the context of globalization, geographic protection from global market forces was thus a key determinant of the survival of local textile manufacturers.Footnote 67

Transportation and transaction costs indeed lowered dramatically over the nineteenth century, and a terms-of-trade boom for agricultural products certainly took place in much of the Global South. However, a close inspection of differences in the supply of industrial inputs in handicraft versus factory production systems suggests that assumptions about the superior cost-reducing advantages of factory-based manufacturing require much nuancing, as do suppositions regarding the necessary trade-off between export-oriented agriculture and locally oriented handicraft manufacturing. Indeed, in this section, we illustrate that alongside the demand-based benefits that helped ‘insulate’ local textile industries from the competition of global substitutes, domestic manufacturers also benefited from specific supply-side advantages that helped them continue to thrive amid rising imports. The particular supply advantages enjoyed by Global South producers were afforded in part by local economic conditions and by new opportunities that emerged with mounting global trade integration.

Seasonality and labour costs

In the context of certain focused differentiation strategies geared toward supplying unique products to elite consumers, price was of little importance. In fact, efforts to reduce price could prove counter-productive since conspicuous consumption among elites often ‘depends on the expensiveness of the product’, a dynamic not lost on weavers catering to a growing population of ‘middle class’ elites, as, for example, in nineteenth-century southern Nigeria and Ghana.Footnote 68 However, for lower-income domestic consumers, price did remain an important consideration. Even here, many Global South handicraft producers serving broader consumer groups enjoyed cost advantages that are obscured in deindustrialization narratives that focus exclusively on technological change as the principal determinant of low prices.

Of particular importance was the nature of supply costs for both labour and raw materials in the Global South, which could partially off-set the cost advantage of machine-made substitutes. Although manufacturing a piece of handicraft cloth is more labour-intensive than mechanized manufacturing, the labour costs of handicraft manufacturing can be remarkably low within certain local contexts. Where agricultural labour burdens are highly seasonal and weavers concentrate their manufacturing work during the dry, non-agricultural season – as in much of the Global South – the cost of industrial labour could be close to zero. Many weavers in the Global South were self-employed artisans and part-time subsistence farmers who could supply their alimentary needs regardless of income, meaning that their cost of living was not passed on to their consumers in the form of elevated cloth prices. As Johnson has reflected, ‘The part-time specialist working for pocket-money […] can undercut the man who has to earn his living by the craft alone, and he can even, under favourable circumstances, undercut factory production’.Footnote 69

Across sub-Saharan Africa, weaving was largely undertaken on a seasonal basis. Consequently, although the continent has historically been comparatively labour-scarce, Austin points out that during the dry season, industrial labour became plentiful and cheap.Footnote 70 Moreover, entire households often engaged in various facets of the manufacturing process. On East Africa’s Benadir Coast, for example, nearly all members of industrial households were integrated into manufacturing tasks, providing substantial supplies of industrial labour that required only the ‘provision of food and shelter’, an advantage that Alpers argues played a significant role in the local industry’s capacity to compete with imports on both a quality and cost basis.Footnote 71 In India, handloom weaving did not always take such a strongly seasonal character, for example, in semi-urban communities in western and southern India where male weaving castes produced cloth year-round.Footnote 72 However, textile-producing households often maximized family labour akin to weaving households on the Benadir Coast, with men weaving and women and children preparing yarn and handling vital domestic tasks.Footnote 73

As in sub-Saharan Africa, observers in nineteenth-century Java remarked on the competitive prices of high-quality indigenous fabrics, in this case owing to the low cost of weaving labour performed by rural Javanese women who wove seasonally and as a form of low-cost by-employment. As was noted in 1890: ‘That which the industrious mother of the house produces more than is needed for the clothing of the family, she brings to the market. Indeed, it is only a plain tissue, but due to the reliability of the good and its low price […], this indigenous fabric can easily compete with the European calicoes, which testifies to the fact that cheap is expensive’.Footnote 74 Indeed, the high durability of cheaply produced, but high quality hand-made cloth – which was similarly noted by observers in sub-Saharan AfricaFootnote 75 – further offset possible cost differences given that lower-quality machine-manufactured cloth required more regular replenishing.

At the same time, the fact that weaving often occurred primarily during the agricultural slack season or as a form of by-employment in much of the Global South undermines deindustrialization assumptions that rising exports of tropical commodities necessarily required a reallocation of labour from industry to agriculture. Weavers, or members of their household, could engage in export-agricultural work for part of the year and then shift labour to textile manufacturing when cultivation tasks temporarily abated in the agricultural off-season. In fact, rather than destroying local industry, a rise in agricultural exporting often stimulated local manufacturing. Iliffe reflects that in West Africa, domestic industry remained most competitive where cash-crop wealth enhanced demand for high-quality garments.Footnote 76 In south-eastern Nigeria’s Igboland, for example, the development of new patterns and brocading methods by Akwete weavers had been stimulated by rising palm-oil export profits that generated demand for new fashions among increasingly variegated consumer classes.Footnote 77

In Java, the extractive Cultivation System (1830-ca. 1870, see below) implemented by the Dutch did lead to a notable rise of cash crop production, which consumed more of farming households’ time, and certainly in the first phase of the system posed an immense financial burden on Javanese peasants, contributing to severe poverty and even famine in the 1840s. In the longer run, however, the system also induced monetization of the economy and the creation of an infrastructure that stimulated local and regional trade – including the exchange of locally produced cloth.Footnote 78 A simultaneous rise in population and incomes in the 1860s and 1870s likely enhanced demand for textiles, both in nominal and per-capita terms. According to Van der Eng, the average annual consumption of cotton cloth increased to 0.9 kilograms per capita (around two sarongs) in the late nineteenth century.Footnote 79 As several authors have suggested, this probably did not result from rising real wage levels, but from the increased time that different members of the Javanese household spent on agricultural labour alongside additional non-agrarian income-generating activities.Footnote 80

Local and global materials

Along with structurally low labour costs for many handicraft manufacturers, Global South artisans also often enjoyed comparatively low prices for material inputs, a cost-reducing advantage afforded by multiple access points – both local and global – to industrial raw and semi-finished materials. These included: household-based cotton cultivation, local raw cotton and yarn markets, and global sources of machine-produced yarn and semi-finished cloth.

Weaver-farmers in climates suited to cotton growing not only had the capacity to produce their own raw materials (which involved only the opportunity cost associated with alternative cultivation or foregoing income generated from exporting raw cotton) but could also buy from local suppliers. In northern Nigeria, for example, large plantations produced raw cotton and indigo for the region’s textile industry.Footnote 81 Likewise, nineteenth-century cotton plantations established in fertile inland areas adjacent to East Africa’s Benadir Coast provided low-cost supplies of raw cotton to textile producers in Mogadishu.Footnote 82 In 1891, an Italian observer pointed to the ‘extremely low price of the cotton which is cultivated in the neighbouring regions and […] the limited cost of labor’ as key variables in the region’s competitive advantage.Footnote 83

In Java, peasants also traditionally grew their own cotton, which was spun by (usually female) household members. Surpluses of yarn were then sold at local markets. However, hand spinning was highly time consuming, and profits for handwoven cloth were higher than for hand-spun yarns. When factory-made cotton yarns became increasingly available through imports, many Javanese women shifted to buying these in local markets and devoting more of their time to weaving (see Table 1). Similarly, in India, machine-made yarns from Britain and, later, Bombay mills considerably reduced production costs for weavers located near rail lines, as did the adoption of imported synthetic dyes from Germany.Footnote 84 However, whereas Indian hand spinners consequently practically disappeared, in Java, local cotton yields continued to increase until at least the First World War,Footnote 85 so we may assume that hand spinning was not entirely eradicated, especially in more peripheral regions where yarn markets were less developed. This all implies that the low-opportunity-cost labour of rural women was extensively employed in handweaving and spinning and that, at least in absolute terms, their numbers swelled up until the mid-1910s, not suggesting outright deindustrialization but rather persisting industrial activity in terms of labour force participation.Footnote 86

Table 1. Estimated woman years of weaving labour needed to process imported yarn (own calculations), Java, 1830–1920

Sources: H. Muller Szoon, De Nederlandsche Katoennijverheid, en het Stelsel van Bescherming in Nederlandsch-Indië (Rotterdam: H.A. Kramers, 1857); Statistisch Instituut, Bijdragen van het Statistisch Instituut (Amsterdam: Het Statistisch Instituut, 1887); W.L. Korthals Altes, General Trade Statistics 1822–1940. Changing Economy of Indonesia, Vol. 12 (Amsterdam: Royal Tropical Institute, 1997), 107–112; G. Dalenoord, ‘Textiel-nijverheid in Nederlandsch-Indië’, Koloniale Studiën (1926): 172.

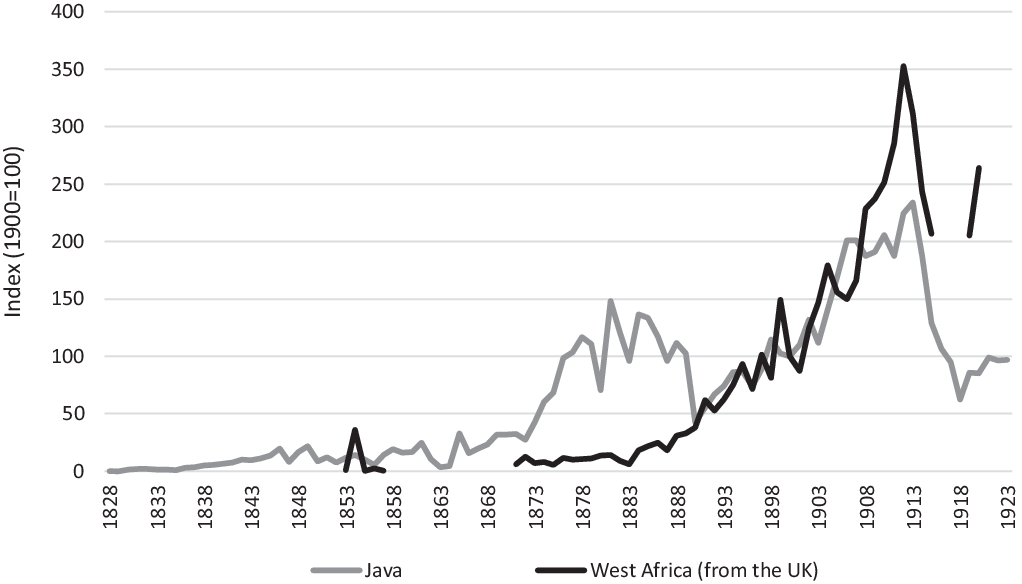

In Africa, too, handicraft producers who were well connected to global markets could purchase imported industrial inputs. Already in the Early Modern period, Portuguese colonists in southern East Africa had noted that artisans often unravelled coloured imported cloth to obtain yarn for domestic weaving.Footnote 87 By the nineteenth century, factory-made yarns were increasingly adopted, diminishing spinning labour and offering weavers a wider range of colours, thus simultaneously increasing quantitative and qualitative output possibilities. Benadir weavers, for example, began employing colourful imported yarns alongside locally made yarn by the late-nineteenth century in the production of their colourful futa benaadir.Footnote 88 Weavers in much of West Africa also began incorporating machine-made yarn by the later part of the nineteenth century, as did weavers in Java (Figure 4).

Figure 4. Index of yarn imports into Java and West Africa, 1828–1923.

Sources: Java: 1828–54: Muller Szoon, De Nederlandsche katoennijverheid; 1855–73: Statistisch Instituut, Bijdragen van het Statistisch Instituut, 415; 1874–1940: Korthals Altes, General Trade Statistics, 107–112; West Africa: Great Britain, Annual Statement of the Trade of the United Kingdom with Foreign Countries and British Possessions (London: HMSO, various issues 1858–1921).

Akwete weavers in southern Nigeria, for example, were almost exclusively using imported yarn by the second half of the twentieth century.Footnote 89 British yarn imports into West Africa would continue to increase through the twentieth century, rising from roughly 418,600 lbs. in 1900 to over 4 million lbs. in the early 1960s.Footnote 90 However, as in Java, domestic cotton cultivation and spinning did not disappear altogether. Locally made yarn remained popular among weavers located far from global trading hubs – which increased the transportation and transaction costs of imported materials – and among artisans serving lower-income segments who made a greater profit by producing on a ‘zero marginal cost basis’. In fact, although yarn imports into West Africa increased substantially from the late-nineteenth century onward, a 1961 survey of the domestic industry revealed that an estimated two-thirds of Nigeria’s handwoven cloth was still manufactured using domestic yarn.Footnote 91

Industrialist dependency and colonial agency

The considerable variation in choice of industrial inputs available to Global South artisans helped minimize overall production costs and partly shielded domestic producers (and their consumers) from the potential industrial consequences of global market shocks. With the exception of the United States, factory producers in the Global North instead relied exclusively on external raw material sources and were thus vulnerable to both the bargaining power of foreign suppliers and the vagaries of the global markets upon which manufacturers depended to feed their machines. This was a grave concern for nineteenth-century mass-manufacturers, who widely pursued ‘cost leadership’ strategies, since any inflation in costs could threaten their ability to maintain enough of a price differential to compete with producers offering more differentiated products.Footnote 92

The global cotton famine of the 1860s, precipitated by the American Civil War (1861–65), is a key example. Between 1860 and 1863, global cotton prices shot up by 340% as global supplies of American-grown cotton dried up, which simultaneously pushed up global textile prices and dampened consumer demand.Footnote 93 In the same period, cloth imports into East Africa from the United States, United Kingdom, and Bombay fell by over 60% as prices for imported cloth rose rapidly, stalling the momentum of import growth into the region until prices began to approach pre-Civil War levels in the 1870s.Footnote 94 Likewise, British cloth exports to West Africa fell off dramatically in the midst of the cotton famine – dropping from over 42 million yards in 1860 to just under 12 million in 1864 before recovering in the early 1870s.Footnote 95

Though far more modest than the price hike of the 1860s, an upturn in global cotton prices at the end of the nineteenth century bolstered European concerns about dependence on foreign sources – specifically that ‘the European textile industry would fall under the tyranny’ of America. This encouraged colonial powers to ramp up their efforts to secure dependable sources of raw cotton from their colonies.Footnote 96 They went to great lengths to secure raw materials from, and inject metropolitan manufactures into, colonial markets. However, as we illustrate in this final section, unforeseen challenges arose throughout the colonial era as local consumers and producers reacted to metropolitan efforts to manipulate local markets, which helps further illustrate the adaptability of local producers and the centrality of consumer demand in buttressing domestic textile industries.

Dutch interventions in Javanese markets

The ongoing development of the Javanese textile industry amid Dutch colonial efforts to capture the local colonial market provides an excellent example of domestic producer resilience in a colonial context. Around 1700, the Dutch East India Company (VOC) had introduced a tax to be paid in yarn instead of cash in some regions of the archipelago in an effort to satisfy the increasing demand for cotton in Europe.Footnote 97 Large volumes of cotton yarn were exported from the Dutch East Indies to the Netherlands, where it was used by handloom weavers for their mixed cotton-linen fustians.Footnote 98 At the same time, however, this initiative resulted in widespread stimulation of cotton hand spinning among rural indigenous women over the eighteenth century, helping to bolster the domestic industry that would so effectively compete with Dutch imports a century later.

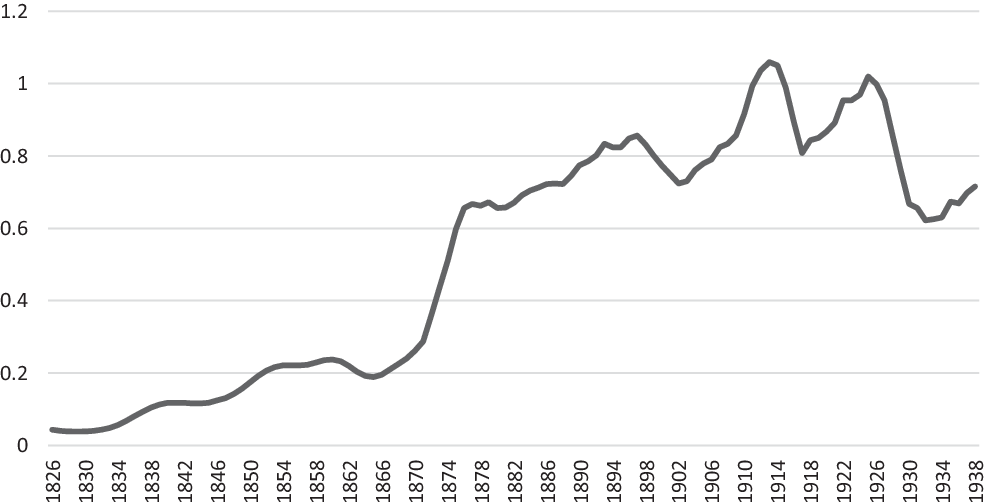

By the first decades of the nineteenth century, Dutch colonial economic policies had been engineered to simultaneously stimulate the cultivation and extraction of raw materials – by implementing a system of forced cultivation, the Kultuurstelsel (Cultivation System, 1830-ca. 1870) – and create new markets for the emerging metropolitan textile industry.Footnote 99 The Dutch actively sought to ensure a position for their textiles among the large population of Java by, for example, introducing discriminatory tariffs of 25–35% for non-Dutch textile imports to the East Indies, whereas Dutch imports were burdened with only 6% tax.Footnote 100 In spite of these colonial schemes, consumers were unmoved to ramp up their consumption of foreign-made textiles. As Figure 5 illustrates, although cloth imports increased from the mid-1830s, a massive increase in per capita Javanese consumption of imported cloth would only occur after the intrusive Cultivation System was disbanded.

Figure 5. Estimates of per capita imports of cotton cloth (in kg), Java, 1822–1940 (5-year moving average).

Based on: Database Indonesian Textiles (Creator: Pierre van der Eng), version 2015.

Note: These import figures exclude yarn.

Local pride in traditional production, sometimes even stirred by anti-colonial sentiments, helped further stimulate consumer preferences for locally produced goods in Java.Footnote 101 As we have seen, metropolitan efforts to replace Javanese batik cloth with Dutch variants failed due to the inability of Dutch versions to effectively substitute for the high-quality local product. Although Dutch factory owners ‘saved [neither] effort nor expenses’, traveling to the East Indies to inform themselves about the consumer preferences of the Javanese,Footnote 102 they often did not succeed. Some contemporaries attributed this to ‘the love of the Javan for monstrous and impossible shapes’,Footnote 103 which were not easily replicated by machines. Others reported that experiments with factory-made blue headscarves containing Quran texts failed miserably due to the ‘unwillingness of Mohamedan priests’ to recommend these imported pieces of cloth to their religious community.Footnote 104 The fact that Dutch merchants had to seek out markets elsewhere in the Global South, where they held no colonial sway, demonstrates both the primacy of local demand and the futility of colonial force in driving consumer habits.

British cotton schemes in colonial Nigeria

Similarly, upon securing the Protectorate of Northern Nigeria in 1900, the British eyed their new territory’s vast production of domestic raw cotton for local looms as an obvious answer to Lancashire industrialists’ demands for low-cost materials and markets for British textiles.Footnote 105 The British Cotton Growing Association (BCGA) took a number of calculated steps to effectuate this shift in the first decades of the twentieth century, but their best-laid plans were quickly foiled as they woefully underestimated Nigerian producers and consumers.

To begin with, the BCGA set an artificial purchase-price ceiling for raw cotton, but Northern Nigerian manufacturers willingly paid the much higher natural local market price, effectively outbidding would-be British buyers. At the same time, British officials had erroneously assumed that the introduction of increasing quantities of British cloth to Northern Nigeria would quickly diminish demand for the region’s popular indigo-dyed domestic cloth.Footnote 106 Rather, local consumers reportedly shunned British imports in favour of local materials.Footnote 107 Moreover, when the British built a railway connecting inland Northern Nigeria with coastal markets to facilitate the export of the region’s raw cotton, local cultivators instead used the transportation boom primarily to export more profitable cash crops, like groundnuts. The resulting increase in local incomes produced a rise in demand for locally made cloth, providing stimulus for the local industry and thus increasing domestic consumption of the region’s raw cotton supplies. In the end, British imports of Northern Nigerian raw cotton – which hopeful reports in 1904 estimated could alone almost entirely ‘supply the wants of Lancashire’Footnote 108 – reached only 363,500 lbs just before the outbreak of the First World War and averaged at only 25,000 bales per year thereafter, a far cry from the 7 million bales that had been projected by proponents of the scheme.Footnote 109

Missteps were likewise made in the Southern Nigeria Protectorate. In Tivland, for example, colonial officials sought to disrupt domestic cloth-currency traditions, partly in the hopes of ousting the local weaving industry and securing the region’s raw cotton for British looms. They rapidly removed large quantities of the domestic woven material by collecting colonial taxes in the form of locally made cloth-currency strips before subsequently demanding that taxes be paid thereafter exclusively in cash, which officials assumed would be accrued by selling locally grown raw cotton. While this indeed disrupted cloth-currency traditions, the scheme only served to bolster the local textile industry as demand for now-scarce domestic cloth surged.Footnote 110 Throughout Nigeria, colonial initiatives continued to struggle to ‘divert the supply of cotton from the Nigerian hand-looms to the power-looms of Lancashire’.Footnote 111 Indeed, Tivland remained a major supplier of textiles to local and regional consumers deep into the twentieth century and continues to produce distinctive black and white striped cloth today.Footnote 112 Like the Dutch in colonial Java, British officials had misjudged the power of unique, high-quality local products to effectively compete with lower-quality, mass-produced substitutes.Footnote 113

Conclusion

The ability of textile producers in Java and sub-Saharan Africa to continue to thrive amid colonial interventions and globalization was due in large part to certain competitive advantages exercised by domestic handicraft manufacturers. Specifically, strategies of product differentiation, responsiveness to shifting consumer needs, and flexibility in manufacturing methods enabled local producers to remain competitive in confrontation with mounting imports from early factory producers, who typically offered cheap, but lower quality and less unique textiles. Moreover, some local manufacturers in the ‘periphery’ could even compete on the basis of price given the very low labour costs involved in seasonally oriented handicraft production, raising questions about the true extent of the comparative advantage enjoyed by early-industrializing nations in the Global North.

The differing production and marketing strategies pursued by handicraft and factory producers provided competitive protection for many artisans during the increasingly global nineteenth century. In fact, rather than condemning domestic industry – as suggested by deindustrialization theorists – access to global trade could provide stimulus for local manufacturing. Industries located far from global trading nodes may have been protected from imports of machine-manufactured cloth, but as we have illustrated, such imports often served a complementary rather than substitutive function. At the same time, geographic isolation excluded several regional textile industries from benefitting from income-generating – and thus demand-stimulating – global trading opportunities, as well as access to a wider array of input supplies. Nevertheless, while largescale factory producers, particularly in Europe, were wholly dependent on external cotton supplies, globally connected handicraft textile manufactures could turn to numerous possible sources of input supplies – including household, local, and global sources. Finally, we have illustrated that the capacity of domestic textile producers to remain competitive amid colonial policies aimed at capturing local markets – and raw cotton sources – highlights not only the importance of product differentiation and the specificity of local demand, but also the agency exercised by both producers and consumers even under colonial rule.

Results from our case studies in many respects confirm what recent revisionist studies have argued for the resilience of local textile production in colonial India in response to forces of globalization and colonialism. There are, however, three pronounced differences. First, India traditionally claimed large export markets alongside its considerable domestic market, both of which were dealt direct blows by factory competition from the Global North; meanwhile, in sub-Saharan Africa and Java, local handicraft producers faced competition primarily in their domestic markets. Second, mechanization of textile production was not stimulated in most of colonial Africa or Java until the 1930s, whereas it did emerge relatively early in colonial India, largely in the hands of indigenous industrialists in towns such as Bombay and Ahmedabad. Third, and perhaps related, rural textile production seems to have waned earlier and faster in India than in Africa and Java. Even today, however, Indian artisans continue to supplement household incomes via craft production.

By highlighting the specific competitive characteristics of handicraft industries in Java and sub-Saharan Africa during the nineteenth and early twentieth centuries, we do not intend to suggest that handloom weaving indefinitely retained its particular advantages relative to mass-manufacturers. As Porter notes, ‘[successful] imitation narrows perceived differentiation, a common occurrence as industries mature’.Footnote 114 Moreover, as the success of Dutch wax-prints in East and West Africa illustrates, a strategy of narrowing in on particular consumer demands within a target market could help foreign manufacturers successfully gain a foothold in domestic markets. Thus, developments in factory manufacturing that enhanced product qualities, coupled with production and marketing strategies geared more directly toward specific consumer groups, could lead to an erosion of handicraft-specific competitive advantages. Such a shift may help account for an eventual decline in handicraft production in parts of the Global South as the twentieth century progressed.

While the products of early mechanized manufacturers struggled to compete with domestic varieties, the rise of Japanese factory production in the first half of the twentieth century seems to have presented a greater competitive challenge. Indeed, it was only with the entrance of Japanese textiles into Javanese markets that handicraft weaving would finally show serious signs of decline.Footnote 115 Japanese textiles also penetrated markets across sub-Saharan Africa, claiming a considerable share of the market previously dominated by British imports, although here handicraft producers continued to fare well in much of the region, with Nigerian producers alone supplying 50 million yards of handmade cloth per year as of the early 1960s.Footnote 116 Meanwhile, Japanese firms began successfully exporting popular Japanese-made kangas to East African markets, effectively competing with European printers. In this respect, Howe has pointed to ‘the pioneering success of the Japanese in researching the needs of consumers in very poor countries and then in developing the most suitable quality, cost and technology choices to satisfy these demands’.Footnote 117 Pinpointing these unique competitive advantages of twentieth-century Japanese producers relative to both nineteenth-century factory-based producers in the West and twentieth-century handicraft manufacturers in some parts of the Global South offers an intriguing avenue for further research.

The more recent development of the Javanese wax-resist dyeing industry also raises questions about the implications of successful capital-intensive imitation industries arising within home markets. The artisanal batik industry that had competed with European imitations during the nineteenth century continued to flourish into the twentieth century. But by the second half of the century, the introduction of capital-intensive technology had given rise to a domestic ‘pseudobatik’ printing industry that cheaply produced successful imitations of handicraft batiks. This led to the displacement of handicraft manufacturers at ‘an alarming rate’. Joseph estimates that as much as 40% of the batik labour force active in the late 1930s had been eradicated by the mid-1970s as a result of domestic imitation printing, particularly in urban areas with large concentrations of capital-intensive factories.Footnote 118 The development of domestic mass-manufacturing sectors in the ‘periphery’ did not necessarily entail deterioration of artisanal production, as we have seen in the case of India, where nineteenth-century artisanal and factory manufacturers pursued very different strategies geared toward serving different segments of the market. Twentieth-century Javanese printers, in contrast, were faced with competition from firms that could effectively combine differentiation and cost-leadership strategies, ultimately reducing the protections that had long been afforded to handicraft producers.

Acknowledgements

We should like to thank William Gervase Clarence-Smith, Keetie Sluyterman, our colleagues from the TextileLab team, as well as the editors and three anonymous referee’s of the Journal of Global History for their valuable comments to earlier versions of this article.

Financial support

This research is part of a project that has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (Grant agreement No. ERC Consolidator Grant #771288).

Competing interests

The authors declare none.

Kate Frederick is assistant professor of Economic and Social History at Utrecht University. She recently published Twilight of an Industry in East Africa. Textile Manufacturing, 1830–1940 (London etc.: Palgrave Macmillan 2020).

Elise van Nederveen Meerkerk is professor of Economic and Social History at Utrecht University and Principal Investigator of the ERC-funded project ‘Race to the Bottom’ (TextileLab). She recently published Women, Work and Colonialism in the Netherlands and Java. Comparisons, contrasts, connections 1830–1940 (London etc.: Palgrave Macmillan 2019).