1. Introduction

Collapsing bubbles can be found in numerous physical systems. Typically this involves bubbles collapsing in proximity to various boundaries. The high surface pressures and shear stresses generated by collapsing bubbles can damage, or clean, the boundary. This cleaning effect can be harnessed through processes such as ultrasonic cleaning (Reuter & Mettin Reference Reuter and Mettin2016) which can involve complex geometries (Verhaagen, Zanderink & Fernandez Rivas Reference Verhaagen, Zanderink and Fernandez Rivas2016).

Single bubbles collapsing near simple geometries, such as flat rigid boundaries, have been widely investigated (Benjamin & Ellis Reference Benjamin and Ellis1966). Much of this research has focused on understanding bubble morphology and jetting (Kröninger et al. Reference Kröninger, Köhler, Kurz and Lauterborn2010; Zhang et al. Reference Zhang, Chang, Ma, Wang and Huang2019) and the effect of bubble collapse on the boundary. Of particular importance for consideration of cleaning and damage are measurements of nearby surface shear stress and pressure, both experimentally (Dijkink & Ohl Reference Dijkink and Ohl2008; Luo et al. Reference Luo, Xu, Deng, Zhai and Zhang2018; Occhicone et al. Reference Occhicone, Sinibaldi, Danz, Casciola and Michelotti2019) and numerically (Li et al. Reference Li, Han, Zhang and Wang2016; Koukouvinis et al. Reference Koukouvinis, Strotos, Zeng, Gonzalez-Avila, Theodorakakos, Gavaises and Ohl2018; Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018). The resulting cleaning and surface damage have also been widely investigated (Ohl et al. Reference Ohl, Arora, Dijkink, Janve and Lohse2006; Sagar & el Moctar Reference Sagar and el Moctar2020; Reuter, Deiter & Ohl Reference Reuter, Deiter and Ohl2022).

There has been a recent effort to characterise single bubble collapse in a range of complex geometries. For example, characterising jet direction in a selection of geometries including in concave corners (Tagawa & Peters Reference Tagawa and Peters2018), inside rectangular and triangular prisms (Molefe & Peters Reference Molefe and Peters2019), above slots (Andrews, Fernández Rivas & Peters Reference Andrews, Fernández Rivas and Peters2020) and in the corner of a wall and a free surface (Kiyama et al. Reference Kiyama, Shimazaki, Gordillo and Tagawa2021). Bubble morphology, flow properties and jetting behaviours have also been investigated in combinations of concave corners and free surfaces (Zhang et al. Reference Zhang, Zhang, Wang and Cui2017; Brujan et al. Reference Brujan, Noda, Ishigami, Ogasawara and Takahira2018), between two parallel rigid boundaries (Brujan, Takahira & Ogasawara Reference Brujan, Takahira and Ogasawara2019; Rodriguez et al. Reference Rodriguez, Beig, Barbier and Johnsen2022), inside a slot (Brujan et al. Reference Brujan, Zhang, Liu, Ogasawara and Takahira2022), on a convex corner (Zhang et al. Reference Zhang, Qiu, Zhang and Tang2020), on a crevice (Trummler et al. Reference Trummler, Bryngelson, Schmidmayer, Schmidt, Colonius and Adams2020) and on ridge-patterned structures (Kim & Kim Reference Kim and Kim2020; Kadivar, el Moctar & Sagar Reference Kadivar, el Moctar and Sagar2022). Nevertheless, there remain fundamental complex geometries that have yet to be explored.

Porous materials are a large family of complex geometries with a wide range of applications. Broadly, they could be categorised as connected or unconnected. One example of an unconnected porous material is a bed of sand, such as those investigated by Sieber, Preso & Farhat (Reference Sieber, Preso and Farhat2022). The sand creates pores which are permeated by water, but the grains are able to separate which allows for significant deformation of the bed. The influence of the bubble on the boundary is shown to depend on the granular size of the sand, including behaviours such as granular jets and displacement of the boundary material. However, the boundary is modelled as a liquid–liquid interface and it is shown that the bubble rebound and displacement are principally driven by the density difference between the pliable granular suspension and the water.

Connected porous materials have a wide range of applications, of which one very practical application is filters. Filters are typically porous materials through which a fluid is passed in order to remove contamination. This contamination builds up on the filter, reducing performance. Ultrasonic cleaning can be applied to filters in order to remove the built-up contamination from the filter (Reuter et al. Reference Reuter, Lauterborn, Mettin and Lauterborn2017).

The simplest example of a porous material is a flat plate with a pattern of through-holes. Some research has investigated the problem of a plate with a through-hole bounding a free surface in relation to breaches of maritime hulls (Cui et al. Reference Cui, Zhou, Huang and Li2021, Reference Cui, Li, Sun, Xu, Zhou and Zhang2022; He et al. Reference He, Wang, Ren and Zhang2021). Similarly, Sun et al. (Reference Sun, Yao, Wen, Zhong and Wang2022b) investigated bubble collapse near a rigid surface with a gas-entrapping hole. This concept was also investigated by Gonzalez-Avila et al. (Reference Gonzalez-Avila, Nguyen, Arunachalam, Domingues, Mishra and Ohl2020) and Sun et al. (Reference Sun, Du, Yao, Zhong, Geng and Wang2022a), who considered surfaces with a pattern of gas-entrapping holes. In all these cases, bubbles were found to translate away from the boundary, acting analogously to a typical free surface.

Liu et al. (Reference Liu, Wu, Zhang and Liu2017) investigated a bubble collapsing between a free surface and a submerged rigid boundary with a through-hole. Bubbles collapsing close to a fully submerged rigid boundary with a single through-hole have also been investigated, both experimentally (Lew, Klaseboer & Khoo Reference Lew, Klaseboer and Khoo2007; Karri et al. Reference Karri, Pillai, Klaseboer, Ohl and Khoo2011; Abboud & Oweis Reference Abboud and Oweis2013) and numerically (Khoo, Klaseboer & Hung Reference Khoo, Klaseboer and Hung2005). Similarly, Moloudi et al. (Reference Moloudi, Dadvand, Dawoodian and Saleki-Haselghoubi2019) numerically investigated bubble collapse dynamics close to a convex boundary with a through-hole. These investigations revealed similar tendencies of the bubbles during collapse, such as the bubble translating towards and through the holes, the bubble surface expanding into the holes, and stronger counter-jetting than plates without holes.

In this research, we investigate a less-studied phenomenon: how a series of porous plates affect bubble collapse dynamics. We include some comments on bubble morphology and measurements of bubble displacement and bubble rebound radius.

2. Problem definition

We define a porous plate as a thin, rigid plate with a pattern of through-holes. The plate thickness is defined as ![]() $H$, with through-holes of characteristic length

$H$, with through-holes of characteristic length ![]() $W$ and spacing

$W$ and spacing ![]() $S$. Three shapes of hole are investigated: circles, squares and triangles. Circles are the smoothest possible hole shape and triangles are the least-smooth regular polygon, with the tightest corner angle. Squares are somewhere between the two and are used to achieve high void fractions due to their efficient tessellation packing. Schematics of these arrangements are shown in figure 1(a–c). The void fraction

$S$. Three shapes of hole are investigated: circles, squares and triangles. Circles are the smoothest possible hole shape and triangles are the least-smooth regular polygon, with the tightest corner angle. Squares are somewhere between the two and are used to achieve high void fractions due to their efficient tessellation packing. Schematics of these arrangements are shown in figure 1(a–c). The void fraction ![]() $\phi$ is defined as the fraction of the total plate area that is occupied by holes. In this work, we describe a void fraction

$\phi$ is defined as the fraction of the total plate area that is occupied by holes. In this work, we describe a void fraction ![]() $\phi = 0$ as ‘non-porous’ and a void fraction

$\phi = 0$ as ‘non-porous’ and a void fraction ![]() $\phi > 0$ as ‘porous’, both of which are assumed to be rigid. For circular holes the void fraction is

$\phi > 0$ as ‘porous’, both of which are assumed to be rigid. For circular holes the void fraction is

for square holes the void fraction is

and for triangular holes the void fraction is

Figure 1. Top-down view schematic diagrams of porous plates with patterns of (a) circular, (b) square or (c) triangular holes. The scales in each diagram are arbitrary. Orange circles mark horizontal positions above a hole and green crosses mark horizontal positions between-holes. (d) Side-on cross-section view of a porous plate with a bubble positioned vertically above it.

Bubbles are positioned vertically at a distance ![]() $Y$ from the boundary with time-variant radius

$Y$ from the boundary with time-variant radius ![]() $R$ and maximum radius

$R$ and maximum radius ![]() $R_0$. These parameters are shown in figure 1(d). Horizontally, the bubble can be positioned in two dimensions with varying proximity to the holes. We identify the two extreme cases as a bubble directly over a hole and a bubble directly over the plate between holes. These two cases represent the minimum and maximum area of solid boundary near the bubble. The horizontal positions of bubbles above holes are shown by the orange circles in figure 1. The horizontal positions of bubbles above the plate between holes are shown by the green crosses in figure 1 and are usually referred to hereafter as ‘between-holes’.

$R_0$. These parameters are shown in figure 1(d). Horizontally, the bubble can be positioned in two dimensions with varying proximity to the holes. We identify the two extreme cases as a bubble directly over a hole and a bubble directly over the plate between holes. These two cases represent the minimum and maximum area of solid boundary near the bubble. The horizontal positions of bubbles above holes are shown by the orange circles in figure 1. The horizontal positions of bubbles above the plate between holes are shown by the green crosses in figure 1 and are usually referred to hereafter as ‘between-holes’.

The vertical distance of the bubble is normalised by the maximum bubble radius to produce the dimensionless standoff distance ![]() $\gamma = Y / R_0$. The hole size is also normalised with the maximum bubble radius,

$\gamma = Y / R_0$. The hole size is also normalised with the maximum bubble radius, ![]() $W / R_0$.

$W / R_0$.

In this research we investigate fixed, rigid plates with a constant thickness ![]() $H = 1\ \mathrm {mm}$ and compare only the effects of bubble position and hole geometry.

$H = 1\ \mathrm {mm}$ and compare only the effects of bubble position and hole geometry.

3. Methods

3.1. Experimental method

Experiments were performed using laser-induced cavitation. Laser-induced cavitation operates by focusing a laser pulse at a point in a volume of water (Lauterborn Reference Lauterborn1972). The high energy at the focal point forms a plasma which rapidly heats and vaporises the surrounding water, creating a bubble. The focusing optics are typically either a microscope objective or a parabolic mirror. In our previous research, using a microscope objective, we showed that bubbles with greater asymmetry lead to greater spread of experimental measurements of bubble displacement (Andrews & Peters Reference Andrews and Peters2022). Thus, following the example of Obreschkow et al. (Reference Obreschkow, Tinguely, Dorsaz, Kobel, De Bosset and Farhat2013), we have implemented an off-axis parabolic mirror set-up, as shown in figure 2. This method produces more consistent bubbles with improved symmetry, reducing the spread of data. In addition, the larger focusing angle (with a higher equivalent numerical aperture), allows for larger bubbles to be generated without nucleating additional bubbles nearby. A statistical comparison between the two methods is available in the supplementary material and movies available at https://doi.org/10.1017/jfm.2023.266.

Figure 2. Schematic showing the experimental set-up for laser-induced cavitation using an off-axis parabolic mirror to generate bubbles near a porous plate.

In this research, a Q-switched Nd:YAG laser (‘Nano PIV’ from Litron Lasers) was used to generate an 8 ns pulse at a wavelength of 532 nm. The laser output energy was approximately 97 mJ and was subsequently attenuated with the attenuator set to between 70 % and 75 %. The beam was restricted by an iris to be approximately 3 mm in diameter, in order to remain well-collimated after expansion, and then expanded with a 10![]() $\times$ beam expander to approximately 30 mm in diameter. The expanded beam was focused by a gold off-axis parabolic mirror with a focusing angle of approximately 41

$\times$ beam expander to approximately 30 mm in diameter. The expanded beam was focused by a gold off-axis parabolic mirror with a focusing angle of approximately 41![]() $^\circ$ (equivalent numerical aperture

$^\circ$ (equivalent numerical aperture ![]() $= 0.35$). This methodology produced bubbles with radii ranging from 1.07 to 1.65 mm, depending primarily on laser input power and attenuation. Each combination of geometry and position was repeated at least three times. The radius varied with a standard deviation of 0.030 mm and the displacement varied with a standard deviation of 0.033 mm. Both of these values are on a comparable scale to the average measurement resolution of 0.025 mm. Notably, the gold surface absorbs most of the laser energy, but is less likely to degrade when immersed in water when compared with mirror materials designed to operate with a 532 nm laser (Obreschkow et al. Reference Obreschkow, Tinguely, Dorsaz, Kobel, De Bosset and Farhat2013). However, a recent study has reported use of an aluminium off-axis parabolic mirror (Sieber et al. Reference Sieber, Preso and Farhat2022) so the degradation concern may not be as significant as assumed originally.

$= 0.35$). This methodology produced bubbles with radii ranging from 1.07 to 1.65 mm, depending primarily on laser input power and attenuation. Each combination of geometry and position was repeated at least three times. The radius varied with a standard deviation of 0.030 mm and the displacement varied with a standard deviation of 0.033 mm. Both of these values are on a comparable scale to the average measurement resolution of 0.025 mm. Notably, the gold surface absorbs most of the laser energy, but is less likely to degrade when immersed in water when compared with mirror materials designed to operate with a 532 nm laser (Obreschkow et al. Reference Obreschkow, Tinguely, Dorsaz, Kobel, De Bosset and Farhat2013). However, a recent study has reported use of an aluminium off-axis parabolic mirror (Sieber et al. Reference Sieber, Preso and Farhat2022) so the degradation concern may not be as significant as assumed originally.

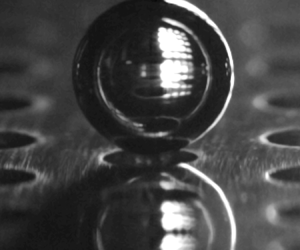

Porous plates were created by laser cutting ![]() $50\ {\rm mm} \times 50\ {\rm mm}$ plates out of stainless steel with a thickness of 1 mm. Stainless steel was selected to ensure rigidity in the plates because other materials, such as 1 mm acrylic, flex significantly under the load of a bubble collapsing, which is known to reduce or reverse displacement (Gibson & Blake Reference Gibson and Blake1982; Brujan et al. Reference Brujan, Nahen, Schmidt and Vogel2001). Holes had characteristic lengths between 0.40 and 4.79 mm, primarily limited at the low end by laser cut quality. Due to the position of the bubble in close proximity to the plate, the diverging laser impinges upon the plate. If the plate is sufficiently close to the focal point, or the focal angle is narrow, the plate can absorb a significant amount of laser energy which can then nucleate a second bubble at the surface of the material. This nucleation is shown in figure 3. In order to stop significant surface nucleation, the plates were polished to reduce laser energy absorption by increasing the reflectivity. All geometries used are listed in table 1 with measurements of the geometric parameters and range of bubble sizes.

$50\ {\rm mm} \times 50\ {\rm mm}$ plates out of stainless steel with a thickness of 1 mm. Stainless steel was selected to ensure rigidity in the plates because other materials, such as 1 mm acrylic, flex significantly under the load of a bubble collapsing, which is known to reduce or reverse displacement (Gibson & Blake Reference Gibson and Blake1982; Brujan et al. Reference Brujan, Nahen, Schmidt and Vogel2001). Holes had characteristic lengths between 0.40 and 4.79 mm, primarily limited at the low end by laser cut quality. Due to the position of the bubble in close proximity to the plate, the diverging laser impinges upon the plate. If the plate is sufficiently close to the focal point, or the focal angle is narrow, the plate can absorb a significant amount of laser energy which can then nucleate a second bubble at the surface of the material. This nucleation is shown in figure 3. In order to stop significant surface nucleation, the plates were polished to reduce laser energy absorption by increasing the reflectivity. All geometries used are listed in table 1 with measurements of the geometric parameters and range of bubble sizes.

Figure 3. Frames showing the expansion and collapse of two bubbles, one nucleated at the laser focal point and one simultaneously nucleated where the laser impinges on a nearby steel plate. An approximate scale bar is given. This high-speed recording is ‘Movie 1’ in the supplementary material and movies.

Table 1. All experimental geometries used in this research. Ordered by void fraction ![]() $\phi$ and showing hole shape; hole characteristic width

$\phi$ and showing hole shape; hole characteristic width ![]() $W$; hole area

$W$; hole area ![]() $A$; and mean bubble size

$A$; and mean bubble size ![]() $\overline {R_0}$.

$\overline {R_0}$.

The porous plates were attached to an arm which was moved by a translation stage. The porous plates were submerged in a ![]() $174\ {\rm mm} \times 180\ {\rm mm} \times 177\ {\rm mm}$ glass tank of purified and partially degassed water as shown in figure 2. The bubbles were back-lit by a 100 W LED panel and recorded at 100 000 frames per second with a high-speed camera (Photron FASTCAM SA-X2 with a 105 mm Nikon Micro-Nikkor lens). A 550 nm longpass filter was used to protect the camera from the laser.

$174\ {\rm mm} \times 180\ {\rm mm} \times 177\ {\rm mm}$ glass tank of purified and partially degassed water as shown in figure 2. The bubbles were back-lit by a 100 W LED panel and recorded at 100 000 frames per second with a high-speed camera (Photron FASTCAM SA-X2 with a 105 mm Nikon Micro-Nikkor lens). A 550 nm longpass filter was used to protect the camera from the laser.

The experiment produced shadowgraph movies of the bubbles which were then analysed with automatic image analysis software written in Python. For each frame, the background was subtracted, and a binary filter was applied to isolate the bubble. The bubble position was measured as the centroid of the isolated pixels and the bubble radius was calculated as the radius of a circle with equal area to the bubble in the image. For deformed bubbles, where no clear single definition of a radius exists, this is the selected equivalent radius. The three parameters that were extracted from these measurements were the maximum bubble radius ![]() $R_0$; the bubble maximum radius after the first rebound

$R_0$; the bubble maximum radius after the first rebound ![]() $R_1$; and the displacement of the bubble between the two radius maxima

$R_1$; and the displacement of the bubble between the two radius maxima ![]() $\varDelta$. These measurements are shown in figure 4.

$\varDelta$. These measurements are shown in figure 4.

Figure 4. (a) Frames from a high-speed recording of a bubble expanding and collapsing near a porous boundary. Frames at radius maxima (![]() $t=140\ \mathrm {\mu }{\rm s}$ and

$t=140\ \mathrm {\mu }{\rm s}$ and ![]() $t=340\ \mathrm {\mu }{\rm s}$) feature a circle overlay with area equivalent to the bubble area. (b) Bubble radius variation with time. (c) Composite image of the two frames recorded at the radius maxima indicated in (b) showing measurements of the radius maxima

$t=340\ \mathrm {\mu }{\rm s}$) feature a circle overlay with area equivalent to the bubble area. (b) Bubble radius variation with time. (c) Composite image of the two frames recorded at the radius maxima indicated in (b) showing measurements of the radius maxima ![]() $R_0$ and

$R_0$ and ![]() $R_1$ and bubble displacement

$R_1$ and bubble displacement ![]() $\varDelta$. This high-speed recording is ‘Movie 2’ in the supplementary material and movies.

$\varDelta$. This high-speed recording is ‘Movie 2’ in the supplementary material and movies.

3.2. Numerical model

Bubbles collapsing in complex geometries experience varied degrees of asymmetry. This asymmetry can be quantified with the ‘anisotropy parameter’ ![]() $\zeta$, a dimensionless equivalent of the Kelvin impulse, which can predict several bubble collapse properties (Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016, Reference Supponen, Obreschkow, Kobel, Tinguely, Dorsaz and Farhat2017; Supponen, Obreschkow & Farhat Reference Supponen, Obreschkow and Farhat2018).

$\zeta$, a dimensionless equivalent of the Kelvin impulse, which can predict several bubble collapse properties (Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016, Reference Supponen, Obreschkow, Kobel, Tinguely, Dorsaz and Farhat2017; Supponen, Obreschkow & Farhat Reference Supponen, Obreschkow and Farhat2018).

We have previously presented a numerical model, based on the boundary element method, capable of predicting the anisotropy parameter for arbitrary rigid geometries (Andrews & Peters Reference Andrews and Peters2022). This model assumes that the bubble is spherical and stationary. Thus, the bubble can be treated as a fixed three-dimensional point sink in potential flow with a strength depending on the bubble radius and radial velocity of the bubble surface which are calculated by numerically solving the Rayleigh–Plesset equation. Nearby boundaries are modelled by a distribution of point sink elements and the no-through-flow boundary condition is imposed at their centroids. Each element ![]() $i$ has a constant sink strength density

$i$ has a constant sink strength density ![]() $\sigma _i$ across its surface and area

$\sigma _i$ across its surface and area ![]() $A_i$ such that the sink strength of the centroid point sink is

$A_i$ such that the sink strength of the centroid point sink is ![]() $\sigma _i A_i$ and the velocity induced at a point

$\sigma _i A_i$ and the velocity induced at a point ![]() $j$ by the element

$j$ by the element ![]() $i$ is

$i$ is

where ![]() $\varPhi$ is the velocity potential,

$\varPhi$ is the velocity potential, ![]() $\boldsymbol {x}_j$ is a point in the fluid and

$\boldsymbol {x}_j$ is a point in the fluid and ![]() $\boldsymbol {x}_i$ is the centroid position of the element

$\boldsymbol {x}_i$ is the centroid position of the element ![]() $i$.

$i$.

The bubble is assumed to be stationary and the integral of pressures on the boundary surface is calculated and integrated over time. This allows the Kelvin impulse to be estimated and then non-dimensionalised to the anisotropy parameter ![]() $\zeta$. Although this model does not fully capture the flow field, it is sufficient to accurately predict the anisotropy parameter while remaining comparatively simple.

$\zeta$. Although this model does not fully capture the flow field, it is sufficient to accurately predict the anisotropy parameter while remaining comparatively simple.

Porous plates could be directly modelled this way, however a high number of elements would be required to adequately resolve the holes. Here we propose an adaptation of the previous model that does not require each hole to be resolved separately.

By assuming that the plate has zero thickness, the plate can be modelled with a single layer of boundary elements. Elements could then be constructed to surround the holes, however this would simply act to redistribute the element centroids and reduce the overall area. Instead, we assume that the plate is homogeneous, and simply scale the element areas using the void fraction so that the porous element area ![]() $A_i$ is

$A_i$ is

where ![]() $A_{is}$ is the area of the equivalent non-porous element. This method assumes that the shape of the holes does not matter, and that the holes are small enough that any difference in horizontal position is negligible. A further description of this area scaling is available in the supplementary material and movies.

$A_{is}$ is the area of the equivalent non-porous element. This method assumes that the shape of the holes does not matter, and that the holes are small enough that any difference in horizontal position is negligible. A further description of this area scaling is available in the supplementary material and movies.

After scaling the areas, the boundary element method solution can proceed as usual, using the reduced ![]() $A_i$ for both the boundary conditions and pressure integration. We have previously presented the core boundary element method procedure (Andrews et al. Reference Andrews, Fernández Rivas and Peters2020) and anisotropy computations (Andrews & Peters Reference Andrews and Peters2022) in detail.

$A_i$ for both the boundary conditions and pressure integration. We have previously presented the core boundary element method procedure (Andrews et al. Reference Andrews, Fernández Rivas and Peters2020) and anisotropy computations (Andrews & Peters Reference Andrews and Peters2022) in detail.

4. Experimental results

4.1. Bubbles close to porous boundaries

Bubbles collapsing in close proximity to porous boundaries show a broad range of interesting dynamics. In this section, frames from high-speed recordings of five bubble collapses are presented, demonstrating some of these dynamics.

When bubbles collapse close to non-porous boundaries, they produce strong jets that often impinge on the boundaries. When the bubble is nucleated above a hole (positioned above the orange circles in figure 1), these jets can propagate through the hole, producing very long regions of entrained vapour. One such example is shown in figure 5. In this figure, by measuring the position of the vapour jet tip, an average jet velocity of 39 m s![]() $^{-1}$ is found between

$^{-1}$ is found between ![]() $t = 279$ and

$t = 279$ and ![]() $319\ \mathrm {\mu }$s. The frame at

$319\ \mathrm {\mu }$s. The frame at ![]() $t = 359\ \mathrm {\mu }$s shows that the vapour entrained by the jet extends beyond the bottom of the frame. This region of vapour then itself very rapidly collapses, as seen at

$t = 359\ \mathrm {\mu }$s shows that the vapour entrained by the jet extends beyond the bottom of the frame. This region of vapour then itself very rapidly collapses, as seen at ![]() $t = 369\ \mathrm {\mu }$s, followed by the rest of the bubble collapsing down towards the hole.

$t = 369\ \mathrm {\mu }$s, followed by the rest of the bubble collapsing down towards the hole.

Figure 5. Frames from a high-speed recording of a bubble collapsing with a strong jet passing through a hole in a porous plate with void fraction ![]() $\phi = 44.7$ % and square holes of size

$\phi = 44.7$ % and square holes of size ![]() $W = 1.94$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 3’ in the supplementary material and movies.

$W = 1.94$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 3’ in the supplementary material and movies.

As well as allowing jets to pass through the holes, the holes reduce the impedance of the boundary. Bubbles collapse towards rigid boundaries because the rigid boundary impedes the flow out from the bubble during expansion and into the bubble during collapse. This results in the opposite side of the bubble expanding and collapsing much faster, leading to the overall motion towards the boundary (Blake Reference Blake1983). When the bubble is directly over a hole (positioned above the orange circles in figure 1), the hole does not impede the bubble expansion and collapse. Figure 6 shows one such configuration. Initially, the bubble expands mostly spherically. However, the bottom of the bubble, positioned directly over the hole, expands more than the rest of the lower side, resulting in a protrusion visible in the frame at ![]() $t = 80\ \mathrm {\mu }$s. The protrusion expands into the hole when the bubble is at its maximum size at

$t = 80\ \mathrm {\mu }$s. The protrusion expands into the hole when the bubble is at its maximum size at ![]() $t = 160\ \mathrm {\mu }$s. Subsequently, during collapse, the protrusion entirely withdraws by

$t = 160\ \mathrm {\mu }$s. Subsequently, during collapse, the protrusion entirely withdraws by ![]() $t = 240\ \mathrm {\mu }$s, with a clear gap visible between the now-flattened lower surface and the boundary. Owing to the low impedance of the hole compared with the surrounding boundary, the centre of the bottom side of the bubble continues collapsing much more rapidly than the surrounding areas. This leads to a full inversion of the bottom of the bubble, visible by the upward-facing triangular jet entering from the bottom side of the bubble at

$t = 240\ \mathrm {\mu }$s, with a clear gap visible between the now-flattened lower surface and the boundary. Owing to the low impedance of the hole compared with the surrounding boundary, the centre of the bottom side of the bubble continues collapsing much more rapidly than the surrounding areas. This leads to a full inversion of the bottom of the bubble, visible by the upward-facing triangular jet entering from the bottom side of the bubble at ![]() $t = 300\ \mathrm {\mu }$s. These qualitative observations agree well with those reported by Khoo et al. (Reference Khoo, Klaseboer and Hung2005). The bubble then fully collapses and re-expands by

$t = 300\ \mathrm {\mu }$s. These qualitative observations agree well with those reported by Khoo et al. (Reference Khoo, Klaseboer and Hung2005). The bubble then fully collapses and re-expands by ![]() $t = 410\ \mathrm {\mu }$s. It is interesting to note in the frame at

$t = 410\ \mathrm {\mu }$s. It is interesting to note in the frame at ![]() $t = 410\ \mathrm {\mu }$s that the bubble undergoes a rapid ejection event on the upper right surface, the cause of which is unknown. The bubble goes on to travel through the hole, breaking up as it goes.

$t = 410\ \mathrm {\mu }$s that the bubble undergoes a rapid ejection event on the upper right surface, the cause of which is unknown. The bubble goes on to travel through the hole, breaking up as it goes.

Figure 6. Frames from a high-speed recording of a bubble collapsing through a hole in a porous plate with void fraction ![]() $\phi = 21.6$ % and circular holes of size

$\phi = 21.6$ % and circular holes of size ![]() $W = 1.14$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 4’ in the supplementary material and movies.

$W = 1.14$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 4’ in the supplementary material and movies.

Bubbles positioned above the solid boundary between holes also expand preferentially towards nearby holes. Figure 7 shows a bubble positioned between four square holes (above the green cross in figure 1b). At the lower edge of the bubble, the areas closest to the holes expand more than the centre. These appear as two sharper protrusions on either side of the bottom of the bubble in the frames at ![]() $t = 60$ and

$t = 60$ and ![]() $80\ \mathrm {\mu }$s. On the boundary, an extremely small bubble is nucleated by the laser impinging on the boundary. This bubble is visible in the first three frames as a shadow directly below the main bubble. The main bubble, however, does not contact the boundary at the centre until the frame at

$80\ \mathrm {\mu }$s. On the boundary, an extremely small bubble is nucleated by the laser impinging on the boundary. This bubble is visible in the first three frames as a shadow directly below the main bubble. The main bubble, however, does not contact the boundary at the centre until the frame at ![]() $t = 230\ \mathrm {\mu }$s, showing how the solid parts of the boundary strongly limit the growth and collapse of the bubble when compared with the holes. As the bubble begins to collapse, surface instabilities become visible in the frame at

$t = 230\ \mathrm {\mu }$s, showing how the solid parts of the boundary strongly limit the growth and collapse of the bubble when compared with the holes. As the bubble begins to collapse, surface instabilities become visible in the frame at ![]() $t = 230\ \mathrm {\mu }$s, growing initially from the holes and spreading across the bubble surface. The top surface of the bubble rapidly collapses, leaving an indentation on the top of the collapsing bubble at

$t = 230\ \mathrm {\mu }$s, growing initially from the holes and spreading across the bubble surface. The top surface of the bubble rapidly collapses, leaving an indentation on the top of the collapsing bubble at ![]() $t = 280\ \mathrm {\mu }$s. The bubble then re-expands along the solid parts of the boundary, splitting into multiple sections visible at

$t = 280\ \mathrm {\mu }$s. The bubble then re-expands along the solid parts of the boundary, splitting into multiple sections visible at ![]() $t = 400\ \mathrm {\mu }$s.

$t = 400\ \mathrm {\mu }$s.

Figure 7. Frames from a high-speed recording of a bubble collapsing above the area between four holes in a porous plate with void fraction ![]() $\phi = 44.7$ % and square holes of size

$\phi = 44.7$ % and square holes of size ![]() $W = 1.94$ mm. A cross-section of the plate through the row of holes in front of the bubble is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 5’ in the supplementary material and movies.

$W = 1.94$ mm. A cross-section of the plate through the row of holes in front of the bubble is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 5’ in the supplementary material and movies.

These effects can be further explored by observing a bubble positioned between just two holes. This case is shown in figure 8. As in figure 7, the bubble in figure 8 expands preferentially towards the nearby holes. Again, protrusions are visible on either side of the lower surface of the bubble. However, as the bubble collapses, the motion of these protrusions is in the camera plane and so can be more clearly observed. The surface of the bubble directly adjacent to the solid part of the boundary remains significantly impeded throughout the collapse and so does not move significantly. At ![]() $t = 170\ \mathrm {\mu }$s the two expanded protrusions have begun to collapse towards bubble centroid. As the collapse advances the protrusions retain their additional curvature, forming ‘ears’ on either side of the bubble which are visible until

$t = 170\ \mathrm {\mu }$s the two expanded protrusions have begun to collapse towards bubble centroid. As the collapse advances the protrusions retain their additional curvature, forming ‘ears’ on either side of the bubble which are visible until ![]() $t = 270\ \mathrm {\mu }$s. The longevity of these ears is a surprising feature as the areas of a bubble with greatest curvature are expected to collapse most rapidly (Lauterborn Reference Lauterborn1982).

$t = 270\ \mathrm {\mu }$s. The longevity of these ears is a surprising feature as the areas of a bubble with greatest curvature are expected to collapse most rapidly (Lauterborn Reference Lauterborn1982).

Figure 8. Frames from a high-speed recording of a bubble collapsing above the area between two holes in a porous plate with void fraction ![]() $\phi = 44.7$ % and square holes of size

$\phi = 44.7$ % and square holes of size ![]() $W = 1.94$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 6’ in the supplementary material and movies.

$W = 1.94$ mm. A cross-section of the plate at the bubble position is superimposed with hatched areas indicating the solid part of the plate. This high-speed recording is ‘Movie 6’ in the supplementary material and movies.

We note here that the rapid jet, often seen around the time of the first re-expansion of the bubble, is not always aligned with the overall motion of the bubble. This suggests that small asymmetries in the initial plasma formation may affect the bubble dynamics beyond the initial formation and expansion, despite the bubble being very spherical at its maximum size. The mechanism for this behaviour could be some history of the initial plasma and expansion being retained due to insufficient mixing and homogenisation of the internal gases of the bubble. An example of an offset jet is shown in figure 9 where the bubble is collapsing near a non-porous plate. Despite the bubble appearing very spherical at its maximum size, and the plate being highly symmetric, the jet that appears at ![]() $t = 400\ \mathrm {\mu }$s is clearly offset from the vertical axis (shown by the grey dashed line). Although this jet is strong, it does not affect the overall motion of the bubble as the bubble proceeds to collapse in the expected vertical direction. This effect is visible in data sets we have used previously (Andrews & Peters Reference Andrews and Peters2022) and can be found in some other publications such as figure 5 in Požar, Agrež & Petkovšek (Reference Požar, Agrež and Petkovšek2021) and figure 4(a) in Sieber et al. (Reference Sieber, Preso and Farhat2022).

$t = 400\ \mathrm {\mu }$s is clearly offset from the vertical axis (shown by the grey dashed line). Although this jet is strong, it does not affect the overall motion of the bubble as the bubble proceeds to collapse in the expected vertical direction. This effect is visible in data sets we have used previously (Andrews & Peters Reference Andrews and Peters2022) and can be found in some other publications such as figure 5 in Požar, Agrež & Petkovšek (Reference Požar, Agrež and Petkovšek2021) and figure 4(a) in Sieber et al. (Reference Sieber, Preso and Farhat2022).

Figure 9. Frames from a high-speed recording of a bubble collapsing above a non-porous boundary. The horizontal position of the bubble at its maximum size is shown by the grey vertical line in each frame. The plate is indicated by the hatched grey area at the bottom of the frame. This high-speed recording is ‘Movie 7’ in the supplementary material and movies.

4.2. Variation of displacement and rebound radius with standoff distance

Bubble displacement ![]() $\varDelta / R_0$ and rebound radius

$\varDelta / R_0$ and rebound radius ![]() $R_1 / R_0$ are known to depend strongly on the standoff distance

$R_1 / R_0$ are known to depend strongly on the standoff distance ![]() $\gamma = Y / R_0$ (Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016, Reference Supponen, Obreschkow and Farhat2018). In figure 10, the blue data points are experimental data from bubbles collapsing near a non-porous plate. As the standoff distance increases, the displacement decreases, approximately following a power law. Similarly, the rebound radius decreases as the standoff distance increases, although this approximately follows a log law rather than a power law. A porous plate impedes flow, but to a lesser degree than a non-porous plate. Thus, it induces a lesser displacement and rebound radius than a non-porous plate as shown by the orange data in figure 10. For the porous plate, the displacement approximately follows a power law and the rebound radius approximately follows a log law, which are the same trends as for the non-porous plate.

$\gamma = Y / R_0$ (Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016, Reference Supponen, Obreschkow and Farhat2018). In figure 10, the blue data points are experimental data from bubbles collapsing near a non-porous plate. As the standoff distance increases, the displacement decreases, approximately following a power law. Similarly, the rebound radius decreases as the standoff distance increases, although this approximately follows a log law rather than a power law. A porous plate impedes flow, but to a lesser degree than a non-porous plate. Thus, it induces a lesser displacement and rebound radius than a non-porous plate as shown by the orange data in figure 10. For the porous plate, the displacement approximately follows a power law and the rebound radius approximately follows a log law, which are the same trends as for the non-porous plate.

Figure 10. (a) Normalised displacement plotted against standoff distance. (b) Normalised rebound radius plotted against standoff distance. Blue diamonds are data from bubbles collapsing near a non-porous plate. Orange circles are data from bubbles collapsing near a porous plate.

4.3. Comparing horizontal position, hole size and hole shape

Many parameters govern the porous plate and a vast number of plates could be considered with a range of hole shapes and sizes. In addition, the bubble can vary in position relative to the plate both horizontally and vertically. In order to reduce the parameter space, it is thus desirable to determine which parameters can be considered negligible.

As discussed in § 2, the horizontal position of the bubble has two extremes: above a hole (above the orange circles in figure 1), or directly above an area of plate between holes (above the green crosses in figure 1). Intuitively, it can be understood that a bubble above a hole will displace less than a bubble above solid boundary because the fluid does not impede the collapse of the bottom of the bubble. In the limiting case of an infinitely large hole, the bubble experiences no asymmetry, and thus no displacement. Conversely, with a fixed void fraction, infinitely large holes produce infinitely large spaces between holes. Thus, for bubbles nucleated between-holes, the bubble is no longer affected by the holes and so tends towards the solution for a simple non-porous plate. However, for sufficiently small holes, the difference between bubbles collapsing above a hole and bubbles collapsing between-holes is expected to become negligible.

Here we define a dimensionless area parameter ![]() $A'$ to be the ratio between the area of one tessellation unit and the projected area of the bubble. The tessellation unit area is the total area that would be used to calculate the void fraction of one hole. These units are shown graphically in figure 11. Thus, the parameter

$A'$ to be the ratio between the area of one tessellation unit and the projected area of the bubble. The tessellation unit area is the total area that would be used to calculate the void fraction of one hole. These units are shown graphically in figure 11. Thus, the parameter ![]() $A'$ is defined as

$A'$ is defined as

where ![]() $A$ is the area of one hole and

$A$ is the area of one hole and ![]() $\overline {R_0}$ is the mean maximum bubble radius of bubble collapse experiments near the plate.

$\overline {R_0}$ is the mean maximum bubble radius of bubble collapse experiments near the plate.

Figure 11. Top-down view diagrams of porous plates with (a) circular holes, (b) square holes and (c) triangular holes. The tessellation pattern is shown by the green dashed lines with a single tessellation area shaded in green. The orange circles indicate the size of a bubble with equal area to each tessellation area such that ![]() $A' = 1$.

$A' = 1$.

Figure 12 shows data for four different plates. One plate has very large tessellation unit area compared with the average bubble size (![]() $A' = 12.54$), whereas the other three have area ratios in the range

$A' = 12.54$), whereas the other three have area ratios in the range ![]() $1.78 \leq A' \leq 3.28$. For each plate, bubbles are positioned above a hole and between-holes. The dashed lines follow bubbles above holes and the solid lines follow bubbles between-holes. It is immediately clear that there is a distinct separation of data, with bubbles above holes displacing significantly less, and rebounding to a smaller size, than bubbles between-holes. However, as the standoff distance increases, the dashed and solid lines converge. For the three plates with smaller holes, at sufficiently large standoff distances, the lines merge completely and the data become independent of horizontal position (within experimental variation). For these three data sets, the data become independent of horizontal position at approximately

$1.78 \leq A' \leq 3.28$. For each plate, bubbles are positioned above a hole and between-holes. The dashed lines follow bubbles above holes and the solid lines follow bubbles between-holes. It is immediately clear that there is a distinct separation of data, with bubbles above holes displacing significantly less, and rebounding to a smaller size, than bubbles between-holes. However, as the standoff distance increases, the dashed and solid lines converge. For the three plates with smaller holes, at sufficiently large standoff distances, the lines merge completely and the data become independent of horizontal position (within experimental variation). For these three data sets, the data become independent of horizontal position at approximately ![]() $\gamma = 3$. In general, as

$\gamma = 3$. In general, as ![]() $A'$ decreases, convergence occurs at lower standoff distances. Thus, the horizontal position of the bubble is unimportant for displacement and rebound size when the pattern of holes is on a scale smaller than the bubble size. This is confirmed by figure 10 where the porous plate data (with

$A'$ decreases, convergence occurs at lower standoff distances. Thus, the horizontal position of the bubble is unimportant for displacement and rebound size when the pattern of holes is on a scale smaller than the bubble size. This is confirmed by figure 10 where the porous plate data (with ![]() $A' = 0.13$) for above a hole and between-holes are plotted together and show no greater spread than the non-porous plate data in the same figure. In addition, for small holes (low

$A' = 0.13$) for above a hole and between-holes are plotted together and show no greater spread than the non-porous plate data in the same figure. In addition, for small holes (low ![]() $W / R_0$) at very low void fractions, the dimensionless area

$W / R_0$) at very low void fractions, the dimensionless area ![]() $A'$ can be large but does not result in significant splitting of the data.

$A'$ can be large but does not result in significant splitting of the data.

Figure 12. (a) Normalised displacement plotted against standoff distance. (b) Normalised rebound radius plotted against standoff distance. Data are plotted for four porous plates with tesselation unit areas ![]() $A' > 1.5$. To more easily distinguish data sets, data for bubbles positioned between-holes are traced by solid lines and data for bubbles positioned above holes are traced by dashed lines. Data markers have shapes corresponding to the shape of holes in the plates (circles, squares and triangles). Similar plots for all data sets are available in the supplementary material and movies.

$A' > 1.5$. To more easily distinguish data sets, data for bubbles positioned between-holes are traced by solid lines and data for bubbles positioned above holes are traced by dashed lines. Data markers have shapes corresponding to the shape of holes in the plates (circles, squares and triangles). Similar plots for all data sets are available in the supplementary material and movies.

The data in figure 12 represent three different hole shapes: a square, a circle and a triangle. The square and smaller circular holes have very similar area ratios and produce almost identical curves for both displacement and rebound size. The triangular holes are slightly smaller and show slightly less splitting of the data. Thus, using the dimensionless area ![]() $A'$, the shape of holes can be considered unimportant. This can be explained by the short timescale on which these flows occur. In less rapid flows, the shape of a hole is important due to the viscous boundary layers that form around the edge of the hole. Shapes such as triangles have a greater perimeter per unit area when compared with circles. This increased surface leads to more boundary layers forming which further restrict the flow. However, for flow induced by a bubble collapsing near a hole, there is insufficient time for a significant viscous boundary layer to form and, thus, the shape of the hole becomes insignificant. This can be shown with the approximate relation

$A'$, the shape of holes can be considered unimportant. This can be explained by the short timescale on which these flows occur. In less rapid flows, the shape of a hole is important due to the viscous boundary layers that form around the edge of the hole. Shapes such as triangles have a greater perimeter per unit area when compared with circles. This increased surface leads to more boundary layers forming which further restrict the flow. However, for flow induced by a bubble collapsing near a hole, there is insufficient time for a significant viscous boundary layer to form and, thus, the shape of the hole becomes insignificant. This can be shown with the approximate relation ![]() $\delta \sim \sqrt {\nu t}$ where

$\delta \sim \sqrt {\nu t}$ where ![]() $\delta$ is the approximate scale of the boundary layer thickness,

$\delta$ is the approximate scale of the boundary layer thickness, ![]() $\nu$ is the kinematic viscosity and

$\nu$ is the kinematic viscosity and ![]() $t$ is the time over which the boundary layer would develop. The kinematic viscosity of water at room temperature is approximately

$t$ is the time over which the boundary layer would develop. The kinematic viscosity of water at room temperature is approximately ![]() $1 \times 10^{-6}$ m

$1 \times 10^{-6}$ m![]() $^2$ s

$^2$ s![]() $^{-1}$. From our experiments, a typical initial growth and collapse cycle occurs in approximately 0.5 ms. Thus, the boundary layer formed in this time would be on the scale of 0.02 mm which is much smaller than the size of the holes and so can be considered insignificant.

$^{-1}$. From our experiments, a typical initial growth and collapse cycle occurs in approximately 0.5 ms. Thus, the boundary layer formed in this time would be on the scale of 0.02 mm which is much smaller than the size of the holes and so can be considered insignificant.

4.4. Variation of displacement and rebound ratio with void fraction

From the observations above, we can neglect the influence of hole size, hole shape and horizontal position for porous plates with dimensionless area ![]() $A' < 1.5$ or with small holes (

$A' < 1.5$ or with small holes (![]() $W / R_0 < 1$). All analysis hereafter relies only on data within this regime and we now further investigate the influence of the void fraction.

$W / R_0 < 1$). All analysis hereafter relies only on data within this regime and we now further investigate the influence of the void fraction.

Starting from a non-porous plate, with zero void fraction and then increasing the void fraction, figure 13(a) shows that displacement decreases as void fraction increases. Similarly, figure 13(b) shows that the rebound size ratio decreases as the void fraction increases. Both of these confirm that higher plate porosity results in less asymmetry in the bubble collapse. Despite the decrease in displacement and rebound ratio with increasing void fraction, the gradient remains remarkably similar for all void fractions.

Figure 13. (a) Normalised displacement plotted against standoff distance for a range of void fractions ![]() $\phi$. (b) Bubble rebound radius ratio plotted against standoff distance for a range of void fractions

$\phi$. (b) Bubble rebound radius ratio plotted against standoff distance for a range of void fractions ![]() $\phi$. Straight-line curve fits are shown for three representative cases in each of (a) and (b). (c) Normalised displacement plotted against void fraction

$\phi$. Straight-line curve fits are shown for three representative cases in each of (a) and (b). (c) Normalised displacement plotted against void fraction ![]() $\phi$ for standoff distances corresponding to the grey dashed lines in (a). (d) Bubble rebound radius ratio plotted against void fraction for standoff distances corresponding to the grey dashed lines in (b). Only data for plates with

$\phi$ for standoff distances corresponding to the grey dashed lines in (a). (d) Bubble rebound radius ratio plotted against void fraction for standoff distances corresponding to the grey dashed lines in (b). Only data for plates with ![]() $A' < 1.5$ or

$A' < 1.5$ or ![]() $W / \overline {R_0} < 1$ are included in these plots.

$W / \overline {R_0} < 1$ are included in these plots.

To find out how the displacement and rebound size depend on void fraction, we take vertical slices at three stand-off distances. For each slice, the displacement and rebound size values at a given void fraction are calculated from straight-line fits to each data set shown in figures 13(a) and 13(b). Three such curve fits are shown on each of figures 13(a) and 13(b) as examples. Figures 13(c) and 13(d) show displacement and rebound size ratio as functions of void fraction for three values of standoff distance. The displacement and rebound radius both decrease as the void fraction increases. Both displacement and rebound radius show fairly uniform sensitivity to void fraction across different standoff distances, although the displacement is marginally more sensitive at low standoff distances.

5. Anisotropy parameter for porous plates

In the previous section, we have shown how displacement and radius ratio vary with both standoff distance and void fraction. In order to unify these parameters, and compare these results with other geometries, it is desirable to formulate the anisotropy parameter as a function of standoff distance and void fraction. We assume that the anisotropy of a porous plate is only a function of void fraction ![]() $\phi$ and standoff distance

$\phi$ and standoff distance ![]() $\gamma$:

$\gamma$:

In this section, we present two methods of determining the function ![]() $f(\phi, \gamma )$.

$f(\phi, \gamma )$.

5.1. Displacement and rebound ratio as a function of anisotropy

The first formulation of the anisotropy parameter is the implementation of the numerical method described in § 3.2. Using this method, experimental measurements of displacement and rebound ratio can be plotted as a function of the anisotropy predictions as shown in figure 14(a,b). Although not perfect, it shows reasonable collapse of most data onto a single curve for each of the two measurements.

Figure 14. (a) Normalised displacement and (b) rebound radius ratio plotted against the anisotropy parameter magnitude ![]() $\zeta$ predicted by the numerical model. (c) Normalised displacement and (d) rebound radius ratio plotted against the anisotropy parameter magnitude

$\zeta$ predicted by the numerical model. (c) Normalised displacement and (d) rebound radius ratio plotted against the anisotropy parameter magnitude ![]() $\zeta$ estimated by fitting displacement data to the non-porous plate data. Data are coloured by void fraction

$\zeta$ estimated by fitting displacement data to the non-porous plate data. Data are coloured by void fraction ![]() $\phi$. The grey data points in (c) and (d) are from Andrews & Peters (Reference Andrews and Peters2022). The black dashed line is a curve fit to the porous plates data. The black dash-dotted line is the curve fit from Andrews & Peters (Reference Andrews and Peters2022). The black dash-dot-dotted line is derived from the curve fit of Supponen et al. (Reference Supponen, Obreschkow and Farhat2018).

$\phi$. The grey data points in (c) and (d) are from Andrews & Peters (Reference Andrews and Peters2022). The black dashed line is a curve fit to the porous plates data. The black dash-dotted line is the curve fit from Andrews & Peters (Reference Andrews and Peters2022). The black dash-dot-dotted line is derived from the curve fit of Supponen et al. (Reference Supponen, Obreschkow and Farhat2018).

Using the numerical model, we find that the anisotropy parameter varies almost exactly with ![]() $\gamma ^{-2}$ across all porous plates (a plot of this is available in the supplementary material and movies). This is consistent with all the other anisotropy functions for flat geometries presented by Supponen et al. (Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016). Thus, we simplify (5.1) to

$\gamma ^{-2}$ across all porous plates (a plot of this is available in the supplementary material and movies). This is consistent with all the other anisotropy functions for flat geometries presented by Supponen et al. (Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016). Thus, we simplify (5.1) to

leaving only the function ![]() $g(\phi )$ to be determined. Using the numerical model, the prefactor

$g(\phi )$ to be determined. Using the numerical model, the prefactor ![]() $g(\phi )$ is plotted as the orange line in figure 15. This was computed for a

$g(\phi )$ is plotted as the orange line in figure 15. This was computed for a ![]() $50\ {\rm mm} \times 50\ {\rm mm}$ plate using 19 756 elements, with element lengths ranging between

$50\ {\rm mm} \times 50\ {\rm mm}$ plate using 19 756 elements, with element lengths ranging between ![]() $0.35$ and

$0.35$ and ![]() $0.42$ mm, where larger elements were used around the edge of the plate. As the void fraction increases, the prefactor

$0.42$ mm, where larger elements were used around the edge of the plate. As the void fraction increases, the prefactor ![]() $g(\phi )$ decreases. At a void fraction

$g(\phi )$ decreases. At a void fraction ![]() $\phi = 0$, identically a non-porous plate, the prefactor approaches the solution for a non-porous plate

$\phi = 0$, identically a non-porous plate, the prefactor approaches the solution for a non-porous plate ![]() $g(0) = 0.195$. Notably, due to differences between the numerical model and analytic solution for a flat plate, the boundary element method solution does not reach

$g(0) = 0.195$. Notably, due to differences between the numerical model and analytic solution for a flat plate, the boundary element method solution does not reach ![]() $0.195$. At the opposite limit, with void fraction

$0.195$. At the opposite limit, with void fraction ![]() $\phi = 1$, the plate does not exist, resulting in zero anisotropy, thus

$\phi = 1$, the plate does not exist, resulting in zero anisotropy, thus ![]() $g(1) = 0$. Between these limits the gradient of the prefactor is highest at low void fractions, indicating higher sensitivity to void fraction when the void fraction is low. This conclusion is also reflected in the shape of the curves in figure 13(c,d).

$g(1) = 0$. Between these limits the gradient of the prefactor is highest at low void fractions, indicating higher sensitivity to void fraction when the void fraction is low. This conclusion is also reflected in the shape of the curves in figure 13(c,d).

Figure 15. Prefactors ![]() $g(\phi )$ where

$g(\phi )$ where ![]() $\zeta = g(\phi ) \gamma ^{-2}$ plotted against void fraction

$\zeta = g(\phi ) \gamma ^{-2}$ plotted against void fraction ![]() $\phi$. Experiment data points are computed from fitting displacement data for porous plates with the non-porous plate data. Horizontal error bars represent the range of possible void fractions for each data point. Vertical error bars are the standard deviation from the least squares fit of

$\phi$. Experiment data points are computed from fitting displacement data for porous plates with the non-porous plate data. Horizontal error bars represent the range of possible void fractions for each data point. Vertical error bars are the standard deviation from the least squares fit of ![]() $g(\phi )$. Points are coloured by the dimensionless width of the holes.

$g(\phi )$. Points are coloured by the dimensionless width of the holes.

The second formulation for the anisotropy parameter assumes that displacement is solely a function of the anisotropy parameter ![]() $\zeta$ and maintains the assumption that the anisotropy can be written as (5.2). The analytic solution for a non-porous plate (

$\zeta$ and maintains the assumption that the anisotropy can be written as (5.2). The analytic solution for a non-porous plate (![]() $g(0) = 0.195$) can be applied to the non-porous plate data to give the measured displacement as a function of anisotropy. Then, for each porous plate data set, the prefactor

$g(0) = 0.195$) can be applied to the non-porous plate data to give the measured displacement as a function of anisotropy. Then, for each porous plate data set, the prefactor ![]() $g(\phi )$ can be fitted such that the porous plate data follows the same curve for displacement against anisotropy. This curve fit is performed using the logarithmic least-squares difference between each data set and the curve fit on the non-porous plate data.

$g(\phi )$ can be fitted such that the porous plate data follows the same curve for displacement against anisotropy. This curve fit is performed using the logarithmic least-squares difference between each data set and the curve fit on the non-porous plate data.

Using the fitted prefactors ![]() $g(\phi )$, the data collapses very well onto single curves for displacement and rebound radius as shown in figure 14(c,d). It should be noted that only the displacement curve is fitted and the resulting values cause the rebound radius data to collapse as well, suggesting that these values are representative of the underlying physics and not simply overfitting to the data.

$g(\phi )$, the data collapses very well onto single curves for displacement and rebound radius as shown in figure 14(c,d). It should be noted that only the displacement curve is fitted and the resulting values cause the rebound radius data to collapse as well, suggesting that these values are representative of the underlying physics and not simply overfitting to the data.

The fitted prefactors are shown alongside the numerically predicted curve in figure 15 with vertical error bars of one standard deviation of the least-squares fit. In this plot, different horizontal positions are treated as distinct data sets, resulting in two data points for each porous plate which are typically very closely aligned.

Figure 15 shows that the boundary element method agrees well with the experimentally determined prefactors. However, at low void fractions the experimental values tend to be below the numerical predictions, whereas at higher void fractions they tend to be above. This may suggest that there are some nuances to the behaviour that the numerical model cannot capture. For example, the model does not account for how bubble deformation and displacement may interact with the porous plates. Despite these differences, the overall agreement with experimentally determined prefactors suggests that the principal effect of porosity on the anisotropy parameter is the reduction in effective area compared with a non-porous plate.

An empirical curve fit for the anisotropy parameter is desirable in order to further reduce the cost of modelling porous boundaries. It is noted that the two limits of ![]() $g(\phi )$ are

$g(\phi )$ are ![]() $g(0) = 0.195$ and

$g(0) = 0.195$ and ![]() $g(1) = 0$. We assume that

$g(1) = 0$. We assume that ![]() $g(\phi )$ is a nonlinear, smooth function between these limits of the form

$g(\phi )$ is a nonlinear, smooth function between these limits of the form

where ![]() $k$ is the single parameter to be fitted. Using the experimental data shown in figure 15, the fitted parameter

$k$ is the single parameter to be fitted. Using the experimental data shown in figure 15, the fitted parameter ![]() $k$ is found to be 0.50 with a standard deviation of 0.03. This curve fit is plotted alongside the data in figure 15 which shows good agreement with experimental data. The anisotropy can therefore be written as

$k$ is found to be 0.50 with a standard deviation of 0.03. This curve fit is plotted alongside the data in figure 15 which shows good agreement with experimental data. The anisotropy can therefore be written as

for all ![]() $\phi \in [0, 1]$, effectively providing a single equation for displacement and rebound radius for any void fraction and standoff distance.

$\phi \in [0, 1]$, effectively providing a single equation for displacement and rebound radius for any void fraction and standoff distance.

5.2. Disparity with other experimental methodologies

Computing the anisotropy for these data allows them to be compared with prior research, as shown in figure 14(c,d). Figure 14(d) shows the curve presented by Supponen et al. (Reference Supponen, Obreschkow, Kobel, Tinguely, Dorsaz and Farhat2017) as well as data points from Andrews & Peters (Reference Andrews and Peters2022) which used a different experimental method than the present research. Although there is significant spread in the data from Andrews & Peters (Reference Andrews and Peters2022), it does not follow the same curve as the present research. The curve presented by Supponen et al. (Reference Supponen, Obreschkow, Kobel, Tinguely, Dorsaz and Farhat2017) is even further different. This reinforces our previous suggestion that there is likely another factor that varies between experimental methodologies that can significantly affect the bubble rebound size (Andrews & Peters Reference Andrews and Peters2022).

Figure 14(c) shows data points and the curve fit for displacement against anisotropy for a range of complex geometries presented by Andrews & Peters (Reference Andrews and Peters2022). This collapsed curve is markedly different to the curve presented in the present research. The principal difference between the two works is that the previous research used a microscope objective to create bubbles whereas the current research uses an off-axis parabolic mirror. This difference in displacement is likely partly due to smaller rebounds, but may also be affected by bubble morphology due to the difference in plasma shapes created by different focusing optical elements.

6. Conclusion

In this research, we have investigated how a pattern of through-holes in a rigid boundary affect the dynamics of a collapsing bubble. We have demonstrated how bubbles expand preferentially towards the holes and less towards the solid parts of the boundaries. We have shown that the displacement and rebound radius do not depend significantly on the shape of the holes, and the size of the holes only becomes important when comparable to the bubble size (dimensionless tessellation unit area ![]() $A' > 1.5$). Bubbles used in ultrasonic cleaning theoretically vary between 0.1 and 100

$A' > 1.5$). Bubbles used in ultrasonic cleaning theoretically vary between 0.1 and 100 ![]() $\mathrm {\mu }$m in radius, depending on the driving frequency and power, with experiments showing typical radii of the order of a few micrometres up to approximately

$\mathrm {\mu }$m in radius, depending on the driving frequency and power, with experiments showing typical radii of the order of a few micrometres up to approximately ![]() $20\ \mathrm {\mu }$m (Brotchie, Grieser & Ashokkumar Reference Brotchie, Grieser and Ashokkumar2009; Fernandez Rivas et al. Reference Fernandez Rivas, Verhaagen, Seddon, Zijlstra, Jiang, van der Sluis, Versluis, Lohse and Gardeniers2012, Reference Fernandez Rivas, Stricker, Zijlstra, Gardeniers, Lohse and Prosperetti2013). The pore size of filters varies depending on the intended application. Reuter et al. (Reference Reuter, Lauterborn, Mettin and Lauterborn2017) reference a pore size of 30 nm, for example. Thus, the applicability of this regime varies with application.

$20\ \mathrm {\mu }$m (Brotchie, Grieser & Ashokkumar Reference Brotchie, Grieser and Ashokkumar2009; Fernandez Rivas et al. Reference Fernandez Rivas, Verhaagen, Seddon, Zijlstra, Jiang, van der Sluis, Versluis, Lohse and Gardeniers2012, Reference Fernandez Rivas, Stricker, Zijlstra, Gardeniers, Lohse and Prosperetti2013). The pore size of filters varies depending on the intended application. Reuter et al. (Reference Reuter, Lauterborn, Mettin and Lauterborn2017) reference a pore size of 30 nm, for example. Thus, the applicability of this regime varies with application.

The bubble displacement and rebound radius depend strongly on both the standoff distance and void fraction of the porous plate. These parameters can be unified in terms of the anisotropy parameter with (5.4). Using this unified parameter, all data for porous plates collapse onto single curves for displacement and rebound radius. However, the collapsed curves vary from those found for our previous work (Andrews & Peters Reference Andrews and Peters2022) which used a different experimental method. Nevertheless, (5.4) can be combined with scaling laws from prior research (Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016) to predict other bubble collapse properties such as jet speed.

This work provides a solid first step towards characterising bubble behaviour near porous plates and connects this geometry to the wider framework of investigations using the anisotropy parameter. Further work is required to connect this framework of single-bubble collapse to applications such as ultrasonic cleaning. For example, understanding the geometric distribution of bubble collapse events induced by an ultrasound field; the combined effect of multiple bubbles; and the relation between surface shear stress and the anisotropy parameter. Investigation of the surface pressure distribution of porous plates, and complex geometries in general, would also provide valuable insight into the cleaning effects of collapsing bubbles. This could be addressed either experimentally or with more complex numerical models than the one employed in the present research.

Supplementary material and movies

Supplementary material and movies are available at https://doi.org/10.1017/jfm.2023.266.

Funding

We acknowledge financial support from the EPSRC under grant no. EP/P012981/1. D.F.R. acknowledges the funding from the European Research Council (ERC) under the European Union's Horizon 2020 research and innovation programme (grant agreement number 851630). Data and code supporting this study are openly available from the University of Southampton repository at https://doi.org/10.5258/SOTON/D2582.

Declaration of interests

The authors report no conflict of interest.