Introduction

In the annually cultivated crops of Australia’s cropping regions, it is annual weed species that are problematic. The persistence of these weeds in cropping systems relies on the maintenance of a viable seed bank; thus, the focus for weed control programs is the prevention of inputs into the weed seed bank (Buhler et al., Reference Buhler, Hartzler and Forcella1997; Mohler, Reference Mohler2001). In reality, all weed management practices will, when effective, act to prevent seed bank inputs. However, as the growing season progresses, the focus for weed management shifts from in-crop weed control concentrated on preventing current-season yield losses to restricting weed seed bank inputs aimed at and avoiding future yield losses.

The retention of high proportions of total seed production at maturity has been identified as a key biological attribute of problematic annual weed species of Australian cropping systems. Rigid ryegrass, wild radish (Raphanus raphanistrum L.), brome grass (Bromus spp. Roth.), and wild oats (Avena fatua L.) all retain significant proportions of total seed production at crop maturity (Walsh and Powles Reference Walsh and Powles2014). During crop harvest these seeds are collected, threshed, separated from the grain, and expelled from the harvester in the chaff fraction (Broster et al. Reference Broster, Walsh and Chambers2016). Modern grain harvesters are fitted with straw and chaff residue spreading systems that redistribute this weed seed–containing material evenly across the field and back into the seedbank (Barroso et al. Reference Barroso, Navarrete, Sánchez Del Arco, Fernandez-Quintanilla, Lutman, Perry and Hull2006; Blanco-Moreno et al. Reference Blanco-Moreno, Chamorro, Masalles, Recasens and Sans2004).

In Australia, for more than 3 decades the harvest operation has been recognized as a weed control opportunity, representing the last chance during the growing season to restrict seed bank inputs of annual weed species (Gill Reference Gill1996; Matthews et al. Reference Matthews, Llewellyn, Powles and Reeves1996). Frequently in Australian cropping systems, seed-bearing annual weeds present at crop maturity have survived in-crop weed control treatments as a result of herbicide resistance (Boutsalis et al. Reference Boutsalis, Gill and Preston2012; Broster et al. Reference Broster, Koetz and Wu2013; Broster and Pratley Reference Broster and Pratley2006; Owen et al. Reference Owen, Martinez and Powles2014, Reference Owen, Martinez and Powles2015). Subsequently, many HWSC systems have been developed for the specific purpose of targeting the seed production of these surviving weeds to restrict contributions to the seed bank (Walsh et al. Reference Walsh, Aves and Powles2017b; Walsh et al. Reference Walsh, Harrington and Powles2012; Walsh and Newman Reference Walsh and Newman2007; Walsh et al. Reference Walsh, Newman and Powles2013).

HWSC is an established weed control practice in Australian cropping systems with high levels of adoption that are expected to dramatically increase over the next decade. A 2014 survey of Australian growers established that 43% were routinely using an HWSC system to target weed seed production during grain harvest (Walsh et al. Reference Walsh, Ouzman, Newman, Powles and Llewellyn2017a). A challenge with the use of current commonly used HWSC systems is that they compromise conservation cropping systems by removing crop residues from across the field or concentrating these residues into restricted areas. The result of this removal or concentration is a loss of nutrients and reduced potential for soil moisture storage. Only the Harrington Seed Destructor (HSD), which processes the weed seed–bearing chaff fraction during harvest, allows the retention of all harvest residues (Walsh et al. Reference Walsh, Harrington and Powles2012). However, the adoption of this approach has been low as a result of grower concerns about the interference with the harvester operation by towing a large trailer-mounted system, as well as the perceived high purchase price (Walsh et al. Reference Walsh, Ouzman, Newman, Powles and Llewellyn2017a). The development and subsequent recent commercial introduction of the iHSD addresses these barriers to adoption of a chaff-processing approach to HWSC. The iHSD system is based on a newly designed impact mill that is powered by the harvester. This system is mounted at the rear of the harvester to specifically collect and process the chaff material as it exits the harvester. The efficacy of this new impact mill on targeting the seeds of Australia’s major crop weeds is currently unknown. Therefore, the aims of this study were to determine the (i) effective operational mill speed that delivered >95% rigid ryegrass seed destruction, (ii) efficacy of the impact mill on common weed species of Australian cropping systems, and (iii) influence of chaff type and moisture content on iHSD mill efficacy.

Materials and Methods

General Testing Procedures

Wheat chaff collected from a farm near Corrigin, WA (32.33°S, 117.88°E) was used in testing the iHSD mill efficacy on rigid ryegrass, wild radish, wild oats, and bromegrass in 2015. Wheat chaff from Rand, NSW, was used for testing the mill efficacy in 2016 on hairy fleabane [Conyza bonariensis (L.) Cronq.], windmillgrass (Chloris truncata R. Br.), feather fingergrass (Chloris virgata Sw.), and annual sowthistle [Sonchus oleraceus (L.) L.]. To facilitate manual recovery of the seed and seed fractions of larger seeded species (rigid ryegrass, wild radish, brome grass, and wild oats), dyed seed lots were mixed in with chaff samples prior to processing. These weed seeds were dyed by immersing in a 2% edicol dye solution for 15 minutes. Seeds were then spread on paper toweling to dry overnight. Three replicated seed lots were counted out for each weed species (Table 1). Wild radish pod segments were counted and then dyed, as seed are contained firmly within pods and pod segments at maturity and during harvest. The viability of dyed seed lots used in iHSD mill testing was established prior to testing by placing three replicates of 100 seeds on 0.6% (w/v) agar solidified in petri dishes in a daytime temperature-controlled laboratory with alternating temperatures 25/15 C and 11- to 13-h photoperiod. Over 28 d, germinating seeds were counted and removed daily. Seeds were classified as viable if they germinated. Seeds were also considered viable but dormant if they did not germinate but did not decay. The resulting average proportion of viable seed was used to adjust the seed lots to total viable seed number used in testing. Wild radish seed viability was determined by counting three replicate lots of 100 segments, then dissecting these segments to remove the seeds. These were then placed on agar and allowed to germinate as previously described. Seed germination was then used to convert pod segment number to viable wild radish seed number.

Table 1 Number of seeds introduced in wheat chaff, individual seed weights, and percentage destruction of seed of 11 weed species of Australian cropping systems used in stationary testing of the iHSD mill. Numbers in parentheses are the standard errors for the mean of eight replicates.

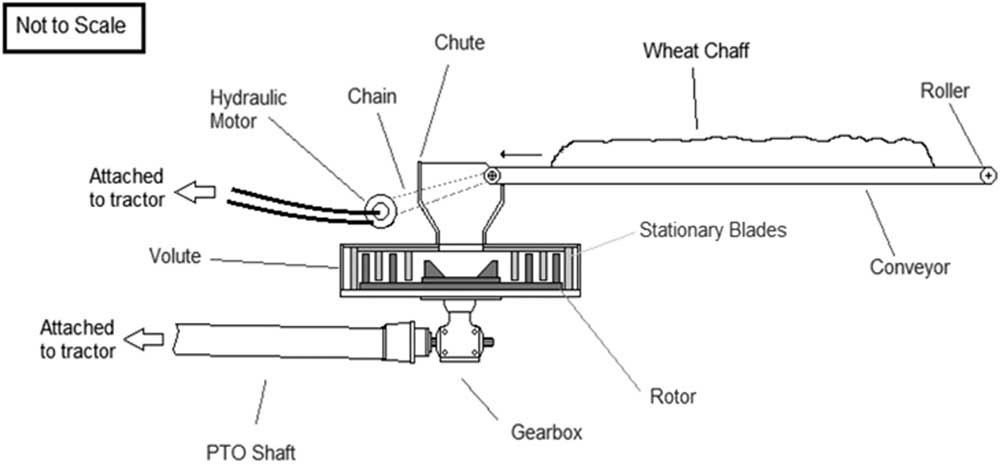

During mill testing, 2-kg samples of wheat chaff were spread across the conveyor belt, and a single weed seed lot was then mixed through the chaff in preparation for delivery into the iHSD mill (Figure 1). The conveyor belt speed was set to provide a chaff delivery rate of 1.5 kg s–1, equivalent to the amount of chaff that a single mill would have to process at a wheat grain harvest rate of 35,000kgh–1. This harvest rate is near maximum operational capacity for current commonly available large-capacity harvesters. For every 1,000 kg of wheat grain harvested, 300 kg of chaff is produced (Broster et al. Reference Broster, Walsh and Chambers2016). Therefore, a wheat harvest rate of 35,000kgh–1 produces 10,600kg chaff h–1. At this rate of chaff production, each mill in a twin-mill iHSD system, must process 1.5 kg chaff s–1.

Figure 1 Schematic of iHSD test stand showing the mill and conveyor belt chaff delivery system. Modified from Guzzomi et al. 2017.

Once the iHSD mill was operating at the required speed, the conveyor belt was activated and the weed seed–bearing chaff material was delivered into the center of the mill. The processed chaff material exiting the mill was collected in a 0.5-mm woven mesh bag fitted to the outlet chute of the mill. Collected chaff was transferred to paper bags for storage prior to the conduct of seed viability testing. Chaff samples were stored for up to 2 mo under ambient (15 to 25 C) dry conditions in temperature-controlled laboratories.

iHSD Mill Speed and Efficacy Testing

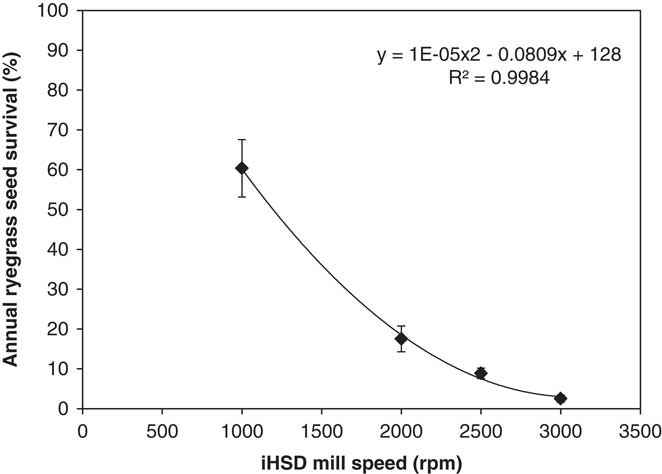

Wheat chaff samples containing 1,000 dyed rigid ryegrass seeds (Table 1) were introduced at a standard delivery rate of 1.5 kg s–1 into the iHSD mill at four speeds (1,000, 2,000, 2,500, and 3,000 rpm). Four replicate samples were processed at each mill speed. Weed seed and seed fragments were manually collected from the processed chaff samples and their viability tested by germinating them on agar-filled petri dishes as previously described. These studies identified the effective operational speed of 3,000 rpm, which was the mill speed used throughout the remaining testing.

The efficacy of the iHSD mill was initially evaluated on four weed species: rigid ryegrass, wild radish, brome grass, and wild oats (Table 1). In each instance, dyed seed lots of each weed species were added to four replicate 2-kg wheat chaff samples spread evenly across the conveyor belt. These samples were then introduced at a feed rate of 1.5 kg ha–1 to the mill operating at 3,000 rpm. For rigid ryegrass, wild radish, brome grass, and wild oats, the weed seeds and seed fragments were manually collected from the chaff samples and viability was tested using the procedures as previously described.

Repeat testing of the iHSD mill was conducted on the previously tested species plus seven additional weed species using wheat chaff sourced from a farm near Culcairn, NSW (Table 1). Weed seed lots were introduced into the mill in 2.0-kg samples of wheat chaff at 1.5 kg s–1 as previously described. This testing was conducted at two timings. At the first timing all 11 species were individually introduced into the iHSD mill in four replicate samples. At the second timing, junglerice [Echinochloa colona (L.) Link], barley grass (Hordeum leporinum L.), hairy fleabane, feather fingergrass, windmillgrass, Oriental mustard (Sisymbrium orientale Torn.), and annual sowthistle were individually tested in four replicate samples. To test weed seed viability in these samples, an alternate method was developed for recording the emergence of weed seedlings from processed chaff samples. Initially, the effect of processed chaff on weed seedling emergence was examined, wherein viable seeds of each species were added to four chaff/potting mix mixtures that were then spread across trays (each 0.1 m2) filled with potting mix. Four replicates of 100-seed lots of each weed species were individually mixed with 0, 10, 20, 40, 50, 100, 150, or 200 g of processed chaff prior to planting in separate trays filled with potting mix. After planting, the trays were thoroughly watered and then maintained at around field capacity for approximately 4 wk, with any seedlings that emerged during this period counted and removed. Weed seedling emergence was reduced by all chaff amounts of 40 g and above. Therefore, to maximize the amount of chaff used for germination testing, 20-g subsamples were used in subsequent seed viability testing.

Each processed chaff sample was thoroughly mixed before collecting five 20-g subsamples. These subsamples were then mixed through the top 2.0 cm of potting mix–filled trays before watering. Trays were maintained near field capacity, and emerging seedlings were counted and removed over a 28-d period.

Influence of Chaff Type and Moisture Content on iHSD Mill Efficacy

Samples of four chaff types (lupine, wheat, barley, and canola) were collected after the 2014 harvest from chaff heaps on a farm near Corrigin, WA. For each chaff type, four 2-kg replicate samples were weighed into plastic buckets and then spread on the conveyor belt. Rigid ryegrass seed and chaff samples were introduced to the iHSD mill operating at 3,000 rpm at a rate of 1.5 kg s–1 as previously described. Seed and seed fragments were manually collected from processed chaff samples and viability assessed by germination on agar as previously described.

Wheat chaff was oven dried for 2 d at 70 C before weighing and 2-kg sub-samples placed into sealable plastic bags. Prescribed amounts of water were added to each 2-kg sample to establish four replicates of four moisture contents: 10%, 12%, 14%, and 16% (w/w). The chaff samples were mixed thoroughly, and the plastic bags were then sealed for 24 h until required for testing. Rigid ryegrass seed was added to these chaff samples after they were spread across the conveyor belt just prior to introduction to the iHSD mill, operating at 3,000 rpm. Rigid ryegrass seeds and seed fragments were manually collected and viability determined using the methods as previously described.

Evaluation of iHSD System during Commercial Harvest

The weed seed destruction efficacy of the iHSD system on rigid ryegrass, brome grass, wild oats, and wild radish was evaluated in 2014 during the harvest of barley and canola crops with an iHSD-fitted Case 8120 harvester. Dyed seed lots, containing the same seed numbers of each weed species used in iHSD mill testing (Table 1), were introduced into the top of an iHSD mill, during the harvest of barley and canola plots. With the harvester operating at near capacity and the iHSD mills operating at 3,000 rpm, each weed species was introduced to a single mill, individually during the harvest of four replicate plots (60 m2 each). A mesh (0.5 mm) bag fitted to the outlet chute of this mill collected the processed chaff. The collected chaff samples were sorted to retrieve seed and seed fragments for viability testing as previously described.

Statistical Analyses

Prior to analysis and presentation, viable seed survival numbers were converted to percentage seed kill values using Equation 1.

Microsoft Excel was used to fit the polynomial curve to the iHSD mill speed test data comparing speed to seed survival (Figure 2). ANOVA of weed species seed kill data confirmed that there was not an interaction effect (P>0.05) due to the two sources of wheat chaff (i.e., Culcairn and Corrigin) in testing iHSD efficacy on rigid ryegrass, wild radish, brome grass, and wild oats. Similarly, ANOVA confirmed that there was not an interaction effect (P>0.05) due to time of testing for the other seven species (Table 1). Data were then pooled for a one-way ANOVA, using a general linear model for seed kill data evaluating the influence of weed species, chaff type, and moisture content on iHSD mill efficacy. For each of these experiments, LSD tests at P=0.05 were used for means separation.

Figure 2 Influence of iHSD mill speed on the survival of annual ryegrass seed processed in wheat chaff.

Results and discussion

Identifying Optimum iHSD Mill Speed

The iHSD mill speed of 3,000 rpm delivered an acceptably high (98%) level of rigid ryegrass seed kill and was therefore chosen as the optimal speed for further testing. At the lowest iHSD mill speed (1,000 rpm), there was only 60% seed kill (Figure 2). When mill speed was doubled to 2,000 rpm, seed kill increased to 83%. From this speed onward, every 500 rpm increase resulted in higher levels of seed kill, indicating a quadratic relationship between mill speed and rigid ryegrass seed kill. It was only at the maximum mill speed that an acceptable level of rigid ryegrass seed kill was achieved. Therefore, the 3,000 rpm speed was subsequently used in all further testing.

Efficacy of iHSD Mill on Australian Weed Species

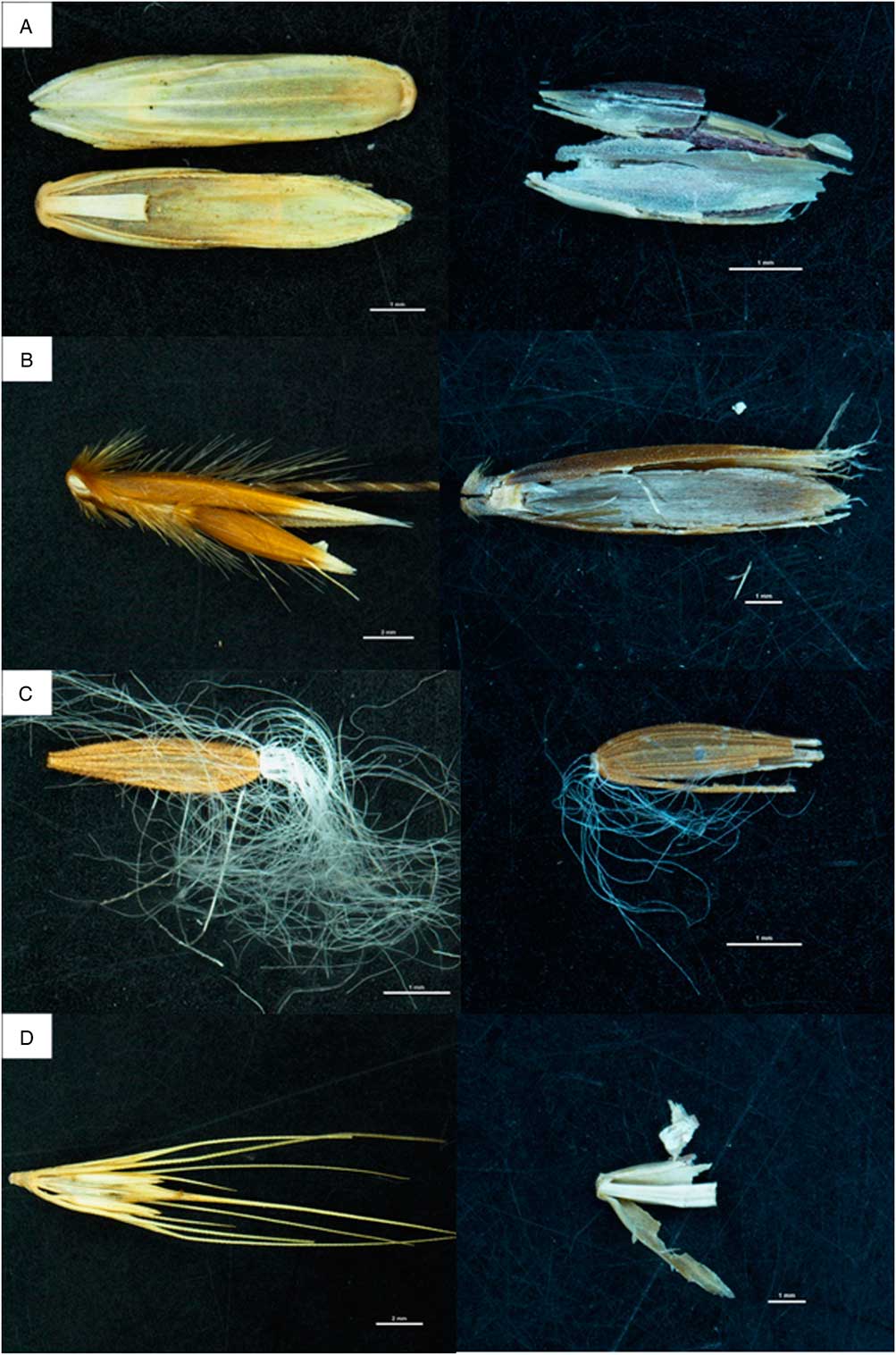

The iHSD mill effectively destroyed the seed of 11 major weed species of Australian cropping systems. The iHSD mill operating at 3,000 rpm produced very high (>95%) seed kill levels of these weed species when they were processed in wheat chaff delivered into the mill at 1.5 kg s–1 (Table 1). For the majority of species, there was 99% seed kill, whereas rigid ryegrass seed proved to be most difficult to control with the lowest (P<0.05) seed kill of 96%. There were also lower (P<0.05) levels of seed kill for feather fingergrass and windmillgrass. Overall seed kill levels were high for all species, demonstrating that the iHSD mill was similarly effective on seed from a range of weed species irrespective of seed size and shape (Figure 3). These results highlight the potential of the iHSD system to effectively destroy weed seeds during grain crop harvest. Similarly, high levels of seed kill with the iHSD mill have been reported for 15 weed species of US soybean and rice production systems (Schwartz et al Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017). Combined, these studies confirm the ability of the iHSD mill to effectively target the seed of a wide range of weed species during grain harvest.

Figure 3 iHSD mill unprocessed (left photo) and processed (right photo) seed of (A) Lolium rigidum, (B) Avena fatua, (C) Sonchus oleraceus, and (D) Hordeum vulgare.

The iHSD mill and the cage mill, used in the HSD, are impact mills that now have proven efficacy in processing high amounts of chaff material to effectively target weed seeds. The action of the cage mill during wheat harvest has produced seed destruction levels of 95%, 99%, 99%, and 93% for rigid ryegrass, brome grass, wild oat, and wild radish, respectively (Walsh et al. Reference Walsh, Harrington and Powles2012). More recently, similarly high (>97%) seed destruction levels of kochia (Kochia scoparia L. Schrad.), green foxtail [Setaria viridis (L.) P.Beauv.], false cleavers (Galium spurium L.), and wild oats in barley chaff, have been reported for the cage mill during stationary testing (Tidemann et al. Reference Tidemann, Hall, Harker and Beckie2017). Impact mills are now established as the most efficient mechanical approach to weed seed destruction during grain crop harvest. The mechanical control of weed seeds during harvest has been a long-held goal, with many studies exploring this approach over the last 3 decades (Balsari et al. Reference Balsari, Finassi and Airoldi1994; Gossen et al. Reference Gossen, Tyrl, Hauhouot, Peeper, Claypool and Solie1998; Hauhouot-O’Hara et al. Reference Hauhouot-O’Hara, Solie, Whitney, Peeper and Brusewitz1998). Most of these studies focused on the use of hammer and roller mills, where when tested on larger sized weed seeds (e.g., Bromus spp.) in the absence of chaff, produced lower levels of seed kill than have subsequently been achieved with impact mills. Despite the differences in size, configuration, and operational speeds between the cage mill and the iHSD mill, both act by impacting weed seeds against steel bars (Berry et al. Reference Berry, Fielke and Saunders2015). Thus, despite the presence of high amounts of chaff material, this impact action is sufficient to render nonviable the vast majority of weed seeds passing through these mills. As observed in these and previous studies, this impacting action is highly effective in killing weed seeds present in chaff material.

Influence of Chaff Type and Moisture on iHSD Efficacy

Rigid ryegrass seed destruction levels were high for all crop species chaff types, but chaff type did influence the efficacy of the iHSD mill. When rigid ryegrass seeds were processed in equivalent amounts of chaff from the four crop species (lupine, wheat, canola, and barley), there were reductions (P<0.05) in seed kill due to chaff type (Table 2). Seed destruction was highest (P<0.05) in lupine chaff, similar in wheat and canola chaff, and lowest in barley chaff. Similarly, chaff type influenced canola seed destruction during stationary testing of an HSD mill (Tidemann et al. Reference Tidemann, Hall, Harker and Beckie2017). Canola seed destruction was reduced (P<0.05) when processed in canola chaff compared to processing in barley or pea chaff. However, under commercial harvest conditions, there was no effect (P>0.05) of chaff type on the rigid ryegrass seed destruction efficacy of the HSD when seed were processed in wheat, barley, and lupine chaff (Walsh et al. Reference Walsh, Harrington and Powles2012). Similarly, in the field trials conducted as part of these studies, under commercial harvest conditions there was no difference (P>0.05) in rigid ryegrass seed destruction by the iHSD mill during harvest of canola and barley crops. In these trials, 99% seed destruction was achieved for rigid ryegrass, wild radish, brome grass, and wild oats during the harvest of canola and barley crops.

Table 2 Influence of chaff type on rigid ryegrass seed kill.a

a Numbers followed by the same letter are not significantly different (P=0.05)

Increasing moisture content of wheat chaff decreased the efficacy of the iHSD mill on rigid ryegrass seed. Seed kill was similar (92%) at the two lowest chaff moisture levels of 10% and 12%. However, when moisture content increased to 14%, there was a 4% reduction (P<0.05) in rigid ryegrass seed kill (from 92% to 88%). There was no additional reduction in seed kill, which remained at 88% when chaff moisture was 16%. In contrast, the iHSD mill maintained high destruction (99%) of both Palmer amaranth (Amaranthus palmeri (S.) Wats.) and morningglory (Ipomoea spp.) seeds processed in soybean chaff with moisture contents of 10%, 12%, 14%, and 16%, respectively (Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017). These contrasting results indicate that the influence of moisture content will vary with chaff type as well as moisture content.

These studies have determined that at the operational mill speed of 3,000 rpm, the iHSD will be effective on a wide range of problematic weeds of Australian cropping systems. Irrespective of seed shape and size, the impact action of the iHSD mill is now confirmed as effective in killing the seed of several weed species when processed in wheat chaff. Additionally, these very high seed kill levels were achieved throughout these studies using a chaff delivery rate equivalent to that produced during grain harvest. As expected, chaff type and moisture content does influence the seed kill efficacy of the iHSD mill, and therefore, these influences should be established for a range of crop species. However, as shown here and elsewhere, any reductions in efficacy are small and the iHSD mill remained highly effective. Thus, these studies confirm that the iHSD will be an effective HWSC system suited for use in conservation cropping systems.

Acknowledgments

Financial support for this study was provided by the Grains Research and Development Corporation. The authors are grateful to Lance Turner, Corrigin farmer, for providing assistance and support in conducting the initial iHSD mill tests. We wish to particularly thank Allison Chambers (Charles Sturt University) and the team of undergraduate students (University of Western Australia) who spent countless hours sorting through processed chaff samples.