1. Introduction

Panel flutter, as a classic problem in the field of aeroelasticity, poses detrimental effects on the structural fatigue life, and compromises the performance and safety of vehicles. Noteworthy contributions on this matter have been made by Dowell (Reference Dowell1970, Reference Dowell1974) and Mei, Abdel-Motagaly & Chen (Reference Mei, Abdel-Motagaly and Chen1999), providing comprehensive reviews. In recent years, hypersonic vehicles have garnered increasing attention (Urzay Reference Urzay2018). Shock phenomena is one of the typical features in hypersonic flow, widely present in both internal and external flow configurations, such as the intricate shock structures found in a scramjet engine inlet (Matsuo, Miyazato & Kim Reference Matsuo, Miyazato and Kim1999; Urzay Reference Urzay2018). The presence of shock gives rise to an accentuation of the nonlinear and unsteady characteristics of aerodynamic loads, which, in turn, lead to even greater complexity in the aeroelastic characteristics of the panel (Shinde et al. Reference Shinde, McNamara, Gaitonde, Barnes and Visbal2019; Boyer et al. Reference Boyer, McNamara, Gaitonde, Barnes and Visbal2021; Brouwer et al. Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021; He et al. Reference He, Shi, Dowell and Li2022; Shinde, McNamara & Gaitonde Reference Shinde, McNamara and Gaitonde2022). Moreover, these complex aeroelastic characteristics significantly impact the performance of the vehicles (Bhattrai et al. Reference Bhattrai, McQuellin, Currao, Neely and Buttsworth2022; Liu et al. Reference Liu, Wu, Li and Chen2022). Hence, the issue of panel flutter in the presence of a shock represents a fundamental problem in the development of hypersonic vehicles (McNamara & Friedmann Reference McNamara and Friedmann2011; Dowell Reference Dowell2015).

The aeroelasticity of the panel in the presence of a shock has been a subject of continuous interest among scholars in the past decade. Numerous preliminary explorations using numerical simulations and experimental approaches have been conducted in this area. In terms of numerical simulations, Visbal (Reference Visbal2012) studied the aeroelasticity of a two-dimensional panel subjected to an oblique shock in inviscid flow. The study unveiled self-excited panel vibrations, and summarised the flutter characteristics and flow field structures under typical shock strengths. Notably, complex nonlinear bifurcation behaviour was observed in the dynamical system under a shock strength of 1.4. An et al. (Reference An, Deng, Feng and Qu2021) investigated the nonlinear aeroelastic responses of four curved panels of different curvature subjected to oblique shock in two-dimensional inviscid flow. The study demonstrated significant nonlinear effects, with the dynamical system exhibiting multiple solutions under different initial conditions. Transitions between these solutions were also observed. Boyer et al. (Reference Boyer, McNamara, Gaitonde, Barnes and Visbal2018, Reference Boyer, McNamara, Gaitonde, Barnes and Visbal2021) extended the investigation to three-dimensional flow and found that shock strength significantly influences the stability characteristics of the panel. In comparison to inviscid flow, the presence of viscosity induces flutter dominated by higher-order modes. Shinde et al. (Reference Shinde, McNamara, Gaitonde, Barnes and Visbal2019) performed a direct numerical simulation (DNS) of the shock/boundary-layer interaction on a flexible wall. The promoting effect of the flexible panel on flow transition was analysed using the proper orthogonal decomposition (POD) method. Brouwer, Gogulapati & McNamara (Reference Brouwer, Gogulapati and McNamara2017) investigated the influence of surface deformation on shock-induced separation using the Reynolds-averaged Navier–Stokes (RANS) method. Based on that study, they further developed the application of enriched piston theory in the context of shock-induced panel flutter (Brouwer & McNamara Reference Brouwer and McNamara2019). Ye & Ye (Reference Ye and Ye2018) conducted stability analysis, and discovered that the critical flutter dynamic pressure exhibits nonlinear and sensitive variations in response to the location of shock impingement. Li et al. (Reference Li, Luo, Chen and Xu2019) investigated the inhibitory effect of surface velocity feedback control on shock-induced panel flutter in both viscous and inviscid flows. He et al. (Reference He, Shi, Dowell and Li2022) studied the aeroelastic behaviour of a panel in the presence of an irregular shock reflection and observed the onset of divergence at low dynamic pressures. In terms of experimental studies, Spottswood, Eason & Beberniss (Reference Spottswood, Eason and Beberniss2013), Spottswood et al. (Reference Spottswood, Beberniss, Eason, Perez, Donbar, Ehrhardt and Riley2019) conducted a series of innovative experiments to investigate the fluid–structure interaction (FSI) behaviour of panels in shock/boundary-layer interaction under different turbulent and thermal flow conditions. Willems, Gülhan & Esser (Reference Willems, Gülhan and Esser2013) experimentally measured the deformation and vibration of panels in a shock/boundary-layer interaction and compared the results with numerical simulations. They observed that panel vibration is influenced by its static deformation component. Brouwer et al. (Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021) investigated the flutter behaviour of panels in turbulent flow and a shock/boundary-layer interaction, measuring the limit cycle oscillations (LCO) induced by shock waves. Daub, Willems & Gülhan (Reference Daub, Willems and Gülhan2016) designed an experimental set-up where the unsteady shock was generated using a pitching oscillating wedge. Under the influence of high-frequency oscillating shock, a larger amplitude vibration of the panel was observed.

In practical engineering applications, the behaviour of the panel is influenced not only by unilateral aerodynamic loads, but also by the combined effect of cavity pressure underneath. Previous studies by Dowell (Reference Dowell1966) and Visbal (Reference Visbal2014) have demonstrated the significant impact of cavity pressure on the aeroelastic characteristics of the panel. The unbalanced cavity pressure induces additional shock/expansion wave systems, resulting in changes in the unsteady aerodynamic force characteristics (Visbal Reference Visbal2014; Gramola, Bruce & Santer Reference Gramola, Bruce and Santer2020). Studies have shown that this phenomenon further enhances the nonlinear characteristics of the system. Under the absence of shock, Dowell (Reference Dowell1966) highlighted the symmetric influence of static pressure difference on the critical dynamic pressure of flutter. Another work (Dowell Reference Dowell1982) reported the suppressive effect of static pressure difference on the chaotic response of buckled panels. Ye & Ye (Reference Ye and Ye2021) theoretically studied the stability boundary of panels in supersonic airflow using the Lyapunov method, emphasising the significant role of the coupling between static deformation and aerodynamic forces in greatly enhancing the aeroelastic stability of the panel. Under the presence of shock, Visbal (Reference Visbal2014) conducted preliminary research on three different cavity pressure cases in inviscid flow, and the results indicated that the variation of cavity pressure has a significant impact on the characteristics of the dynamical system. Experimental findings by Spottswood et al. (Reference Spottswood, Beberniss, Eason, Perez, Donbar, Ehrhardt and Riley2019) revealed that the dynamical characteristics of the panel are highly sensitive to sudden changes in cavity pressure. However, due to the inherent limitations of the experiment, drawing mechanistic conclusions becomes challenging. Gramola et al. (Reference Gramola, Bruce and Santer2020) found through experiments that cavity pressure significantly alters the deformation of the panel, thereby affecting the flow field structure. However, the study does not address the dynamic behaviour of the panel. Liu et al. (Reference Liu, Wu, Li and Chen2022) investigated the aeroelastic behaviour of the panel in an isolator under different cavity pressures using the URANS method. Their findings indicated a significant influence of cavity pressure on the motion of shock trains and the unsteady aerodynamic characteristics. Brouwer et al. (Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021, Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2022) examined the influence of the shock/boundary-layer interaction on the flutter characteristics of the panel through experiments and enriched piston theory. The advanced experiment unveiled that even subtle variations in cavity pressure exhibit intricate nonlinear effects on the aeroelastic system of the panel subjected to an oblique shock. The vibration characteristics of the panel exhibited disparities with the cavity pressure increasing or decreasing.

In summary, cavity pressure plays a pivotal role in modulating the aeroelastic characteristics of the panel subjected to an oblique shock. Presently, ongoing research has identified three primary configurations concerning the cavity pressure underneath the panel: (1) average pressure on the upper surface (e.g. Visbal Reference Visbal2012; Li et al. Reference Li, Luo, Chen and Xu2019; An et al. Reference An, Deng, Feng and Qu2021); (2) pressure distribution that maintains zero initial static pressure difference (e.g. Ye & Ye Reference Ye and Ye2018; He et al. Reference He, Shi, Dowell and Li2022); (3) specific pressure value (e.g. Visbal Reference Visbal2014; Daub et al. Reference Daub, Willems and Gülhan2016; Gramola et al. Reference Gramola, Bruce and Santer2020; Brouwer et al. Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021, Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2022). These studies demonstrate that the aeroelastic system of the panel subjected to both cavity pressure and oblique shock exhibits rich nonlinear behaviour. A certain level of cavity pressure can either enhance the stability boundary, thereby suppressing instability (e.g. Visbal Reference Visbal2014), or alter the characteristics of the system, leading to complex bifurcation and chaotic phenomena (e.g. Brouwer et al. Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021). However, the current research on this issue is still in its early stages, and the underlying mechanisms through which cavity pressure affects this dynamical system are not yet fully understood.

To examine the nonlinear dynamical behaviour and mechanisms of a panel subjected to both cavity pressure and inviscid oblique shock, a reduced-order model (ROM) for unsteady aerodynamic loads based on computational fluid dynamics (CFD) is established. Then, an FSI analysis method is developed by coupling computational structure dynamics (CSD). The calculations consider the variation of non-dimensional dynamic pressure in both ascending and descending directions, and the tracking of solutions is achieved through continuous parameter variation. The study investigates the aeroelastic system of the panel subjected to both cavity pressure and inviscid oblique shock, exploring hysteresis behaviour, catastrophe phenomena and bifurcation characteristics.

2. Physical model

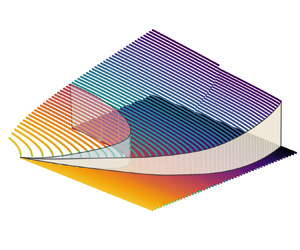

The computational model is depicted in figure 1. A two-dimensional flexible panel is embedded in a rigid plane with simple supports at both ends, i.e. no deflection and zero-moment conditions. The free stream of Mach 2 is parallel to the rigid plane. The structural parameters are consistent with those of Visbal (Reference Visbal2012) and Gordnier & Visbal (Reference Gordnier and Visbal2002). The midpoint of the flexible panel is subjected to an oblique shock. The incident and reflected shocks divide the flow region into three parts, with pressure denoted as ![]() $p_{1}$,

$p_{1}$, ![]() $p_{2}$ and

$p_{2}$ and ![]() $p_{3}$, respectively, where

$p_{3}$, respectively, where ![]() $p_{1} = p_{\infty }$. This study represents the shock strength by the pressure ratio of

$p_{1} = p_{\infty }$. This study represents the shock strength by the pressure ratio of ![]() $p_{3}/p_{1}$, which corresponds to the inviscid shock reflection on the rigid plate. This definition aligns with those presented by Visbal (Reference Visbal2012) and Brouwer & McNamara (Reference Brouwer and McNamara2019). The pressure inside the cavity underneath the panel is denoted as

$p_{3}/p_{1}$, which corresponds to the inviscid shock reflection on the rigid plate. This definition aligns with those presented by Visbal (Reference Visbal2012) and Brouwer & McNamara (Reference Brouwer and McNamara2019). The pressure inside the cavity underneath the panel is denoted as ![]() $p_{c}$. The present study investigates the nonlinear dynamical behaviour of the panel under different cavity pressures and incoming dynamic pressures for the case of

$p_{c}$. The present study investigates the nonlinear dynamical behaviour of the panel under different cavity pressures and incoming dynamic pressures for the case of ![]() $p_{3}/p_{1} = 1.4$. During the vibration of the panel, the cavity pressure is assumed to be constant. It means that the cavity pressure is manifested through the pressure difference across the panel. This study does not consider the dynamic changes in cavity pressure caused by the motion of the panel.

$p_{3}/p_{1} = 1.4$. During the vibration of the panel, the cavity pressure is assumed to be constant. It means that the cavity pressure is manifested through the pressure difference across the panel. This study does not consider the dynamic changes in cavity pressure caused by the motion of the panel.

Figure 1. Schematic of a panel subjected to both cavity pressure and oblique shock.

3. Numerical method

The calculation framework in this study, as shown in figure 2, mainly consists of three parts: the calculation of structural deformation (see § 3.1), the calculation of aerodynamic loads (see § 3.2) and the time marching method that couples the two (see § 3.3).

Figure 2. Aeroelastic calculation framework.

3.1. Calculation method for structural deformations

The von Kármán large deformation equation is solved by using Galerkin's method, which serves as the computational structure dynamics module in this study. Considering a one-dimensional isotropic flat plate, the upper surface of the panel is subjected to unsteady aerodynamic load ![]() $p$, while the lower surface is exposed to a constant cavity pressure

$p$, while the lower surface is exposed to a constant cavity pressure ![]() $p_{c}$. Following the approaches outlined by Dowell (Reference Dowell1966), Gordnier & Visbal (Reference Gordnier and Visbal2002) and Visbal (Reference Visbal2012), the equation of motion for the panel is derived based on Hamilton's principle and von Kármán large deformation theory as

$p_{c}$. Following the approaches outlined by Dowell (Reference Dowell1966), Gordnier & Visbal (Reference Gordnier and Visbal2002) and Visbal (Reference Visbal2012), the equation of motion for the panel is derived based on Hamilton's principle and von Kármán large deformation theory as

where

where ![]() $D$ is plate stiffness,

$D$ is plate stiffness, ![]() $N_x$ is applied in-plane force, and

$N_x$ is applied in-plane force, and ![]() $\Delta p$ represents the pressure difference between the upper and lower surfaces of the panel. See the nomenclature (Appendix G) for definitions of the other symbols. To simplify the equations, the following non-dimensional parameters are introduced:

$\Delta p$ represents the pressure difference between the upper and lower surfaces of the panel. See the nomenclature (Appendix G) for definitions of the other symbols. To simplify the equations, the following non-dimensional parameters are introduced:

\begin{gather} W \equiv \frac{w}{h} ,\quad \xi \equiv \frac{x}{l} ,\quad \tau \equiv t \sqrt{\frac{D}{\rho h l^4}} , \end{gather}

\begin{gather} W \equiv \frac{w}{h} ,\quad \xi \equiv \frac{x}{l} ,\quad \tau \equiv t \sqrt{\frac{D}{\rho h l^4}} , \end{gather}By substituting the aforementioned non-dimensional parameters, (3.1) can be written as

Equation (3.4) is discretised into ordinary differential equations by the use of Galerkin's method. According to the simply supported boundary condition, the non-dimensional displacement of the panel, denoted as ![]() $W$, satisfies

$W$, satisfies

\begin{equation} W(\xi,\tau) =

\sum_{i=1}^{\infty}[ q_{i}(\tau) \sin(i{\rm \pi} \xi)],

\end{equation}

\begin{equation} W(\xi,\tau) =

\sum_{i=1}^{\infty}[ q_{i}(\tau) \sin(i{\rm \pi} \xi)],

\end{equation}

where ![]() $q_i$ is the

$q_i$ is the ![]() $i$th generalised displacement and

$i$th generalised displacement and ![]() $\sin (i{\rm \pi} \xi )$ is the

$\sin (i{\rm \pi} \xi )$ is the ![]() $i$th mode. Substituting (3.5) into (3.4) and multiplying both sides of the equation by

$i$th mode. Substituting (3.5) into (3.4) and multiplying both sides of the equation by ![]() $\sin (n{\rm \pi} \xi )$, by using the orthogonality of the mode shapes, we can integrate both sides of the equation over the panel length, resulting in

$\sin (n{\rm \pi} \xi )$, by using the orthogonality of the mode shapes, we can integrate both sides of the equation over the panel length, resulting in

\begin{align}

&\frac{\mathrm{d}^2q_{n}}{\mathrm{d}\tau^2} + \left(

(n{\rm \pi} )^4 +R_0(n{\rm \pi} )^2

+3(n{\rm \pi} )^2\sum_{i=1}^{N_{{\textit{mode}}}}(i{\rm \pi}

q_{i})^2 \right)q_{n}\nonumber\\ &\quad + 2

\underbrace{\int_{0}^{1}(\overline{\Delta p}

\sin(n{\rm \pi} \xi))\,\mathrm{d}\xi}_\mathit{aerodynamic\ term} = 0.

\end{align}

\begin{align}

&\frac{\mathrm{d}^2q_{n}}{\mathrm{d}\tau^2} + \left(

(n{\rm \pi} )^4 +R_0(n{\rm \pi} )^2

+3(n{\rm \pi} )^2\sum_{i=1}^{N_{{\textit{mode}}}}(i{\rm \pi}

q_{i})^2 \right)q_{n}\nonumber\\ &\quad + 2

\underbrace{\int_{0}^{1}(\overline{\Delta p}

\sin(n{\rm \pi} \xi))\,\mathrm{d}\xi}_\mathit{aerodynamic\ term} = 0.

\end{align}

Here we consider that the deformation of the panel is mainly composed of the superposition of the first ![]() $N_{mode}$ modes, i.e.

$N_{mode}$ modes, i.e. ![]() $n = 1, 2, \ldots, N_{mode}$. Based on the experience from Dowell (Reference Dowell1966) and Visbal (Reference Visbal2012), this study considers

$n = 1, 2, \ldots, N_{mode}$. Based on the experience from Dowell (Reference Dowell1966) and Visbal (Reference Visbal2012), this study considers ![]() $N_{mode} = 6$.

$N_{mode} = 6$.

Expanding the last term in (3.6), and introducing pressure coefficient ![]() $C_{p} \equiv (p-p_\infty )/q_\infty$ and cavity pressure coefficient

$C_{p} \equiv (p-p_\infty )/q_\infty$ and cavity pressure coefficient ![]() $C_{pc} \equiv {p_{c}}/{p_\infty }$, we obtain

$C_{pc} \equiv {p_{c}}/{p_\infty }$, we obtain

\begin{align}

&\int_{0}^{1}(\overline{\Delta p} \sin(n{\rm \pi}

\xi))\,\mathrm{d}\xi\nonumber\\

&\quad=\int_{0}^{1}\left(\frac{l^4}{Dh}(p-p_{c})

\sin(n{\rm \pi} \xi)\right)\mathrm{d}\xi\nonumber\\

&\quad=\lambda \frac{l}{2 h} \beta \Biggl(

\underbrace{\int_{0}^{1}(C_{p} \sin(n{\rm \pi}

\xi))\,\mathrm{d}\xi}_{\mathit{generalised\

aerodynamic\ force}} - \frac{2}{\gamma M^2}

\underbrace{\frac{1-\cos(n{\rm \pi} )}{n{\rm \pi}

}(C_{pc}-1)}_{\mathit{cavity\ pressure\ term}} \Biggr).

\end{align}

\begin{align}

&\int_{0}^{1}(\overline{\Delta p} \sin(n{\rm \pi}

\xi))\,\mathrm{d}\xi\nonumber\\

&\quad=\int_{0}^{1}\left(\frac{l^4}{Dh}(p-p_{c})

\sin(n{\rm \pi} \xi)\right)\mathrm{d}\xi\nonumber\\

&\quad=\lambda \frac{l}{2 h} \beta \Biggl(

\underbrace{\int_{0}^{1}(C_{p} \sin(n{\rm \pi}

\xi))\,\mathrm{d}\xi}_{\mathit{generalised\

aerodynamic\ force}} - \frac{2}{\gamma M^2}

\underbrace{\frac{1-\cos(n{\rm \pi} )}{n{\rm \pi}

}(C_{pc}-1)}_{\mathit{cavity\ pressure\ term}} \Biggr).

\end{align}The generalised aerodynamic force (Lucia, Beran & Silva Reference Lucia, Beran and Silva2004) is defined as

By introducing the state variable ![]() $\boldsymbol {e} = \{q_{1}, q_{2}, \ldots, q_{{N_{mode}}}, \dot {q}_{1}, \dot {q}_{2}, \ldots, \dot {q}_{{N_{mode}}}\}^{\mathrm {T}}$, and combining (3.6), the nonlinear dynamics equations of the panel can be rewritten as

$\boldsymbol {e} = \{q_{1}, q_{2}, \ldots, q_{{N_{mode}}}, \dot {q}_{1}, \dot {q}_{2}, \ldots, \dot {q}_{{N_{mode}}}\}^{\mathrm {T}}$, and combining (3.6), the nonlinear dynamics equations of the panel can be rewritten as

\begin{equation} \left.\begin{aligned}

\frac{\mathrm{d}{e}_{{n}}}{\mathrm{d} \tau} & =

e_{{n+N_{mode}}} ,\\

\frac{\mathrm{d}{e}_{{n+N_{mode}}}}{\mathrm{d} \tau} & ={-}

\left( (n{\rm \pi} )^4 +R_0(n{\rm \pi} )^2 +3(n{\rm \pi}

)^2\sum_{i=1}^{N_{mode}}(i{\rm \pi} e_{i})^2 \right)

e_{n} \\ & \quad - \lambda \frac{l}{h} \beta

\left(f_{n} -\frac{2}{\gamma M^2} \frac{1-\cos(n{\rm \pi}

)}{n{\rm \pi} }(C_{pc}-1) \right) . \end{aligned}\right\}

\end{equation}

\begin{equation} \left.\begin{aligned}

\frac{\mathrm{d}{e}_{{n}}}{\mathrm{d} \tau} & =

e_{{n+N_{mode}}} ,\\

\frac{\mathrm{d}{e}_{{n+N_{mode}}}}{\mathrm{d} \tau} & ={-}

\left( (n{\rm \pi} )^4 +R_0(n{\rm \pi} )^2 +3(n{\rm \pi}

)^2\sum_{i=1}^{N_{mode}}(i{\rm \pi} e_{i})^2 \right)

e_{n} \\ & \quad - \lambda \frac{l}{h} \beta

\left(f_{n} -\frac{2}{\gamma M^2} \frac{1-\cos(n{\rm \pi}

)}{n{\rm \pi} }(C_{pc}-1) \right) . \end{aligned}\right\}

\end{equation}According to the general framework for dynamical systems, the equivalent system of (3.9) is

where ![]() $\boldsymbol {e}$ is the vector of state variable and

$\boldsymbol {e}$ is the vector of state variable and ![]() $\boldsymbol {f}$ is the vector of generalised aerodynamic force.

$\boldsymbol {f}$ is the vector of generalised aerodynamic force.

3.2. Calculation method for aerodynamic loads

3.2.1. Computational fluid dynamics method

The Euler equations described by the arbitrary Lagrangian–Eulerian (ALE) method are solved in this study using a verified in-house code (Ye et al. Reference Ye, Zhang, Chen and Ye2022). The cell-centred finite-volume method is applied to solve the above governing equations. The main numerical methods are as follows. The improved advection upstream splitting method (AUSM![]() $^+$) is used to derive the convective flux. The implicit dual time-stepping (DTS) method is employed for time marching, and the lower–upper symmetric Gauss–Seidel (LU-SGS) algorithm is used in the iteration of the pseudo-time step. In terms of boundary conditions, the free-slip boundary condition is applied at the wall, and the non-reflecting boundary condition is applied at the far field.

$^+$) is used to derive the convective flux. The implicit dual time-stepping (DTS) method is employed for time marching, and the lower–upper symmetric Gauss–Seidel (LU-SGS) algorithm is used in the iteration of the pseudo-time step. In terms of boundary conditions, the free-slip boundary condition is applied at the wall, and the non-reflecting boundary condition is applied at the far field.

3.2.2. Reduced-order model for unsteady aerodynamic loads

To improve the calculation efficiency, a reduced-order model for unsteady aerodynamic loads based on the AutoRegressive with eXogenous input (ARX) model (Gao & Zhang Reference Gao and Zhang2020; Ye et al. Reference Ye, Zhang, Chen and Ye2022) is established through the system identification technique. The ARX model for a multi-input multi-output system can be given by

\begin{equation} \boldsymbol{y}^{[k]} =\sum_{i=1}^{n_a} \boldsymbol{\mathsf{A}}_i\, \boldsymbol{y}^{[k-i]} + \sum_{i=0}^{n_b-1} \boldsymbol{\mathsf{B}}_i\, \boldsymbol{u}^{[k-i]} +\boldsymbol{e}^{[k]} , \end{equation}

\begin{equation} \boldsymbol{y}^{[k]} =\sum_{i=1}^{n_a} \boldsymbol{\mathsf{A}}_i\, \boldsymbol{y}^{[k-i]} + \sum_{i=0}^{n_b-1} \boldsymbol{\mathsf{B}}_i\, \boldsymbol{u}^{[k-i]} +\boldsymbol{e}^{[k]} , \end{equation}

where ![]() $\boldsymbol {y}^{[k]}$ and

$\boldsymbol {y}^{[k]}$ and ![]() $\boldsymbol {u}^{[k]}$ are the output and input in the

$\boldsymbol {u}^{[k]}$ are the output and input in the ![]() $k$th observation, respectively;

$k$th observation, respectively; ![]() $\boldsymbol {e}^{[k]}$ is the noise in the

$\boldsymbol {e}^{[k]}$ is the noise in the ![]() $k$th observation;

$k$th observation; ![]() $\boldsymbol{\mathsf{A}}_i$ and

$\boldsymbol{\mathsf{A}}_i$ and ![]() $\boldsymbol{\mathsf{B}}_i$ are the parameter matrices to be identified; and

$\boldsymbol{\mathsf{B}}_i$ are the parameter matrices to be identified; and ![]() $n_a$ and

$n_a$ and ![]() $n_b$ are the order of output and input terms, respectively, which are hyper-parameters of the model.

$n_b$ are the order of output and input terms, respectively, which are hyper-parameters of the model.

For the specific issue in this study, we have

An appropriate training signal (![]() $\boldsymbol {u}$ series) should be designed based on prior knowledge, and the corresponding response signal (

$\boldsymbol {u}$ series) should be designed based on prior knowledge, and the corresponding response signal (![]() $\kern 1.5pt \boldsymbol {y}$ series) can be obtained by CFD/CSD computations. The parameter matrices

$\kern 1.5pt \boldsymbol {y}$ series) can be obtained by CFD/CSD computations. The parameter matrices ![]() $\boldsymbol{\mathsf{A}}_i$ and

$\boldsymbol{\mathsf{A}}_i$ and ![]() $\boldsymbol{\mathsf{B}}_i$ will be determined through the least squares method using these training data, i.e.

$\boldsymbol{\mathsf{B}}_i$ will be determined through the least squares method using these training data, i.e. ![]() $\boldsymbol {u}$ series and

$\boldsymbol {u}$ series and ![]() $\boldsymbol {y}$ series (Gao & Zhang Reference Gao and Zhang2020).

$\boldsymbol {y}$ series (Gao & Zhang Reference Gao and Zhang2020).

3.3. Time marching method for aeroelastic equations

In this study, an improved Runge–Kutta method, as proposed by Zhang, Jiang & Ye (Reference Zhang, Jiang and Ye2007), is employed to solve (3.9). This method uses a third-order Lagrange polynomial interpolation for the aerodynamic forces, offering both efficiency and robustness. Combining with (3.10), the specific marching steps are given by

\begin{gather}\left.\begin{array}{c@{}} \boldsymbol{k_{1}} = \mathcal{F} ( \boldsymbol{e}^{[n]}, \quad \boldsymbol{f}^{[n]}) ,\\ \boldsymbol{k_{2}} = \mathcal{F} ( \boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{1}}/2, \quad \boldsymbol{f}^{[n+0.5]}),\\ \boldsymbol{k_{3}} = \mathcal{F} (\boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{2}}/2, \quad \boldsymbol{f}^{[n+0.5]}),\\ \boldsymbol{k_{4}} = \mathcal{F} (\boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{3}}, \quad \boldsymbol{f}^{[n+1]}) , \end{array}\right\} \end{gather}

\begin{gather}\left.\begin{array}{c@{}} \boldsymbol{k_{1}} = \mathcal{F} ( \boldsymbol{e}^{[n]}, \quad \boldsymbol{f}^{[n]}) ,\\ \boldsymbol{k_{2}} = \mathcal{F} ( \boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{1}}/2, \quad \boldsymbol{f}^{[n+0.5]}),\\ \boldsymbol{k_{3}} = \mathcal{F} (\boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{2}}/2, \quad \boldsymbol{f}^{[n+0.5]}),\\ \boldsymbol{k_{4}} = \mathcal{F} (\boldsymbol{e}^{[n]}+\Delta \tau\,\boldsymbol{k_{3}}, \quad \boldsymbol{f}^{[n+1]}) , \end{array}\right\} \end{gather} \begin{gather}\left.\begin{array}{c@{}} \boldsymbol{f}^{[n+1]} = (4\,\boldsymbol{f}^{[n]} -6\,\boldsymbol{f}^{[n-1]} +4\,\boldsymbol{f}^{[n-2]} -\boldsymbol{f}^{[n-3]}) ,\\ \boldsymbol{f}^{[n+0.5]} = (35\,\boldsymbol{f}^{[n]} -35\,\boldsymbol{f}^{[n-1]} +21\,\boldsymbol{f}^{[n-2]} -5\,\boldsymbol{f}^{[n-3]})/16. \end{array}\right\} \end{gather}

\begin{gather}\left.\begin{array}{c@{}} \boldsymbol{f}^{[n+1]} = (4\,\boldsymbol{f}^{[n]} -6\,\boldsymbol{f}^{[n-1]} +4\,\boldsymbol{f}^{[n-2]} -\boldsymbol{f}^{[n-3]}) ,\\ \boldsymbol{f}^{[n+0.5]} = (35\,\boldsymbol{f}^{[n]} -35\,\boldsymbol{f}^{[n-1]} +21\,\boldsymbol{f}^{[n-2]} -5\,\boldsymbol{f}^{[n-3]})/16. \end{array}\right\} \end{gather}4. Computational configuration

4.1. Computational model

Figure 3 presents the grid and corresponding boundary conditions used in the CFD simulation. This study does not involve the calculation of flow in the boundary layer, but for computational accuracy and grid deformation considerations, the grid near the panel has been appropriately refined. The shock is generated through a designed wedge, with a shock strength of ![]() $p_{3}/p_{1} = 1.4$. The compression surface of the wedge is extended appropriately to ensure that the expansion fan behind the wedge does not affect the load on the flexible panel. Figure 4 presents the contour of the density gradient in the initial flow field. The positions of the shock and expansion waves in the initial flow field are consistent with the scope of this study.

$p_{3}/p_{1} = 1.4$. The compression surface of the wedge is extended appropriately to ensure that the expansion fan behind the wedge does not affect the load on the flexible panel. Figure 4 presents the contour of the density gradient in the initial flow field. The positions of the shock and expansion waves in the initial flow field are consistent with the scope of this study.

Figure 3. Computational grid and boundary conditions.

Figure 4. Contour of the density gradient in the initial flow field.

4.2. Establishment of the reduced-order model for unsteady aerodynamic loads

The main source of time cost in this study is the prediction of complex unsteady aerodynamic loads. A reduced-order model for unsteady aerodynamic loads is established based on the ARX model (Sjöberg et al. Reference Sjöberg, Zhang, Ljung, Benveniste, Delyon, Glorennec, Hjalmarsson and Juditsky1995; Raveh Reference Raveh2004; Gao et al. Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017), which possesses the advantages of simple form and efficient computation.

Figure 5(a) shows the training signals of generalised displacement used to drive the forced vibration. A sweeping signal with a wide frequency range is employed as the training signal (Gao et al. Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017), with a length of 3000 and a sampling frequency of 4000 ![]() ${\tau }^{-1}$. Figure 6 displays the power spectral density (PSD) of the training signals, covering the main frequencies of the actual CFD/CSD response (Ljung Reference Ljung1999). Figure 5(b) presents the generalised aerodynamic forces obtained through CFD/CSD computations for each mode of the panel under the excitation of the training signals.

${\tau }^{-1}$. Figure 6 displays the power spectral density (PSD) of the training signals, covering the main frequencies of the actual CFD/CSD response (Ljung Reference Ljung1999). Figure 5(b) presents the generalised aerodynamic forces obtained through CFD/CSD computations for each mode of the panel under the excitation of the training signals.

Figure 5. Training data for the unsteady aerodynamic model: (a) training signals and (b) generalised aerodynamic forces.

Figure 6. Power spectral density of training signals.

Determining the hyperparameters, namely ![]() $n_a$ and

$n_a$ and ![]() $n_b$, is pivotal in the process of model establishment. For the problem addressed in this study, with a Mach number of 2, preliminary calculations indicated no subsonic conditions in the flow field at any given moment. This implies that disturbances from the structure to the flow field can only propagate downstream within the Mach cone at the disturbance location. However, for a finite-length plate, the duration of this disturbance's impact on the generalised aerodynamic forces of the panel is also finite. In other words, the generalised aerodynamic forces at any given moment should be determined by the unsteady effects of structural disturbances over a finite period, along with the unsteady flow itself. In the case of the supersonic flow investigated in this study, the inherent unsteady effects of the flow are notably weak. This is evident in the response to forced vibrations (see figure 5): the aerodynamic force stabilises rapidly after the cessation of displacement input. Hence, for this problem, it can be approximately considered that the generalised forces are dominated by the generalised displacements, i.e. the current generalised force is independent of past generalised forces. The model's parameter

$n_b$, is pivotal in the process of model establishment. For the problem addressed in this study, with a Mach number of 2, preliminary calculations indicated no subsonic conditions in the flow field at any given moment. This implies that disturbances from the structure to the flow field can only propagate downstream within the Mach cone at the disturbance location. However, for a finite-length plate, the duration of this disturbance's impact on the generalised aerodynamic forces of the panel is also finite. In other words, the generalised aerodynamic forces at any given moment should be determined by the unsteady effects of structural disturbances over a finite period, along with the unsteady flow itself. In the case of the supersonic flow investigated in this study, the inherent unsteady effects of the flow are notably weak. This is evident in the response to forced vibrations (see figure 5): the aerodynamic force stabilises rapidly after the cessation of displacement input. Hence, for this problem, it can be approximately considered that the generalised forces are dominated by the generalised displacements, i.e. the current generalised force is independent of past generalised forces. The model's parameter ![]() $n_a$ characterises the intrinsic unsteady effects of flow, while

$n_a$ characterises the intrinsic unsteady effects of flow, while ![]() $n_b$ characterises the structural disturbances’ unsteady effects on the flow. Based on the above analysis,

$n_b$ characterises the structural disturbances’ unsteady effects on the flow. Based on the above analysis, ![]() $n_a$ can be assumed as 0, while

$n_a$ can be assumed as 0, while ![]() $n_b$ should be assigned an appropriate value. To ascertain the optimal value of

$n_b$ should be assigned an appropriate value. To ascertain the optimal value of ![]() $n_b$, we construct models with different

$n_b$, we construct models with different ![]() $n_b$ values and assess the corresponding modelling errors. A comparative analysis of these errors enables us to determine the most suitable

$n_b$ values and assess the corresponding modelling errors. A comparative analysis of these errors enables us to determine the most suitable ![]() $n_b$ value. The modelling error, as defined by (4.1), quantifies the extent to which the model accurately captures the training generalised aerodynamic forces (Ye et al. Reference Ye, Zhang, Chen and Ye2022):

$n_b$ value. The modelling error, as defined by (4.1), quantifies the extent to which the model accurately captures the training generalised aerodynamic forces (Ye et al. Reference Ye, Zhang, Chen and Ye2022):

\begin{equation} \boldsymbol{e}_{model} = \frac{{\displaystyle \sum_{i=1}^{N}}|\, \hat{\boldsymbol{f}}^{[i]}-\boldsymbol{f}^{[i]} | } {{\displaystyle \sum_{i=1}^{N}}| \boldsymbol{f}^{[i]} |} . \end{equation}

\begin{equation} \boldsymbol{e}_{model} = \frac{{\displaystyle \sum_{i=1}^{N}}|\, \hat{\boldsymbol{f}}^{[i]}-\boldsymbol{f}^{[i]} | } {{\displaystyle \sum_{i=1}^{N}}| \boldsymbol{f}^{[i]} |} . \end{equation} Figure 7 presents the variation of normalised modelling errors versus different values of ![]() $n_b$. The modelling errors of individual modal orders are normalised using their maximum and minimum values. It can be observed that the range of

$n_b$. The modelling errors of individual modal orders are normalised using their maximum and minimum values. It can be observed that the range of ![]() $n_b$ between 60 and 140 exhibits favourable error performance. Additionally, a comparison with the CFD/CSD results demonstrates that the model displays enhanced robustness when

$n_b$ between 60 and 140 exhibits favourable error performance. Additionally, a comparison with the CFD/CSD results demonstrates that the model displays enhanced robustness when ![]() $n_b$ is set to 60, resulting in a strong agreement between the predicted values of the reduced-order model and the actual CFD/CSD results. Table 1 provides the modelling errors, root mean square errors (RMSEs) and

$n_b$ is set to 60, resulting in a strong agreement between the predicted values of the reduced-order model and the actual CFD/CSD results. Table 1 provides the modelling errors, root mean square errors (RMSEs) and ![]() $R^2$ scores for the case of

$R^2$ scores for the case of ![]() $n_a=0$ and

$n_a=0$ and ![]() $n_b=60$. In this case, the model is equivalent to the Volterra model or Wiener filter (Silva Reference Silva1993; Raveh Reference Raveh2001; Silva Reference Silva2005; Balajewicz & Dowell Reference Balajewicz and Dowell2012). Further evaluation of the model is detailed in Appendix C.

$n_b=60$. In this case, the model is equivalent to the Volterra model or Wiener filter (Silva Reference Silva1993; Raveh Reference Raveh2001; Silva Reference Silva2005; Balajewicz & Dowell Reference Balajewicz and Dowell2012). Further evaluation of the model is detailed in Appendix C.

Figure 7. Normalised modelling error versus ![]() $n_b$.

$n_b$.

Table 1. Modelling error.

5. Stability analysis of fixed points

Non-equilibrium cavity pressure significantly influences the fixed point (i.e. the static equilibrium position of the panel) (see Dowell Reference Dowell1966; Visbal Reference Visbal2014). However, conventional numerical simulation methods based on CFD/CSD are limited to detecting stable fixed points. The analysis of unstable fixed points relies more on theoretical methods, which further require the existence of analytic expressions (see Ye & Ye Reference Ye and Ye2018). The reduced-order model established in § 4.2 provides a pathway for establishing a theoretical analysis framework based on CFD/CSD.

5.1. Static deformation characteristics

The static aerodynamic force expression is derived from the reduced order model. For (3.11), considering a static process, we have ![]() $\boldsymbol {y}^{[k]} = \boldsymbol {y}^{[k-1]} = \cdots = \boldsymbol {y}^{[k-n_a]}$,

$\boldsymbol {y}^{[k]} = \boldsymbol {y}^{[k-1]} = \cdots = \boldsymbol {y}^{[k-n_a]}$, ![]() $\boldsymbol {u}^{[k]} = \boldsymbol {u}^{[k-1]} = \cdots = \boldsymbol {u}^{[k-n_b+1]}$. Thus, the static aerodynamic force can be simplified as

$\boldsymbol {u}^{[k]} = \boldsymbol {u}^{[k-1]} = \cdots = \boldsymbol {u}^{[k-n_b+1]}$. Thus, the static aerodynamic force can be simplified as

where ![]() $\tilde {\boldsymbol{\mathsf{A}}} = \sum _{i=1}^{n_a} \boldsymbol{\mathsf{A}}_i$,

$\tilde {\boldsymbol{\mathsf{A}}} = \sum _{i=1}^{n_a} \boldsymbol{\mathsf{A}}_i$, ![]() $\tilde {\boldsymbol{\mathsf{B}}} = \sum _{i=0}^{n_b-1} \boldsymbol{\mathsf{B}}_i$,

$\tilde {\boldsymbol{\mathsf{B}}} = \sum _{i=0}^{n_b-1} \boldsymbol{\mathsf{B}}_i$, ![]() $\tilde {\boldsymbol {u}}$ is the generalised displacement vector of the panel with static deformation, while

$\tilde {\boldsymbol {u}}$ is the generalised displacement vector of the panel with static deformation, while ![]() $\tilde {\boldsymbol {y}}$ is the generalised aerodynamic force under the static deformation.

$\tilde {\boldsymbol {y}}$ is the generalised aerodynamic force under the static deformation.

For the structural equation, setting the time derivative of the left-hand side of (3.9) to zero yields the static structural equation as ![]() $\mathcal {F}(\boldsymbol {e},\boldsymbol {f}) = 0$, where

$\mathcal {F}(\boldsymbol {e},\boldsymbol {f}) = 0$, where ![]() $\boldsymbol {f}$ can be given by (5.1) as

$\boldsymbol {f}$ can be given by (5.1) as

where ![]() $\boldsymbol {f_0}$ is a constant vector related to the training of the reduced-order model (Gao et al. Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017). Note that (5.2) stands as an explicit expression. Therefore, within the equation

$\boldsymbol {f_0}$ is a constant vector related to the training of the reduced-order model (Gao et al. Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017). Note that (5.2) stands as an explicit expression. Therefore, within the equation ![]() $\mathcal {F} = 0$,

$\mathcal {F} = 0$, ![]() $\mathcal {F}$ is a function dependent solely on

$\mathcal {F}$ is a function dependent solely on ![]() $\boldsymbol {e}$. We term this equation derived from the reduced-order model as the static aeroelastic equation based on ROM. This study employs the trust region method (see Moré & Sorensen Reference Moré and Sorensen1983) to solve this nonlinear equation with multiple inputs and outputs, considering various cavity pressures and dynamic pressures.

$\boldsymbol {e}$. We term this equation derived from the reduced-order model as the static aeroelastic equation based on ROM. This study employs the trust region method (see Moré & Sorensen Reference Moré and Sorensen1983) to solve this nonlinear equation with multiple inputs and outputs, considering various cavity pressures and dynamic pressures.

Figure 8(a) presents the deformations of the panel at several cavity pressures when ![]() $\lambda = 300$. Even at this relatively low dynamic pressure, CFD/CSD computations are capable of capturing these stable fixed points. The results obtained from both methods are in excellent agreement. Furthermore, figure 8(b) provides a bar graph of generalised displacements, with the transparent blue plane representing the zero plane. The first generalised displacement exhibits evident variations with cavity pressure. Overall, the deformations are primarily attributed to the contributions from the first three generalised displacements. The proportion of the first mode increases rapidly and dominates as the cavity pressure deviates further from the mean pressure. Figure 9 illustrates the variations of the first three generalised displacements with cavity pressure, indicating larger dynamic pressures induce greater changes. It is noteworthy that the second generalised displacement displays non-monotonic variations, with its maximum values exhibiting nonlinear changes with dynamic pressure, while the cavity pressures corresponding to the maximum values generally exhibit linear changes with dynamic pressure.

$\lambda = 300$. Even at this relatively low dynamic pressure, CFD/CSD computations are capable of capturing these stable fixed points. The results obtained from both methods are in excellent agreement. Furthermore, figure 8(b) provides a bar graph of generalised displacements, with the transparent blue plane representing the zero plane. The first generalised displacement exhibits evident variations with cavity pressure. Overall, the deformations are primarily attributed to the contributions from the first three generalised displacements. The proportion of the first mode increases rapidly and dominates as the cavity pressure deviates further from the mean pressure. Figure 9 illustrates the variations of the first three generalised displacements with cavity pressure, indicating larger dynamic pressures induce greater changes. It is noteworthy that the second generalised displacement displays non-monotonic variations, with its maximum values exhibiting nonlinear changes with dynamic pressure, while the cavity pressures corresponding to the maximum values generally exhibit linear changes with dynamic pressure.

Figure 8. (a) Plate deformations and (b) bar graph of generalised displacements with ![]() $\lambda = 300$.

$\lambda = 300$.

Figure 9. First three generalised displacements versus cavity pressure.

5.2. Linear stability of fixed points

Note that the calculations in § 5.1 demonstrate the existence of fixed point solutions under a wide range of cavity pressures and dynamic pressures. This section will examine the stability of these fixed points.

To begin, an analytic expression for the aeroelastic system is established. Following the procedures outlined in Appendix D, a state-space model corresponding to the aerodynamic reduced-order model can be obtained. Combining this model with the structural equation, i.e. (3.10), leads to

where

correspond to the output equation and state equation of the state-space model, respectively. A similar coupling method is also adopted by Gao et al. (Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017), Silva & Bartels (Reference Silva and Bartels2004) and Ye et al. (Reference Ye, Zhang, Chen and Ye2022). Let the state variables be denoted as ![]() $\boldsymbol {r} = \{ \boldsymbol {e},\boldsymbol {x} \}$. The aeroelastic equation, denoted as (5.3), can be expressed as

$\boldsymbol {r} = \{ \boldsymbol {e},\boldsymbol {x} \}$. The aeroelastic equation, denoted as (5.3), can be expressed as ![]() $\dot {\boldsymbol {r}} = \mathcal {H}( \boldsymbol {r})$. Linearising the system at its fixed points, the Jacobian matrix is given by

$\dot {\boldsymbol {r}} = \mathcal {H}( \boldsymbol {r})$. Linearising the system at its fixed points, the Jacobian matrix is given by

\begin{equation}

\boldsymbol{\mathsf{J}} =\left\{\begin{array}{ccc}

\boldsymbol{\mathsf{I}} & \boldsymbol{\mathsf{O}}

& \boldsymbol{\mathsf{O}} \\

\boldsymbol{\mathsf{E}}-\lambda\displaystyle\dfrac{l}{h}\beta\

\boldsymbol{\mathsf{D}}_c &

\boldsymbol{\mathsf{O}} &

-\lambda\displaystyle\dfrac{l}{h}\beta\

\boldsymbol{\mathsf{C}}_c \\ \boldsymbol{\mathsf{B}}_c &

\boldsymbol{\mathsf{O}} &

\boldsymbol{\mathsf{A}}_c \end{array}\right\}.

\end{equation}

\begin{equation}

\boldsymbol{\mathsf{J}} =\left\{\begin{array}{ccc}

\boldsymbol{\mathsf{I}} & \boldsymbol{\mathsf{O}}

& \boldsymbol{\mathsf{O}} \\

\boldsymbol{\mathsf{E}}-\lambda\displaystyle\dfrac{l}{h}\beta\

\boldsymbol{\mathsf{D}}_c &

\boldsymbol{\mathsf{O}} &

-\lambda\displaystyle\dfrac{l}{h}\beta\

\boldsymbol{\mathsf{C}}_c \\ \boldsymbol{\mathsf{B}}_c &

\boldsymbol{\mathsf{O}} &

\boldsymbol{\mathsf{A}}_c \end{array}\right\}.

\end{equation}

The elements of the matrix ![]() $\boldsymbol{\mathsf{E}}$ are

$\boldsymbol{\mathsf{E}}$ are

\begin{equation}

\boldsymbol{\mathsf{E}}_{ij} =\left\{\begin{array}{ll}

-6 (i{\rm \pi} )^2 (j{\rm \pi} )^2 q_{{0,i}}

q_{{0,j}} & \mathrm{if} \ i \ne j ,\\ -(i{\rm \pi}

)^4(1+9q_{{0,i}}^2) - R_0(i{\rm \pi} )^2 \displaystyle -3(i{\rm \pi} )^2\sum_{n=1,n \ne i}^{N_{mode}} (n

{\rm \pi} q_{{0,n}})^2 & \mathrm{if} \ i =

j , \end{array}\right.

\end{equation}

\begin{equation}

\boldsymbol{\mathsf{E}}_{ij} =\left\{\begin{array}{ll}

-6 (i{\rm \pi} )^2 (j{\rm \pi} )^2 q_{{0,i}}

q_{{0,j}} & \mathrm{if} \ i \ne j ,\\ -(i{\rm \pi}

)^4(1+9q_{{0,i}}^2) - R_0(i{\rm \pi} )^2 \displaystyle -3(i{\rm \pi} )^2\sum_{n=1,n \ne i}^{N_{mode}} (n

{\rm \pi} q_{{0,n}})^2 & \mathrm{if} \ i =

j , \end{array}\right.

\end{equation} where ![]() $q_{{0,i}}$ is the

$q_{{0,i}}$ is the ![]() $i$th generalised displacement of the fixed point under corresponding cavity pressure and dynamic pressure, which has been calculated in § 5.1. Examining the eigenvalues

$i$th generalised displacement of the fixed point under corresponding cavity pressure and dynamic pressure, which has been calculated in § 5.1. Examining the eigenvalues ![]() $\varOmega$ of the matrix

$\varOmega$ of the matrix ![]() $\boldsymbol{\mathsf{J}}$ at each fixed point, any

$\boldsymbol{\mathsf{J}}$ at each fixed point, any ![]() $\mathrm {Real}\ \varOmega _i > 0$ signifies an unstable fixed point; otherwise, it is deemed stable (see Khalil Reference Khalil2002, chap. 4).

$\mathrm {Real}\ \varOmega _i > 0$ signifies an unstable fixed point; otherwise, it is deemed stable (see Khalil Reference Khalil2002, chap. 4).

Figure 10 presents the stability of the fixed points. The influence of cavity pressure on stability does not exhibit symmetric distribution about the mean pressure, differing notably from the case of a free stream condition (see Dowell Reference Dowell1966; Gordnier & Visbal Reference Gordnier and Visbal2002). For cases where the cavity pressure is less than the mean pressure, all fixed points are stable. The unstable region is mainly concentrated in the ![]() $C_{pc} > 1.208$ range, where the critical value exhibits a significant slope. This implies that cavity pressures below this threshold significantly enhance the stability of the panel with static deformation. The important threshold of

$C_{pc} > 1.208$ range, where the critical value exhibits a significant slope. This implies that cavity pressures below this threshold significantly enhance the stability of the panel with static deformation. The important threshold of ![]() $C_{pc}=1.208$ will be referenced frequently in subsequent discussions. The minimum critical dynamic pressure appears at approximately

$C_{pc}=1.208$ will be referenced frequently in subsequent discussions. The minimum critical dynamic pressure appears at approximately ![]() $C_{pc} = 1.215$. Furthermore, after

$C_{pc} = 1.215$. Furthermore, after ![]() $C_{pc} > 1.248$, the unstable region disappears. In other words, fixed points can be unstable only when

$C_{pc} > 1.248$, the unstable region disappears. In other words, fixed points can be unstable only when ![]() $1.208 < C_{pc} < 1.248$; otherwise, the panel always has a stable static deformation solution. This leads to two changes in the stability of the system as the cavity pressure varies.

$1.208 < C_{pc} < 1.248$; otherwise, the panel always has a stable static deformation solution. This leads to two changes in the stability of the system as the cavity pressure varies.

Figure 10. Stability of fixed points in the ![]() $\lambda - C_{pc}$ plane.

$\lambda - C_{pc}$ plane.

5.3. Stability from the perspective of energy transfer

The findings in § 5.2 indicate that fixed points become unstable only under limited cavity pressure for a certain dynamic pressure. The stability characteristics of FSI systems are fundamentally governed by the energy transfer between the fluid and the structure. From an energy perspective, numerous scholars have investigated the stability of FSI systems (Morse & Williamson Reference Morse and Williamson2009; Zhu, Su & Breuer Reference Zhu, Su and Breuer2020; Menon & Mittal Reference Menon and Mittal2021; Cheng et al. Reference Cheng, Lien, Dowell, Yee, Wang and Zhang2023).

The energy extracted from the flow to the flexible panel over a cycle can be expressed as

Using the non-dimensionalisation procedure detailed in § 3.1 and substituting the definition of generalised aerodynamic forces (3.8), we have

\begin{align} E^*(\tau) &= h l \sum_{i=1}^{N_{mode}} \int_{\tau-\Delta\tau}^{\tau} \int_{0}^{1} (p_{c}-p) \sin(i{\rm \pi} \xi)\dot{q_i} \, \mathrm{d}\xi \, \mathrm{d}\tau\nonumber\\ &=\lambda \frac{D h}{2l^2} \beta \sum_{i=1}^{N_{mode}} \int_{\tau-\Delta\tau}^{\tau} \left( \frac{2}{\gamma M^2} {\frac{1-\cos(i{\rm \pi} )}{i{\rm \pi} }(C_{pc}-1)} -f_i \right) \dot{q_i} \, \mathrm{d}\tau . \end{align}

\begin{align} E^*(\tau) &= h l \sum_{i=1}^{N_{mode}} \int_{\tau-\Delta\tau}^{\tau} \int_{0}^{1} (p_{c}-p) \sin(i{\rm \pi} \xi)\dot{q_i} \, \mathrm{d}\xi \, \mathrm{d}\tau\nonumber\\ &=\lambda \frac{D h}{2l^2} \beta \sum_{i=1}^{N_{mode}} \int_{\tau-\Delta\tau}^{\tau} \left( \frac{2}{\gamma M^2} {\frac{1-\cos(i{\rm \pi} )}{i{\rm \pi} }(C_{pc}-1)} -f_i \right) \dot{q_i} \, \mathrm{d}\tau . \end{align}

Note that there is no damping term in the structural equation (3.9), thus, the sign of ![]() $E^*$ directly indicates the amplification or suppression of oscillation amplitude (Cheng et al. Reference Cheng, Lien, Dowell, Yee, Wang and Zhang2023).

$E^*$ directly indicates the amplification or suppression of oscillation amplitude (Cheng et al. Reference Cheng, Lien, Dowell, Yee, Wang and Zhang2023).

We investigated three cases with ![]() $C_{pc} = 1.2$, 1.23 and 1.25 corresponding to the unstable fixed point and two stable fixed points on either side, as shown in figure 10. CFD/CSD calculations are performed under specific initial conditions. For the unstable fixed point, the panel is released from the fixed point position. For the stable fixed points, the panel is displaced from their fixed point positions and then released (with a negative offset of 10 % in the second generalised displacement

$C_{pc} = 1.2$, 1.23 and 1.25 corresponding to the unstable fixed point and two stable fixed points on either side, as shown in figure 10. CFD/CSD calculations are performed under specific initial conditions. For the unstable fixed point, the panel is released from the fixed point position. For the stable fixed points, the panel is displaced from their fixed point positions and then released (with a negative offset of 10 % in the second generalised displacement ![]() $q_2$). Figure 11 illustrates the energy transfer at these three fixed points. When the cavity pressure is low (

$q_2$). Figure 11 illustrates the energy transfer at these three fixed points. When the cavity pressure is low (![]() $C_{pc} = 1.2$, blue line), the additional energy input from displacing the fixed point causes

$C_{pc} = 1.2$, blue line), the additional energy input from displacing the fixed point causes ![]() $E^*$ to fluctuate around 0 initially, and quickly tends to 0 over time, indicating an equilibrium energy transfer between the flow and the structure (Cheng et al. Reference Cheng, Lien, Dowell, Yee, Wang and Zhang2023). Considering the total energy transfer over time 0 to 1, we have

$E^*$ to fluctuate around 0 initially, and quickly tends to 0 over time, indicating an equilibrium energy transfer between the flow and the structure (Cheng et al. Reference Cheng, Lien, Dowell, Yee, Wang and Zhang2023). Considering the total energy transfer over time 0 to 1, we have ![]() $\int _{0}^{1} E^* \,\mathrm {d}\tau < 0$, which means the structure releases energy to the flow. This energy dissipation causes structural vibration decay and tends towards the fixed point, corresponding to the stable region in figure 10. As the cavity pressure increases to the unstable region (

$\int _{0}^{1} E^* \,\mathrm {d}\tau < 0$, which means the structure releases energy to the flow. This energy dissipation causes structural vibration decay and tends towards the fixed point, corresponding to the stable region in figure 10. As the cavity pressure increases to the unstable region (![]() $C_{pc} = 1.23$, red line), a significant reversal in the direction of energy transfer occurs. It can be observed that

$C_{pc} = 1.23$, red line), a significant reversal in the direction of energy transfer occurs. It can be observed that ![]() $E^*$ diverges towards the positive half-axis during oscillations, with

$E^*$ diverges towards the positive half-axis during oscillations, with ![]() $\int _{0}^{1} E^* \,\mathrm {d}\tau > 0$. This indicates that the structure periodically absorbs energy from the flow, with increasing absorption, preventing the structure from stabilising at the fixed point. With further increase in cavity pressure (

$\int _{0}^{1} E^* \,\mathrm {d}\tau > 0$. This indicates that the structure periodically absorbs energy from the flow, with increasing absorption, preventing the structure from stabilising at the fixed point. With further increase in cavity pressure (![]() $C_{pc} = 1.25$, green line), the direction of energy transfer reverses again. This makes the

$C_{pc} = 1.25$, green line), the direction of energy transfer reverses again. This makes the ![]() $C_{pc} = 1.25$ case similar to that of

$C_{pc} = 1.25$ case similar to that of ![]() $C_{pc} = 1.2$, with

$C_{pc} = 1.2$, with ![]() $\int _{0}^{1} E^* \,\mathrm {d}\tau < 0$. In this case, the structure releases energy to the flow and the system returns to the stable region.

$\int _{0}^{1} E^* \,\mathrm {d}\tau < 0$. In this case, the structure releases energy to the flow and the system returns to the stable region.

Figure 11. Time series of energy transfer at fixed points with ![]() $\lambda = 1000$.

$\lambda = 1000$.

In summary, changes in cavity pressure result in two reversals in the direction of energy transfer between the flow and the structure. This leads to an evolution of the stability of the fixed points from stable to unstable and back to stable, as depicted in figure 10. Therefore, the unstable region in figure 10 is limited.

6. Panel flutter characteristics

6.1. Limit cycle oscillation characteristics

Numerical simulations based on ROM/CSD are conducted to analyse the flutter characteristics of the panel under different cavity pressures. The time marching method in § 3.3 is used. The simulations are performed for states within the ranges of cavity pressure coefficient ![]() $C_{pc}=1.18$ to

$C_{pc}=1.18$ to ![]() $1.23$ and non-dimensional dynamic pressure

$1.23$ and non-dimensional dynamic pressure ![]() $\lambda =320$ to

$\lambda =320$ to ![]() $580$. The initial state is set to

$580$. The initial state is set to ![]() $C_{pc}=1.2$ and

$C_{pc}=1.2$ and ![]() $\lambda =580$ with specific initial conditions, i.e. first generalised velocity

$\lambda =580$ with specific initial conditions, i.e. first generalised velocity ![]() $\dot {q}_{1}=100.0$, while the remaining generalised displacements and velocities are 0. The selection of this initial condition is aimed at steering the system into a limit cycle trajectory rather than a fixed point. The initial conditions satisfying this requirement are not unique, and one of them is chosen here. A more detailed discussion will follow in § 7. The response of the displacement, generalised displacements and generalised velocities are presented in figures 12 and 13, which indicate the panel exhibits a limit cycle oscillation. The deflection of the panel is primarily governed by the first three generalised displacements. The first generalised displacement exhibits only slight oscillation, whereas the second and third generalised displacements have larger amplitudes. Furthermore, the equilibrium positions of the first and second generalised oscillations significantly deviate from the zero point.

$\dot {q}_{1}=100.0$, while the remaining generalised displacements and velocities are 0. The selection of this initial condition is aimed at steering the system into a limit cycle trajectory rather than a fixed point. The initial conditions satisfying this requirement are not unique, and one of them is chosen here. A more detailed discussion will follow in § 7. The response of the displacement, generalised displacements and generalised velocities are presented in figures 12 and 13, which indicate the panel exhibits a limit cycle oscillation. The deflection of the panel is primarily governed by the first three generalised displacements. The first generalised displacement exhibits only slight oscillation, whereas the second and third generalised displacements have larger amplitudes. Furthermore, the equilibrium positions of the first and second generalised oscillations significantly deviate from the zero point.

Figure 12. Response at 3/4 chord of the panel with ![]() $C_{pc} = 1.2$,

$C_{pc} = 1.2$, ![]() $\lambda = 580$.

$\lambda = 580$.

Figure 13. (a) Generalised displacement and (b) generalised velocity with ![]() $C_{pc} = 1.2$,

$C_{pc} = 1.2$, ![]() $\lambda = 580$.

$\lambda = 580$.

Responses under different cavity pressures are obtained by altering cavity pressure after the initial state has been fully developed. Figure 14 illustrates the limit cycle amplitudes for different cavity pressures, with the dash-dotted line indicating the slope of amplitude at ![]() $C_{pc, mean}$. It can be observed that the amplitudes exhibit a nonlinear decrease with the cavity pressure increasing, and this nonlinear trend becomes more pronounced for cavity pressure coefficients exceeding 1.208, which is the critical threshold where the unstable fixed points begin to appear in § 5. These regularities indicate that in the computation of panel flutter under the influence of an oblique shock, the presence of uncertainties in the calculation results can be attributed to the deviation between the actual and target cavity pressures. Specifically, in practical computations, achieving a pressure distribution that strictly conforms to the theoretical results of inviscid shock is challenging due to factors such as grid distribution, numerical schemes and even the characteristics of the solver itself. This can lead to a biased estimation of the mean pressure. In figure 14, even slight variations in cavity pressure can induce considerable changes in amplitude. This observation provides a partial explanation for the dispersed results based on calculations designed according to mean cavity pressure, e.g. results reported by Visbal (Reference Visbal2012) and Li et al. (Reference Li, Luo, Chen and Xu2019) (see figure 37).

$C_{pc, mean}$. It can be observed that the amplitudes exhibit a nonlinear decrease with the cavity pressure increasing, and this nonlinear trend becomes more pronounced for cavity pressure coefficients exceeding 1.208, which is the critical threshold where the unstable fixed points begin to appear in § 5. These regularities indicate that in the computation of panel flutter under the influence of an oblique shock, the presence of uncertainties in the calculation results can be attributed to the deviation between the actual and target cavity pressures. Specifically, in practical computations, achieving a pressure distribution that strictly conforms to the theoretical results of inviscid shock is challenging due to factors such as grid distribution, numerical schemes and even the characteristics of the solver itself. This can lead to a biased estimation of the mean pressure. In figure 14, even slight variations in cavity pressure can induce considerable changes in amplitude. This observation provides a partial explanation for the dispersed results based on calculations designed according to mean cavity pressure, e.g. results reported by Visbal (Reference Visbal2012) and Li et al. (Reference Li, Luo, Chen and Xu2019) (see figure 37).

Figure 14. Amplitude for different cavity pressures.

6.2. Hysteresis behaviour and catastrophe phenomena

The direction of parameter changes in nonlinear systems can induce different branches of solutions, leading to complex hysteresis behaviour (Visbal Reference Visbal2014; Boyer et al. Reference Boyer, McNamara, Gaitonde, Barnes and Visbal2021; Brouwer et al. Reference Brouwer, Perez, Beberniss, Spottswood and Ehrhardt2021). Therefore, following Visbal (Reference Visbal2014) and An et al. (Reference An, Deng, Feng and Qu2021), this study considers both ascending and descending ![]() $\lambda$ under different cavity pressures. In the case of ascending

$\lambda$ under different cavity pressures. In the case of ascending ![]() $\lambda$, the dynamical system initiates from a static solution at

$\lambda$, the dynamical system initiates from a static solution at ![]() $\lambda = 320$ and, after the response is fully developed, increases

$\lambda = 320$ and, after the response is fully developed, increases ![]() $\lambda$ to compute the subsequent state. Conversely, in the case of descending

$\lambda$ to compute the subsequent state. Conversely, in the case of descending ![]() $\lambda$, the dynamical system initiates from a flutter solution at

$\lambda$, the dynamical system initiates from a flutter solution at ![]() $\lambda = 580$ and, after the response is fully developed, decreases

$\lambda = 580$ and, after the response is fully developed, decreases ![]() $\lambda$ to compute the subsequent state. To minimise disturbances caused by parameter changes and ensure a smoother evolution of the system, small increments are employed for parameter progression

$\lambda$ to compute the subsequent state. To minimise disturbances caused by parameter changes and ensure a smoother evolution of the system, small increments are employed for parameter progression ![]() $(\Delta \lambda = 0.25, \Delta C_{pc} = 0.001)$.

$(\Delta \lambda = 0.25, \Delta C_{pc} = 0.001)$.

The amplitude at the 3/4 chord of the panel versus ![]() $\lambda$ is shown in figure 15 when the cavity pressure changes around the mean pressure (i.e.

$\lambda$ is shown in figure 15 when the cavity pressure changes around the mean pressure (i.e. ![]() $C_{pc, mean} \equiv 1.2$). The amplitudes for different

$C_{pc, mean} \equiv 1.2$). The amplitudes for different ![]() $\lambda$ are represented by coloured dots, and the amplitudes at the same cavity pressure are connected by grey solid lines. The presence of a visible grey line indicates a discontinuous jump of the system at that point.

$\lambda$ are represented by coloured dots, and the amplitudes at the same cavity pressure are connected by grey solid lines. The presence of a visible grey line indicates a discontinuous jump of the system at that point.

Figure 15. Hysteresis behaviour and its evolution with cavity pressure.

The results in figure 15 indicate that the system is highly sensitive to changes in cavity pressure. The system exhibits complex hysteretic behaviour, particularly when the pressure is above the mean value (i.e. ![]() $C_{pc, mean} \equiv 1.2$). The range of pressure is classified into three phases based on the hysteresis characteristics exhibited by the system.

$C_{pc, mean} \equiv 1.2$). The range of pressure is classified into three phases based on the hysteresis characteristics exhibited by the system.

Phase I ![]() $(1.18< C_{pc}\leqslant 1.208)$: within the range of investigated dynamic pressures, no flutter occurs in the ascending process, while a critical dynamic pressure is observed in the descending process. The system transitions from the flutter state to the static deformed state through a discontinuous jump at the critical dynamic pressure during

$(1.18< C_{pc}\leqslant 1.208)$: within the range of investigated dynamic pressures, no flutter occurs in the ascending process, while a critical dynamic pressure is observed in the descending process. The system transitions from the flutter state to the static deformed state through a discontinuous jump at the critical dynamic pressure during ![]() $\lambda$ descent. The hysteresis loop has not fully formed in this phase.

$\lambda$ descent. The hysteresis loop has not fully formed in this phase.

Phase II ![]() $(1.208< C_{pc}\leqslant 1.227)$: critical dynamic pressures are observed in both ascending and descending processes, with different critical values for each. In both processes, the system transitions through discontinuous jumps. In this phase, a complete hysteresis loop is formed within the investigated

$(1.208< C_{pc}\leqslant 1.227)$: critical dynamic pressures are observed in both ascending and descending processes, with different critical values for each. In both processes, the system transitions through discontinuous jumps. In this phase, a complete hysteresis loop is formed within the investigated ![]() $\lambda$, and the hysteresis loop is compressed as the cavity pressure increases.

$\lambda$, and the hysteresis loop is compressed as the cavity pressure increases.

Phase III ![]() $(1.227< C_{pc}\leqslant 1.23)$: critical dynamic pressures are observed in both ascending and descending processes, with identical critical values for each. The system transitions through continuous evolution, where hysteresis behaviour completely vanishes, and the ascending and descending solutions perfectly coincide.

$(1.227< C_{pc}\leqslant 1.23)$: critical dynamic pressures are observed in both ascending and descending processes, with identical critical values for each. The system transitions through continuous evolution, where hysteresis behaviour completely vanishes, and the ascending and descending solutions perfectly coincide.

The structure of the hysteresis loop in Phase II as a function of cavity pressure coefficient is presented in figure 16. In figure 16(a), the width of the hysteresis loop monotonically decreases with cavity pressure, eventually converging to 0 at the end of Phase II. In figure 16(b), the centre position of the hysteresis loop initially decreases and then increases with the cavity pressure, reaching its minimum value at a cavity pressure coefficient of 1.213. By examining figures 15 and 16, an important observation can be made, i.e. with the change of cavity pressure, the process of compression and vanishing of the hysteresis loop is precisely the gradual attenuation of discontinuous transitions in the dynamical system, which leads to a smooth evolution system.

Figure 16. Structure of hysteresis loop for different cavity pressure: (a) width of the hysteresis loop; (b) centre position of the hysteresis loop.

In the hysteresis phenomena of Phases I and II, the solutions of the system exhibit high sensitivity to initial conditions. Conducting simulations with fixed initial conditions under different dynamic pressures can lead to unexpected results, where the solutions fall into either the upper or lower branch of the hysteresis loop, thus potentially yielding biased conclusions. This finding provides supplementary and comparative insights into the phenomenon of solution jumps observed in the calculations presented by An et al. (Reference An, Deng, Feng and Qu2021). However, for solutions already in the upper or lower branch, a small disturbance will not change their branch. At this point, the system exhibits a certain level of self-sustaining behaviour (Wei & Yabuno Reference Wei and Yabuno2019). Systems within the hysteresis loop inherently possess multiple solutions, and significant disturbance can still change the branch of the solution. The states before the disturbance depicted in figure 17 correspond to the flutter and static solutions at ![]() $\lambda = 400$ in figure 15(d). As shown in figure 17(a), at

$\lambda = 400$ in figure 15(d). As shown in figure 17(a), at ![]() $\tau = 110.22$, we suppress 80 % of the amplitudes of the first three generalised velocities, resulting in the system transitioning from the flutter state to the static deformation state after sufficient development. Conversely, as shown in figure 17(b), at

$\tau = 110.22$, we suppress 80 % of the amplitudes of the first three generalised velocities, resulting in the system transitioning from the flutter state to the static deformation state after sufficient development. Conversely, as shown in figure 17(b), at ![]() $\tau = 36.74$, a gain on the first three generalised velocities is applied. The magnitude of this gain is equivalent to 80 % of their amplitudes in the corresponding flutter solution. This stimulation induces a transition from the static deformation state to the flutter state after sufficient development.

$\tau = 36.74$, a gain on the first three generalised velocities is applied. The magnitude of this gain is equivalent to 80 % of their amplitudes in the corresponding flutter solution. This stimulation induces a transition from the static deformation state to the flutter state after sufficient development.

Figure 17. Response at 3/4 chord of the panel before and after the disturbance that (a) transitions the flutter state into static deformation and (b) transitions the static deformation into flutter state.

The preceding analysis indicates that the evolution of these hysteresis loops exhibits typical characteristics of a cusp catastrophe (Lopez Reference Lopez1994; Arnold Reference Arnold2003). Our focus now shifts to examining the variations of solutions within the parameter plane of ![]() $\lambda$ and

$\lambda$ and ![]() $C_{pc}$. Figure 18 provides more states of different cavity pressures and visualises them in a three-dimensional space. The figure showcases the catastrophe surface (Strogatz Reference Strogatz2018, chap. 3) in the

$C_{pc}$. Figure 18 provides more states of different cavity pressures and visualises them in a three-dimensional space. The figure showcases the catastrophe surface (Strogatz Reference Strogatz2018, chap. 3) in the ![]() $\lambda - C_{pc}$ plane, as represented by the amplitudes at the 3/4 chord of the panel. It allows us to know the forms of solutions and their evolutionary trends within the parameter plane. Figure 18(a,b) represent the cases of ascending and descending dynamic pressure, respectively, and figure 18(c) combines the information from panels (a) and (b). The directional arrows in the figure indicate the direction of dynamic pressure change. The red lines beneath the surface illustrate the projection of the critical dynamic pressure onto the

$\lambda - C_{pc}$ plane, as represented by the amplitudes at the 3/4 chord of the panel. It allows us to know the forms of solutions and their evolutionary trends within the parameter plane. Figure 18(a,b) represent the cases of ascending and descending dynamic pressure, respectively, and figure 18(c) combines the information from panels (a) and (b). The directional arrows in the figure indicate the direction of dynamic pressure change. The red lines beneath the surface illustrate the projection of the critical dynamic pressure onto the ![]() $\lambda - C_{pc}$ plane. To provide a more intuitive explanation, a schematic representation of figure 18(a,b) is presented in figure 19, where the red arrows describe the behaviour of the solutions as the dynamic pressure changes.

$\lambda - C_{pc}$ plane. To provide a more intuitive explanation, a schematic representation of figure 18(a,b) is presented in figure 19, where the red arrows describe the behaviour of the solutions as the dynamic pressure changes.

Figure 18. Amplitudes in the ![]() $\lambda - C_{pc}$ plane with (a)

$\lambda - C_{pc}$ plane with (a) ![]() $\lambda$ ascending, (b)

$\lambda$ ascending, (b) ![]() $\lambda$ descending and (c) the combination of panels (a) and (b).

$\lambda$ descending and (c) the combination of panels (a) and (b).

Figure 19. Schematic representation of the catastrophe surface with (a) ![]() $\lambda$ ascending and (b)

$\lambda$ ascending and (b) ![]() $\lambda$ descending.

$\lambda$ descending.

Combining figures 18 and 19, it can be observed that regardless of whether the dynamic pressure is ascending or descending, the system undergoes a sharp and discontinuous transition between the flutter and static deformation states at specific positions where the surface cracks. As the cavity pressure increases, the intensity of this transition gradually attenuates and eventually transforms into a continuous evolution after ![]() $C_{pc}>1.227$. The projection of the critical dynamic pressure in figure 18(c) highlights the region between the

$C_{pc}>1.227$. The projection of the critical dynamic pressure in figure 18(c) highlights the region between the ![]() $\lambda _{cr,ascend}$ and

$\lambda _{cr,ascend}$ and ![]() $\lambda _{cr, descend}$, which represents the hysteresis structure. Based on figure 18, the critical dynamic pressures of ascending and descending processes intersect at the boundary between Phase II and Phase III. After entering Phase III, the ascending and descending critical dynamic pressures merge into the same line.

$\lambda _{cr, descend}$, which represents the hysteresis structure. Based on figure 18, the critical dynamic pressures of ascending and descending processes intersect at the boundary between Phase II and Phase III. After entering Phase III, the ascending and descending critical dynamic pressures merge into the same line.

To sum up, the variations in ![]() $\lambda$ and

$\lambda$ and ![]() $C_{pc}$ lead to the following phenomena.

$C_{pc}$ lead to the following phenomena.

1. The stability boundaries of the system (i.e. the critical dynamic pressures of ascending and descending processes) intersect and form a cusp.

2. At the cusp, the changes in the system stability transition from discontinuous jumps to continuous smooth evolutions.

These analyses indicate that the disappearance of the hysteresis loop and the formation of the cusp are induced by the variations in cavity pressure. The variations trigger a cusp catastrophe phenomenon (Arnold Reference Arnold2003) in the parameter plane of cavity pressure coefficient and non-dimensional dynamic pressure. Due to the inherent complexity of the dynamical system, providing rigorous theoretical proof for this catastrophe phenomenon is challenging. Following the methodology presented by Liu & Dowell (Reference Liu and Dowell2004), this study employs meticulous numerical methods to determine the evolution pattern of the dynamical system in the parameter plane. The results demonstrate that the system exhibits the principal characteristics of a cusp catastrophe phenomenon.

Similar cusp catastrophe phenomena have also been observed in various other nonlinear systems (Lopez Reference Lopez1994; Böttcher, Nagler & Herrmann Reference Böttcher, Nagler and Herrmann2017), indicating the existence of perilous explosive branch transitions in the dynamical system (Arnold Reference Arnold2003). As depicted in figure 18, such branch transitions occur between Phase II and Phase III, highlighting a crucial finding: the cavity pressure can modulate the stability characteristics of the system. In contrast to the sharp transitions in Phases I and II, when the cavity pressure falls within Phase III, the dynamical system exhibits a more moderate response and the critical dynamic pressure for flutter is higher. Effectively harnessing this favourable feature might potentially enhance the performance of vehicles in extreme operating conditions.

7. Three types of bifurcation induced by cavity pressure

The fundamental nature of the cusp catastrophe phenomenon triggered by cavity pressure lies in its influence on the critical dynamic pressure and how the system transitions at the critical point. Furthermore, the cavity pressure modifies the locations and types of the bifurcations in the system. To examine the variations in system bifurcations under different cavity pressures, an analysis is conducted on the changes in the critical dynamic pressure, which represents the location of the bifurcation occurrence.