1. Introduction

Comprehensive studies of the fluid mechanics of turbulence in porous media are only now emerging with the advancements in modern computational fluid dynamics (CFD) techniques. A fundamental understanding of how turbulent flow influences heat transfer in porous media is still lacking. Turbulence in porous media is different from turbulence in unconfined fluids because of the restrictions on the size and distribution of turbulent eddies imposed by the finite pore size. The porous medium geometry will determine the properties of the turbulence inside it. The repeating solid obstacles will enhance turbulent mixing, which promotes heat and mass transfer inside the porous medium. These unique properties of porous medium flows introduce features in microscale flow and thermal transport that are not ubiquitous. For instance, the porous medium imposes a restriction on the length and time scales of turbulence. In this work, microscale refers to a length scale whose order of magnitude is equal to or less than that of the size of the solid obstacle. Macroscale is a mathematically determined scale by applying the volume average theory (Slattery Reference Slattery1967) to the microscale governing equations. Macroscale turbulent structures will not be encountered in this study since the porous medium is assumed to be periodic. This has been demonstrated in the work of Jin et al. (Reference Jin, Uth, Kuznetsov and Herwig2015) and Uth et al. (Reference Uth, Jin, Kuznetsov and Herwig2016). The pore-scale prevalence of turbulence has been shown in Jin & Kuznetsov (Reference Jin and Kuznetsov2017). Direct numerical simulation (DNS) studies by He et al. (Reference He, Apte, Finn and Wood2019) verified that the turbulence integral length scale is ~10 % of the obstacle diameter in a closely packed porous medium. These observations suggest that the largest turbulent eddies will be formed as microscale vortices (micro-vortices) behind the solid obstacle.

As a result of the size limitation, turbulence flow phenomena are also limited to the microscale. For example, Chu, Weigand & Vaikuntanathan (Reference Chu, Weigand and Vaikuntanathan2018) showed that turbulence kinetic energy is produced near the surface of the solid obstacle at the microscale. It follows from these observations that the size and shape of the solid obstacles will determine the turbulence energy cascade. Convection heat transfer from the solid obstacle surface will also be affected by the flow surrounding the solid obstacle, which is determined by the solid obstacle shape. It is vital to understand the influence of microscale flow structures on turbulent heat transfer in porous media to develop robust macroscale models. The macroscale turbulence models can be used in emerging technologies such as heat management in electronics (Hetsroni, Gurevich & Rozenblit Reference Hetsroni, Gurevich and Rozenblit2006), long term energy storage systems (Nazir et al. Reference Nazir, Batool, Bolivar Osorio and Kannan2019) and forest fire modelling (Mell et al. Reference Mell, Maranghides, McDermott and Manzello2009). Macroscale turbulence models for porous medium flows have followed the Reynolds averaged, volume average approach (Lage, de Lemos & Nield Reference Lage, de Lemos and Nield2007; Vafai et al. Reference Vafai, Bejan, Minkowycz and Khanafer2009; de Lemos Reference de Lemos2012; Vafai Reference Vafai2015), due to the limited availability of computational resources. The macroscale energy models make use of the gradient diffusion hypothesis in conjunction with the assumption of thermal equilibrium between the solid and fluid phases (Nakayama, Kuwahara & Kodama Reference Nakayama, Kuwahara and Kodama2006). More sophisticated macroscale turbulence models have started to follow the large eddy simulation (LES) approach by including the temporal dynamics of the flow (Wood, He & Apte Reference Wood, He and Apte2020). To the best of the authors’ knowledge, such a model for macroscale thermal energy does not exist.

A budget for the macroscale thermal energy equation suggests that macroscale thermal transport is determined by only a few processes. Jouybari, Lundström & Hellström (Reference Jouybari, Lundström and Hellström2020) noted that macroscale heat transfer is dominated by turbulent convection. Interfacial heat transfer at the microscale plays a critical role in the macroscale thermal energy budget. In the past, interfacial heat transfer has been modelled empirically using Reynolds averaged Navier–Stokes (RANS) simulations of microscale porous medium flow (Kuwahara & Nakayama Reference Kuwahara and Nakayama1998; Pedras & de Lemos Reference Pedras and de Lemos2003; Kundu, Kumar & Mishra Reference Kundu, Kumar and Mishra2014). Note that the results from microscale RANS simulations are constrained by the modelling error (Iacovides, Launder & West Reference Iacovides, Launder and West2014) and that these errors are carried forward into the macroscale models based on these RANS simulations. Physical models of the thermal transport in porous media require an understanding of the underlying microscale flow physics.

Previous studies were mostly limited to investigations of microscale turbulent heat convection in tube banks. Wang, Jackson & Phaneuf (Reference Wang, Jackson and Phaneuf2006) reported high turbulence intensity in the regions behind the solid obstacles in a staggered tube bank. High turbulence is indicative of enhanced fluid mixing, which could promote heat transfer. Their RANS study has shown that vortex shedding is characterized by a single frequency. This observation can greatly simplify the dynamics of turbulence and heat transfer in porous media. The vortex region behind the heated solid obstacles is associated with a high temperature resulting in a low local Nusselt number (Wilson & Bassiouny Reference Wilson and Bassiouny2000). Recirculation in the micro-vortices smooths the temperature gradient at the solid obstacle surface for the Reynolds-averaged flow (Saito & de Lemos Reference Saito and de Lemos2006). The link between the micro-vortices and surface Nusselt number has not been investigated. Wilson & Bassiouny (Reference Wilson and Bassiouny2000) showed that the Nusselt number increases with in-line tube spacing until a spacing-to-diameter ratio of 3, although the underlying reason was not stated. The LES study by Blackall, Iacovides & Uribe (Reference Blackall, Iacovides and Uribe2020) and the DNS study by Chu et al. (Reference Chu, Yang, Pandey and Weigand2019) provided confirmation of the inhomogeneous distribution of the Nusselt number on the solid obstacle surface, which was previously observed in the RANS study by Sharatchandra & Rhode (Reference Sharatchandra and Rhode1997). The Nusselt number at the flow stagnation region was more than twice that of the vortex region. LES studies have also shown that the microscale turbulent structures introduce wrinkles in the iso-surface of temperature which in turn influence heat transfer (Linsong, Ping & Antonio Reference Linsong, Ping and Antonio2021).

The dynamics of turbulent flow has been studied for two-tandem cylinders with a focus on the vortices that are formed behind the cylinders. The vortex shedding process behind the downstream cylinder of the two-tandem cylinders was reported to be characterized by two frequencies (Zhou & Yiu Reference Zhou and Yiu2006; Alam & Zhou Reference Alam and Zhou2008). The low frequency vortex shedding was caused by the interaction of the vortex shedding behind the upstream cylinder with that of the downstream cylinder. For tandem cylinders, low Reynolds numbers were more conducive for the appearance of two peak frequencies for vortex shedding (Zhou et al. Reference Zhou, Feng, Alam and Bai2009). The vortex co-shedding mechanism at high Reynolds numbers was responsible for the disappearance of the second frequency. In addition to the Reynolds number, the separation distance between the cylinders (corresponding to porosity in the present study) also influenced the free shear layers formed behind the cylinder and its interaction with the neighbouring cylinder. This interaction is reported to control the transport efficiency of heat and momentum depending on the separation distance between the cylinders. The vortex strength is reported to be a good measure of the heat transfer efficiency, which is controlled by the separation distance. For a low separation distance such as that typically seen in porous media, the vortices transport heat and momentum with similar efficiency, which is different from an isolated cylinder where heat transport is more efficient. Dual frequency dynamics is also observed in porous media in the present work, as shown in § 3.2. However, there is a lack of a systematic study of the turbulent flow dynamics and its influence on heat transfer in porous media. It is an important study, especially since there are numerous applications of porous media with a Reynolds number large enough for the flow to transition to the turbulent regime.

It was shown in the literature that vortices induce intense turbulence mixing; however, low Nusselt numbers have also been reported in the vortex region. There is an inadequate understanding of this counterintuitive result. There is also a lack of studies that contrast the heat transfer in different regimes of turbulent flow in porous media. For example, heat transfer properties involving recirculating and shedding vortices are different. The contribution of the different flow regions on the solid obstacle surface to heat transfer has not been studied. Although researchers have reported a high Nusselt number in the stagnation region and a low Nusselt number in the vortex region, the surface areas covered by these regions are different. The geometry of the porous medium introduces a unique distribution of flow regions. Therefore, the previous observations of the relative contributions of these flow features to heat transfer are inconclusive.

In this paper, we address the shortcomings of the previous research described above. The goal of this study is to determine the influence of the micro-vortices on turbulent convection heat transfer inside porous media. Our preliminary work shows that the turbulent structures inside porous media can either insulate the solid obstacles or carry heat away from them, depending on the porous medium geometry (Huang et al. Reference Huang, Srikanth, Li and Kuznetsov2019; Huang, Srikanth & Kuznetsov Reference Huang, Srikanth and Kuznetsov2021). The micro-vortices will play a vital role in convection heat transfer, especially since they are formed on the solid obstacle surface. The porosity of the porous medium and the shape of the solid obstacles both influence the size, shape and dynamics of the microscale turbulent structures. At high porosity, the size of the micro-vortex scales with the diameter of the solid obstacle. The space in between the solid obstacles is large enough that the micro-vortices are not restricted. At low porosity, the size of the micro-vortex scales with the space in between the solid obstacle surfaces. The formation of a recirculating vortex restricted in between the solid obstacles of the porous medium at low porosity is also reported in Linsong et al. (Reference Linsong, Hongsheng, Dan, Jiansheng and Maozhao2018). The solid surfaces restrict the vortices from growing larger than the pore space (Huang et al. Reference Huang, Su, Srikanth and Kuznetsov2018). Desai & Vafai (Reference Desai and Vafai1994) showed that higher gap width in an annulus geometry decreases the heat transfer rate in natural convection. This suggests that porosity is a critical parameter for heat transfer in the present study. The solid obstacle shape has a higher influence on the turbulent structures when the porosity is low, compared with when the porosity is high. For square cylindrical solid obstacles, slow recirculating vortices were observed that restrict heat transfer. For circular cylindrical solid obstacles, the vortices were able to shed into the primary flow, dissipating heat during the process (Huang et al. Reference Huang, Srikanth, Li and Kuznetsov2019). We note that an effective way of increasing the heat transfer rate from bluff objects is to increase the Reynolds number of the flow, as shown by Khanafer & Vafai (Reference Khanafer and Vafai2021). In order to change heat transfer characteristics for a given Reynolds number, either the properties of the solid obstacle shape or the fluid can be changed.

Establishing a direct connection between the micro-vortices and the heat transfer is a novel contribution of the present work. Understanding the properties of the microscale flow is also important for macroscale heat transfer modelling. Microscale studies have shown that the heat transfer efficiency between the solid obstacle surface and the fluid increases with an increase in the Reynolds number and obstacle diameter (Suga, Chikasue & Kuwata Reference Suga, Chikasue and Kuwata2017; Chu et al. Reference Chu, Yang, Pandey and Weigand2019). The microscale simulations for square rods (Kuwahara & Nakayama Reference Kuwahara and Nakayama1998), circular rods (Rocamore Reference Rocamore2001) and elliptic rods (Pedras & de Lemos Reference Pedras and de Lemos2008) revealed that the thermal dispersion varies drastically with the solid obstacle shape. The functional dependence of the Nusselt number on porosity changes with the solid obstacle shape (Torabi et al. Reference Torabi, Torabi, Yazdi and Peterson2019). High resolution LES studies of finite pebble beds show that hot spots that appear on the surface of the pebbles are highly unsteady, and their locations move over time (Shams et al. Reference Shams, Roelofs, Komen and Baglietto2014). Turbulent thermal mixing for circular rods increases with an increase in the Reynolds number and approaches an asymptotic value at higher Reynolds numbers (Li & Wu Reference Li and Wu2013). Therefore, heat transfer in porous media is highly unsteady and closely linked to the formation, propagation and dissipation of flow structures. For instance, the temperature fluctuation intensity observed in the present work is ~15 % in the vortex region for a porous medium with a porosity of 0.50. The fluctuations come from vortex shedding and flow instabilities (discussed in § 3). These time-dependent effects are important when simulating turbulent convection heat transfer in porous media.

In this paper, we focus on investigating the relation between microscale turbulent structure dynamics and heat transfer in forced convection in porous media. We used LES to simulate the microscale flow inside of a periodic porous medium consisting of an array of cylinders. The simulation conditions and the details of the numerical method are discussed in § 2. We used a multiscale approach to analyse the flow in § 3. We used the flow streamlines and coherent structure visualization using the Q-criterion to visualize the vortex dynamics and overlaid the temperature distribution to determine its influence on heat transfer. We analysed the dynamics of the micro-vortices and heat transfer at the macroscale using a frequency transformation of the time series of the drag coefficient ![]() $({C_D})$, lift coefficient (CL) and Nusselt number

$({C_D})$, lift coefficient (CL) and Nusselt number ![]() $(N{u_m})$. We identified the relation between the surface heat transfer and shear using the surface skin-friction lines, Nusselt number distributions and joint probability density functions (PDFs) on the solid obstacle surface. Using these techniques, we show that the microscale turbulent structures dynamics directly influences heat transfer in forced convection in porous media.

$(N{u_m})$. We identified the relation between the surface heat transfer and shear using the surface skin-friction lines, Nusselt number distributions and joint probability density functions (PDFs) on the solid obstacle surface. Using these techniques, we show that the microscale turbulent structures dynamics directly influences heat transfer in forced convection in porous media.

2. Solution methods

2.1. Simulation geometry and boundary conditions

A homogeneous porous medium is constructed by arranging cylindrical solid obstacles in a simple square lattice (see figure 1). The simulation domain is three-dimensional spanning four unit cells along the x- and y-directions, and two unit cells in the z-direction. The dimensions are chosen based on the decorrelation width for turbulence two-point velocity correlation functions from Jin et al. (Reference Jin, Uth, Kuznetsov and Herwig2015) and Uth et al. (Reference Uth, Jin, Kuznetsov and Herwig2016). This forms a representative elementary volume (REV) of size ![]() $4s \times 4s \times 2s$, where s is the pore size (figure 1). In Appendix A, it is shown that the REV of size

$4s \times 4s \times 2s$, where s is the pore size (figure 1). In Appendix A, it is shown that the REV of size ![]() $4s \times 4s \times 2s$ is sufficient to calculate the macroscale quantities. The simulations were performed using the commercial CFD code ANSYS Fluent 16.0. The details of the numerical method presented in § 2 are taken from the Fluent theory guide (ANSYS Inc. 2016). Periodic boundary conditions are used to impose an infinite span in all directions to represent a homogenous porous medium. The pressure and velocity variables are periodic in all three Cartesian directions. The no-slip boundary condition is imposed at the solid obstacle surfaces. The temperature variable is periodic in the y- and z-directions. A temperature gradient is imposed in the x-direction such that the bulk temperature at the inlet of the REV is 323 K by following the methodology given in the Fluent theory guide (ANSYS Inc. 2016). The temperature of the solid obstacle surfaces

$4s \times 4s \times 2s$ is sufficient to calculate the macroscale quantities. The simulations were performed using the commercial CFD code ANSYS Fluent 16.0. The details of the numerical method presented in § 2 are taken from the Fluent theory guide (ANSYS Inc. 2016). Periodic boundary conditions are used to impose an infinite span in all directions to represent a homogenous porous medium. The pressure and velocity variables are periodic in all three Cartesian directions. The no-slip boundary condition is imposed at the solid obstacle surfaces. The temperature variable is periodic in the y- and z-directions. A temperature gradient is imposed in the x-direction such that the bulk temperature at the inlet of the REV is 323 K by following the methodology given in the Fluent theory guide (ANSYS Inc. 2016). The temperature of the solid obstacle surfaces ![]() $({T_w})$ was set to a constant value of 353 K. This results in a characteristic temperature difference

$({T_w})$ was set to a constant value of 353 K. This results in a characteristic temperature difference ![]() $\Delta T$ of 30 K. For this temperature change, we do not expect any changes in the physical state of the fluid or the occurrence of chemical reactions. The independence of the Nusselt number distribution from the characteristic temperature difference near the chosen value of 30 K is shown in Appendix B. The Prandtl number

$\Delta T$ of 30 K. For this temperature change, we do not expect any changes in the physical state of the fluid or the occurrence of chemical reactions. The independence of the Nusselt number distribution from the characteristic temperature difference near the chosen value of 30 K is shown in Appendix B. The Prandtl number ![]() $(Pr)$ was kept constant at 7. The fluid used for simulation is water (properties listed in table 1). Two values of porosity (φ), 0.50 and 0.87, are studied to represent two different regimes of turbulent flow in porous media. The flow features at

$(Pr)$ was kept constant at 7. The fluid used for simulation is water (properties listed in table 1). Two values of porosity (φ), 0.50 and 0.87, are studied to represent two different regimes of turbulent flow in porous media. The flow features at ![]() $\varphi = 0.50\; $ are similar to that of internal flow (such as channel flow), while the flow at

$\varphi = 0.50\; $ are similar to that of internal flow (such as channel flow), while the flow at ![]() $\varphi = 0.87\; $ resembles external flow (such as flow around a bluff body). At φ = 0.50, the solid obstacle surfaces are close to each other such that the separated shear layer bridges the gap between the two obstacles. A channel-like flow is observed in between the recirculating vortices. The recirculating vortices are also driven by the shear layer in a manner that is similar to lid-driven cavity flows. At φ = 0.87, the solid obstacle surfaces are far apart such that the vortices are able to form, detach and be transported away from the solid obstacle surface. The Reynolds number

$\varphi = 0.87\; $ resembles external flow (such as flow around a bluff body). At φ = 0.50, the solid obstacle surfaces are close to each other such that the separated shear layer bridges the gap between the two obstacles. A channel-like flow is observed in between the recirculating vortices. The recirculating vortices are also driven by the shear layer in a manner that is similar to lid-driven cavity flows. At φ = 0.87, the solid obstacle surfaces are far apart such that the vortices are able to form, detach and be transported away from the solid obstacle surface. The Reynolds number ![]() $(R{e_p})$ is 300 for a majority of the cases. A single case with a Reynolds number of 500 is used to understand how the Reynolds number affects the observations put forth in this paper. The square solid obstacle shape is used at high Reynolds number to avoid the deviatory flow observed in Srikanth et al. (Reference Srikanth, Huang, Su and Kuznetsov2021). The flow rate was sustained by using a constant applied pressure gradient

$(R{e_p})$ is 300 for a majority of the cases. A single case with a Reynolds number of 500 is used to understand how the Reynolds number affects the observations put forth in this paper. The square solid obstacle shape is used at high Reynolds number to avoid the deviatory flow observed in Srikanth et al. (Reference Srikanth, Huang, Su and Kuznetsov2021). The flow rate was sustained by using a constant applied pressure gradient ![]() $(\rho {g_1}$, where g i is the applied acceleration) as the driving force. The porosity (φ) and the Reynolds number are defined as

$(\rho {g_1}$, where g i is the applied acceleration) as the driving force. The porosity (φ) and the Reynolds number are defined as

where d is the hydraulic diameter of the solid obstacles, ![]() ${u_m}$ is the superficially averaged macroscale mean velocity in the x-direction and

${u_m}$ is the superficially averaged macroscale mean velocity in the x-direction and ![]() $\nu $ is the kinematic viscosity of the fluid. LES with the dynamic one-equation turbulence kinetic energy (DOTKE) subgrid model (Kim & Menon Reference Menon1997) is used to simulate the microscale flow field inside the porous medium. Rodi (Reference Rodi1997) demonstrated the superior performance of LES in simulating bluff body flows compared with RANS. Dynamic LES models are able to reproduce experimental results with reasonable accuracy at a fraction of the cost of DNS (Jin et al. Reference Jin, Potts, Swailes and Reeks2016). Krajnovic & Davidson (Reference Krajnovic and Davidson2000) have also demonstrated the ability of the DOTKE model to predict parameters associated with vortex shedding. The simulations were run on the North Carolina State University Linux Cluster. Representative computation time for one LES case is 25 000 CPU-hours (1 CPU-hour = computation time in hours for a single CPU). Each simulation is run using 80 cores with nodes consisting of Intel® Xeon® E5-2650 v4 processors. Each simulation is run for 200 non-dimensional time units (8000 CPU-hours) to equilibrate the solution followed by the collection of turbulence statistics for 400 non-dimensional time units (17 000 CPU-hours).

$\nu $ is the kinematic viscosity of the fluid. LES with the dynamic one-equation turbulence kinetic energy (DOTKE) subgrid model (Kim & Menon Reference Menon1997) is used to simulate the microscale flow field inside the porous medium. Rodi (Reference Rodi1997) demonstrated the superior performance of LES in simulating bluff body flows compared with RANS. Dynamic LES models are able to reproduce experimental results with reasonable accuracy at a fraction of the cost of DNS (Jin et al. Reference Jin, Potts, Swailes and Reeks2016). Krajnovic & Davidson (Reference Krajnovic and Davidson2000) have also demonstrated the ability of the DOTKE model to predict parameters associated with vortex shedding. The simulations were run on the North Carolina State University Linux Cluster. Representative computation time for one LES case is 25 000 CPU-hours (1 CPU-hour = computation time in hours for a single CPU). Each simulation is run using 80 cores with nodes consisting of Intel® Xeon® E5-2650 v4 processors. Each simulation is run for 200 non-dimensional time units (8000 CPU-hours) to equilibrate the solution followed by the collection of turbulence statistics for 400 non-dimensional time units (17 000 CPU-hours).

Figure 1. The REV geometry of a porous medium. The distance between the centres of the solid obstacles s (pore size) and the solid obstacle diameter d are also shown in the figure.

Table 1. The properties of the fluid used in simulation corresponding to water at 323 K.

2.2. Details of the physical model and numerical method

The governing equations for the LES are the filtered Navier–Stokes equations (2.3) and (2.4). The tilde notation ![]() $(\tilde{u})$ denotes the spatial filtering operator. The pressure variable

$(\tilde{u})$ denotes the spatial filtering operator. The pressure variable ![]() $\tilde{p}$ here is the filtered periodic pressure (terminology adopted from the ANSYS Inc. 2016 theory guide). The pressure gradient term in the governing equations in periodic flows can be split into a constant pressure gradient term

$\tilde{p}$ here is the filtered periodic pressure (terminology adopted from the ANSYS Inc. 2016 theory guide). The pressure gradient term in the governing equations in periodic flows can be split into a constant pressure gradient term ![]() $\rho {g_i}$ and the gradient of the periodic pressure

$\rho {g_i}$ and the gradient of the periodic pressure ![]() $\partial \tilde{p}/\partial {x_i}$. To calculate the static pressure, we take the sum of the periodic pressure and the linearly varying pressure. The subgrid velocity scale is estimated by solving a transport equation for the subgrid turbulence kinetic energy

$\partial \tilde{p}/\partial {x_i}$. To calculate the static pressure, we take the sum of the periodic pressure and the linearly varying pressure. The subgrid velocity scale is estimated by solving a transport equation for the subgrid turbulence kinetic energy ![]() ${k_{SGS}}$ (2.5). The subgrid-scale filter length

${k_{SGS}}$ (2.5). The subgrid-scale filter length ![]() $\varDelta $ is set as the cube root of the cell volume. Kim (2004) has demonstrated that setting the grid filter length as the cube root of the cell volume yields accurate results using unstructured, stretched grids for simulating the flow inside channels and around square cylinders. We note that there are other procedures used to calculate the filter width such as the maximum side length of the hexahedral cell or by using the van Driest damping function. Equation (2.6) estimates the subgrid turbulence eddy viscosity. The characteristic subgrid length scale for the calculation of subgrid turbulent viscosity is estimated as

$\varDelta $ is set as the cube root of the cell volume. Kim (2004) has demonstrated that setting the grid filter length as the cube root of the cell volume yields accurate results using unstructured, stretched grids for simulating the flow inside channels and around square cylinders. We note that there are other procedures used to calculate the filter width such as the maximum side length of the hexahedral cell or by using the van Driest damping function. Equation (2.6) estimates the subgrid turbulence eddy viscosity. The characteristic subgrid length scale for the calculation of subgrid turbulent viscosity is estimated as ![]() $\varDelta $. The model constants

$\varDelta $. The model constants ![]() ${C_k}$ and

${C_k}$ and ![]() ${C_\varepsilon }$ are determined by the localized dynamic subgrid-scale model from Kim & Menon (Reference Menon1997). The grid-scale velocity field is filtered to a test-scale velocity field. The test filter length

${C_\varepsilon }$ are determined by the localized dynamic subgrid-scale model from Kim & Menon (Reference Menon1997). The grid-scale velocity field is filtered to a test-scale velocity field. The test filter length ![]() $\hat{\varDelta }$ is equal to twice the grid filter length

$\hat{\varDelta }$ is equal to twice the grid filter length ![]() $\varDelta $ (ANSYS Inc. 2016). The similarity between the stresses at the two scales is invoked to determine the model constants. The model constant

$\varDelta $ (ANSYS Inc. 2016). The similarity between the stresses at the two scales is invoked to determine the model constants. The model constant ![]() ${C_k}$ is determined in (2.7a,b) and (2.8a–c) by using the similarity between the subgrid-scale (SGS) stress tensor

${C_k}$ is determined in (2.7a,b) and (2.8a–c) by using the similarity between the subgrid-scale (SGS) stress tensor ![]() ${\tau _{ij}}$ and the test Leonard stress tensor

${\tau _{ij}}$ and the test Leonard stress tensor ![]() ${L_{ij}}$. The value of

${L_{ij}}$. The value of ![]() ${C_k}$ is limited by

${C_k}$ is limited by ![]() $- \mu /(k_{SGS}^{1/2}\varDelta )$ to avoid a negative total viscosity. Model constant

$- \mu /(k_{SGS}^{1/2}\varDelta )$ to avoid a negative total viscosity. Model constant ![]() ${C_\varepsilon }$ is determined in (2.9) by using the similarity between the dissipation rate at the grid level

${C_\varepsilon }$ is determined in (2.9) by using the similarity between the dissipation rate at the grid level ![]() ${\varepsilon _{SGS}}$ and the test level

${\varepsilon _{SGS}}$ and the test level ![]() ${\varepsilon _{test}}$. The governing equations of thermal energy are given in (2.10)–(2.12). The turbulent Prandtl number

${\varepsilon _{test}}$. The governing equations of thermal energy are given in (2.10)–(2.12). The turbulent Prandtl number ![]() $(P{r_T})$ is assumed to take a constant value of 0.85. Dynamic methods are available for the calculation of turbulent Prandtl number in a manner using the Germano identity at the cost of added complexity in the numerical model. It is noted in the literature that the use of a variable turbulent Prandtl number has a negligible effect on the prediction of thermal characteristics in wall bounded flows when compared with using the constant value of 0.85 (Kakka & Anupindi Reference Kakka and Anupindi2020). The filtered governing equations are solved in conjunction with the DOTKE subgrid model using the finite volume method (FVM). A box filter is implicitly applied by the computational grid in the FVM

$(P{r_T})$ is assumed to take a constant value of 0.85. Dynamic methods are available for the calculation of turbulent Prandtl number in a manner using the Germano identity at the cost of added complexity in the numerical model. It is noted in the literature that the use of a variable turbulent Prandtl number has a negligible effect on the prediction of thermal characteristics in wall bounded flows when compared with using the constant value of 0.85 (Kakka & Anupindi Reference Kakka and Anupindi2020). The filtered governing equations are solved in conjunction with the DOTKE subgrid model using the finite volume method (FVM). A box filter is implicitly applied by the computational grid in the FVM

\begin{gather}\frac{{\partial {k_{SGS}}}}{{\partial t}} + \frac{{\partial (\widetilde {{u_j}}{k_{SGS}})}}{{\partial {x_j}}} = \left[ {{C_k}k_{SGS}^{1/2}\varDelta \left( {\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} + \frac{{\partial \widetilde {{u_j}}}}{{\partial {x_i}}}} \right)} \right]\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} - {C_\varepsilon }\frac{{k_{SGS}^{3/2}}}{\varDelta } + \frac{\partial }{{\partial {x_j}}}\left( {{\mu_{T,SGS}}\frac{{\partial {k_{SGS}}}}{{\partial {x_j}}}} \right),\end{gather}

\begin{gather}\frac{{\partial {k_{SGS}}}}{{\partial t}} + \frac{{\partial (\widetilde {{u_j}}{k_{SGS}})}}{{\partial {x_j}}} = \left[ {{C_k}k_{SGS}^{1/2}\varDelta \left( {\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} + \frac{{\partial \widetilde {{u_j}}}}{{\partial {x_i}}}} \right)} \right]\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} - {C_\varepsilon }\frac{{k_{SGS}^{3/2}}}{\varDelta } + \frac{\partial }{{\partial {x_j}}}\left( {{\mu_{T,SGS}}\frac{{\partial {k_{SGS}}}}{{\partial {x_j}}}} \right),\end{gather} \begin{gather}{C_\varepsilon } = \frac{{\overbrace{{(\partial \widetilde {{u_i}}/\partial {x_j})(\partial \widetilde {{u_i}}/\partial {x_j})}}^{{\widehat {\textrm{ }}}} - (\partial \widehat {\widetilde {{u_i}}}/\partial {x_j})(\partial \widehat {\widetilde {{u_i}}}/\partial {x_j})}}{{{{((\mu + {\mu _{T,SGS}})\hat{\varDelta })}^{ - 1}}k_{test}^{3/2}}},\end{gather}

\begin{gather}{C_\varepsilon } = \frac{{\overbrace{{(\partial \widetilde {{u_i}}/\partial {x_j})(\partial \widetilde {{u_i}}/\partial {x_j})}}^{{\widehat {\textrm{ }}}} - (\partial \widehat {\widetilde {{u_i}}}/\partial {x_j})(\partial \widehat {\widetilde {{u_i}}}/\partial {x_j})}}{{{{((\mu + {\mu _{T,SGS}})\hat{\varDelta })}^{ - 1}}k_{test}^{3/2}}},\end{gather} \begin{gather}\frac{{\partial \rho E}}{{\partial t}} + \frac{{\partial (\rho E + \tilde{p})\widetilde {{u_j}}}}{{\partial {x_j}}} = \; \frac{\partial }{{\partial {x_j}}}\left[ {({k_{eff}})\frac{{\partial \tilde{T}}}{{\partial {x_j}}}} \right] + \frac{\partial }{{\partial {x_j}}}\left[ {\widetilde {{u_j}}(\mu + {\mu_{T,SGS}})\left( {\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} + \frac{{\partial \widetilde {{u_j}}}}{{\partial {x_i}}}} \right)} \right],\end{gather}

\begin{gather}\frac{{\partial \rho E}}{{\partial t}} + \frac{{\partial (\rho E + \tilde{p})\widetilde {{u_j}}}}{{\partial {x_j}}} = \; \frac{\partial }{{\partial {x_j}}}\left[ {({k_{eff}})\frac{{\partial \tilde{T}}}{{\partial {x_j}}}} \right] + \frac{\partial }{{\partial {x_j}}}\left[ {\widetilde {{u_j}}(\mu + {\mu_{T,SGS}})\left( {\frac{{\partial \widetilde {{u_i}}}}{{\partial {x_j}}} + \frac{{\partial \widetilde {{u_j}}}}{{\partial {x_i}}}} \right)} \right],\end{gather}The bounded second-order central scheme (according to the work of Leonard Reference Leonard1991) is used to discretize the convective terms and a second-order central scheme is used for the viscous terms in the momentum equation. The thermal energy equation is discretized using the Quadratic Upstream Interpolation for Convective Kinematics (QUICK) scheme for increased stability without compromising accuracy. The locations of the pressure and velocity variables are staggered. The pressure is stored at the centroid of the face of the cell, while the velocity is stored at the cell centre. The momentum and pressure Poisson equations are solved in a segregated manner using a pressure-implicit scheme with splitting of operators. The thermal energy equation is solved at the end of the time step. The simulation is advanced in time using a second-order implicit backward Euler method. The no-slip boundary condition is enforced at the solid obstacle walls by specifying the surface tangential and normal velocities at the solid obstacle wall to be equal to zero. We note that there are other methods of implementing the no-slip boundary condition at the wall, such as mirroring or by polynomial reconstruction of the fluid velocity distribution in the solid obstacle domain for accurate gradient representation. In this work, we are modelling only the fluid domain and there are no nodes inside the solid obstacle to model the solid phase. Therefore, we explicitly specify velocity boundary conditions at the solid surface. For the periodic boundary conditions, the grid point locations are conformal for each pair of periodic faces. Each pair of periodic faces is treated as a connected interface with connected nodes to periodically repeat the velocity and pressure distributions. A similar procedure is followed for the temperature distribution in the y- and z-periodic faces. For the x-periodic faces, the temperature distribution at the exit face is copied to the inlet face after adjusting the magnitude to specify the desired bulk inlet temperature.

2.3. Validation of the physical model and numerical method

In this section, we demonstrate that the numerical method described in § 2.2 is appropriate for simulating turbulent flow in porous media by comparing the simulated flow field with that of an experimental study. The ANSYS Fluent code used in this paper is well validated for canonical turbulent flows (Fluent Inc. 2006). However, the code must be validated for turbulent flows in porous media since the features of both flows inside channels and flows around a single solid obstacle are observed. The experimental results of Aiba, Tsuchida & Ota (Reference Aiba, Tsuchida and Ota1982) for turbulent flow through a tube bank in a channel are viable for validation due to the small size of the tube bank. A limitation of this comparison is that the Reynolds number of the flow used in the experimental work is an order of magnitude larger than that used in the present work. The computational grid used in the validation simulation is capable of capturing the large-scale eddies. The DOTKE subgrid-scale model is able to predict the small-scale eddies. At high Reynolds numbers, a larger portion of the turbulence energy spectrum is predicted by the subgrid model than that at low Reynolds numbers. Therefore, the use of a large Reynolds number for validation is beneficial to determine the performance of the LES subgrid model. An excellent agreement between the simulation and experiment at the high Reynolds number implies an even better simulation accuracy at low Reynolds numbers. This is because the subgrid flow properties are close to the subgrid model assumptions at low Reynolds numbers.

The geometry used for the validation simulation is shown in figure 2. The validation simulation models the experimental case with a dimensionless tube spacing of 1.6 and a Reynolds number of 41 000. The Reynolds number is calculated using the mean flow velocity at the minimum clearance and the tube diameter as per Aiba et al. (Reference Aiba, Tsuchida and Ota1982). Note that all the lengths are non-dimensionalized using the tube diameter. The fluid properties are those of air at 25 °C. The following approximations are made while modelling the experimental set-up.

(i) The flow at the centre of the tube span is modelled by introducing a periodic boundary condition in the z-direction. The approximation follows from the nearly constant velocity distribution in the middle of the channel for turbulent flow. The span of the periodic domain in the z-direction is two times the pore size. The turbulence two-point correlation width is less than the span of the domain.

(ii) Sufficiently long entrance and exit sections to the test section are introduced such that the flow becomes fully developed. The entrance and exit sections of the computational domain are 30 times the channel width.

(iii) Grid stretching is used to increase the grid size at the inlet and outlet since high grid resolution in these regions is not important to the flow in the test section.

(iv) The constant velocity boundary condition is specified at the inlet. Spectrally synthesized perturbations are imposed on the velocity inlet to simulate a 5 % turbulence intensity, as per the work of Aiba et al. (Reference Aiba, Tsuchida and Ota1982). Atmospheric pressure is specified at the outlet.

(v) In the experiment, only the tube that is being considered for measurement is heated at any given time. We follow the same procedure in the simulation by assigning a constant heat flux boundary to the surface of a single cylinder. The experimental heat flux has not been reported in the original article. We have assumed the heat flux to be equal to 2 W m−2 following the experimental work of Sarma & Sukhatme (Reference Sarma and Sukhatme1977) for the flow over a single cylinder. The induced temperature increase is low enough that it does not violate the assumptions of the physical model used for the simulation.

(vi) In the experiment, the heat transfer measurements correspond to a more complex conjugate heat transfer problem that considers both the effects of the solid and the fluid phases. In the simulation, we are assuming that the solid surfaces that are not heated are adiabatic.

Figure 2. A sketch of the computational domain used to reproduce the experimental results of Aiba et al. (Reference Aiba, Tsuchida and Ota1982) for validation of the numerical method. The simulations are performed to compare the coefficient of pressure and Nusselt number on the coloured tubes shown in the figure with that of the experiment. All the lengths are non-dimensionalized using the tube diameter.

The LES model equations used for the simulation are described in § 2.2. The distributions of the coefficient of pressure ![]() $({C_{pressure}})$ on the surface of the fourth and seventh tubes are used for comparison (figure 3a). The value of

$({C_{pressure}})$ on the surface of the fourth and seventh tubes are used for comparison (figure 3a). The value of ![]() ${C_{pressure}}$ is calculated as per the definition given by Aiba et al. (Reference Aiba, Tsuchida and Ota1982). The simulated

${C_{pressure}}$ is calculated as per the definition given by Aiba et al. (Reference Aiba, Tsuchida and Ota1982). The simulated ![]() ${C_{pressure}}$ distribution follows the same trend as that of the experiment. The simulated stagnation pressure is less than that of the experiment. In the low pressure regions, the quantitative agreement between the simulation and the experiment is excellent. The disparity between the simulation and the experiment is due to turbulence model limitations, coarse grid resolution and differences between the simulation and experimental set-ups.

${C_{pressure}}$ distribution follows the same trend as that of the experiment. The simulated stagnation pressure is less than that of the experiment. In the low pressure regions, the quantitative agreement between the simulation and the experiment is excellent. The disparity between the simulation and the experiment is due to turbulence model limitations, coarse grid resolution and differences between the simulation and experimental set-ups.

Figure 3. The distribution of the (a) coefficient of pressure, and (b) Nusselt number on the surfaces of tubes 4 and 7 in the centre row of the tube bank (figure 2) for the LES and the experiment.

The distribution of the Nusselt number on the surface of the tubes is shown in figure 3(b). There exists an average error of 15 % between the simulation and the experimental Nusselt number distributions. It should be noted that Iacovides et al. (Reference Iacovides, Launder and West2014) reported a close to zero average error in the Nusselt number distribution with the experimental result of Aiba et al. (Reference Aiba, Tsuchida and Ota1982) by assuming periodicity in the flow in all three directions and that all of the cylinders are heated. In the present work, we observe an excellent qualitative agreement in the distribution of the Nusselt number. The distribution of the Nusselt number is virtually an exact match between the simulation and the experiment after adjusting for the mismatch in the magnitude of the Nusselt number. This suggests that the simulation adequately captures the features of the flow at the solid obstacle surface and the dependence of heat transfer on these flow features. There are several differences between the simulation and the experiment that could have led to the quantitative difference in Nusselt number:

(i) The incomplete specification of the wind tunnel inlet and outlet conditions in the simulation geometry leading to potential discrepancies with the experimental set-up.

(ii) The assumption of an infinitely periodic span for the tubes.

(iii) The assumption of adiabatic tunnel and tube walls and the lack of a conjugate heat transfer model in the simulation to consider the heat transfer inside the solid tube.

Sources of experimental error could also be a contributing factor. The margin of error in the temperature measurements is not reported in the original paper, but similar experiments report a 3 % margin of error in the temperature measurements. Errors in the temperature value from both the experiment and the simulation become accentuated during the calculation of the Nusselt number since the inverse of temperature difference is considered.

Excellent quantitative agreement of ![]() ${C_{pressure}}$ in the low pressure region demonstrates the ability of the model to predict the vortex region, which is the primary focus of the paper. We also note that the coarse grid resolution is adequate to capture the main features of the flow. Resolution up to the Kolmogorov scale will not contribute new information in this study. Therefore, we have established that the numerical method described in § 2.2 is able to reproduce the flow behaviour in porous media that is observed in experimental work. We are proceeding to use the numerical method for our analysis. The numerical accuracy will improve further when compared with the validation case due to the high-resolution grids and the low Reynolds number used in the present work.

${C_{pressure}}$ in the low pressure region demonstrates the ability of the model to predict the vortex region, which is the primary focus of the paper. We also note that the coarse grid resolution is adequate to capture the main features of the flow. Resolution up to the Kolmogorov scale will not contribute new information in this study. Therefore, we have established that the numerical method described in § 2.2 is able to reproduce the flow behaviour in porous media that is observed in experimental work. We are proceeding to use the numerical method for our analysis. The numerical accuracy will improve further when compared with the validation case due to the high-resolution grids and the low Reynolds number used in the present work.

2.4. Choice of grid resolution

To determine a suitable grid resolution for the simulations, we perform a grid convergence study using a smaller REV size of ![]() $2\;\textrm{s} \times 2\;\textrm{s} \times 2\;\textrm{s}$ since the study concerns the smallest scales. The grids used in this work are unstructured and follow a block structured O-grid topology that stretches the grid around the solid obstacle surface. The grid cells in the bulk of the computational domain are cubical in shape with an aspect ratio of ~1. The grid cells at the solid obstacle surface have a grid step size that is one order of magnitude smaller than the maximum grid step size. The clustering of the cells at the solid obstacle surface is to accurately capture the boundary layer. The maximum value of the grid spacing Δxmax and the non-dimensional near-wall grid spacing

$2\;\textrm{s} \times 2\;\textrm{s} \times 2\;\textrm{s}$ since the study concerns the smallest scales. The grids used in this work are unstructured and follow a block structured O-grid topology that stretches the grid around the solid obstacle surface. The grid cells in the bulk of the computational domain are cubical in shape with an aspect ratio of ~1. The grid cells at the solid obstacle surface have a grid step size that is one order of magnitude smaller than the maximum grid step size. The clustering of the cells at the solid obstacle surface is to accurately capture the boundary layer. The maximum value of the grid spacing Δxmax and the non-dimensional near-wall grid spacing ![]() $\Delta y_{max}^ +$ are shown in table 2. The distribution of Δy + on the solid obstacle surface is shown in figure S1 in the supplementary material and movies are available at https://doi.org/10.1017/jfm.2022.291. First, the LES index of quality (LES_IQ) (Celik, Cehreli & Yavuz Reference Celik, Cehreli and Yavuz2005) is used to estimate the fraction of the total turbulence kinetic energy that is resolved by the grid. Pope (Reference Pope2004) recommends resolving 80 % of the turbulence kinetic energy for LES. Remarks from Celik et al. (Reference Celik, Cehreli and Yavuz2005) indicate that simulations may be considered to be of DNS quality with LES_IQ > 0.9. The volume weighted average of the LES_IQ for all the LES simulations in this work is greater than 0.8. The minimum and volume-averaged values of LES_IQ at an instant in time are reported in table 3. LES_IQ values less than 0.8 are observed in the near-wall region for the instantaneous flow as spots on the solid obstacle surface. The location of these spots coincides with the impingement of turbulent structures on the solid obstacle surface. This implies an increased reliance on the subgrid model in the near-wall region. The subgrid model has been validated in § 2.2 and its performance has been deemed adequate.

$\Delta y_{max}^ +$ are shown in table 2. The distribution of Δy + on the solid obstacle surface is shown in figure S1 in the supplementary material and movies are available at https://doi.org/10.1017/jfm.2022.291. First, the LES index of quality (LES_IQ) (Celik, Cehreli & Yavuz Reference Celik, Cehreli and Yavuz2005) is used to estimate the fraction of the total turbulence kinetic energy that is resolved by the grid. Pope (Reference Pope2004) recommends resolving 80 % of the turbulence kinetic energy for LES. Remarks from Celik et al. (Reference Celik, Cehreli and Yavuz2005) indicate that simulations may be considered to be of DNS quality with LES_IQ > 0.9. The volume weighted average of the LES_IQ for all the LES simulations in this work is greater than 0.8. The minimum and volume-averaged values of LES_IQ at an instant in time are reported in table 3. LES_IQ values less than 0.8 are observed in the near-wall region for the instantaneous flow as spots on the solid obstacle surface. The location of these spots coincides with the impingement of turbulent structures on the solid obstacle surface. This implies an increased reliance on the subgrid model in the near-wall region. The subgrid model has been validated in § 2.2 and its performance has been deemed adequate.

Table 2. The maximum value of non-dimensional near-wall grid spacing, ![]() $\Delta y_{max}^ +$, calculated on the surface of the solid obstacles for the grid resolution test cases. These are small areas with high Δy + values, overall Δy + values on the solid obstacle surfaces are kept below 1.

$\Delta y_{max}^ +$, calculated on the surface of the solid obstacles for the grid resolution test cases. These are small areas with high Δy + values, overall Δy + values on the solid obstacle surfaces are kept below 1.

Table 3. The value of LES_IQ calculated for the grid resolution test cases. Both the minimum and the volume-averaged values are reported (ranges from 0 to 1, values close to 1 indicate high resolution with a large fraction of the turbulence kinetic energy being resolved).

Next, the turbulence kinetic energy spectrum is calculated using the one-dimensional turbulence two-point velocity fluctuation correlation functions. The turbulence kinetic energy spectrum is used to confirm that the large-scale eddies and a substantial portion of the inertial subrange have been resolved in this work. The turbulence kinetic energy spectra ![]() $({E_{ii}}/3)$ versus the non-dimensional wavenumber

$({E_{ii}}/3)$ versus the non-dimensional wavenumber ![]() $(ks)$ for the LES test cases are shown in figure 4. A portion of the turbulence energy spectrum aligns with −5/3 slope for all the cases, which indicates that the inertial subrange has been captured. At the small scales of turbulence, the turbulence kinetic energy declines by three orders of magnitude when compared with the largest scales. Therefore, the smallest scales of turbulence are not significant in our study. An experimental study by Nguyen et al. (Reference Nguyen, Muyshondt, Hassan and Anand2019) shows a lack of small-scale coherent structures in randomly packed porous media. This further supports the notion that the small length scale motions do not contribute significantly to surface heat transfer. In some cases, a portion of the energy spectrum at the high non-dimensional wavenumbers is excited due to numerical noise. This is also observed in the energy spectrum plots shown in Eggels et al. (Reference Eggels, Unger, Weiss and Nieuwstadt1994). Comparing the turbulence energy spectrum produced by the three grid sizes, the grid sizes Δxmax/s of 0.025 and 0.0125 show similar trends for a wider range of length scales until the dissipative scales of turbulence are reached. Note that the spectra will not be coincident due to the limitations of discrete Fourier transforms that introduce oscillations in the spectra that are unique to each case. Since we are interested in the trends in the spectra rather than an exact point-by-point comparison, the oscillations do not impact our study. Since we are using a subgrid model for the dissipative scales, we are proceeding with the analysis using a grid size Δxmax/s of 0.025.

$(ks)$ for the LES test cases are shown in figure 4. A portion of the turbulence energy spectrum aligns with −5/3 slope for all the cases, which indicates that the inertial subrange has been captured. At the small scales of turbulence, the turbulence kinetic energy declines by three orders of magnitude when compared with the largest scales. Therefore, the smallest scales of turbulence are not significant in our study. An experimental study by Nguyen et al. (Reference Nguyen, Muyshondt, Hassan and Anand2019) shows a lack of small-scale coherent structures in randomly packed porous media. This further supports the notion that the small length scale motions do not contribute significantly to surface heat transfer. In some cases, a portion of the energy spectrum at the high non-dimensional wavenumbers is excited due to numerical noise. This is also observed in the energy spectrum plots shown in Eggels et al. (Reference Eggels, Unger, Weiss and Nieuwstadt1994). Comparing the turbulence energy spectrum produced by the three grid sizes, the grid sizes Δxmax/s of 0.025 and 0.0125 show similar trends for a wider range of length scales until the dissipative scales of turbulence are reached. Note that the spectra will not be coincident due to the limitations of discrete Fourier transforms that introduce oscillations in the spectra that are unique to each case. Since we are interested in the trends in the spectra rather than an exact point-by-point comparison, the oscillations do not impact our study. Since we are using a subgrid model for the dissipative scales, we are proceeding with the analysis using a grid size Δxmax/s of 0.025.

Figure 4. Turbulence kinetic energy Eii/3 versus the non-dimensional wavenumber ks for LES cases: (a) ![]() $\varphi = 0.50$ with circular solid obstacles; (b)

$\varphi = 0.50$ with circular solid obstacles; (b) ![]() $\varphi = 0.87$ with circular solid obstacles; (c)

$\varphi = 0.87$ with circular solid obstacles; (c) ![]() $\varphi = 0.87$ with square solid obstacles. The dashed line corresponds to the −5/3 slope on the log plot.

$\varphi = 0.87$ with square solid obstacles. The dashed line corresponds to the −5/3 slope on the log plot.

3. Results and discussion

The investigation of the turbulent flow physics and heat transfer inside a porous medium requires a multiscale analysis with an emphasis on the microscale flow behaviour. In this section, we analyse the microscale vortex transport and its effect on heat transfer using the following approach.

(i) First, we identify the regions inside the REV that contribute significantly to heat transfer by visualizing the three-dimensional flow field. We visualize the flow patterns using the instantaneous flow streamlines and the three-dimensional coherent structures using the Q-criterion. We identify significant regions of heat transfer by locations with a high temperature gradient. We use skin-friction lines overlaid on the Nusselt number distribution on the solid obstacle surfaces to investigate the influence of the surface shear on heat transfer.

(ii) With an understanding of how the different flow features observed in porous medium flow influence the heat transfer, we investigated the dynamics of the surface-averaged flow properties. This helps reduce the complexity of the analysis when compared with a high frame rate visualization of the three-dimensional flow structures. We use the fast Fourier transform of the time series of the lift coefficient (CL), drag coefficient

$({C_D})$ and Nusselt number

$({C_D})$ and Nusselt number  $(N{u_m})$ to transform them into the frequency domain and correlate them with our observations from the three-dimensional flow visualization. We determine whether the spectra of CL,

$(N{u_m})$ to transform them into the frequency domain and correlate them with our observations from the three-dimensional flow visualization. We determine whether the spectra of CL,  ${C_D}$ and

${C_D}$ and  $N{u_m}$ have any similarities.

$N{u_m}$ have any similarities.(iii) Next, we determine the fractional contribution of the different flow features to heat transfer. We constructed a joint PDF of the surface pressure and skin-friction coefficients with the surface Nusselt number to map surface processes on the solid obstacle. We have also used it to test our hypothesis that the pressure and shear dominated processes during stages of vortex shedding have high impact on heat transfer.

We have applied this approach to the simulation cases listed in table 4. We discuss our results in the following sections.

Table 4. Summary of simulation cases used in this paper to represent different regimes of flow in porous media.

3.1. Visualization of the turbulent structures and temperature distribution

Our previous work suggests that the micro-vortices thermally insulate the solid obstacle since the vortices have a smaller velocity than the surrounding flow (Huang et al. Reference Huang, Srikanth, Li and Kuznetsov2019, Reference Huang, Srikanth and Kuznetsov2021). The heat transfer rate of the obstacle surface increases as the contact area between the micro-vortices and the solid obstacle decreases. This suggests that the micro-vortices reduce the effective surface area that is available for heat transfer. These inferences need to be supplemented by LES of the vortex dynamics, since only the Reynolds-averaged flow field was considered in the past. In the present work, we have identified that two types of vortex systems can occur in porous media, namely recirculating (figure 5a) and shedding vortices (figure 5b–d). The dynamic characteristics of the two vortex systems are distinct, and they impart unique attributes to the heat transfer, as shown in § 3.2. The occurrence of each vortex system depends on the porous medium geometry, primarily the porosity. The stark contrast in the dynamics of the two vortex systems warrants a time-dependent analysis, which is the methodology adopted in this paper.

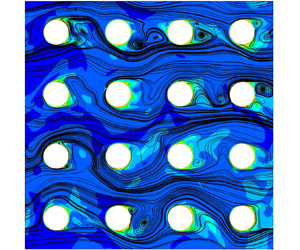

Figure 5. Instantaneous three-dimensional streamlines projected on the xy plane and temperature distribution at ![]() $z = 0$ for cases (a) A1, (b) A2, (c) A3 and (d) A4 (table 4). A sub-volume of the REV of size (2 s, 2 s) is shown here. The locations of the streamwise and lateral void spaces are shown in red and yellow dotted lines, respectively.

$z = 0$ for cases (a) A1, (b) A2, (c) A3 and (d) A4 (table 4). A sub-volume of the REV of size (2 s, 2 s) is shown here. The locations of the streamwise and lateral void spaces are shown in red and yellow dotted lines, respectively.

The instantaneous flow field is first examined to identify the influence of the micro-vortices on the temperature distribution inside the porous medium. Qualitative observations are made using the representative cases shown in table 4 for different flow regimes observed in porous medium turbulence. The time-averaged total drag force and total heat transfer rate of all of the solid obstacles inside the REV for each case are reported in table 4. The solid obstacle hydraulic diameter and the characteristic temperature difference are identical for all the cases. The time-averaged total drag force is higher for the low porosity case A1 (circle, φ = 0.50, Rep = 300) when compared with the high porosity cases A2 (circle, φ = 0.87, Rep = 300) and A3 (square, φ = 0.87, Rep = 300) due to the constricting geometry in case A1. The time-averaged total heat transfer rate is lower for the low porosity case A1 when compared with the high porosity cases A2 and A3. This indicates that a higher surface area per unit volume is not necessarily favourable since the heat transfer rate is less even although there is a higher drag. At the higher porosity, the time-averaged total drag force for the square cylinder solid obstacles is higher than that of the circular cylinder solid obstacles. However, the time-averaged total heat transfer rate is also higher for the square cylinder solid obstacles compared with that of the circular cylinder solid obstacles. The heat transfer rate is the highest for case A4 (square, φ = 0.87, Rep = 500) since it has the highest Reynolds number. However, it should be noted that the increased heat transfer comes at the cost of a high drag force. These trends in the time-averaged flow can be attributed to the micro-vortices and their dynamics as shown below. For ease of reference, we divide the REV into primary and secondary flow regions based on the underlying flow features. In all the cases, we define the primary flow region as the region in between the separation shear layers formed behind the solid obstacle. The primary flow is characterized by virtually unobstructed, high velocity flow from the inlet of the periodic domain. The secondary flow region is the region behind the solid obstacles occupied by the vortices. We define the lateral and streamwise void spaces in the porous medium geometry in the regions of the primary and secondary flows, respectively (figures 5a and 5b).

In case A1, recirculating vortex systems are observed in the secondary flow region (figure 5a). Sharp gradients in the temperature distribution are present at the boundary between the secondary and primary flow regions. The velocity of the recirculating vortex core is close to zero (stationary). As a result, the vortex core temperature at a statistically steady state is the closest to the solid obstacle surface temperature among all the cases studied here. A high vortex core temperature lowers the temperature gradient at the solid obstacle surface covered by the recirculating vortex. By this mechanism, the recirculating vortex system renders the vortex-covered portion of the solid obstacle surface less conducive to heat transfer, storing heat in the streamwise pore space. In contrast, a more diffuse temperature distribution is observed in the case of a shedding vortex system at high porosity, such as in cases A2−A4. The shedding process carries heat away from the solid obstacle surface that is stored in the vortices. In figure 5(b–d), vortex structures with elevated core temperatures are being transported away from the solid obstacle surface. The temperature distribution near the solid obstacle surface in the secondary flow region in cases A2−A4 will have sharper gradients than in case A1. The core temperature of the vortices is also lower in cases A2−A4 than in case A1 since the vortices are not stationary in the streamwise void space. Therefore, the vortex regions in cases A2−A4 have a higher surface heat transfer rate when compared with case A1. The shedding vortex system facilitates convection heat transfer better than the recirculating vortex system.

The change in the solid obstacle shapes between cases A2 and A3 influences the location of the flow separation. For square solid obstacles, the flow separation is prescribed at the sharp corners of the square solid obstacle shape. This results in a smaller intensity of oscillation of the path followed by the streamlines in the secondary flow region, which is reflected in the time series of the solid obstacle surface forces shown in § 3.2. There is also a consistent contact area between the vortices and the solid obstacle surface throughout the vortex shedding cycle. The change in the Reynolds number between cases A3 and A4 does not appear to change the flow patterns in any apparent way. It is shown in table 4 that both the heat transfer rate and drag force are substantially higher for the high Reynolds number case, case A4, compared with the remaining cases. This increase is not caused by any apparent qualitative change that occurs between cases A3 and A4 when the Reynolds number is increased.

In all of the cases, the micro-vortices introduce spatial inhomogeneity in the heat transfer characteristics on the surface of the solid obstacle. The temporal evolution of the vortex systems at the high and low porosities possesses unique characteristics that determine the heat transfer rate as well. For all the cases, the vortex shedding process starts by vortex formation on the solid obstacle surface due to flow separation in the region of the porous medium with an intrinsically adverse pressure gradient. The formation of the vortex entrains cold fluid into the streamwise void space from the primary flow region. The definition of the void space labels is illustrated in figure 5. After the vortex is formed, the vortex core diameter increases while being attached to the surface and the vortex core temperature approaches the solid obstacle surface temperature. Due to the high core temperature, the vortex acts as an ‘insulation’ on the solid obstacle surface at this stage. Next, the vortex detaches from the solid obstacle surface and a new vortex forms as this cycle continues. The evolution of the detached vortex is different for each case. The vortex evolution process is illustrated in figure 6 by plotting the instantaneous flow streamlines. The animated sequence of streamline plots is available in supplementary movies 1–4 for cases A1−A4. The three-dimensional coherent turbulent structures are visualized using iso-surfaces of the Q-criterion in figure 7. The animated sequence of coherent turbulent structures is available in supplementary movies 5–8 for cases A1–A4.

Figure 6. Instantaneous flow streamlines showing the vortex shedding process and its contribution to heat transfer for cases A1−A4. Streamlines are three-dimensional streamlines projected onto the xy plane for the solid obstacle in the second row and second column of the REV. Animations of these sequences are shown in supplementary movies 1–4.

Figure 7. Three-dimensional coherent structures visualized using the Q-criterion for cases (a) A1, (b) A2, (c) A3 and (d) A4. Iso-surfaces of the Q-criterion at 0.020 Qmax are plotted in this figure. Vortices A, B and C from figure 6 are highlighted and their vortex core lines are shown as solid lines of colours brown, magenta and red, respectively. The remaining vortices are shown with 50 % colour saturation to remove clutter in the figure. The animated sequences are available in supplementary movies 5–8.

In case A1, the detached vortex (vortex A in figure 6a-i) recirculates within the streamwise void space for a shorter period of time than case A2 and A3. The short-lived nature of the vortex in case A1 is best visualized in the animation of the three-dimensional coherent structures in supplementary movie 5. The detached vortex A is visible in figure 7(a) as a tubular coherent structure oriented in the z-direction. The tubular structure has deformations and a non-uniform size along the z-direction, but consistently appears at every xy-plane along the z-axis in the streamline plots. The coherent turbulent structures in case A1 are concentrated in the primary flow region and at the lower side of the separation shear layer at the boundary with the secondary flow region. There are very few coherent structures visible in the secondary flow region since the vorticity in the secondary flow region is low. Slow, sustained recirculation over several vortex cycles is responsible for the high temperature inside the secondary flow region. Heat transfer is further diminished by the fact that the micro-vortices are in contact with both solid obstacles surfaces in the streamwise void space. When a new vortex (vortex B in figures 6a-i and 7a) begins to form and grow in size over time, it is limited in space to the separation shear layer. Vortex B impinges on vortex A as it grows due to the small void space at ![]() $\varphi = 0.50$ causing vortex A to deform (figure 6a-ii). The instantaneous streamlines then indicate that there is only one vortex that remains, as seen in the bottom half of the streamwise void space in figure 6(a-iii). The outcome of the interaction between vortices A and B is the sustenance of the recirculating motion in the secondary flow region leading to high core temperature (figure 6a-iii). This is inferred from both the temperature contours in figure 6(a), and the three-dimensional coherent structures in figure 7 and movie 5. A detailed analysis of the interaction between vortices A and B may be obtained by using a very high grid resolution, but it is not critical for the message in this paper. There is some evidence in the present work that the newly formed vortex B primarily influences the separation shear layer. The temperature distribution at the separation shear layer shows ‘waves’ of high temperature synchronized with the formation of vortex B. The ‘waves’ appear only in the separation shear layer and not inside the streamwise void space. The three-dimensional coherent structures clearly show the formation of vortex B, which is then advected in the separation shear layer. Vortex A consistently recirculates in the streamwise void space until it diminishes and is advected into the primary flow (top half of the streamwise void space in figure 6a-iii). The breakup of vortex A is less frequent than the formation of vortex B and the vortex breakup is not periodic in time.

$\varphi = 0.50$ causing vortex A to deform (figure 6a-ii). The instantaneous streamlines then indicate that there is only one vortex that remains, as seen in the bottom half of the streamwise void space in figure 6(a-iii). The outcome of the interaction between vortices A and B is the sustenance of the recirculating motion in the secondary flow region leading to high core temperature (figure 6a-iii). This is inferred from both the temperature contours in figure 6(a), and the three-dimensional coherent structures in figure 7 and movie 5. A detailed analysis of the interaction between vortices A and B may be obtained by using a very high grid resolution, but it is not critical for the message in this paper. There is some evidence in the present work that the newly formed vortex B primarily influences the separation shear layer. The temperature distribution at the separation shear layer shows ‘waves’ of high temperature synchronized with the formation of vortex B. The ‘waves’ appear only in the separation shear layer and not inside the streamwise void space. The three-dimensional coherent structures clearly show the formation of vortex B, which is then advected in the separation shear layer. Vortex A consistently recirculates in the streamwise void space until it diminishes and is advected into the primary flow (top half of the streamwise void space in figure 6a-iii). The breakup of vortex A is less frequent than the formation of vortex B and the vortex breakup is not periodic in time.

The entire vortex formation process occurs simultaneously on both the upper and lower halves of the streamwise void space, which is different from the alternating characteristic of the von Kármán vortex shedding process. The vortex structures are produced by the shear layer between the primary and secondary flow regions due to the Kelvin–Helmholtz (K-H) instability. The K-H instability is not translated into a von Kármán instability in case A1 due to: (i) the absence of interaction between the top and bottom shear layers, (ii) the absence of the alternating shedding process and (iii) the sustained recirculation in the streamwise void space resembling a lid driven cavity flow at steady state. Vortices A and B are the primary vortices in case A1 on the basis of vorticity magnitude and the relevance to transport in porous media. It is shown in § 3.3 that the interaction between the shear layer and the vortex pair results in a peak in the Nusselt number. This supports the experimental observations of Nguyen et al. (Reference Nguyen, Muyshondt, Hassan and Anand2019) that the shear layer and the vortex pair are important coherent structures in porous medium turbulence.

The recirculating motion of vortices A and B promote mixing and heat transfer when compared with a still fluid. This can be visualized in the temperature distribution shown in figure 6(a), where the recirculating vortex entrains low temperature fluid into the streamwise void space near the stagnation point. The entrained fluid absorbs heat from the solid obstacle surface and recirculates with a higher temperature. This enhances the heat transfer of the front half of the solid obstacle surface more than the rear half. This is discussed further in § 3.3. Another pair of recirculating vortices is also present in the space between the primary vortices (figures 6a-i and 6a-ii), which are the secondary vortices in this case. The secondary vortices are detrimental to convection heat transfer in porous media since they are characterized by low vorticity and their core is virtually stationary. Additionally, the secondary vortices are not in direct contact with the incoming flow (the primary flow) since they are sandwiched between the two primary vortices. Therefore, the temperature in the region occupied by the secondary vortex is higher than that in the region occupied by the primary vortex and the primary flow region. The temperature gradient at the solid obstacle surface in the region occupied by the secondary vortex is low, which results in a low Nusselt number in the part of the solid obstacle surface in this region.

These stages are also shown as an animated sequence of the coherent turbulent structures using the Q-criterion in supplementary movie 5. The animated sequence shows that a majority of the fast-moving coherent structures are located in the primary flow region. These coherent structures only have a small interaction with the recirculating vortex system (vortex A in figure 7a). The turbulent structures in the primary flow have a significantly faster time scale than in the secondary flow. This indicates that a majority of the fast turbulent structures do not come into contact with the solid obstacle surface to effectively engage in convection heat transfer.

In case A2, the porosity is higher than in case A1. The porous medium geometry is less confined since the solid obstacles are farther apart. The vortex shedding process more closely resembles the von Kármán vortex shedding in flows around a single cylinder. Vortex formation alternates between the upper side and the lower side of the solid obstacle surface (figure 6b). This is different from case A1 where the two vortices on both sides of the solid obstacle form independently. Once the newly formed vortex grows and detaches from the solid obstacle surface, it is advected by the primary flow (vortex C in figure 6b). The vortex in case A2 is in contact with only one solid obstacle surface at a given time. The vortex is either attached to the solid obstacle where it is formed or it impinges on the downstream solid obstacle. Vortex C breaks up after impingement on the downstream solid obstacle and enters the primary flow region (figure 6b-iii), where it ceases to recirculate in the xy-plane and diminishes in strength. The breakup of vortex C is also influenced by the formation and growth of a new vortex behind the solid obstacle (figures 6b-ii and b-iii). The vortex C is deformed into coherent turbulent structures elongated in the streamwise direction (figure 7b).

Note that the location of the stagnation point on the downstream solid obstacle (yellow dots in figure 6) switches from the upper half of the solid obstacle surface in figure 6(b-i) to the lower half in figure 6(b-ii). This can also be observed in supplementary movie 2. The switch is an indication of a secondary flow instability, which can also be visualized in the tortuosity in the path of the streamlines in figure 6(b). The vortex shedding process in the constrained space of the porous medium in case A2 introduces the secondary instability that causes the fluctuation of the flow separation and stagnation points on the solid obstacle surface. The three-dimensional coherent structures also indicate the presence of the instability, which becomes evident from the propagation direction of the structures. In figure 7(b), the propagation direction of the coherent turbulent structure has a positive y-component for the current cycle of the secondary instability and a negative y-component for the previous cycle. The frequency of the secondary flow instability is smaller than the frequency of the vortex formation and it is implicitly linked to the vortex shedding process. The secondary flow instability in case A2 is clearly exhibited in the flow visualization since the porosity is high and the solid obstacle shape is circular, making it the least constrained geometry among all the cases studied.