Published online by Cambridge University Press: 22 March 2023

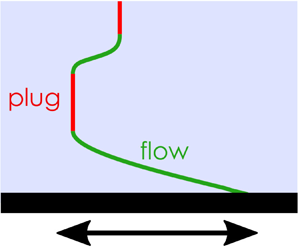

The motion of a finite layer of Bingham material on a solid plate that executes in-plane oscillations was reported previously by Balmforth et al. (J. Non-Newtonian Fluid Mech., vol. 158, issue 1–3, 2009, pp. 46–53). There, it was suggested that multiple yielded regions may arise within the material; this contrasts to start-up flow of the same material for which only one yielded region is generated. Here, we explore quantitatively the fluid physics of this oscillatory flow problem through analytical approximations and further numerical computation. Four new key topological properties concerning the generation and termination of the yielded regions are reported. It is shown that the existence of multiple yielded regions is equivalent to the layer never becoming entirely rigid during the periodic motion. For small inertia, the flow is approximately time-reversible with only a single yielded region generated at the plate. For large inertia, shear stress in the material decays rapidly as a function of distance from the plate. A thin zone of yielded material detaches periodically from the plate, and subsequently terminates within the layer. At high oscillation frequency, there can be any number  $N$ of distinct rigid regions, satisfying

$N$ of distinct rigid regions, satisfying  $N= \lfloor 1- {\rm \pi}^{-1} \log B \rfloor$ where

$N= \lfloor 1- {\rm \pi}^{-1} \log B \rfloor$ where  $B$ is the Bingham number. It is also shown that for

$B$ is the Bingham number. It is also shown that for  $B>0.5370$, there are at most one yielded region and one rigid region throughout the motion. These theoretical results can be used as a basis for oscillatory rheometry, allowing for measurement of the yield stress using existing apparatus.

$B>0.5370$, there are at most one yielded region and one rigid region throughout the motion. These theoretical results can be used as a basis for oscillatory rheometry, allowing for measurement of the yield stress using existing apparatus.