1. Introduction

Swimming mechanisms of marine animals can be categorized generally into lift-based, drag-based and jetting forms of propulsion, based on how thrust is generated (Vogel Reference Vogel2003). While lift-based propulsion by undulating motion is commonly adopted for high-performance swimming or by more aquatically adapted animals (Fish Reference Fish1996), drag-based propulsion has been adopted by many aquatic animals because of its better performance in low-speed swimming and in manoeuvring (Walker & Westneat Reference Walker and Westneat2000). Studies of the mechanism of drag-based propulsion have covered a broad range of topics, including, for example, three-dimensional kinematics of pectoral fins and their relation to the movement of a swimming fish (Lauder & Jayne Reference Lauder and Jayne1996), dynamic modelling of swimming gaits and evaluation of their performance (Walker & Westneat Reference Walker and Westneat2000) combined with actual measurements of fin motion (Walker & Westneat Reference Walker and Westneat2002), three-dimensional vortex formation coupled with thrust generation considering different propulsor geometries (Kim & Gharib Reference Kim and Gharib2011a) and flexibility effects (Kim & Gharib Reference Kim and Gharib2011b), and application of a passive hinge design for the orientation control of pectoral fins of a fish robot (Behbahani & Tan Reference Behbahani and Tan2016). As a fundamental strategy of drag-based propulsion, enhancement of net thrust over a cycle is achieved by modulating the effective area of the propulsor during both power and recovery strokes (Walker Reference Walker2002).

In the context of bio-inspired engineering design, the unique configuration of the arms of crinoids (also known as feather stars) possesses great potential as a propulsor structure that incorporates a significant change in area between power and recovery strokes. The arms of crinoids are feather-like, with lateral extensions known as pinnules that resemble the barbs of a feather. During the recovery stroke, reconfiguring of the arm and its pinnules leads to a dramatic decrease in the area of the arm. Although the swimming performance of actual crinoids has been evaluated using simple biomechanical models (Janevski & Baumiller Reference Janevski and Baumiller2010), the form and function of their unique arms still remain unclear from the perspective of thrust generation.

On the other hand, the reconfiguration represented by passive adaptation of an elastic structure to surrounding flow was first investigated in the context of drag reduction in vegetation, including the pioneering studies by Vogel (Reference Vogel1984, Reference Vogel1989) that introduced the well-known Vogel exponent. Subsequent studies of reconfiguration have characterized successfully the dynamics of elastic structures coupled with steady flow for various geometries and flexibilities, ranging from elastic fibres (Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2002; Gosselin & de Langre Reference Gosselin and de Langre2011) or plates (Gosselin, de Langre & Machado-Almeida Reference Gosselin, de Langre and Machado-Almeida2010; Luhar & Nepf Reference Luhar and Nepf2011; Leclercq & de Langre Reference Leclercq and de Langre2016; Pezzulla et al. Reference Pezzulla, Strong, Gallaire and Reis2020) to various plants (Whittaker et al. Reference Whittaker, Wilson, Aberle, Rauch and Xavier2013; Whittaker, Wilson & Aberle Reference Whittaker, Wilson and Aberle2015). Furthermore, the transient dynamics of elastic structures coupled with unsteady flow conditions has been examined in work by Luhar & Nepf (Reference Luhar and Nepf2016), Leclercq & de Langre (Reference Leclercq and de Langre2018) and Zhang & Nepf (Reference Zhang and Nepf2021). In these studies, for both steady and unsteady flow conditions, the theoretical modelling of the fluid–structure interaction has enabled reasonable estimates to be obtained of the flow-induced forces and resulting deformation of the structures.

In this study, motivated by the unique propulsive feature of a crinoid arm, we investigate experimentally the fluid–structure interaction of a simplified feather-like elastic structure composed of a centre rod to which barb-like rigid side flaps are attached by elastic hinges, aiming to reveal the principles of the complex deformation involving multiple elastic parts (figure 1). For both power and recovery strokes, one end of the centre rod is prescribed to undergo linear translation, resulting in deformation of the centre rod and hinges by interaction with quiescent surrounding fluid. Passive folding of the rigid flaps via the elastic hinges occurs generally in the recovery stroke, which is achieved by allowing the hinges to bend in only one direction. We also establish a theoretical model of the dynamics of the elastic structure. Because the flaps as well as the centre rod undergo reconfiguration in each stroke, the two-dimensional deflections of the centre rod and the flaps need to be coupled in an appropriate manner to fully reconstruct the three-dimensional deformation of the elastic structure. The present study focuses primarily on the quasi-static interaction of the elastic structure with the surrounding flow as a prerequisite to draw general relations between the flow-induced drag and three-dimensional reconfiguration of the structure. Extending the quasi-static analysis, we explore the unsteady dynamics of the elastic structure, although not comprehensively, to identify key differences arising from oscillatory motion.

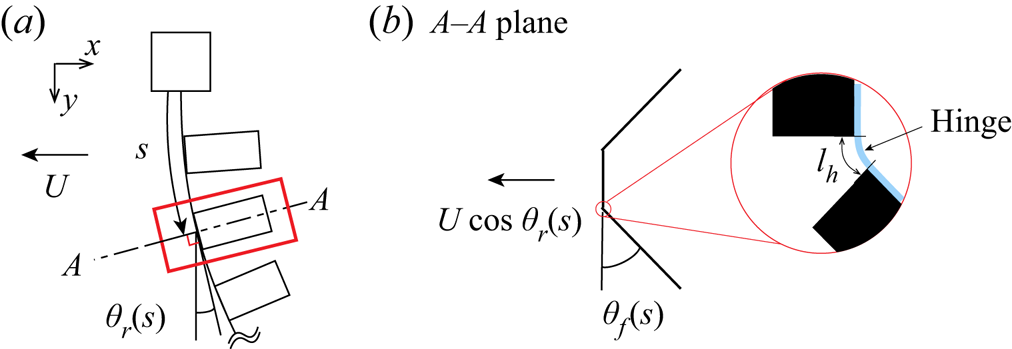

Figure 1. (a) Schematic of the experimental set-up. The initial position of the elastic structure is shown by the dashed line. (b) Schematic of the elastic structure. (c) Illustration of how tape and strips are placed to connect the side flaps to the centre rod. (d) Orientation of (i) the side flaps and (ii) the elastic structure during power and recovery strokes; the arrows in (d) indicate the direction of translation.

Our experimental set-up is described in § 2, and theoretical modelling of the deformation of the elastic structure is conducted in § 3. The characteristics of structural deformation under steady translation are identified, and their dependence on several parameters, such as dimensionless bending stiffness and translational speed, is discussed in § 4.1. In addition, the effects of flap geometry and hinge stiffness on the drag exerted on the elastic structure are examined in § 4.2. The theoretical model is extended to cases with a extremely rigid or flexible centre rod in § 4.3. Finally, the unsteady dynamics of the elastic structure under oscillatory motion is discussed in § 4.4. Our concluding remarks are presented in § 5.

2. Experimental set-up

Experiments were conducted in a water tank with internal dimensions 490 mm width, 1200 mm length and 500 mm height. The elastic structure under consideration was connected to the block of a linear guide (MW-EQB45, NTRexLAB) placed above the water tank (figure 1a). Driven by a stepper motor controlled via a data acquisition board (PCIe-6321, National Instrument Co.), the linear guide block and the clamped top end of the elastic structure underwent translation where a simple code in MATLAB (Mathworks Inc.) was used to prescribe the motion. Both steady and unsteady translational motions of the top end were considered. For the cases of steady motion, translation at a constant speed ![]() $U=U_0$ was prescribed for the power stroke along the positive

$U=U_0$ was prescribed for the power stroke along the positive ![]() $x$ axis and for the recovery stroke along the negative

$x$ axis and for the recovery stroke along the negative ![]() $x$ axis, with each stroke being of length 85 cm. For smooth acceleration at the start of each stroke, a quarter of a sinusoidal velocity profile was implemented within the first 10 cm displacement of each stroke. For the cases of unsteady motion, simple oscillation was considered with sinusoidal speed profile

$x$ axis, with each stroke being of length 85 cm. For smooth acceleration at the start of each stroke, a quarter of a sinusoidal velocity profile was implemented within the first 10 cm displacement of each stroke. For the cases of unsteady motion, simple oscillation was considered with sinusoidal speed profile ![]() $U(t) = U_0 \sin (2{\rm \pi} f t)$ repeated for 10 cycles, where

$U(t) = U_0 \sin (2{\rm \pi} f t)$ repeated for 10 cycles, where ![]() $U_0$ and

$U_0$ and ![]() $f$ are translational speed amplitude and oscillation frequency, respectively. For both steady translation and harmonic oscillation, we waited a couple of minutes between successive cases to settle perturbed flow.

$f$ are translational speed amplitude and oscillation frequency, respectively. For both steady translation and harmonic oscillation, we waited a couple of minutes between successive cases to settle perturbed flow.

An elastic structure was fabricated with acrylic sheets of thickness ![]() $h = 1.10$–1.75 mm; in this study, the elastic structure comprises the combination of the centre rod and all side flaps. The overall shape of the elastic structure is feather-like, as shown in figure 1(b). Both the centre rod and side flaps were fabricated from a single acrylic sheet to minimize local variations in sheet thickness as much as possible; such local variations were within 5 % of the mean value. The length of the centre rod,

$h = 1.10$–1.75 mm; in this study, the elastic structure comprises the combination of the centre rod and all side flaps. The overall shape of the elastic structure is feather-like, as shown in figure 1(b). Both the centre rod and side flaps were fabricated from a single acrylic sheet to minimize local variations in sheet thickness as much as possible; such local variations were within 5 % of the mean value. The length of the centre rod, ![]() $l_{r}$, had fixed value 20 cm, and the length of the side flaps,

$l_{r}$, had fixed value 20 cm, and the length of the side flaps, ![]() $l_{f}$, varied from 2 to 4 cm. The widths of the centre rod and side flaps,

$l_{f}$, varied from 2 to 4 cm. The widths of the centre rod and side flaps, ![]() $w_{r}$ and

$w_{r}$ and ![]() $w_{f}$, respectively, were 1 cm. A total of 20 side flaps were placed along the longitudinal direction of the centre rod, with 1 cm spacing between adjacent flaps. The Reynolds number

$w_{f}$, respectively, were 1 cm. A total of 20 side flaps were placed along the longitudinal direction of the centre rod, with 1 cm spacing between adjacent flaps. The Reynolds number ![]() $\mbox {{Re}} = U_0 w_{r} /\nu$ was between 400 and 6000, where

$\mbox {{Re}} = U_0 w_{r} /\nu$ was between 400 and 6000, where ![]() $U_0$ is the speed amplitude (

$U_0$ is the speed amplitude (![]() $U_0 = 4$–60 cm s

$U_0 = 4$–60 cm s![]() $^{-1}$), and

$^{-1}$), and ![]() $\nu$ is the kinematic viscosity of water (

$\nu$ is the kinematic viscosity of water (![]() $\nu = 1.0\times 10^{-6}$ m

$\nu = 1.0\times 10^{-6}$ m![]() $^2$ s

$^2$ s![]() $^{-1}$ at 20

$^{-1}$ at 20 ![]() $^{\circ }$C). The main experimental parameters are summarized in table 1.

$^{\circ }$C). The main experimental parameters are summarized in table 1.

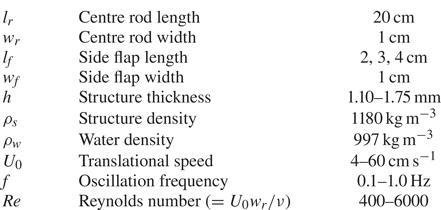

Table 1. Experimental parameters.

A high-speed camera (FASTCAM MINI-UX50, Photron, Inc.) with resolution ![]() $1280 \times 1024$ pixels was used to capture the deflected profile of the translating elastic structure in water at 250 f.p.s. for cases with

$1280 \times 1024$ pixels was used to capture the deflected profile of the translating elastic structure in water at 250 f.p.s. for cases with ![]() $U_0$ over 30 cm s

$U_0$ over 30 cm s![]() $^{-1}$, and 125 f.p.s. for the other cases. The image plane was illuminated using an LED lamp. To acquire the deflected profile, raw images were processed using a MATLAB code. A force transducer (MB-5, Interface Inc.) was attached between the linear stage and the model to obtain the drag force acting on the entire model (figure 1a). The transducer was calibrated using various static loads and exhibited repeatable and reliable results with resolution approximately 0.01 N. For a steady translation case, the quasi-steady drag force was acquired at sampling rate 100 Hz by taking the arithmetic mean of the measured values over a certain period of constant translational speed during which the time series data of the force formed a plateau. The time history of the force shows minor variations during steady translation despite highly unsteady wakes behind the elastic structure. The standard deviation of the drag in a plateau is less than 4 % of its mean value for cases with

$^{-1}$, and 125 f.p.s. for the other cases. The image plane was illuminated using an LED lamp. To acquire the deflected profile, raw images were processed using a MATLAB code. A force transducer (MB-5, Interface Inc.) was attached between the linear stage and the model to obtain the drag force acting on the entire model (figure 1a). The transducer was calibrated using various static loads and exhibited repeatable and reliable results with resolution approximately 0.01 N. For a steady translation case, the quasi-steady drag force was acquired at sampling rate 100 Hz by taking the arithmetic mean of the measured values over a certain period of constant translational speed during which the time series data of the force formed a plateau. The time history of the force shows minor variations during steady translation despite highly unsteady wakes behind the elastic structure. The standard deviation of the drag in a plateau is less than 4 % of its mean value for cases with ![]() $U_0 > 20$ cm s

$U_0 > 20$ cm s![]() $^{-1}$, although the standard deviation tends to be relatively larger for low-speed cases with small drag. To eliminate the effect of the submerged part connecting the elastic structure to the linear stage mount, force measurements were also conducted without the elastic structure. By subtracting the force measured in the absence of the elastic structure from the force measured with it present, the drag force of the elastic structure alone could be obtained. Measurements were repeated three times, and the standard deviation was within 5 % of the mean value of the three repetitions for cases with

$^{-1}$, although the standard deviation tends to be relatively larger for low-speed cases with small drag. To eliminate the effect of the submerged part connecting the elastic structure to the linear stage mount, force measurements were also conducted without the elastic structure. By subtracting the force measured in the absence of the elastic structure from the force measured with it present, the drag force of the elastic structure alone could be obtained. Measurements were repeated three times, and the standard deviation was within 5 % of the mean value of the three repetitions for cases with ![]() $U_0 > 10$ cm s

$U_0 > 10$ cm s![]() $^{-1}$. Owing to the limitations on the resolution of the force transducer, the error tended to be amplified for cases with small drag (

$^{-1}$. Owing to the limitations on the resolution of the force transducer, the error tended to be amplified for cases with small drag (![]() $U_0 < 10$ cm s

$U_0 < 10$ cm s![]() $^{-1}$), where measured drag is comparable to the resolution of the transducer. For an oscillation case, the drag force was acquired at sampling rate 500 Hz over the entire 10 cycles. Similar to the steady translation cases, measurements were also conducted without the elastic structure to eliminate the contribution of the connecting part. As the cyclic motion of the elastic structure was observed after two cycles, the drag force was phase-averaged over the last eight cycles. The root-mean-square error of the phase-averaged data with respect to the raw data was within 6 % of the standard deviation of the raw data over a cycle, indicating good periodicity of the time series data.

$^{-1}$), where measured drag is comparable to the resolution of the transducer. For an oscillation case, the drag force was acquired at sampling rate 500 Hz over the entire 10 cycles. Similar to the steady translation cases, measurements were also conducted without the elastic structure to eliminate the contribution of the connecting part. As the cyclic motion of the elastic structure was observed after two cycles, the drag force was phase-averaged over the last eight cycles. The root-mean-square error of the phase-averaged data with respect to the raw data was within 6 % of the standard deviation of the raw data over a cycle, indicating good periodicity of the time series data.

The main feature of the elastic structure is the unidirectional bending of the side flaps. The centre rod and side flap were as close as possible to each other, and they were connected using an adhesive tape (3M Scotch Transparent Film Tape 550, 3M) which functioned as an elastic hinge (figure 1c). The tape was attached on only one side of the centre rod and side flap so that the side flap could hinge to the side to which it was taped during the recovery stroke (figure 1d). During the power stroke, the side flaps could not hinge to the other side past the initial flat configuration owing to the restriction on their motion: the side surfaces of the centre rod and the side flaps were in contact with each other because of the finite thickness of the acrylic sheets, thus prohibiting hinge motion. That is, during the power stroke, the side flaps were eventually aligned parallel along the centre rod (figure 1d-i). Because of the asymmetric motion of the side flaps, the deformed shape of the model differed between the two strokes.

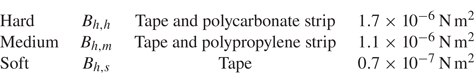

To realize various bending stiffness values of the elastic hinge, a 1 mm wide strip of polycarbonate (PC) or polypropylene (PP) sheet, of thickness 0.2 mm, was placed under the tape (figure 1c); the tape itself was made of 0.038 mm thick PP backing. Thus a total of three types of hinges were tested: only tape, tape with a polycarbonate strip, and tape with a polypropylene strip. These three hinges are hereinafter termed hard, medium and soft, respectively, according to their relative stiffnesses (table 3). The bending stiffness of the hinges will be assessed in § 3.

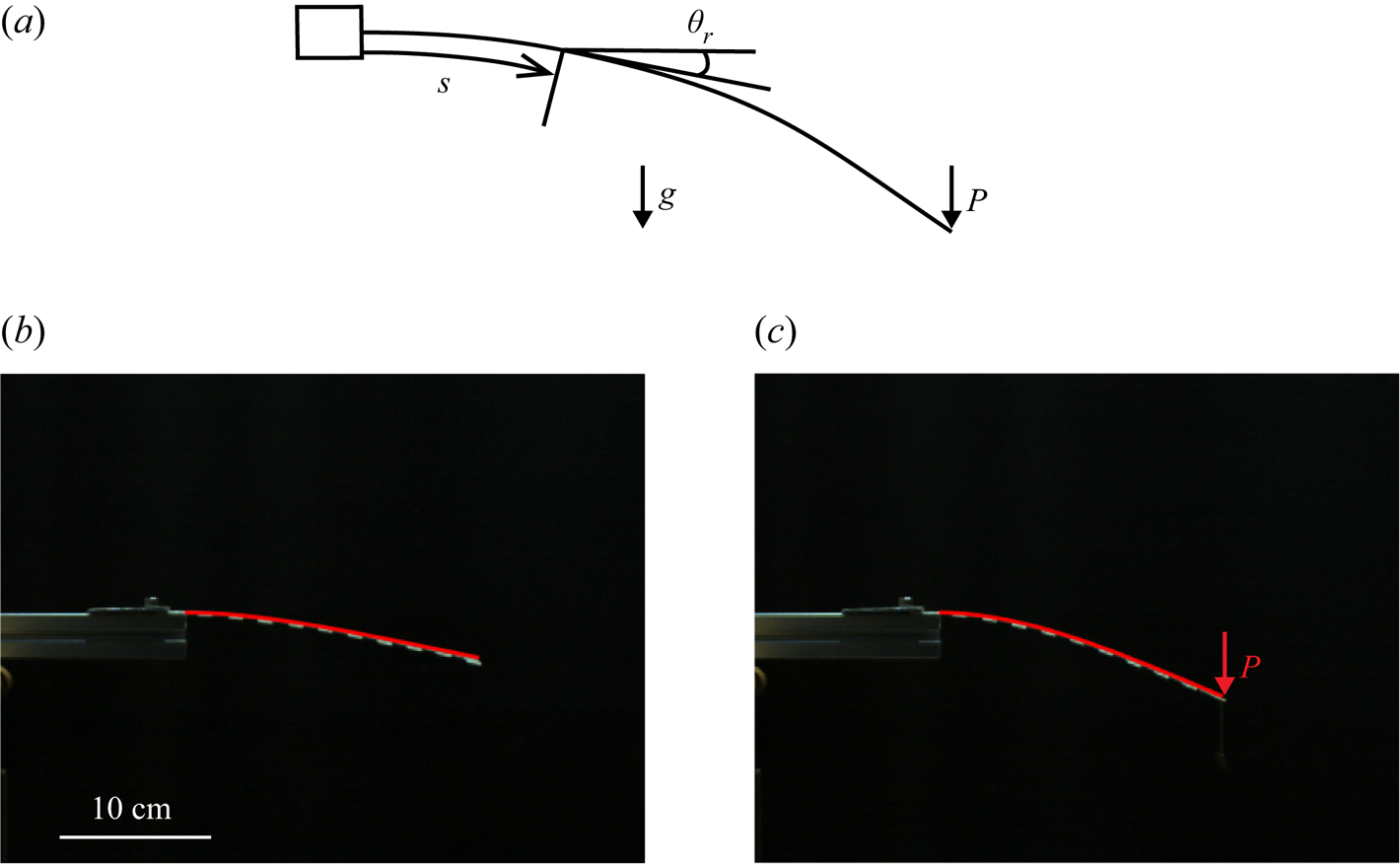

Even slight variations in the thickness of the acrylic sheet will result in dramatic changes in the bending stiffness of the centre rod, ![]() $B_{r}$. Furthermore, although small, the contributions of the acrylic tape and the elastic strips, providing elastic connections of the multiple side flaps to the centre rod, should be considered. To obtain an accurate measurement of the bending stiffness of the centre rod in its longitudinal direction (along the curvilinear coordinate

$B_{r}$. Furthermore, although small, the contributions of the acrylic tape and the elastic strips, providing elastic connections of the multiple side flaps to the centre rod, should be considered. To obtain an accurate measurement of the bending stiffness of the centre rod in its longitudinal direction (along the curvilinear coordinate ![]() $s$ in figure 2a), the effective bending stiffness

$s$ in figure 2a), the effective bending stiffness ![]() $B_{r}$ was calculated by fitting the actual deflected profile of the elastic structure under gravity, which was obtained from a filmed image, with a theoretically estimated profile based on the nonlinear elastica theory, assuming the centre rod to be a slender body because

$B_{r}$ was calculated by fitting the actual deflected profile of the elastic structure under gravity, which was obtained from a filmed image, with a theoretically estimated profile based on the nonlinear elastica theory, assuming the centre rod to be a slender body because ![]() $l_{r}/w_{r} = 20$ (figure 2); the elastic structure was initially horizontal with its left end clamped. Note that this particular set of experiments was conducted in air rather than water. For the theoretically estimated profile, the following equation was used, which represents a balance between the internal bending force, the gravitational force, and a point load

$l_{r}/w_{r} = 20$ (figure 2); the elastic structure was initially horizontal with its left end clamped. Note that this particular set of experiments was conducted in air rather than water. For the theoretically estimated profile, the following equation was used, which represents a balance between the internal bending force, the gravitational force, and a point load ![]() $P$ at the free end:

$P$ at the free end:

\begin{equation} B_{r}\,\frac{\mathrm{d}^2 \theta_{r}(s)}{\mathrm{d}s^2} + \left[\rho_{s} gh \int_{s}^{l_{r}} (w_{r} + 2 l_{sf})\,\mathrm{d}s^* + P\right] \cos \theta_{r}(s) = 0, \end{equation}

\begin{equation} B_{r}\,\frac{\mathrm{d}^2 \theta_{r}(s)}{\mathrm{d}s^2} + \left[\rho_{s} gh \int_{s}^{l_{r}} (w_{r} + 2 l_{sf})\,\mathrm{d}s^* + P\right] \cos \theta_{r}(s) = 0, \end{equation}

where ![]() $l_{sf}$ is a shape function defined to take account of the existence of the side flaps,

$l_{sf}$ is a shape function defined to take account of the existence of the side flaps,

\begin{equation} l_{sf} =\begin{cases} 0 & \textrm{for regions without side flaps}, \\ l_{f} & \textrm{for regions with side flaps}, \end{cases} \end{equation}

\begin{equation} l_{sf} =\begin{cases} 0 & \textrm{for regions without side flaps}, \\ l_{f} & \textrm{for regions with side flaps}, \end{cases} \end{equation}

![]() $\rho _{s}$ is the density of the elastic structure, and

$\rho _{s}$ is the density of the elastic structure, and ![]() $\theta _{r}$ is the deflection angle with respect to the

$\theta _{r}$ is the deflection angle with respect to the ![]() $x$ axis (figure 2a).

$x$ axis (figure 2a).

Figure 2. (a) Schematic of the elastic structure under gravity and with a point load ![]() $P$ at the free end. (b,c) Raw images of the bent elastic structure and theoretically estimated profiles (red solid lines) using (2.1): (b) under gravity only; (c) under gravity with the point load at the free end.

$P$ at the free end. (b,c) Raw images of the bent elastic structure and theoretically estimated profiles (red solid lines) using (2.1): (b) under gravity only; (c) under gravity with the point load at the free end.

To obtain the deflected profile, (2.1) is solved numerically with the following boundary conditions at the clamped and free ends: ![]() $\theta _{r} = 0$ at

$\theta _{r} = 0$ at ![]() $s = 0$, and

$s = 0$, and ![]() $\mathrm {d}\theta _{r}/\mathrm {d}s = 0$ at

$\mathrm {d}\theta _{r}/\mathrm {d}s = 0$ at ![]() $s = l_{r}$. A total of 15 elastic structures with different hinge types and side-flap lengths were tested, both with and without a point load

$s = l_{r}$. A total of 15 elastic structures with different hinge types and side-flap lengths were tested, both with and without a point load ![]() $P$ of 0.23 N for more accurate measurement. The point load was applied at the free end of the elastic structure by attaching a load vertically to the end of the centre rod with a string. The effective bending stiffness

$P$ of 0.23 N for more accurate measurement. The point load was applied at the free end of the elastic structure by attaching a load vertically to the end of the centre rod with a string. The effective bending stiffness ![]() $B_{r}$ acquired by fitting the actual experimental profile with the theoretical profile from (2.1) is used throughout this study (table 2). The cases in table 2 are divided into those in which the centre rod is thin and those in which it is thick, based on the magnitude of

$B_{r}$ acquired by fitting the actual experimental profile with the theoretical profile from (2.1) is used throughout this study (table 2). The cases in table 2 are divided into those in which the centre rod is thin and those in which it is thick, based on the magnitude of ![]() $B_{r}$. In the thin-centre-rod cases,

$B_{r}$. In the thin-centre-rod cases, ![]() $B_{r}$ ranges from

$B_{r}$ ranges from ![]() $3.33\times 10^{-3}$ to

$3.33\times 10^{-3}$ to ![]() $5.49\times 10^{-3}$ N m

$5.49\times 10^{-3}$ N m![]() $^{2}$, and in the thick-centre-rod cases, it ranges from

$^{2}$, and in the thick-centre-rod cases, it ranges from ![]() $10.83\times 10^{-3}$ to

$10.83\times 10^{-3}$ to ![]() $13.40\times 10^{-3}$ N m

$13.40\times 10^{-3}$ N m![]() $^{2}$.

$^{2}$.

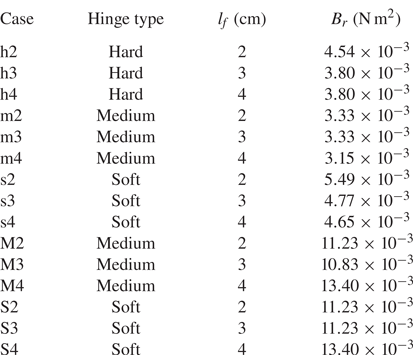

Table 2. Hinge type, side-flap length ![]() $l_{f}$ and effective bending stiffness

$l_{f}$ and effective bending stiffness ![]() $B_{r}$ for the 15 cases considered in this study. Case names with small letters and capital letters indicate a thin centre rod and a thick centre rod, respectively.

$B_{r}$ for the 15 cases considered in this study. Case names with small letters and capital letters indicate a thin centre rod and a thick centre rod, respectively.

3. Theoretical model

3.1. Characterization of hinge deflection

Although the present study covers both quasi-steady and unsteady dynamics of the elastic structure, only the quasi-static deformation with constant translational speed (![]() $U = U_0$) will be addressed in this section to determine a relation between the deflection angle of the side flap and the applied torque. Before considering the deflection of the centre rod, we first examine the deflection of the elastic hinges attached to this rod. Elastic sheets were used as hinges to act as torsional springs by Ishihara, Horie & Denda (Reference Ishihara, Horie and Denda2009a) and Ishihara et al. (Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009b). A similar hinge model was adopted recently by Wu, Nowak & Breuer (Reference Wu, Nowak and Breuer2019), where the deformation of an elastic sheet could be estimated from a linear relation between deflection angle and flow-induced torque. However, in the present study, the side flaps are connected as closely as possible to the centre rod, almost eliminating any gap between the two components. Because the hinge region located between the centre rod and a side flap is very confined, the local deflection of the hinge is so large that the deflection of the hinge cannot be predicted accurately by a linear relation between the deflection angle and the flow-induced torque.

$U = U_0$) will be addressed in this section to determine a relation between the deflection angle of the side flap and the applied torque. Before considering the deflection of the centre rod, we first examine the deflection of the elastic hinges attached to this rod. Elastic sheets were used as hinges to act as torsional springs by Ishihara, Horie & Denda (Reference Ishihara, Horie and Denda2009a) and Ishihara et al. (Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009b). A similar hinge model was adopted recently by Wu, Nowak & Breuer (Reference Wu, Nowak and Breuer2019), where the deformation of an elastic sheet could be estimated from a linear relation between deflection angle and flow-induced torque. However, in the present study, the side flaps are connected as closely as possible to the centre rod, almost eliminating any gap between the two components. Because the hinge region located between the centre rod and a side flap is very confined, the local deflection of the hinge is so large that the deflection of the hinge cannot be predicted accurately by a linear relation between the deflection angle and the flow-induced torque.

As a first step in modelling the response of the elastic hinge and the resulting deflection angle of a side flap (and a hinge) under the influence of surrounding fluid, the external torque applied on the side flap needs to be identified. Although the model translates in a quiescent fluid, we will consider a reference frame fixed with the model; in this reference frame, the relative incoming flow with respect to the model has uniform velocity ![]() $U$. Owing to the reconfiguration of the model by the flow-induced force, the normal velocity along the centre rod can be expressed as

$U$. Owing to the reconfiguration of the model by the flow-induced force, the normal velocity along the centre rod can be expressed as ![]() $U \cos \theta _{r}$. Then the normal velocity component of the relative flow with respect to the side flap is

$U \cos \theta _{r}$. Then the normal velocity component of the relative flow with respect to the side flap is ![]() $U \cos \theta _{f} \cos \theta _{r}$, where

$U \cos \theta _{f} \cos \theta _{r}$, where ![]() $\theta _{f}$ is the deflection angle of the side flap; see figure 3 for the definitions of

$\theta _{f}$ is the deflection angle of the side flap; see figure 3 for the definitions of ![]() $\theta _{r}$ and

$\theta _{r}$ and ![]() $\theta _{f}$. With the assumption of quasi-steady flow, the resistive fluid force acting normally to the surface of a single side flap deflected by

$\theta _{f}$. With the assumption of quasi-steady flow, the resistive fluid force acting normally to the surface of a single side flap deflected by ![]() $\theta _{f}$ is

$\theta _{f}$ is ![]() $\frac {1}{2} C_{N} \rho _{w} w_{f}l_{f} (U \cos \theta _{f} \cos \theta _{r})^2$ (where

$\frac {1}{2} C_{N} \rho _{w} w_{f}l_{f} (U \cos \theta _{f} \cos \theta _{r})^2$ (where ![]() $\rho _{w}$ is the density of water), and the fluid-induced torque

$\rho _{w}$ is the density of water), and the fluid-induced torque ![]() $T$ can be obtained by multiplying by the moment arm

$T$ can be obtained by multiplying by the moment arm ![]() $\frac {1}{2} l_{f}$:

$\frac {1}{2} l_{f}$: ![]() $T=\frac {1}{2} C_{N} \rho _{w} w_{f}l_{f} (U \cos \theta _{f} \cos \theta _{r})^2 \frac {1}{2} l_{f}$. The bending of the side flap itself by the normal force is marginal, therefore the side flap is assumed to be straight.

$T=\frac {1}{2} C_{N} \rho _{w} w_{f}l_{f} (U \cos \theta _{f} \cos \theta _{r})^2 \frac {1}{2} l_{f}$. The bending of the side flap itself by the normal force is marginal, therefore the side flap is assumed to be straight.

Figure 3. (a) Side view of the elastic structure during the recovery stroke in the ![]() $(x,y)$ plane. (b) Cross-sectional view of the deflected side flaps in the

$(x,y)$ plane. (b) Cross-sectional view of the deflected side flaps in the ![]() $A$–

$A$–![]() $A$ plane marked in (a). Here,

$A$ plane marked in (a). Here, ![]() $\theta _{r}$ is the deflection angle of the centre rod, and

$\theta _{r}$ is the deflection angle of the centre rod, and ![]() $\theta _{f}$ is the deflection angle of the side flap.

$\theta _{f}$ is the deflection angle of the side flap.

The fluid-induced torque ![]() $T$ should be balanced by the internal torque of the hinge, which can be modelled as a torsional spring. According to Wu et al. (Reference Wu, Nowak and Breuer2019), the torsional stiffness of a short elastic sheet (i.e. a hinge in our study) takes the form

$T$ should be balanced by the internal torque of the hinge, which can be modelled as a torsional spring. According to Wu et al. (Reference Wu, Nowak and Breuer2019), the torsional stiffness of a short elastic sheet (i.e. a hinge in our study) takes the form ![]() $B_{h}/l_{h}$, where

$B_{h}/l_{h}$, where ![]() $B_{h}$ and

$B_{h}$ and ![]() $l_{h}$ are the bending stiffness and length of the hinge, respectively (figure 3b). Then the torque due to the linear torsional spring is

$l_{h}$ are the bending stiffness and length of the hinge, respectively (figure 3b). Then the torque due to the linear torsional spring is ![]() $(B_{h}/l_{h})\theta _{f}$. To compensate for the nonlinearity of the relation between the flow-induced torque and the structural deformation, we assume that

$(B_{h}/l_{h})\theta _{f}$. To compensate for the nonlinearity of the relation between the flow-induced torque and the structural deformation, we assume that ![]() $(B_{h}/l_{h})\theta _{f}$ is multiplied by a trigonometric function

$(B_{h}/l_{h})\theta _{f}$ is multiplied by a trigonometric function ![]() $\cos \theta _{f}$ as follows:

$\cos \theta _{f}$ as follows:

where ![]() $B_{h}$ is obtained from

$B_{h}$ is obtained from ![]() $B_{h} = E_{h}I$ (table 3). Young's modulus

$B_{h} = E_{h}I$ (table 3). Young's modulus ![]() $E_{h}$ of the hinge was measured in a uniaxial tensile test using a universal tensile testing machine (AGX-V, Shimadzu), and the second moment of area

$E_{h}$ of the hinge was measured in a uniaxial tensile test using a universal tensile testing machine (AGX-V, Shimadzu), and the second moment of area ![]() $I$ was calculated using the dimensions of the hinge.

$I$ was calculated using the dimensions of the hinge.

Table 3. Bending stiffness ![]() $B_{h}$ of three hinge types.

$B_{h}$ of three hinge types.

The use of a trigonometric function in (3.1) is based on empirical observations. The linear spring relation ![]() $(B_{h}/l_{h})\theta _{f}$ balanced with the flow-induced torque

$(B_{h}/l_{h})\theta _{f}$ balanced with the flow-induced torque ![]() $T$ can be reasonably fitted to the experimental results for small deflections occurring at low

$T$ can be reasonably fitted to the experimental results for small deflections occurring at low ![]() $U$. However, as

$U$. However, as ![]() $U$ increases, the balance equation diverges from the experimental results, where

$U$ increases, the balance equation diverges from the experimental results, where ![]() $\theta _{f}$ at a given

$\theta _{f}$ at a given ![]() $U$ is underestimated; i.e. the torque required for the side flap to be deflected by

$U$ is underestimated; i.e. the torque required for the side flap to be deflected by ![]() $\theta _{f}$ is overestimated. The experimental results show a gradual decrease in the growth rate of the torque to achieve a greater deflection angle

$\theta _{f}$ is overestimated. The experimental results show a gradual decrease in the growth rate of the torque to achieve a greater deflection angle ![]() $\theta _{f}$. Therefore, for the relation to hold for the higher range of

$\theta _{f}$. Therefore, for the relation to hold for the higher range of ![]() $U$, the left-hand side of (3.1) requires an additional function of

$U$, the left-hand side of (3.1) requires an additional function of ![]() $\theta _{f}$ that decreases as

$\theta _{f}$ that decreases as ![]() $\theta _{f}$ increases. We found that the addition of

$\theta _{f}$ increases. We found that the addition of ![]() $\cos \theta _{f}$ in (3.1) could eliminate the error in the high-

$\cos \theta _{f}$ in (3.1) could eliminate the error in the high-![]() $U$ range, yielding a better approximation of the internal torque; the validity of the model will be addressed later, in figure 4.

$U$ range, yielding a better approximation of the internal torque; the validity of the model will be addressed later, in figure 4.

Figure 4. (a) Hinge angle ![]() $\theta _{f}$ obtained from experiment (

$\theta _{f}$ obtained from experiment (![]() $\square$) and theoretical prediction using (3.1) (solid lines). (b) Drag force obtained from force transducer measurement (

$\square$) and theoretical prediction using (3.1) (solid lines). (b) Drag force obtained from force transducer measurement (![]() $\Diamond$) and theoretical prediction using (3.1) and (3.2) (solid lines). Red, blue and black correspond to hard, medium and soft hinges, respectively. Straight centre rods with

$\Diamond$) and theoretical prediction using (3.1) and (3.2) (solid lines). Red, blue and black correspond to hard, medium and soft hinges, respectively. Straight centre rods with ![]() $\theta _{r} = 0$ are used to neglect the effect of centre-rod deflection on the folding of the side flaps.

$\theta _{r} = 0$ are used to neglect the effect of centre-rod deflection on the folding of the side flaps.

To solve (3.1) and find ![]() $\theta _{f}$, the values of the normal force coefficient

$\theta _{f}$, the values of the normal force coefficient ![]() $C_{N}$ and hinge length

$C_{N}$ and hinge length ![]() $l_{h}$ need to be determined a priori. The geometry of the side flap is rectangular, with aspect ratio

$l_{h}$ need to be determined a priori. The geometry of the side flap is rectangular, with aspect ratio ![]() $l_{f}/w_{f}$ between 2 and 4. Although the value of

$l_{f}/w_{f}$ between 2 and 4. Although the value of ![]() $C_{N}$ for a rectangular flat plate varies with the angle of incidence and the aspect ratio (Tavallaeinejad, Païdoussis & Legrand Reference Tavallaeinejad, Païdoussis and Legrand2018), a constant

$C_{N}$ for a rectangular flat plate varies with the angle of incidence and the aspect ratio (Tavallaeinejad, Païdoussis & Legrand Reference Tavallaeinejad, Païdoussis and Legrand2018), a constant ![]() $C_{N}$ value of 1.95 was used by Luhar & Nepf (Reference Luhar and Nepf2011) to model the dynamics of elastic blades with aspect ratio ranging from 5 to 25 in steady flow. In a later study by Luhar & Nepf (Reference Luhar and Nepf2016), implementation of a constant

$C_{N}$ value of 1.95 was used by Luhar & Nepf (Reference Luhar and Nepf2011) to model the dynamics of elastic blades with aspect ratio ranging from 5 to 25 in steady flow. In a later study by Luhar & Nepf (Reference Luhar and Nepf2016), implementation of a constant ![]() $C_{N}$ value for a two-dimensional plate from the work of Keulegan & Carpenter (Reference Keulegan and Carpenter1958) was successful in modelling the dynamics of elastic plates with aspect ratios ranging from 2.5 to 10, showing that the use of a constant coefficient value is plausible in modelling reconfiguration under quasi-steady conditions, even for relatively low-aspect-ratio plates. Moreover, Fernando & Rival (Reference Fernando and Rival2016) and Tavallaeinejad et al. (Reference Tavallaeinejad, Païdoussis and Legrand2018) suggested a steady-state

$C_{N}$ value for a two-dimensional plate from the work of Keulegan & Carpenter (Reference Keulegan and Carpenter1958) was successful in modelling the dynamics of elastic plates with aspect ratios ranging from 2.5 to 10, showing that the use of a constant coefficient value is plausible in modelling reconfiguration under quasi-steady conditions, even for relatively low-aspect-ratio plates. Moreover, Fernando & Rival (Reference Fernando and Rival2016) and Tavallaeinejad et al. (Reference Tavallaeinejad, Païdoussis and Legrand2018) suggested a steady-state ![]() $C_{N}$ value of approximately 1.9 for plates oriented normal to the flow. On the basis of these previous studies, the assumption

$C_{N}$ value of approximately 1.9 for plates oriented normal to the flow. On the basis of these previous studies, the assumption ![]() $C_{N} = 2$ appears to be acceptable for our side flap with aspect ratio between 2 and 4.

$C_{N} = 2$ appears to be acceptable for our side flap with aspect ratio between 2 and 4.

As mentioned earlier, the deflection of the hinge occurs within a very narrow region less than ![]() $O(10^{-1})$ cm in length. Due to the difficulty of measuring the hinge length directly, its value should be estimated with an alternative experimental approach. A set of experiments to determine the hinge length was conducted using an elastic structure similar to that shown in figure 1(b) for all three hinge types, but with a centre rod sufficiently rigid that it remained vertically straight under translational motion, with only the side flaps being deflected backwards. This is equivalent to

$O(10^{-1})$ cm in length. Due to the difficulty of measuring the hinge length directly, its value should be estimated with an alternative experimental approach. A set of experiments to determine the hinge length was conducted using an elastic structure similar to that shown in figure 1(b) for all three hinge types, but with a centre rod sufficiently rigid that it remained vertically straight under translational motion, with only the side flaps being deflected backwards. This is equivalent to ![]() $\theta _{r} = 0$ along the entire length of the centre rod. To obtain the deflection angles of the side flaps, a high-speed camera was placed below the water tank to capture directly the deflected side flaps. Although the hinges were made as uniform as possible, a slight variation in the deflection angle among the side flaps was observed, thus the averaged value of the deflection angles was used.

$\theta _{r} = 0$ along the entire length of the centre rod. To obtain the deflection angles of the side flaps, a high-speed camera was placed below the water tank to capture directly the deflected side flaps. Although the hinges were made as uniform as possible, a slight variation in the deflection angle among the side flaps was observed, thus the averaged value of the deflection angles was used.

For a translational speed ![]() $U$ between 4 and 60 cm s

$U$ between 4 and 60 cm s![]() $^{-1}$, the deflection angles obtained from the filmed images are presented in figure 4(a) as square symbols; the last four data points in

$^{-1}$, the deflection angles obtained from the filmed images are presented in figure 4(a) as square symbols; the last four data points in ![]() $U = 48$–60 cm s

$U = 48$–60 cm s![]() $^{-1}$ for the soft hinge type are excluded because of periodic oscillations observed only in these cases. With the value of the hinge length

$^{-1}$ for the soft hinge type are excluded because of periodic oscillations observed only in these cases. With the value of the hinge length ![]() $l_{h}$ set as 0.085 cm, the theoretical prediction using (3.1) (solid lines in figure 4a) fits the experimental measurements well.

$l_{h}$ set as 0.085 cm, the theoretical prediction using (3.1) (solid lines in figure 4a) fits the experimental measurements well.

To verify further our theoretical approach for the hinge model, drag forces along the ![]() $x$ axis were measured using a force transducer for the aforementioned vertically straight centre rod with deflected side flaps, and they are compared in figure 4(b) with those predicted by integrating (3.2) over the whole elastic structure. The normal force acting on the elastic structure per unit longitudinal length of the centre rod in regions without side flaps is given by

$x$ axis were measured using a force transducer for the aforementioned vertically straight centre rod with deflected side flaps, and they are compared in figure 4(b) with those predicted by integrating (3.2) over the whole elastic structure. The normal force acting on the elastic structure per unit longitudinal length of the centre rod in regions without side flaps is given by ![]() $\frac {1}{2} C_{N} \rho _{w} w_{r} (U \cos \theta _{r})^2$. Where side flaps are present, from the normal fluid force (3.1) acting on a side flap, the component of the normal force acting on the two side flaps in the direction normal to the centre rod is given by

$\frac {1}{2} C_{N} \rho _{w} w_{r} (U \cos \theta _{r})^2$. Where side flaps are present, from the normal fluid force (3.1) acting on a side flap, the component of the normal force acting on the two side flaps in the direction normal to the centre rod is given by ![]() $\frac {1}{2} C_{N} \rho _{w} (2l_{f}) (U \cos \theta _{r} \cos \theta _{f})^2 \cos \theta _{f}$, where the extra factor

$\frac {1}{2} C_{N} \rho _{w} (2l_{f}) (U \cos \theta _{r} \cos \theta _{f})^2 \cos \theta _{f}$, where the extra factor ![]() $\cos \theta _{f}$ ensures that only the component normal to the centre rod is considered. In regions with side flaps, this term should be added to the normal fluid force exerted on the centre rod per unit length. Thus the normal force

$\cos \theta _{f}$ ensures that only the component normal to the centre rod is considered. In regions with side flaps, this term should be added to the normal fluid force exerted on the centre rod per unit length. Thus the normal force ![]() $f_{nor}$ acting on the elastic structure per unit longitudinal length of the centre rod is given by

$f_{nor}$ acting on the elastic structure per unit longitudinal length of the centre rod is given by

\begin{equation} f_{nor} =\begin{cases}

\frac{1}{2} C_{N} \rho_{w} w_{r} (U \cos \theta_{r})^2 &

\textrm{for regions without side flaps}, \\

\frac{1}{2} C_{N} \rho_{w} (w_{r} + 2l_{f} \cos ^3

\theta_{f}) (U \cos \theta_{r})^2 & \textrm{for regions

with side flaps}. \end{cases}

\end{equation}

\begin{equation} f_{nor} =\begin{cases}

\frac{1}{2} C_{N} \rho_{w} w_{r} (U \cos \theta_{r})^2 &

\textrm{for regions without side flaps}, \\

\frac{1}{2} C_{N} \rho_{w} (w_{r} + 2l_{f} \cos ^3

\theta_{f}) (U \cos \theta_{r})^2 & \textrm{for regions

with side flaps}. \end{cases}

\end{equation}

Because straight centre rods are used in the cases shown in figure 4(b), ![]() $\theta _{r} = 0$ for these particular cases. In figure 4(b), solid lines are obtained by substituting

$\theta _{r} = 0$ for these particular cases. In figure 4(b), solid lines are obtained by substituting ![]() $\theta _{f}$ values from (3.1) (solid lines in figure 4a) into (3.2). In summary, the theoretical model of the hinge can predict successfully the drag exerted on the entire structure, as well as the deflection angle of the side flap. Our empirical model (3.1) has a shortcoming. Extreme side-flap deflection, close to

$\theta _{f}$ values from (3.1) (solid lines in figure 4a) into (3.2). In summary, the theoretical model of the hinge can predict successfully the drag exerted on the entire structure, as well as the deflection angle of the side flap. Our empirical model (3.1) has a shortcoming. Extreme side-flap deflection, close to ![]() $\theta _{f}=90^{\circ }$, results in a significant decrease in the term on the left-hand side of (3.1). This is contradictory to the fact that larger deflection induces greater internal bending torque. However, such extreme deflection is limited to some cases with soft hinges and high speed

$\theta _{f}=90^{\circ }$, results in a significant decrease in the term on the left-hand side of (3.1). This is contradictory to the fact that larger deflection induces greater internal bending torque. However, such extreme deflection is limited to some cases with soft hinges and high speed ![]() $U$.

$U$.

3.2. Coupling of side-flap and centre-rod deflections

With the hinge model proposed in § 3.1, the deformation of the elastic structure in translational motion is now examined analytically, using an approach similar to those of previous studies (Luhar & Nepf Reference Luhar and Nepf2016; Leclercq & de Langre Reference Leclercq and de Langre2018). The unsteady force-balance equation of the centre rod, which consists of internal bending force/tensile force, external hydrodynamic force, buoyancy force and inertial force, is modelled based on the nonlinear elastica theory:

\begin{align} & B_{r}\,\frac{\partial^2 \theta_{r}(s,t)}{\partial s^2} + {\rm i} T + \exp({-{\rm i}\theta_{r}(s,t)}) \nonumber\\ &\qquad \times\left[ \int_{s}^{l_{r}} f_{nor}(s^*,t) \exp({{\rm i}\theta_{r}(s^*,t)})\, \mathrm{d} s^* - {\rm i}\,{\Delta} \rho\,gh \int_{s}^{l_{r}}(w_{r} + 2l_{sf})\,\mathrm{d} s^* \right] \nonumber\\ &\quad = \exp({-{\rm i}\theta_{r}(s,t)}) \int_{s}^{l_{r}} f_{I}(s^*,t)\,\mathrm{d} s^*, \end{align}

\begin{align} & B_{r}\,\frac{\partial^2 \theta_{r}(s,t)}{\partial s^2} + {\rm i} T + \exp({-{\rm i}\theta_{r}(s,t)}) \nonumber\\ &\qquad \times\left[ \int_{s}^{l_{r}} f_{nor}(s^*,t) \exp({{\rm i}\theta_{r}(s^*,t)})\, \mathrm{d} s^* - {\rm i}\,{\Delta} \rho\,gh \int_{s}^{l_{r}}(w_{r} + 2l_{sf})\,\mathrm{d} s^* \right] \nonumber\\ &\quad = \exp({-{\rm i}\theta_{r}(s,t)}) \int_{s}^{l_{r}} f_{I}(s^*,t)\,\mathrm{d} s^*, \end{align}

where ![]() $s$ is the curvilinear coordinate from the clamped end along the axis of the centre rod (figure 3a), and

$s$ is the curvilinear coordinate from the clamped end along the axis of the centre rod (figure 3a), and ![]() ${\rm i}$ is an imaginary unit. Also,

${\rm i}$ is an imaginary unit. Also, ![]() $T$ denotes the tensile force,

$T$ denotes the tensile force, ![]() $\Delta \rho$ is the density difference between the structure

$\Delta \rho$ is the density difference between the structure ![]() $\rho _{s}$ and water

$\rho _{s}$ and water ![]() $\rho _{w}$, and

$\rho _{w}$, and ![]() $l_{sf}$ is the shape function defined in (2.2);

$l_{sf}$ is the shape function defined in (2.2); ![]() $f$ is used to denote several loads, in the form of force per unit length,

$f$ is used to denote several loads, in the form of force per unit length, ![]() $f_{nor}$ is the external hydrodynamic load composed of the resistive force based on quasi-steady flow assumption and the added-mass force, whose direction is normal to the surface of the centre rod, and

$f_{nor}$ is the external hydrodynamic load composed of the resistive force based on quasi-steady flow assumption and the added-mass force, whose direction is normal to the surface of the centre rod, and ![]() $f_{I}$ is the inertial load from the acceleration of the structure itself. Here,

$f_{I}$ is the inertial load from the acceleration of the structure itself. Here, ![]() $f_{nor}$ and

$f_{nor}$ and ![]() $f_{I}$ are composed of both centre-rod and side-flap components:

$f_{I}$ are composed of both centre-rod and side-flap components:

where the subscripts ![]() ${R}$,

${R}$, ![]() ${A}$ and

${A}$ and ![]() ${I}$ denote resistive, added-mass and inertial loads, respectively. Also, as used previously, the subscripts

${I}$ denote resistive, added-mass and inertial loads, respectively. Also, as used previously, the subscripts ![]() ${r}$ and

${r}$ and ![]() ${f}$ indicate the centre rod and the side flaps, respectively.

${f}$ indicate the centre rod and the side flaps, respectively.

The external and inertial loads acting on the centre rod are given as

where ![]() $U_{r}$ denotes the relative flow velocity of the centre rod (

$U_{r}$ denotes the relative flow velocity of the centre rod (![]() $U_{r}= U-\dot {z}$), the dot denotes a time derivative, and

$U_{r}= U-\dot {z}$), the dot denotes a time derivative, and ![]() $z= x + {\rm i}y$ is the position of the centre rod on the complex plane in the Cartesian coordinate system. For unsteady motion of the elastic structure, the normal force coefficient

$z= x + {\rm i}y$ is the position of the centre rod on the complex plane in the Cartesian coordinate system. For unsteady motion of the elastic structure, the normal force coefficient ![]() $C_{N}$ and added-mass force coefficient

$C_{N}$ and added-mass force coefficient ![]() $C_{M}$ will vary locally by the Keulegan–Carpenter number

$C_{M}$ will vary locally by the Keulegan–Carpenter number ![]() $KC$ (Keulegan & Carpenter Reference Keulegan and Carpenter1958). Instead of

$KC$ (Keulegan & Carpenter Reference Keulegan and Carpenter1958). Instead of ![]() $C_{N} = 2$ used for the quasi-steady condition,

$C_{N} = 2$ used for the quasi-steady condition, ![]() $C_{N}$ dependent on

$C_{N}$ dependent on ![]() $KC$ is used for unsteady simulations:

$KC$ is used for unsteady simulations: ![]() $C_{N} = \max (10KC^{-1/3},1.95)$ from Luhar & Nepf (Reference Luhar and Nepf2016). However, the value of

$C_{N} = \max (10KC^{-1/3},1.95)$ from Luhar & Nepf (Reference Luhar and Nepf2016). However, the value of ![]() $C_{M}$ with respect to

$C_{M}$ with respect to ![]() $KC$ cannot be determined simply. Therefore, a constant value

$KC$ cannot be determined simply. Therefore, a constant value ![]() $C_{M} = 1$ is chosen in this study for simplification, which is identical to the approach adopted by Leclercq & de Langre (Reference Leclercq and de Langre2018). According to the earlier study by Luhar & Nepf (Reference Luhar and Nepf2016), a constant value

$C_{M} = 1$ is chosen in this study for simplification, which is identical to the approach adopted by Leclercq & de Langre (Reference Leclercq and de Langre2018). According to the earlier study by Luhar & Nepf (Reference Luhar and Nepf2016), a constant value ![]() $C_{M} = 1$ did not alter the results significantly.

$C_{M} = 1$ did not alter the results significantly.

On the other hand, the force acting on the side flap is determined by integrating the individual load along the lengthwise direction of the side flap. The external and inertial loads acting on the side flaps are given as

\begin{align} f_{R, f} &= C_{N}\rho_{w} \cos \theta_{f} \int_0^{l_{sf}} | U_{f} - \dot\theta_{f}l^*|\, (U_{f}-\dot{\theta_{f}} l^*)\,\mathrm{d}l^* \nonumber\\ &= \frac{1}{3}\,C_{N}\rho_{w} \cos \theta_{f} l_{sf} [\hat{l}_{f1} U_{f}^2 + |U_{f}-\dot\theta_{f} l_{sf}|\,(2U_{f} - \dot\theta_{f}l_{sf})], \end{align}

\begin{align} f_{R, f} &= C_{N}\rho_{w} \cos \theta_{f} \int_0^{l_{sf}} | U_{f} - \dot\theta_{f}l^*|\, (U_{f}-\dot{\theta_{f}} l^*)\,\mathrm{d}l^* \nonumber\\ &= \frac{1}{3}\,C_{N}\rho_{w} \cos \theta_{f} l_{sf} [\hat{l}_{f1} U_{f}^2 + |U_{f}-\dot\theta_{f} l_{sf}|\,(2U_{f} - \dot\theta_{f}l_{sf})], \end{align} \begin{align} f_{A, f} &=

\frac{\rm \pi}{2}\,C_{M} \rho_{w} w_{f} \cos\theta_{f}

\int_0^{l_{sf}} (\dot U_{f} - \ddot \theta_{f} l^*

)\,\mathrm{d} l^* \nonumber\\ &= \frac{\rm \pi}{2}\,C_{M}

\rho_{w} w_{f} \cos\theta_{f} l_{sf} \left( \dot

U_{f}-\frac{1}{2}\,\ddot\theta_{f}l_{sf} \right),

\end{align}

\begin{align} f_{A, f} &=

\frac{\rm \pi}{2}\,C_{M} \rho_{w} w_{f} \cos\theta_{f}

\int_0^{l_{sf}} (\dot U_{f} - \ddot \theta_{f} l^*

)\,\mathrm{d} l^* \nonumber\\ &= \frac{\rm \pi}{2}\,C_{M}

\rho_{w} w_{f} \cos\theta_{f} l_{sf} \left( \dot

U_{f}-\frac{1}{2}\,\ddot\theta_{f}l_{sf} \right),

\end{align}

\begin{align}

f_{I,f} &= 2\rho_{s}h \int_0^{l_{sf}}[\ddot{z} +(\ddot\theta_{f}\cos\theta_{f}+

\dot\theta_{f}^2 \sin\theta_{f})l^*]\mathrm{d} l^* \nonumber\\ &= 2\rho_{s}h

l_{sf}\left[\ddot{z} + \frac{l_{sf}}{2}\,(\ddot\theta_{f}

\cos\theta_{f} + \dot\theta_{f}^2 \sin\theta_{f} )\right].

\end{align}

\begin{align}

f_{I,f} &= 2\rho_{s}h \int_0^{l_{sf}}[\ddot{z} +(\ddot\theta_{f}\cos\theta_{f}+

\dot\theta_{f}^2 \sin\theta_{f})l^*]\mathrm{d} l^* \nonumber\\ &= 2\rho_{s}h

l_{sf}\left[\ddot{z} + \frac{l_{sf}}{2}\,(\ddot\theta_{f}

\cos\theta_{f} + \dot\theta_{f}^2 \sin\theta_{f} )\right].

\end{align}

Here, ![]() $U_{f}$ and

$U_{f}$ and ![]() $\dot U_{f}$ denote the relative flow velocity and acceleration at the hinge-connected end of the side flap, in the direction normal to the side-flap orientation:

$\dot U_{f}$ denote the relative flow velocity and acceleration at the hinge-connected end of the side flap, in the direction normal to the side-flap orientation:

Also, ![]() $\hat {l}_{f1}$ in (3.6a) is defined as follows to express different integrated forms, depending on the motion of the side flap:

$\hat {l}_{f1}$ in (3.6a) is defined as follows to express different integrated forms, depending on the motion of the side flap:

\begin{equation}

\hat {l}_{f1} =\begin{cases}

(|U_{f}|-|U_{f}-\dot\theta_{f} l_{sf}|)/\dot\theta_{f} l_{sf} & \textrm{if } \dot\theta_{f} \neq 0,\\

1 & \textrm{if } \dot\theta_{f} = 0\ \&\ U_{f}>0,\\

-1 & \textrm{if } \dot\theta_{f} = 0\ \&\ U_{f}<0. \end{cases}

\end{equation}

\begin{equation}

\hat {l}_{f1} =\begin{cases}

(|U_{f}|-|U_{f}-\dot\theta_{f} l_{sf}|)/\dot\theta_{f} l_{sf} & \textrm{if } \dot\theta_{f} \neq 0,\\

1 & \textrm{if } \dot\theta_{f} = 0\ \&\ U_{f}>0,\\

-1 & \textrm{if } \dot\theta_{f} = 0\ \&\ U_{f}<0. \end{cases}

\end{equation}

Moreover, from the definition of ![]() $l_{sf}$ in (2.2), the loads induced by the side flaps (

$l_{sf}$ in (2.2), the loads induced by the side flaps (![]() $f_{R,f}$,

$f_{R,f}$, ![]() $f_{A,f}$ and

$f_{A,f}$ and ![]() $f_{I,f}$) are eliminated for the regions without the side flaps in which

$f_{I,f}$) are eliminated for the regions without the side flaps in which ![]() $l_{sf} = 0$.

$l_{sf} = 0$.

With the complete set of relations describing the loads acting on the centre rod and side flaps provided, we can find that when the centre rod is rigid (![]() $\theta _{r}=0$) and the motion is steady (

$\theta _{r}=0$) and the motion is steady (![]() $\dot \theta _{f}=0$),

$\dot \theta _{f}=0$), ![]() $\hat {l}_{f1}$ is 1, and the relative flow velocities normal to the centre rod (

$\hat {l}_{f1}$ is 1, and the relative flow velocities normal to the centre rod (![]() ${\rm Re}(U_{r}\exp ({-{\rm i}\theta _{r}}))$) and the side flaps (

${\rm Re}(U_{r}\exp ({-{\rm i}\theta _{r}}))$) and the side flaps (![]() $U_{f}$) become

$U_{f}$) become ![]() $U$ and

$U$ and ![]() $U\cos \theta _{f}$, respectively. Eventually, (3.4a) becomes identical to (3.2).

$U\cos \theta _{f}$, respectively. Eventually, (3.4a) becomes identical to (3.2).

Next, for the dynamics of the side flaps, the deflection angle of the side flap, ![]() $\theta _{f}$, is evaluated from the following unsteady torque-balance equation for the hinge, which is extended from the quasi-steady (3.1):

$\theta _{f}$, is evaluated from the following unsteady torque-balance equation for the hinge, which is extended from the quasi-steady (3.1):

where the first term on the left-hand side is the bending moment of the hinge described in § 3.1, and ![]() $\tau _{R}$,

$\tau _{R}$, ![]() $\tau _{A}$,

$\tau _{A}$, ![]() $\tau _{B}$ and

$\tau _{B}$ and ![]() $\tau _{I}$ are the torques induced by the resistive, added-mass, buoyancy and inertial forces, respectively. The value of

$\tau _{I}$ are the torques induced by the resistive, added-mass, buoyancy and inertial forces, respectively. The value of ![]() $\theta _{f}$ for each side flap can be estimated individually since the side flaps are not connected to each other. We have

$\theta _{f}$ for each side flap can be estimated individually since the side flaps are not connected to each other. We have

\begin{align} \tau_{R} &= \frac{1}{2}\,C_{N} \rho_{w} w_{f} \int_0^{l_{sf}} |U_{f} - \dot\theta_{f} l^* |\,(U_{f} - \dot\theta_{f} l^*) l^* \,\mathrm{d} l^* \nonumber\\ &= \frac{1}{24}\,C_{N} \rho_{w} w_{f} l_{sf}^2 [\hat{l}_{f2}U_{f}^2 + |U_{f}-\dot\theta_{f} l_{sf}|\,(5U_{f}-3\dot\theta_{f} l_{sf})], \end{align}

\begin{align} \tau_{R} &= \frac{1}{2}\,C_{N} \rho_{w} w_{f} \int_0^{l_{sf}} |U_{f} - \dot\theta_{f} l^* |\,(U_{f} - \dot\theta_{f} l^*) l^* \,\mathrm{d} l^* \nonumber\\ &= \frac{1}{24}\,C_{N} \rho_{w} w_{f} l_{sf}^2 [\hat{l}_{f2}U_{f}^2 + |U_{f}-\dot\theta_{f} l_{sf}|\,(5U_{f}-3\dot\theta_{f} l_{sf})], \end{align} \begin{align} \tau_{A} &= \frac{\rm \pi}{4}\,C_{M} \rho_{w} w_{f}^2 \int_0^{l_{sf}} ( \dot U_{f} - \ddot \theta_{f} l^* )l^*\,\mathrm{d} l^* \nonumber\\ &= \frac{\rm \pi}{24}\,C_{M} \rho_{w} w_{f}^2 l_{sf}^2 ( 3\dot U_{f} - 2\ddot \theta_{f} l_{sf} ), \end{align}

\begin{align} \tau_{A} &= \frac{\rm \pi}{4}\,C_{M} \rho_{w} w_{f}^2 \int_0^{l_{sf}} ( \dot U_{f} - \ddot \theta_{f} l^* )l^*\,\mathrm{d} l^* \nonumber\\ &= \frac{\rm \pi}{24}\,C_{M} \rho_{w} w_{f}^2 l_{sf}^2 ( 3\dot U_{f} - 2\ddot \theta_{f} l_{sf} ), \end{align} \begin{align}

\tau_{I} &= \rho_{s}h w_{f} \int_0^{l_{sf}}\left[\ddot{z}

\cos \theta_{f} + \ddot\theta_{f} l^*\right]l^* \,\mathrm{d} l^*\nonumber\\

&= \rho_{s}h w_{f} l_{sf}^2 \left[\frac{1}{2}\,\ddot{z} \cos

\theta_{f} + \frac{1}{3}\,\ddot\theta_{f} l_{sf} \right],

\end{align}

\begin{align}

\tau_{I} &= \rho_{s}h w_{f} \int_0^{l_{sf}}\left[\ddot{z}

\cos \theta_{f} + \ddot\theta_{f} l^*\right]l^* \,\mathrm{d} l^*\nonumber\\

&= \rho_{s}h w_{f} l_{sf}^2 \left[\frac{1}{2}\,\ddot{z} \cos

\theta_{f} + \frac{1}{3}\,\ddot\theta_{f} l_{sf} \right],

\end{align}

where ![]() $\hat {l}_{f2}$ is defined as

$\hat {l}_{f2}$ is defined as

\begin{equation}

\hat{l}_{f2} =\begin{cases} \dfrac{1}{\dot\theta_{f} l_{sf}}

\left[U_{f}\, \dfrac{|U_{f}|-|U_{f}-\dot\theta_{f}

l_{sf}|}{\dot\theta_{f} l_{sf}} - |U_{f}-\dot\theta_{f}

l_{sf}|\right] & \textrm{if } \dot\theta_{f} \neq 0, \\

1 & \textrm{if } \dot\theta_{f} = 0 \ \& \ U_{f}>0, \\

{-1} & \textrm{if } \dot\theta_{f} = 0 \ \& \ U_{f}<0.

\end{cases} \end{equation}

\begin{equation}

\hat{l}_{f2} =\begin{cases} \dfrac{1}{\dot\theta_{f} l_{sf}}

\left[U_{f}\, \dfrac{|U_{f}|-|U_{f}-\dot\theta_{f}

l_{sf}|}{\dot\theta_{f} l_{sf}} - |U_{f}-\dot\theta_{f}

l_{sf}|\right] & \textrm{if } \dot\theta_{f} \neq 0, \\

1 & \textrm{if } \dot\theta_{f} = 0 \ \& \ U_{f}>0, \\

{-1} & \textrm{if } \dot\theta_{f} = 0 \ \& \ U_{f}<0.

\end{cases} \end{equation}

The detailed numerical procedure for solving (3.3) in terms of ![]() $\theta _{r}$ and (3.9) in terms of

$\theta _{r}$ and (3.9) in terms of ![]() $\theta _{f}$ is described in Appendix A.

$\theta _{f}$ is described in Appendix A.

3.3. Simplification for quasi-steady motion

The full dynamic model derived in § 3.2 is simplified to represent the quasi-static interaction of the elastic structure with the flow. For steady translation with constant speed ![]() $U = U_0$ during either the power stroke or the recovery stroke and resultant quasi-static deformation, time derivative terms

$U = U_0$ during either the power stroke or the recovery stroke and resultant quasi-static deformation, time derivative terms ![]() $\dot \theta _{r}$ and

$\dot \theta _{r}$ and ![]() $\dot \theta _{f}$ are assumed to be zero, yielding zero added-mass and inertial loads. Consequently, the real components in (3.3) are simplified as

$\dot \theta _{f}$ are assumed to be zero, yielding zero added-mass and inertial loads. Consequently, the real components in (3.3) are simplified as

\begin{align} & B_{r}\,\frac{\mathrm{d}^2 \theta_{r}(s)}{\mathrm{d}s^2} + \int_{s}^{l_{r}} [f_{R,r}(s^*) + f_{R,f}(s^*)] \cos (\theta_{r}(s) - \theta_{r}(s^*))\,\mathrm{d} s^* \nonumber\\ &\quad -\Delta \rho\,gh \sin \theta_{r}(s) \int_{s}^{l_{r}} (w_{r} + 2l_{sf})\, \mathrm{d} s^* = 0, \end{align}

\begin{align} & B_{r}\,\frac{\mathrm{d}^2 \theta_{r}(s)}{\mathrm{d}s^2} + \int_{s}^{l_{r}} [f_{R,r}(s^*) + f_{R,f}(s^*)] \cos (\theta_{r}(s) - \theta_{r}(s^*))\,\mathrm{d} s^* \nonumber\\ &\quad -\Delta \rho\,gh \sin \theta_{r}(s) \int_{s}^{l_{r}} (w_{r} + 2l_{sf})\, \mathrm{d} s^* = 0, \end{align}

which is similar to the forms given by Gosselin et al. (Reference Gosselin, de Langre and Machado-Almeida2010), Luhar & Nepf (Reference Luhar and Nepf2011) and Pezzulla et al. (Reference Pezzulla, Strong, Gallaire and Reis2020). Since the model is for steady translation, (3.1) can be used directly to obtain ![]() $\theta _{f}$.

$\theta _{f}$.

To solve (3.12) and (3.1) simultaneously, and find ![]() $\theta _{r}$ and

$\theta _{r}$ and ![]() $\theta _{f}$, the centre rod is discretized into equally spaced segments each of length

$\theta _{f}$, the centre rod is discretized into equally spaced segments each of length ![]() $\Delta s$ along the

$\Delta s$ along the ![]() $s$ axis:

$s$ axis: ![]() $\Delta s = l_{r}/N$, where

$\Delta s = l_{r}/N$, where ![]() $N = 20$. With the central difference scheme being used for the differential term and the mensuration by parts for the integral terms, (3.12) becomes

$N = 20$. With the central difference scheme being used for the differential term and the mensuration by parts for the integral terms, (3.12) becomes

\begin{align} & B_{r}\,\frac{\theta_{{r},j+1} - 2\theta_{{r},j} + \theta_{{r},j-1}}{(\Delta s)^2} + \sum_{k=j+1}^{N} (f_{{R,r},k} + f_{{R,f},k}) \cos (\theta_{{r},j} - \theta_{{r},k})\,\Delta s \nonumber\\ &\quad - \Delta \rho\,gh \sin \theta_{{r},j} \sum_{k=j+1}^{N} (w_{r} + 2l_{{sf},k})\, \Delta s = 0,\quad j = 1, \ldots, N-1. \end{align}

\begin{align} & B_{r}\,\frac{\theta_{{r},j+1} - 2\theta_{{r},j} + \theta_{{r},j-1}}{(\Delta s)^2} + \sum_{k=j+1}^{N} (f_{{R,r},k} + f_{{R,f},k}) \cos (\theta_{{r},j} - \theta_{{r},k})\,\Delta s \nonumber\\ &\quad - \Delta \rho\,gh \sin \theta_{{r},j} \sum_{k=j+1}^{N} (w_{r} + 2l_{{sf},k})\, \Delta s = 0,\quad j = 1, \ldots, N-1. \end{align}

With the boundary conditions ![]() $\theta _{r} = 0$ at

$\theta _{r} = 0$ at ![]() $s = 0$ (

$s = 0$ (![]() $j = 0$) and

$j = 0$) and ![]() $\mathrm {d}\theta _{r}/\mathrm {d}s = 0$ at

$\mathrm {d}\theta _{r}/\mathrm {d}s = 0$ at ![]() $s = l_{r}$ (

$s = l_{r}$ (![]() $j = N$), iterations were performed to solve the boundary value problem using Newton's method until the left-hand side of (3.13) fell below

$j = N$), iterations were performed to solve the boundary value problem using Newton's method until the left-hand side of (3.13) fell below ![]() $10^{-5}$ times the second term in (3.12) at every node.

$10^{-5}$ times the second term in (3.12) at every node.

4. Results and discussion

4.1. Reconfiguration of the elastic structure under quasi-steady motion

The quasi-static deformation of the elastic structure under steady translation (![]() $U = U_0$) is first considered in §§ 4.1–4.3. A notable feature in the quasi-static deformation is the difference in the orientation of the side flaps along the longitudinal direction of the centre rod (along the curvilinear coordinate

$U = U_0$) is first considered in §§ 4.1–4.3. A notable feature in the quasi-static deformation is the difference in the orientation of the side flaps along the longitudinal direction of the centre rod (along the curvilinear coordinate ![]() $s$ in figure 3) between the power stroke and the recovery stroke. Although the centre rod bends backwards during the power stroke, the motion of the side flaps is constrained by the unidirectional hinge, and they remain almost straight with respect to the centre rod, without deflection (see figures 5a-i,b-i). Thus, regardless of the hinge type, the deflections of the centre rod are similar. By contrast, owing to the deflection of the side flaps during the recovery stroke and the consequent reduction in the projection area normal to the direction of translation, less drag is exerted on the structure during the recovery stroke than the power stroke, resulting in less deflection of the centre rod (see figures 5a-ii,b-ii). Because the reconfiguration of the centre rod causes a reduction in the magnitude of the relative flow velocity normal to the elastic structure along the longitudinal direction,

$s$ in figure 3) between the power stroke and the recovery stroke. Although the centre rod bends backwards during the power stroke, the motion of the side flaps is constrained by the unidirectional hinge, and they remain almost straight with respect to the centre rod, without deflection (see figures 5a-i,b-i). Thus, regardless of the hinge type, the deflections of the centre rod are similar. By contrast, owing to the deflection of the side flaps during the recovery stroke and the consequent reduction in the projection area normal to the direction of translation, less drag is exerted on the structure during the recovery stroke than the power stroke, resulting in less deflection of the centre rod (see figures 5a-ii,b-ii). Because the reconfiguration of the centre rod causes a reduction in the magnitude of the relative flow velocity normal to the elastic structure along the longitudinal direction, ![]() $\theta _{f}$ values of the side flaps decrease as well along the longitudinal direction, as shown clearly in figure 5(b-ii).

$\theta _{f}$ values of the side flaps decrease as well along the longitudinal direction, as shown clearly in figure 5(b-ii).

Figure 5. Raw images of the deformed elastic structure during (i) the power stroke and (ii) the recovery stroke: (a) soft-hinge case (s4), and (b) medium-hinge case (m4), in table 2. Here, ![]() $U = 40$ cm s

$U = 40$ cm s![]() $^{-1}$. See the supplementary movies available at https://doi.org/10.1017/jfm.2022.970.

$^{-1}$. See the supplementary movies available at https://doi.org/10.1017/jfm.2022.970.

We now compare the deflection profiles of the centre rod as estimated by the theoretical model in § 3.3 with experimental results. The deflection profiles of the thin-centre-rod cases with soft hinges are exemplified in figure 6. With varying side-flap length ![]() $l_{f}$, the deflection profiles can be predicted to a reasonable extent. As well as the centre rod, the deflection angles of the side flaps for the cases presented in figures 5 and 6 also show a good match between the experimental results and theoretical estimates (figure 7). These results indicate that our theoretical model incorporating two deflecting parts, namely the centre rod and hinges, is appropriate for characterizing the quasi-static dynamics of the elastic structure.

$l_{f}$, the deflection profiles can be predicted to a reasonable extent. As well as the centre rod, the deflection angles of the side flaps for the cases presented in figures 5 and 6 also show a good match between the experimental results and theoretical estimates (figure 7). These results indicate that our theoretical model incorporating two deflecting parts, namely the centre rod and hinges, is appropriate for characterizing the quasi-static dynamics of the elastic structure.

Figure 6. Deflection profiles of the thin centre rod with soft hinges (cases s2, s3 and s4 in table 2) for (a) the power stroke and (b) the recovery stroke, where (i) is from the experimental measurement, and (ii) is from the theoretical model. Black, blue and red indicate ![]() $l_{f} = 4$, 3 and 2 cm, respectively. In each panel, the three lines of each colour correspond to the cases with

$l_{f} = 4$, 3 and 2 cm, respectively. In each panel, the three lines of each colour correspond to the cases with ![]() $U = 12$, 32 and 52 cm s

$U = 12$, 32 and 52 cm s![]() $^{-1}$, respectively; backward deformation is greater for larger

$^{-1}$, respectively; backward deformation is greater for larger ![]() $U$.

$U$.

Figure 7. Deflection angle ![]() $\theta _{f}$ of the 10 side flaps along the longitudinal direction of the centre rod during the recovery stroke, for: (a) the s4 (

$\theta _{f}$ of the 10 side flaps along the longitudinal direction of the centre rod during the recovery stroke, for: (a) the s4 (![]() $\square$) and m4 (

$\square$) and m4 (![]() $\Diamond$) cases with

$\Diamond$) cases with ![]() $U = 40$ cm s

$U = 40$ cm s![]() $^{-1}$ (the cases shown in figures 5a-ii,b-ii); (b) the s2 (

$^{-1}$ (the cases shown in figures 5a-ii,b-ii); (b) the s2 (![]() $\circ$, thin line) and s4 (

$\circ$, thin line) and s4 (![]() $\square$, thick line) cases with

$\square$, thick line) cases with ![]() $U = 12$ cm s

$U = 12$ cm s![]() $^{-1}$ (blue) and 52 cm s

$^{-1}$ (blue) and 52 cm s![]() $^{-1}$ (red) (the cases shown in figures 6b-i to b-ii). Symbols indicate experimental measurements, and short horizontal lines indicate theoretical estimates.

$^{-1}$ (red) (the cases shown in figures 6b-i to b-ii). Symbols indicate experimental measurements, and short horizontal lines indicate theoretical estimates.

In previous studies of the reconfiguration of elastic bodies under steady flow, the Cauchy number ![]() $C_Y$ was introduced to characterize the deformation of the body subjected to the flow (e.g. de Langre Reference de Langre2008; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Whittaker et al. Reference Whittaker, Wilson and Aberle2015; Leclercq & de Langre Reference Leclercq and de Langre2016). This number is defined as the ratio of inertial fluid force to elastic force:

$C_Y$ was introduced to characterize the deformation of the body subjected to the flow (e.g. de Langre Reference de Langre2008; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Whittaker et al. Reference Whittaker, Wilson and Aberle2015; Leclercq & de Langre Reference Leclercq and de Langre2016). This number is defined as the ratio of inertial fluid force to elastic force: ![]() $C_Y = \rho _{f} U^2/E$, where

$C_Y = \rho _{f} U^2/E$, where ![]() $\rho _{f}$ and

$\rho _{f}$ and ![]() $E$ are the fluid density and Young's modulus of the elastic body, respectively. Similarly, a dimensionless flow velocity in the form

$E$ are the fluid density and Young's modulus of the elastic body, respectively. Similarly, a dimensionless flow velocity in the form

\begin{equation} \eta = U\left(\frac{\rho_{f} L^3 f}{B}\right)^{1/2}, \end{equation}

\begin{equation} \eta = U\left(\frac{\rho_{f} L^3 f}{B}\right)^{1/2}, \end{equation}

which indicates the relative magnitudes of the inertial fluid force and the bending force of the elastic body, has been suggested by several studies (e.g. Alben et al. Reference Alben, Shelley and Zhang2002; Shelley & Zhang Reference Shelley and Zhang2011; Kim et al. Reference Kim, Cossé, Cerdeira and Gharib2013; Kim, Kang & Kim Reference Kim, Kang and Kim2017). In (4.1), ![]() $B$ is the bending stiffness,

$B$ is the bending stiffness, ![]() $L$ is a characteristic length, and

$L$ is a characteristic length, and ![]() $f$ is a geometric parameter that determines the effective cross-sectional width of the elastic body. In the present study, a modified version of the dimensionless flow velocity is proposed in which

$f$ is a geometric parameter that determines the effective cross-sectional width of the elastic body. In the present study, a modified version of the dimensionless flow velocity is proposed in which ![]() $f$ is replaced with a combination of

$f$ is replaced with a combination of ![]() $w_{r}$,

$w_{r}$, ![]() $l_{f}$ and

$l_{f}$ and ![]() $\theta _{f}$ to give a more appropriate characterization of the elastic deformation.

$\theta _{f}$ to give a more appropriate characterization of the elastic deformation.

Because the drag force scales roughly with the projection area of the structure on the plane normal to the direction of translation, its magnitude is determined by the geometric parameters of the centre rod and the side flaps, such as ![]() $l_{r}$,

$l_{r}$, ![]() $w_{r}$,

$w_{r}$, ![]() $l_{f}$,

$l_{f}$, ![]() $w_{f}$,

$w_{f}$, ![]() $\theta _{r}$ and

$\theta _{r}$ and ![]() $\theta _{f}$. Along with the fixed values of

$\theta _{f}$. Along with the fixed values of ![]() $l_{r}$,

$l_{r}$, ![]() $w_{r}$ and

$w_{r}$ and ![]() $w_{f}$, the parameter varied in the present study is the side-flap length

$w_{f}$, the parameter varied in the present study is the side-flap length ![]() $l_{f}$, with the deflection angle of the centre rod,

$l_{f}$, with the deflection angle of the centre rod, ![]() $\theta _{r}$, and those of the individual side flaps,

$\theta _{r}$, and those of the individual side flaps, ![]() $\theta _{f}$, being dependent on various experimental parameters. In the quasi-static theoretical model, the normal force acting on the elastic structure per unit length was defined as (3.2), where

$\theta _{f}$, being dependent on various experimental parameters. In the quasi-static theoretical model, the normal force acting on the elastic structure per unit length was defined as (3.2), where ![]() $w_{r}$ and

$w_{r}$ and ![]() $l_{f} \cos ^3 \theta _{f}$ can be considered as the effective cross-sectional widths of the centre rod and the side flap, respectively. Although the value of

$l_{f} \cos ^3 \theta _{f}$ can be considered as the effective cross-sectional widths of the centre rod and the side flap, respectively. Although the value of ![]() $\theta _{f}$ decreases along the longitudinal direction of the centre rod owing to the reduction in the normal component of the flow relative to the deformed centre rod (figures 5b-ii and 7), the value of

$\theta _{f}$ decreases along the longitudinal direction of the centre rod owing to the reduction in the normal component of the flow relative to the deformed centre rod (figures 5b-ii and 7), the value of ![]() $\theta _{f}$ when the centre rod is vertically straight and rigid (

$\theta _{f}$ when the centre rod is vertically straight and rigid (![]() $\theta _{r} = 0$), and completely perpendicular to the relative flow, is chosen as a reference

$\theta _{r} = 0$), and completely perpendicular to the relative flow, is chosen as a reference ![]() $\theta _{f}$ for simplicity and is denoted by

$\theta _{f}$ for simplicity and is denoted by ![]() $\theta _{f,ref}$. This value can be estimated with reasonable accuracy using (3.1); the limitations of such a choice will be discussed later. Therefore,

$\theta _{f,ref}$. This value can be estimated with reasonable accuracy using (3.1); the limitations of such a choice will be discussed later. Therefore, ![]() $l_{f} \cos ^3 \theta _{f,ref}$ is determined for each case, and

$l_{f} \cos ^3 \theta _{f,ref}$ is determined for each case, and ![]() $\theta _{f,ref}$ differs between the power and recovery strokes;

$\theta _{f,ref}$ differs between the power and recovery strokes; ![]() $\theta _{f,ref} = 0$ for the power stroke.

$\theta _{f,ref} = 0$ for the power stroke.

The effective area of the centre rod scales with ![]() $w_{r} l_{r}$, and that of all the side flaps scales with

$w_{r} l_{r}$, and that of all the side flaps scales with ![]() $N_{f} w_{f}l_{f} \cos ^3 \theta _{f,ref}$, where

$N_{f} w_{f}l_{f} \cos ^3 \theta _{f,ref}$, where ![]() $N_{f} = 20$ is the total number of the side flaps (10 for each side). By dividing the effective area by the centre-rod length

$N_{f} = 20$ is the total number of the side flaps (10 for each side). By dividing the effective area by the centre-rod length ![]() $l_{r}$, the effective cross-sectional width of the elastic structure is expressed as

$l_{r}$, the effective cross-sectional width of the elastic structure is expressed as ![]() $(w_{r}l_{r} + N_{f} w_{f}l_{f} \cos ^3 \theta _{f,ref})/l_{r}$. Replacing

$(w_{r}l_{r} + N_{f} w_{f}l_{f} \cos ^3 \theta _{f,ref})/l_{r}$. Replacing ![]() $f$ and

$f$ and ![]() $L$ in (4.1) with the defined effective cross-sectional width and the centre-rod length, respectively, we propose the following dimensionless speed for characterizing the reconfiguration of our model that accompanies the deformations of the centre rod and the hinges together: